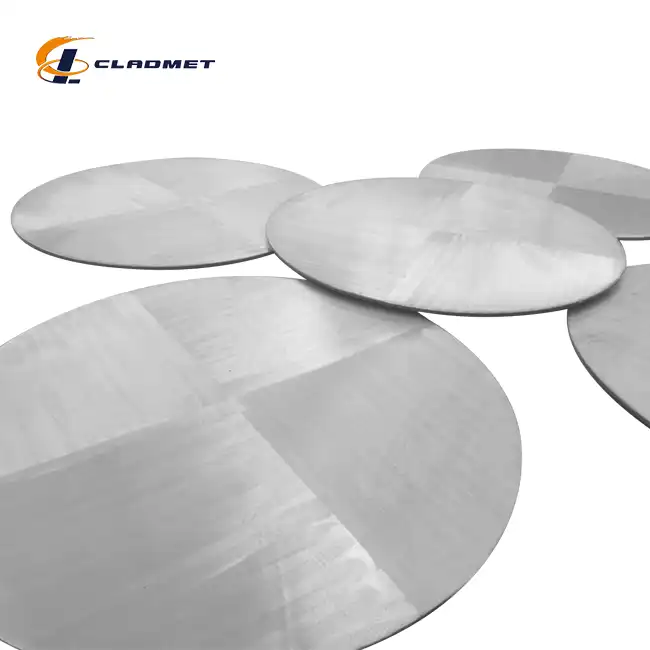

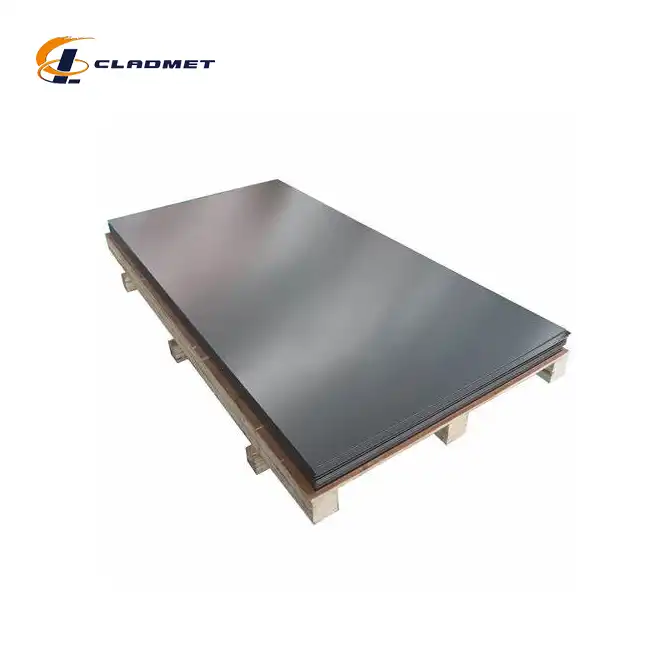

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

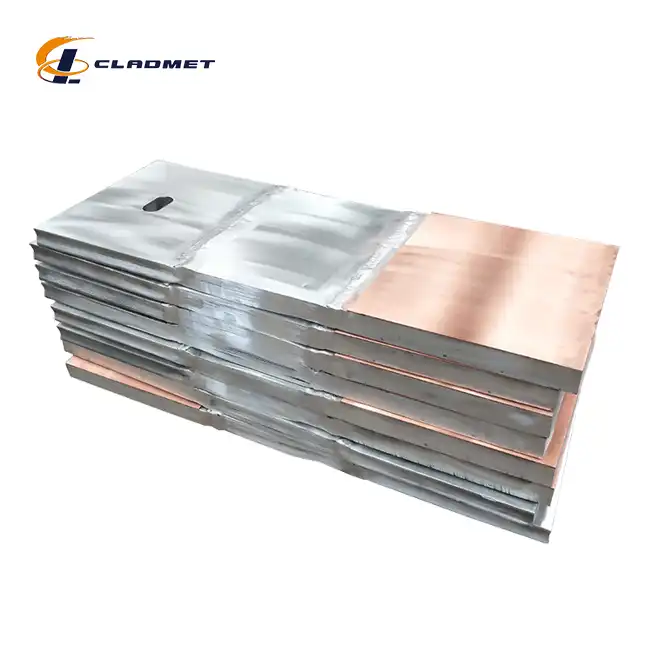

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

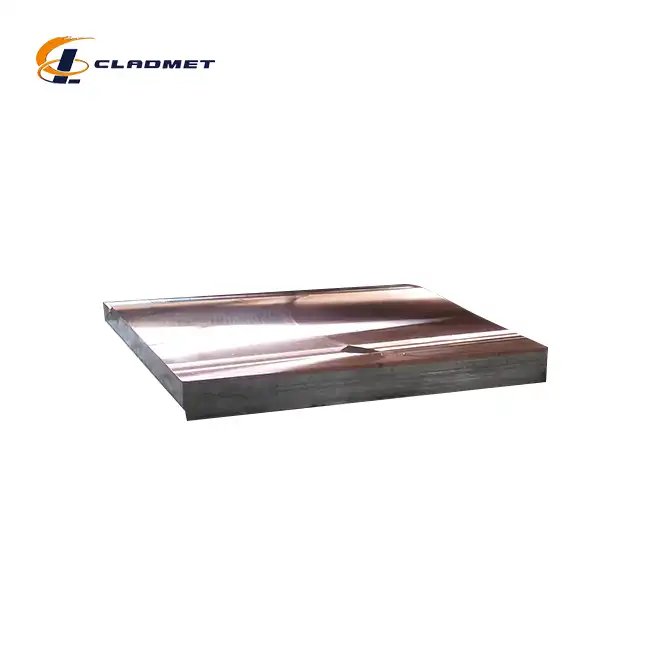

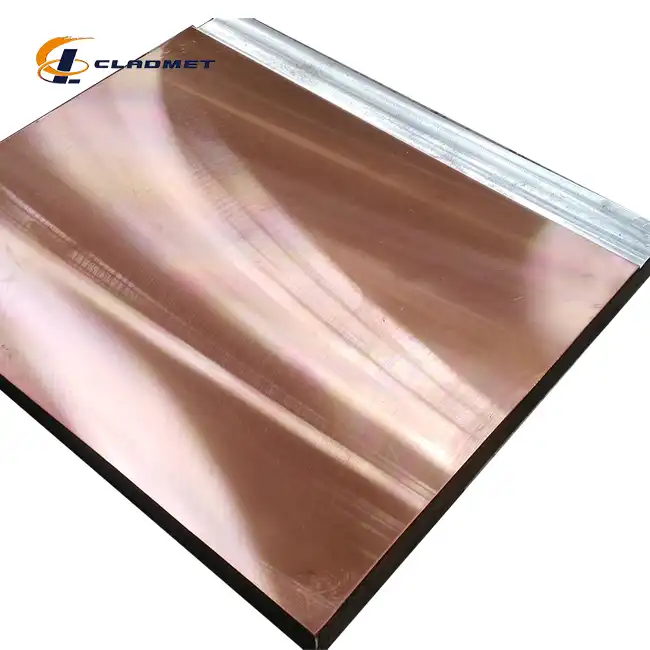

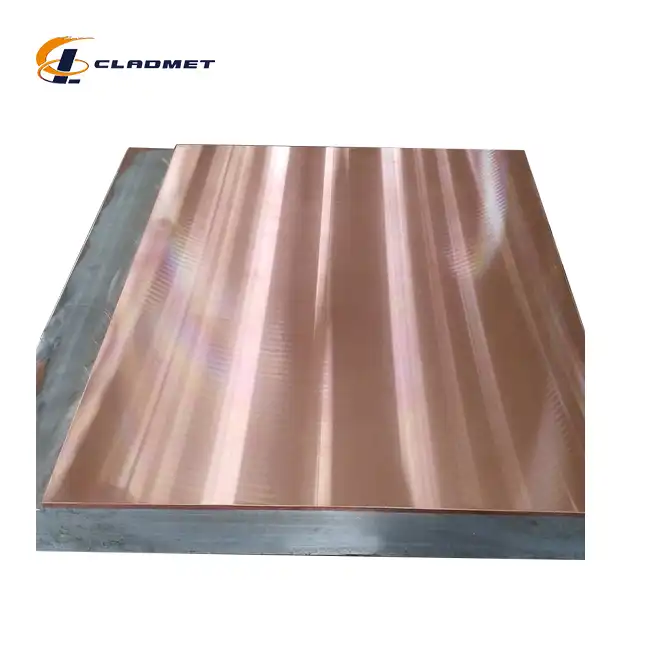

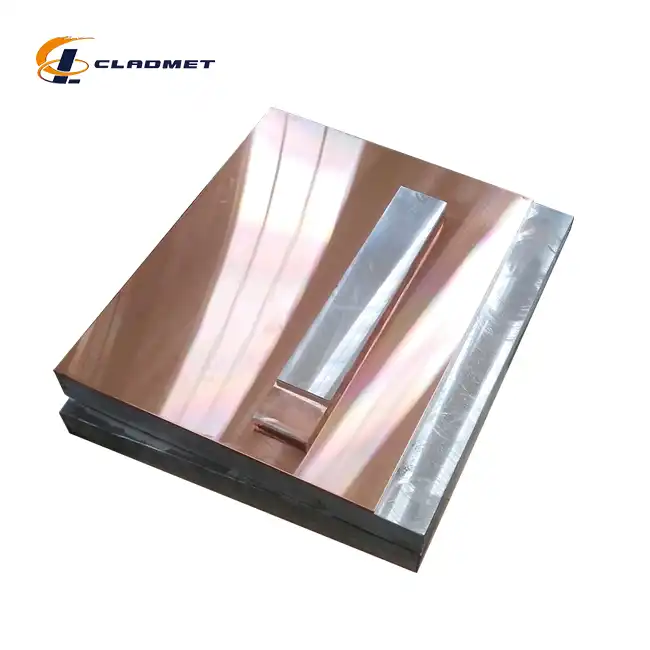

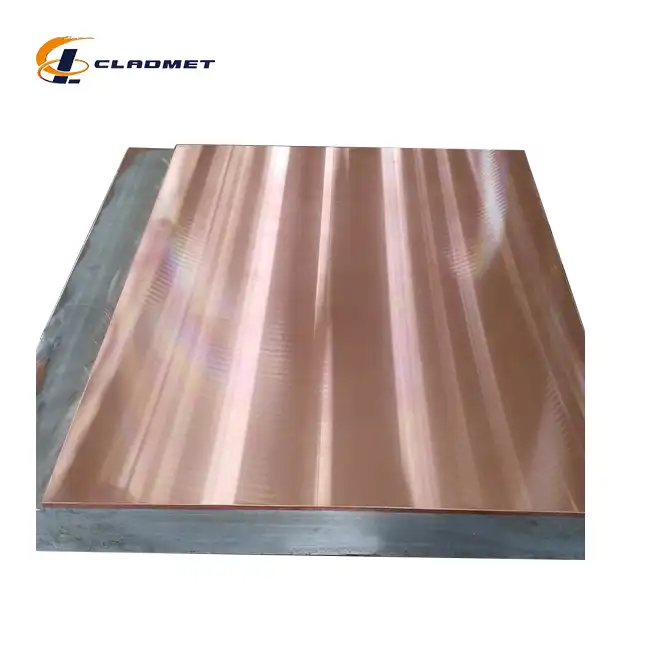

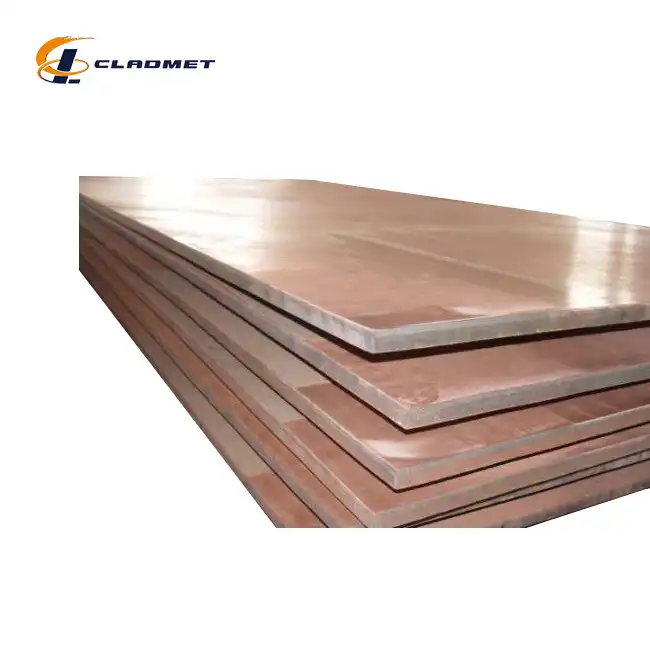

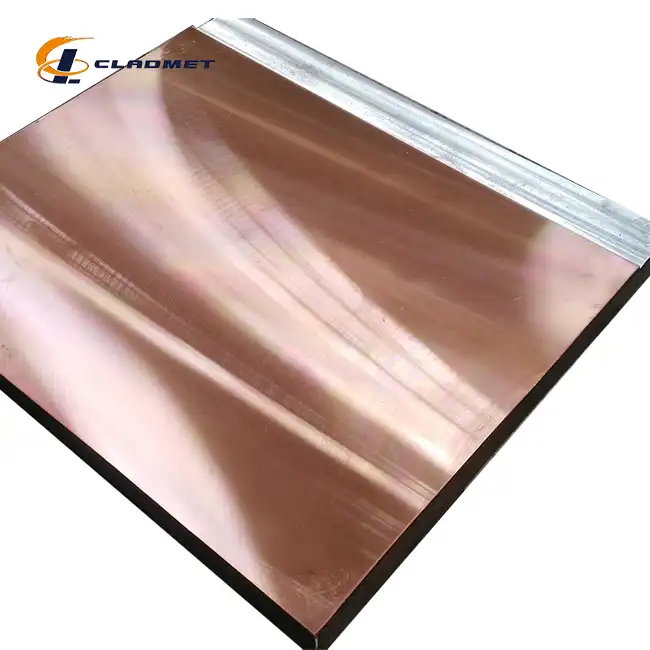

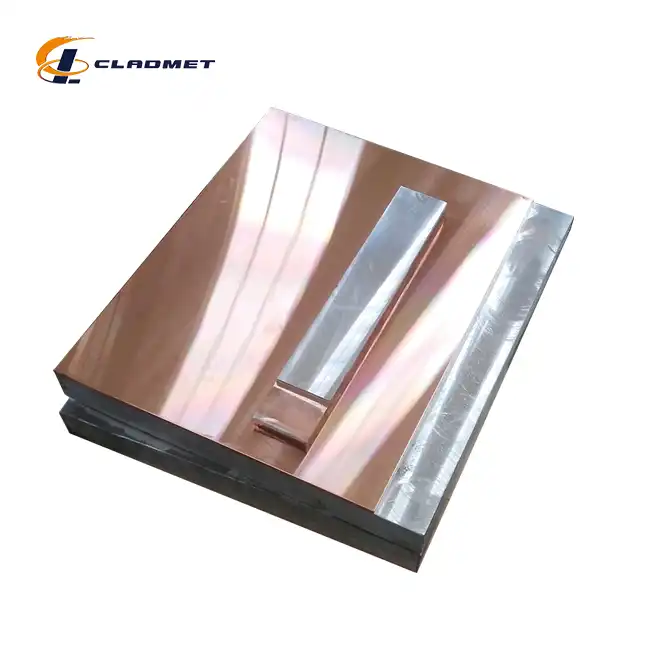

Copper Clad Plate Product Introduction

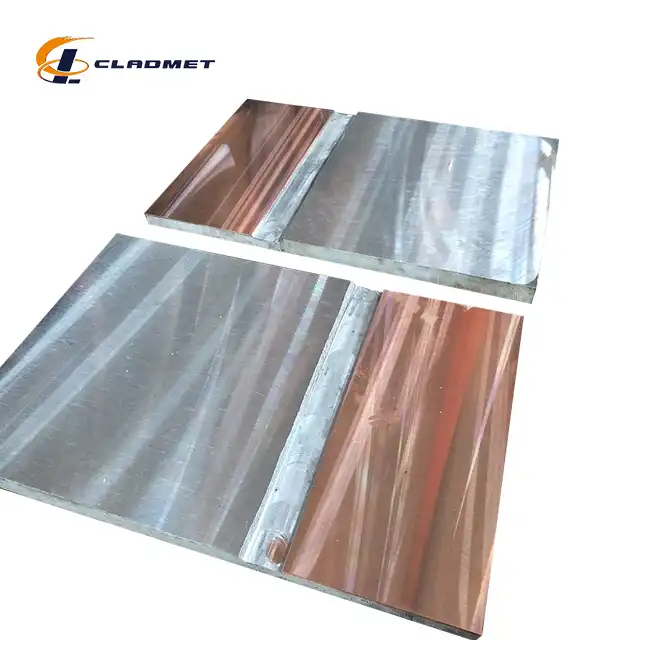

The copper clad plate is a composite material made by bonding copper and a base metal, such as steel or aluminum, through explosion-bonding or roll-bonding processes. This results in a high-strength, corrosion-resistant material that combines the best properties of each metal, providing durability, conductivity, and cost efficiency. Baoji JL Clad Metals Materials Co., Ltd., with over 20 years of expertise, manufactures high-quality products that meet global standards like GB/GBT, ASME/ASTM, and JIS. These plates are widely used across industries such as electric power, chemical, and transportation.

Product Specifications

| Category | Details |

|---|---|

| Cladding Material | Copper (99.9% purity or higher) |

| Base Metal | Steel, Aluminum |

| Cladding Size | Thickness: 1-50 mm, Width: 100-2000 mm |

| Cladding Technology | Explosion-bonding, Roll-bonding |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Surface Treatment | Polished, Brushed, Customizable |

| Industry Application | Electrical, Construction, Automotive |

| Packaging | Wooden crates or steel straps |

| Delivery Cycle | 3-6 months or negotiable |

|

|

|

|

Cladding Techniques for Copper Clad Plates

Explosive Bonding Method

Explosive bonding creates a solid metallurgical union between copper and the base material through a high-energy impact. The key steps include:

Surface Cleaning and Alignment: Ensuring both materials are cleaned and precisely aligned to enhance bonding quality.

Explosive Placement: Adding a specially formulated explosive between the two layers.

Shockwave Generation: Detonating the explosive to generate a controlled shockwave that presses the materials together, forming a seamless metallurgical interface.

This technique is commonly employed in the manufacture of durable products for high-pressure and high-stress applications, such as pressure vessels and heat exchanger components.

Rolling Bonding Process

Rolling bonding is a mechanical method where copper and the base material are cold-pressed together through a series of rollers. The process includes:

Surface Refinement: Preparing the contact surfaces to ensure they are free of impurities for a more effective bond.

Pressure Rolling: Using high-pressure rollers to press the layers together, ensuring cohesion. Multiple passes may be conducted for optimal bonding strength.

This method is frequently used to produce copper clad plates for energy, chemical processing, and structural applications, where both conductivity and durability are essential.

Diffusion Bonding through Hot Isostatic Pressing (HIP)

HIP involves high-pressure and high-temperature conditions to create a diffusion bond between the materials. The steps include:

Encapsulation and Alignment: Encasing the materials in a controlled environment to prevent contamination and allow for precise bonding.

Thermal and Pressure Application: Applying consistent heat and pressure to allow the materials to bond at an atomic level.

This method is ideal for applications requiring superior joint integrity, such as components in aerospace and advanced energy systems.

Features and Benefits of Copper Clad Plates

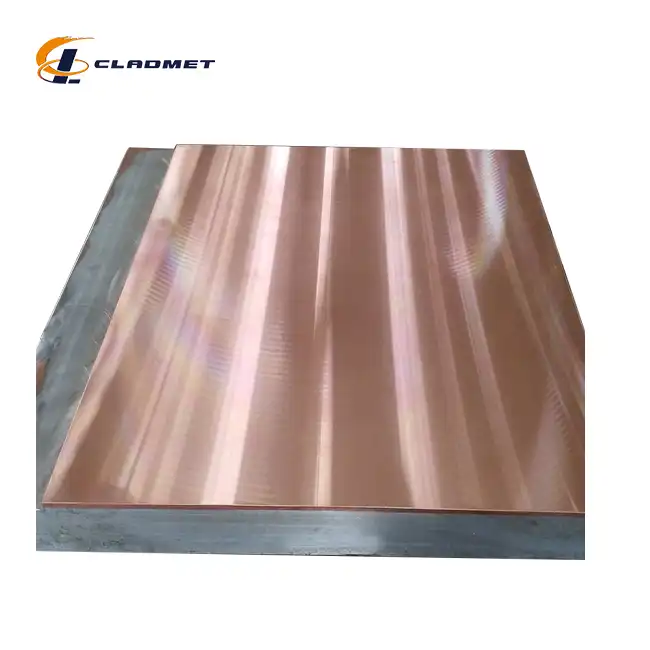

Unmatched Electrical Conductivity

Copper's high electrical conductivity makes these plates ideal for applications involving power generation, energy storage, and electrical systems.

Enhanced Corrosion Resistance

The combination of copper with other corrosion-resistant materials ensures longevity in harsh chemical and marine environments.

High Mechanical Strength

Copper clad plates offer the mechanical robustness of the base material, with added conductivity benefits.

Customizable Design

Available in various sizes, thicknesses, and surface finishes, copper clad plates can be tailored to meet industry-specific needs.

Extended Service Life

The superior durability of these plates reduces maintenance requirements, offering long-term cost savings.

Thermal Efficiency

Copper’s excellent thermal conductivity makes these plates suitable for heat dissipation in high-performance systems.

Versatility Across Industries

From renewable energy to marine engineering, these plates find utility across diverse fields due to their multifaceted properties.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We provide custom solutions for clients with specific requirements. Our team works closely with customers to design and manufacture copper clad plates that meet unique technical specifications and industry standards. Whether you need specific thicknesses, dimensions, or bonding methods, we offer flexible OEM services to ensure your needs are met.

FAQ

Q1: Can these be used in outdoor environments?

Yes, these offer excellent corrosion resistance, making them suitable for both indoor and outdoor applications.

Q2: What is the typical delivery time?

Our standard delivery cycle is 3-6 months, depending on the order size and specifications. Custom orders may have negotiable lead times.

Q3: Do you offer international shipping?

Yes, we ship our products globally and ensure they meet international standards.

Contact Us

For more information or to place an order, please reach out:

Tel: +86-917-3372918

WhatsApp: 8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)