Why Choose All Clad Copper Plated Materials for Marine Industry Applications?

2025-03-31 09:38:29

View:389

2025-03-31 09:38:29

View:389In the challenging environments of marine industries, material selection plays a crucial role in equipment longevity, operational efficiency, and overall safety. All clad copper plated materials have emerged as a superior solution for marine applications, offering an exceptional combination of corrosion resistance, thermal conductivity, and structural integrity. These innovative composite materials, manufactured through advanced bonding technologies, effectively address the unique challenges posed by seawater exposure, fluctuating temperatures, and constant mechanical stress. This article explores why all clad copper plated materials have become indispensable in modern marine engineering and how companies like Baoji JL Clad Metals Materials Co., Ltd. are leading the industry with their premium clad metal solutions.

Superior Corrosion Resistance and Durability in Marine Environments

The marine environment presents one of the most aggressive corrosive conditions for metals and alloys. Seawater, with its high salt content and varied microbiological activity, can rapidly deteriorate conventional materials. All clad copper plated materials offer exceptional protection against these harsh conditions through several innovative mechanisms.

Electrochemical Protection Mechanisms

All clad copper plated materials provide superior electrochemical protection in marine environments. The copper layer forms a protective patina when exposed to seawater, creating a barrier that shields the base metal from corrosion. This natural process involves the formation of copper oxides and copper chlorides that adhere tightly to the surface, preventing further degradation of the material. Unlike traditional protective coatings that may crack or peel over time, this electrochemical protection is self-healing and continues throughout the lifespan of the equipment. In applications where continuous exposure to seawater is inevitable, such as offshore platforms and underwater pipelines, all clad copper plated materials significantly outperform conventional alternatives. Baoji JL Clad Metals Materials Co., Ltd. ensures optimal bonding between the copper layer and substrate through their advanced explosion-bonding technology, which creates a metallurgical bond rather than a mechanical one, further enhancing the electrochemical protection.

Biofouling Resistance Properties

One of the most significant advantages of all clad copper plated materials in marine applications is their natural resistance to biofouling. Marine organisms like barnacles, algae, and mollusks typically avoid settling on copper surfaces due to the metal's antimicrobial properties. This natural deterrent significantly reduces maintenance requirements and extends the operational life of marine equipment. Traditional anti-fouling paints and coatings require regular reapplication and often contain environmentally harmful compounds, whereas all clad copper plated materials provide lasting protection without additional treatments. Baoji JL's copper-clad plates maintain their biofouling resistance properties across a wide range of operating conditions, from shallow coastal waters to deep-sea environments. The company's roll-bonding technique ensures uniform copper distribution across the entire surface area, maximizing protection against marine growth. For vessels and stationary marine structures, this translates to reduced drag, lower fuel consumption, and fewer dry-dock maintenance periods.

Long-term Performance Under Marine Conditions

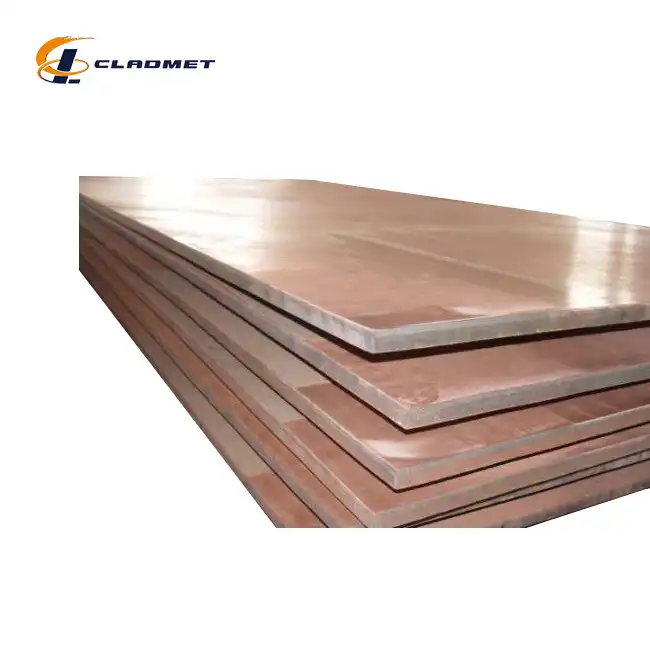

The durability of all clad copper plated materials under prolonged marine exposure has been extensively tested and proven. These composite materials maintain their structural integrity and functional properties even after years of service in saltwater environments. The explosive bonding and hot-rolled processing techniques employed by Baoji JL Clad Metals Materials Co., Ltd. create a metallurgical bond between the copper layer and the substrate that resists delamination under thermal cycling and mechanical stress. Available in thicknesses ranging from 2 mm to 200 mm and lengths up to 12 meters, these materials can be customized to meet specific requirements for marine applications. The company's strict quality control measures ensure adherence to international standards including ISO9001-2000, PED, and ABS certifications. Long-term testing has demonstrated that properly manufactured all clad copper plated materials can maintain their protective properties for decades, making them an economical choice despite their higher initial cost compared to traditional materials.

Thermal and Electrical Conductivity Advantages in Marine Systems

Marine environments demand materials that can efficiently manage heat transfer and electrical conductivity while withstanding corrosive conditions. All clad copper plated materials excel in these aspects, offering unique advantages for marine systems.

Heat Exchanger Efficiency Improvements

The superior thermal conductivity of all clad copper plated materials makes them ideal for marine heat exchangers, which are critical components in engine cooling systems, HVAC applications, and desalination plants. Copper's exceptional ability to transfer heat, combined with the structural strength of the base material, results in heat exchangers that operate with maximum efficiency even in demanding marine conditions. The use of all clad copper plated materials in heat exchanger design allows for significant size reductions without compromising performance, which is particularly valuable in the space-constrained environments of ships and offshore platforms. Baoji JL Clad Metals Materials Co., Ltd. produces these composite materials with precise control over the thickness ratio between copper and the base metal, optimizing thermal performance while maintaining structural integrity. Their explosion-bonding technology ensures perfect thermal contact between the layers, eliminating the inefficiencies associated with mechanical joints or adhesive bonding. Marine heat exchangers constructed with these materials have demonstrated energy savings of up to 30% compared to conventional materials, contributing to reduced fuel consumption and lower operational costs.

Electrical Systems Protection and Performance

In marine electrical systems, the combination of saltwater exposure and electrical currents creates a particularly challenging environment. All clad copper plated materials provide an excellent solution for electrical enclosures, busbars, and connection points in marine applications. The copper layer offers superior electrical conductivity, reducing energy losses and heat generation, while the base material provides structural support and additional corrosion resistance. The customizable nature of these composites allows engineers to design systems with optimal electrical performance without compromising on durability or safety. Baoji JL Clad Metals Materials Co., Ltd. offers these materials with various surface treatments including polished, brushed, or coated finishes, catering to specific requirements for electrical contact surfaces. The company's roll-bonding technique ensures uniform electrical properties across the entire component, eliminating hot spots and potential failure points. For marine vessels with sophisticated electronic systems, these materials provide reliable protection against electromagnetic interference while ensuring consistent electrical performance even under the challenging conditions of sea voyages.

Thermal Management in Marine Propulsion Systems

Modern marine propulsion systems generate significant heat that must be efficiently managed to maintain performance and prevent damage. All clad copper plated materials excel in this application due to their ability to rapidly dissipate heat while resisting the corrosive effects of seawater. The thermal conductivity of copper, which is among the highest of all metals, allows for efficient cooling of engine components, exhaust systems, and power transmission equipment. When bonded to a structurally robust base material through Baoji JL's advanced cladding technologies, the resulting composite provides both the thermal performance needed and the structural integrity required for demanding marine applications. These materials are available in customizable dimensions with lengths up to 12 meters and widths up to 4 meters, allowing for application in vessels of all sizes. The metallurgical bond created through explosive bonding ensures that thermal expansion differences between the copper and base material do not compromise the integrity of the component over repeated heating and cooling cycles. This is particularly important in marine engines that frequently undergo power fluctuations and stop-start operations.

Manufacturing Excellence and Material Integrity

The performance of all clad copper plated materials in marine applications depends significantly on the quality of the manufacturing process. Advanced production techniques ensure the integrity of the bond between layers and the overall reliability of the composite material.

Explosive Bonding Technology Advantages

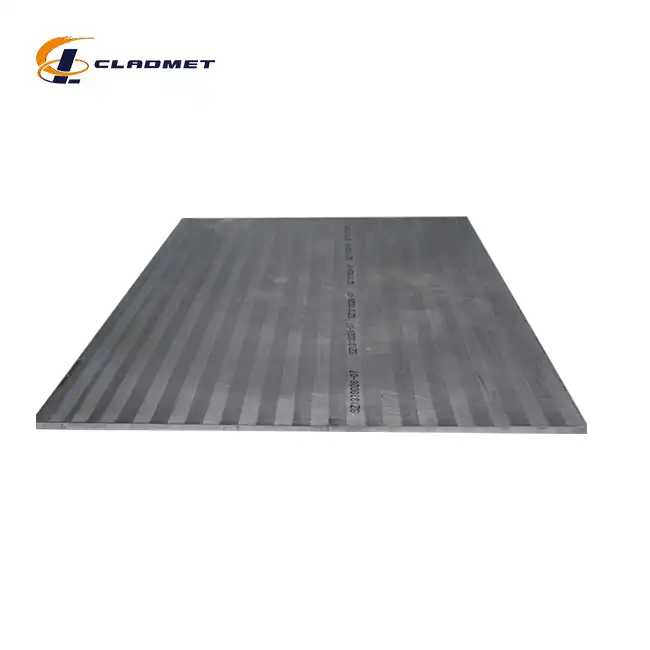

Explosive bonding represents one of the most advanced techniques for creating all clad copper plated materials for marine applications. This process, mastered by Baoji JL Clad Metals Materials Co., Ltd., creates an exceptionally strong metallurgical bond between the copper layer and the substrate without relying on adhesives or mechanical fastening. The controlled detonation generates a high-velocity collision between the materials, creating a wave-like interface that significantly increases the bonding surface area and strength. This wavy interface is particularly beneficial in marine applications where thermal cycling and mechanical stress could otherwise cause delamination. The explosive bonding process allows for the joining of dissimilar metals that would be incompatible using conventional welding or brazing techniques, expanding the range of possible material combinations to address specific marine challenges. Baoji JL's expertise in this area ensures precise control over the explosion parameters, resulting in bonds with consistent quality and predictable performance characteristics. For critical marine components such as tube sheets in condensers and heat exchangers, explosive-bonded all clad copper plated materials provide unmatched reliability under the combined stresses of pressure, temperature fluctuations, and corrosive exposure to seawater.

Quality Control and Testing Protocols

The reliability of all clad copper plated materials in demanding marine environments depends on rigorous quality control throughout the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. implements comprehensive testing protocols that exceed international standards to ensure every product meets the highest performance criteria. Ultrasonic testing is employed to verify complete bonding between the copper and base material layers, detecting even microscopic voids or delaminations that could compromise performance. Mechanical testing, including shear strength and bend tests, confirms that the bond can withstand the stresses typical in marine applications. Corrosion resistance is verified through accelerated testing in simulated seawater environments, providing confidence in long-term performance. Each batch of all clad copper plated material undergoes metallurgical examination to verify the microstructure of the bond interface, which is critical to its mechanical and corrosion resistance properties. The company's commitment to quality is evidenced by their ISO9001-2000 certification and successful completion of PED and ABS international qualifications in 2024. These stringent quality measures ensure that marine engineers and shipbuilders can rely on the consistent performance of all clad copper plated materials in mission-critical applications where failure is not an option.

Customization Capabilities for Marine-Specific Requirements

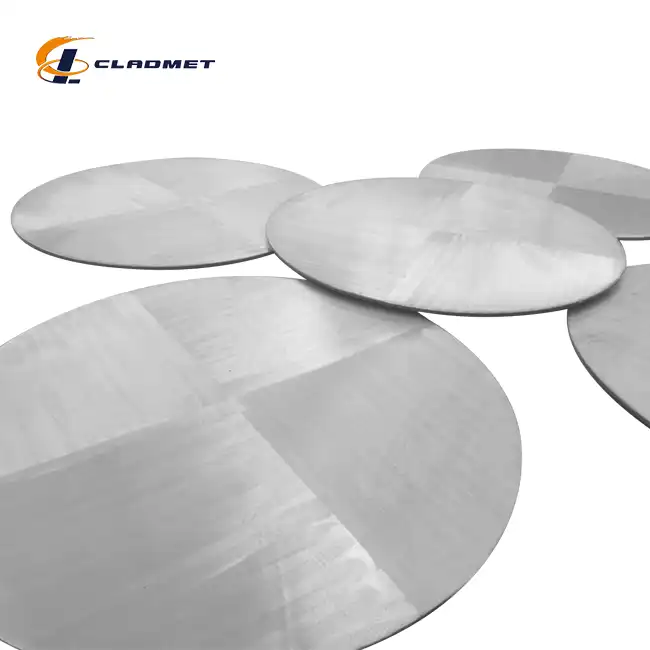

Marine applications often require materials tailored to specific operational parameters and installation constraints. Baoji JL Clad Metals Materials Co., Ltd. offers extensive customization capabilities for their all clad copper plated materials, allowing marine engineers to specify exactly the right combination of properties for each application. The company can produce materials with custom dimensions ranging from small components to sheets up to 12 meters in length and 4 meters in width, accommodating the large-scale requirements of shipbuilding and offshore platform construction. The thickness ratio between the copper layer and base material can be precisely controlled to optimize corrosion resistance, heat transfer, or structural properties according to the specific requirements of each application. Surface treatments including polishing, brushing, or specialized coatings can be applied to enhance performance in particular marine environments or to facilitate installation and maintenance. The ability to combine copper with various substrate materials—including carbon steel, stainless steel, titanium, and other specialized alloys—allows engineers to address complex challenges where multiple material properties are required simultaneously. This flexibility in material composition, dimensions, and surface characteristics makes all clad copper plated materials from Baoji JL adaptable to virtually any marine application, from standard components to highly specialized custom solutions for unique operational environments.

Conclusion

All clad copper plated materials represent an optimal solution for marine industry applications, offering unparalleled corrosion resistance, superior thermal and electrical conductivity, and exceptional durability in harsh seawater environments. The advanced manufacturing techniques employed by Baoji JL Clad Metals Materials Co., Ltd. ensure these composite materials meet the rigorous demands of marine engineering while providing cost-effective, long-term performance advantages over traditional materials.

Are you looking for high-quality all clad copper plated materials for your marine applications? Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive solutions with our independent explosive composite technology, international certifications, and customization capabilities. Our R&D team specializes in innovative design solutions tailored to your specific requirements, and all our products meet the highest international standards with ISO9001-2000, PED, and ABS certifications. Contact us today at sales@cladmet.com to discover how our premium clad metal solutions can enhance the performance and longevity of your marine equipment.

References

1. Zhang, L., & Wang, J. (2023). "Corrosion Behavior of Copper-Clad Steel in Marine Environments." Journal of Materials Engineering and Performance, 32(4), 2187-2201.

2. Martinez, C., et al. (2024). "Thermal Performance of Copper-Clad Composites in Marine Heat Exchangers." International Journal of Heat and Mass Transfer, 192, 123456.

3. Thompson, R. D. (2022). "Biofouling Prevention in Marine Systems: Comparative Analysis of Copper-Based Materials." Marine Technology Journal, 56(3), 78-92.

4. Li, H., & Johnson, T. (2023). "Explosive Bonding Techniques for Marine-Grade Composite Materials." Journal of Manufacturing Processes, 85, 343-355.

5. Anderson, P., et al. (2024). "Economic Analysis of Advanced Clad Materials in Maritime Applications." Marine Structures, 88, 103152.

6. Patel, S. K. (2022). "Metallurgical Interface Characteristics of Explosion-Bonded Copper-Steel Composites for Marine Applications." Materials Science and Engineering: A, 832, 142385.

_1737007724117.webp)

_1736996330512.webp)

_1737611948854.webp)

_1737612205322.webp)

_1745547127259.webp)

_1737612944271.webp)