Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

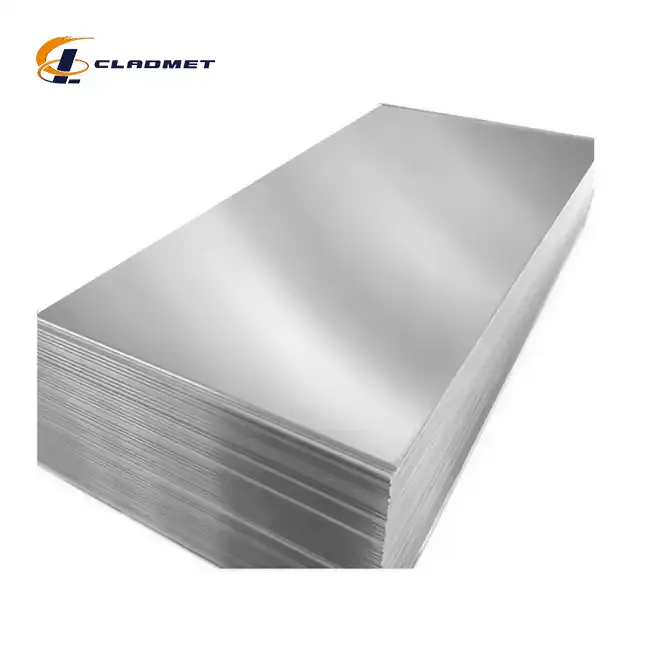

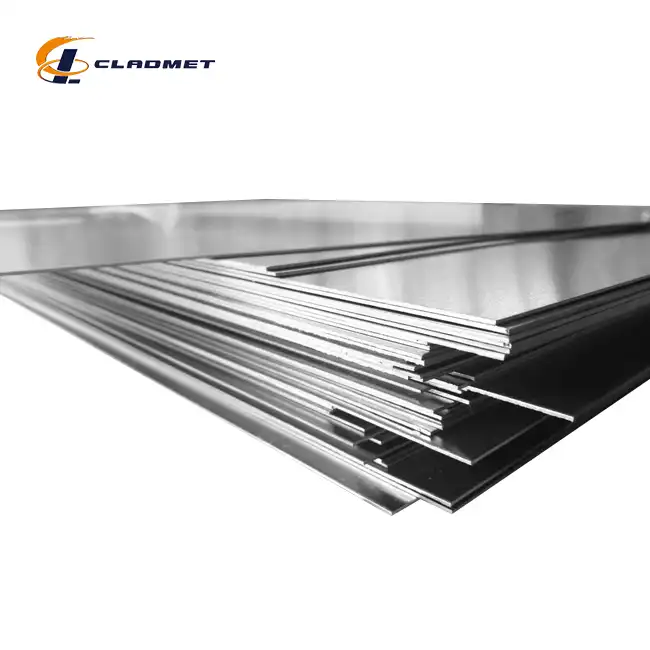

Pressure Vessel Clad Metal Plate Introduction

Welcome to Baoji JL Clad Metals Materials Co., Ltd! We proudly present our Pressure Vessel Clad Metal Plate, an innovative solution designed to meet the rigorous demands of various industries. Our clad metal plates combine different metals to enhance strength, corrosion resistance, and durability, making them ideal for pressure vessels in sectors such as oil and gas, chemical processing, and nuclear power. With a commitment to quality and compliance with international standards, our products guarantee reliability and performance.

Product Material Requirements

Our Pressure Vessel Clad Metal Plates are manufactured using a combination of high-quality metals to ensure optimal performance and durability. The primary materials include:

- Titanium and its alloys

- Nickel and nickel-based alloys

- Stainless steel

- Aluminum

- Copper

- Zirconium

These materials are selected for their exceptional properties, providing enhanced resistance to corrosion and wear, which are critical for pressure vessel applications.

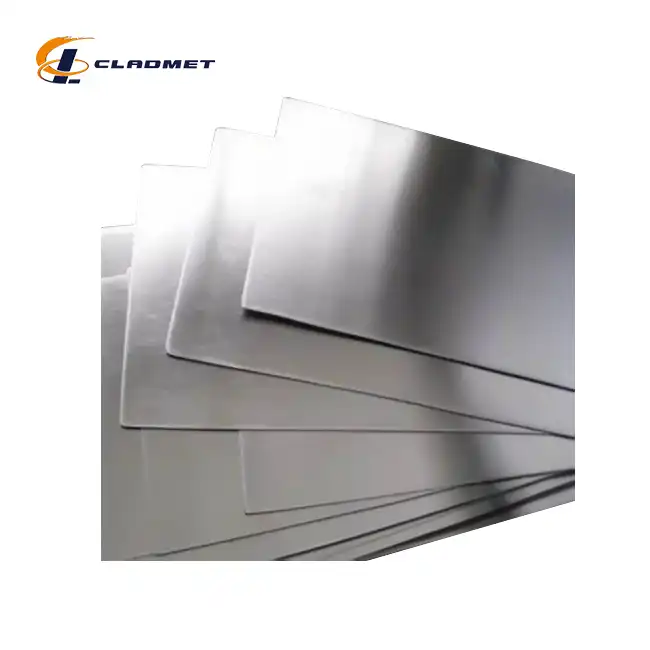

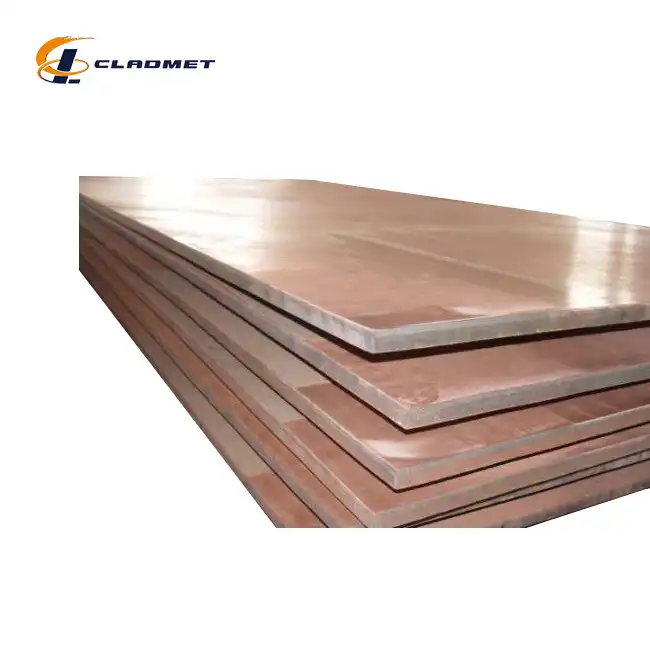

Product Specifications

| Parameter | Description |

|---|---|

| Base Material | Carbon Steel, Low Alloy Steel (e.g., Q235B, Q345B, A516 Gr.70, SA387, etc.) |

| Cladding Material | Stainless Steel (304, 316L, 321, etc.), Titanium (Gr1, Gr2, TA1, TA2), Copper (T2, C11000), Nickel Alloy (Inconel, Monel), or Customized Materials |

| Total Thickness Range | 6 mm - 200 mm (e.g., 2 mm Cladding + 8 mm Base Steel) |

| Clad Layer Thickness | 1 mm - 20 mm (customizable) |

| Base Layer Thickness | 5 mm - 180 mm (customizable) |

| Width Range | Up to 4000 mm |

| Length Range | Up to 12000 mm |

| Bonding Technology | Explosion Bonding, Hot Rolling, or Explosion + Rolling |

| Bonding Strength | ≥ 140 MPa |

| Shear Strength | ≥ 105 MPa |

| Corrosion Resistance | Excellent resistance to corrosive environments based on cladding material (acid, alkali, seawater, etc.) |

| Heat Resistance | High-temperature performance depending on cladding material |

| Application Industries | Pressure Vessels, Chemical Reactors, Heat Exchangers, Storage Tanks, Desalination Plants, Oil & Gas, etc. |

| Standards Compliance | ASTM A264, ASME SA-264, ASTM B898, ASME SB-898, GB/T 8165, and other relevant standards |

| Surface Finish | Polished, Sandblasted, or Customized |

| Customizations Available | Thickness Ratio, Material Combination, Dimensions, Surface Finish, etc. |

|

|

Manufacturing Techniques

Explosive Welding

Explosive welding is a highly effective method used to bond materials with differing properties, such as carbon steel and titanium or stainless steel cladding. The process involves detonating an explosive charge between the two layers, causing a high-energy impact that forces the materials to bond at a molecular level. This technique creates a highly robust and reliable bond, making it ideal for pressure vessel clad metal plates, especially in industries like oil and gas, where reliability and strength are paramount.

Roll Bonding

Roll bonding is a cold welding process in which the base material and cladding are fed through rollers under high pressure. This method results in a physical bond between the two materials, ensuring they adhere together without the need for heat. Multiple passes through the rollers may be required to form a complete bond, making roll bonding an effective choice for pressure vessel clad metal plates in industries like chemical processing and power generation. The process also allows for precise control over the thickness of the cladding and base material, offering flexibility in design.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) involves placing the cladding and base material inside a sealed container, where heat and pressure are applied uniformly to create a diffusion bond. The HIP process is particularly useful for applications requiring high integrity in bonding, ensuring that the titanium or stainless steel cladding tightly adheres to the base material. This technique is commonly used for pressure vessel clad metal plates in aerospace, power generation, and oil and gas applications, where the plates must meet stringent safety and performance standards.

Key Features and Advantages

Superior Corrosion Resistance

The primary advantage of pressure vessel clad metal plates is their exceptional resistance to corrosion, especially in aggressive environments such as offshore platforms or chemical plants. The cladding, typically made of materials like titanium, stainless steel, or nickel alloys, provides a protective barrier against corrosion, extending the life of pressure vessels and reducing maintenance costs.

High Mechanical Strength

The combination of a high-strength base material (such as carbon steel) with corrosion-resistant cladding ensures that pressure vessel clad metal plates can withstand the high pressures and mechanical stresses encountered in critical applications. The robust construction of these plates guarantees safety and reliability in demanding environments.

Thermal Stability

Pressure vessel clad metal plates are designed to perform well under high temperatures, ensuring that the materials maintain their structural integrity and functionality even in extreme conditions. This thermal stability makes them ideal for industries like power generation, where pressure vessels must endure high thermal loads over extended periods.

Customization for Specific Needs

One of the significant benefits of pressure vessel clad metal plates is their versatility. They can be customized to meet the specific needs of various industries, including adjustments to the thickness, material composition, and surface finish. This flexibility allows manufacturers to create solutions tailored to the unique demands of each application.

Cost Efficiency

While materials like titanium and stainless steel are expensive, using them as cladding over a more affordable base material (such as carbon steel) helps reduce overall costs without sacrificing performance. This cost-effective approach ensures that pressure vessels remain durable and resistant to corrosion while keeping material expenses in check.

Enhanced Safety

The bonding of cladding to the base material through processes like explosive welding and roll bonding ensures that pressure vessel clad metal plates remain intact and functional under high stress. This is especially crucial in industries like oil and gas, where safety is a top priority and failures can result in costly and dangerous consequences.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

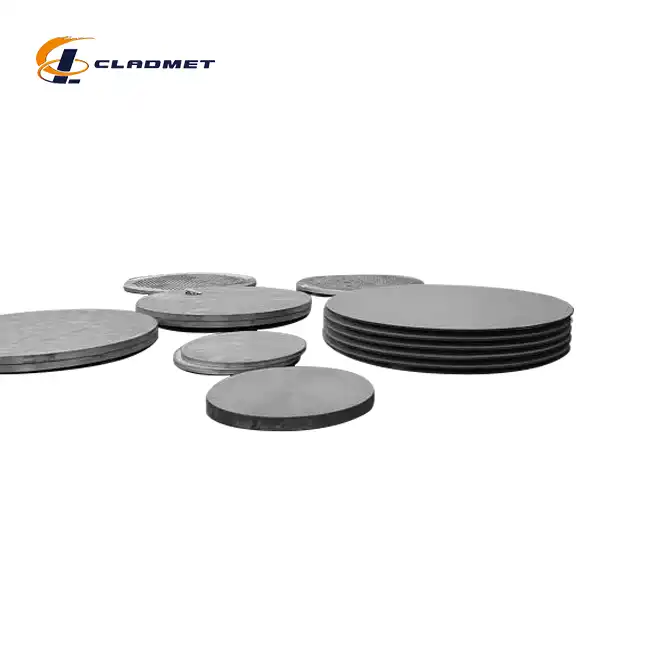

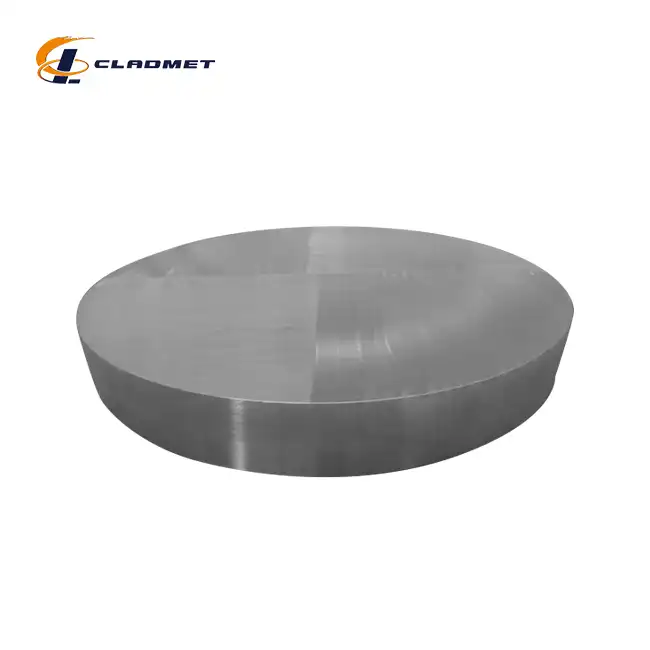

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals Materials Co., Ltd, we offer comprehensive OEM services to meet the unique requirements of our clients. Our team works closely with customers to develop tailored solutions that align with their specific applications and operational needs. From design to production, we ensure quality and performance are never compromised. Our tailored approach involves close collaboration with you throughout the design and manufacturing process, ensuring that every detail is meticulously addressed. We pride ourselves on our flexibility and responsiveness, allowing us to adapt to the evolving needs of your project with agility and precision.

FAQ

Q1: What are clad metal plates?

A1: Pressure Vessel Clad Metal Plates are composite plates made from two or more layers of different metals bonded together to enhance their properties, such as strength and corrosion resistance.

Q2: What industries use Pressure Vessel Clad Metal Plates?

A2: These plates are primarily used in the oil and gas, chemical, nuclear, aerospace, and marine engineering industries.

Q3: What is the lead time for delivery?

A3: Our standard delivery cycle ranges from 3 to 6 months, but this can be negotiated based on your specific requirements.

Q4: Do you provide custom sizes?

A4: Yes, we can manufacture custom sizes and specifications to meet your specific needs.

Contact Us

For more information or to discuss your specific requirements about Pressure Vessel Clad Metal Plates, please reach out to us:

- Phone: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)

_1737612205322.webp)