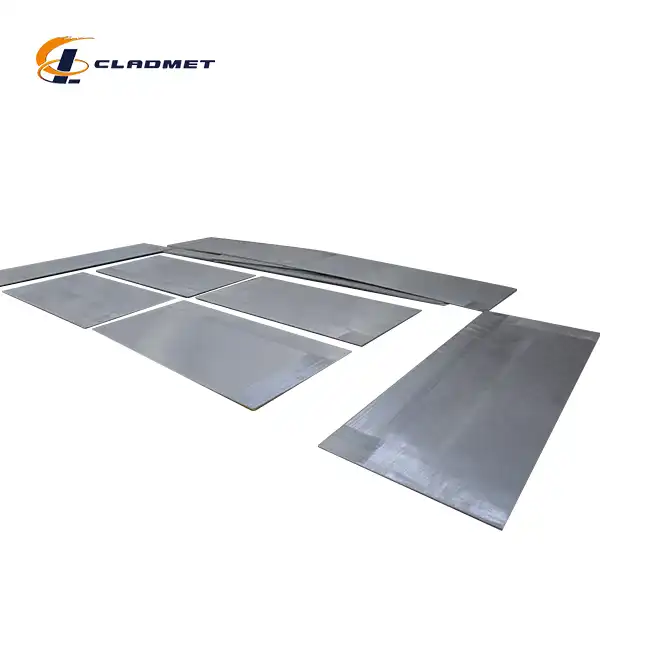

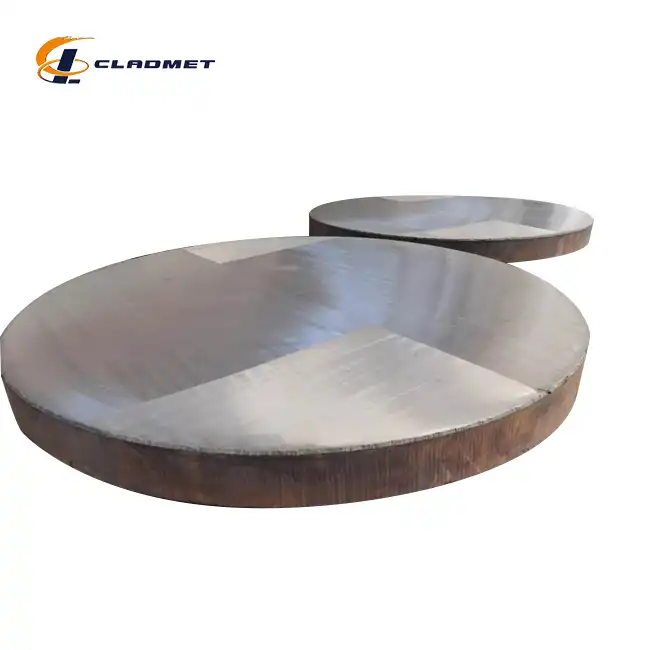

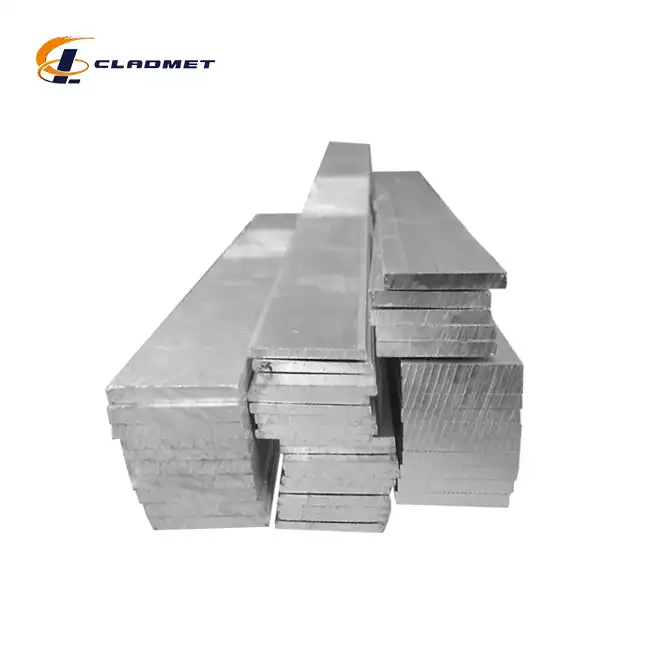

Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

The Copper Carbon Steel Clad Rod from Baoji JL Clad Metals Materials Co., Ltd. is a high-performance, composite material designed for industries requiring the strength of carbon steel combined with the conductivity and corrosion resistance of copper. This clad rod is manufactured using explosive welding (EXW) technology, ensuring a durable bond between the two materials. It is an ideal solution for applications such as electrical engineering, chemical equipment, and marine construction where both mechanical strength and corrosion resistance are crucial.

Product Specifications

| Parameter | Details |

|---|---|

| Cladding Material | Copper |

| Base Metal | Carbon Steel |

| Cladding Thickness | 2mm – 10mm |

| Base Metal Thickness | 5mm – 50mm |

| Cladding Size | Customizable based on client requirements |

| Cladding Technology | Explosive Welding (EXW) |

| Product Standards | ASME, ASTM, GB/T, JIS |

| Length | 2m – 12m |

| Surface Treatment | Polished or as requested |

| Packaging Method | Wooden crates, steel strips, or custom packaging |

| Transportation | Sea, air, or land transport available |

| Delivery Cycle | 3–6 months (negotiable depending on order size) |

|

|

|

|

Manufacturing Techniques for Copper Carbon Steel Clad Rods

Explosive Bonding

Explosive bonding is a highly effective method used to join copper and carbon steel at a molecular level. In this process, a precisely controlled explosive charge is applied between the copper and carbon steel layers, creating an intense shockwave that forces the materials to fuse together. The explosive force ensures a strong metallurgical bond without the need for welding, making this method ideal for applications requiring robust bond strength under harsh conditions, such as pressure vessels and heat exchangers.

Roll Bonding

Roll bonding is a cold welding process in which the copper and carbon steel layers are subjected to high pressure as they pass through rollers. This technique creates a strong and uniform bond between the materials, which can be enhanced by making multiple passes through the rollers. Roll bonding is particularly suitable for producing clad rods and plates used in industrial applications, such as chemical processing, automotive parts, and offshore structures.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is another advanced technique that involves sealing the copper and carbon steel materials in a container and subjecting them to high temperature and pressure. This process leads to atomic diffusion, where the metals bond at a molecular level. HIP is ideal for situations where exceptional bond integrity is required, such as in aerospace, oil and gas industries, and high-performance equipment.

Advantages of Copper Carbon Steel Clad Rods

Corrosion Resistance

The copper layer in these rods provides natural resistance to corrosion, especially in environments exposed to moisture, chemicals, and gases. The carbon steel core offers mechanical strength while the copper cladding ensures durability, making these rods highly effective in environments where corrosion is a major concern.

Electrical Conductivity

With a copper core, these rods provide excellent electrical conductivity, which is essential in various electrical applications. They are ideal for power transmission, electrical wiring, and components that require efficient current flow while maintaining durability in harsh conditions.

High Strength and Durability

The carbon steel core provides the rods with outstanding strength, making them suitable for structural applications that require both strength and resistance to wear and fatigue. The copper cladding enhances the rods' performance by adding resistance to corrosion and improving long-term durability, making them a cost-effective solution for industries with demanding operational requirements.

Lightweight and Cost-Effective

Despite the strong and durable construction, copper carbon steel clad rods remain relatively lightweight compared to all-metal options. This characteristic is particularly beneficial in applications where weight is a crucial factor. Additionally, the combined properties of both copper and carbon steel reduce costs by decreasing the need for frequent replacements or repairs.

Customization Options

These rods can be tailored to meet the specific needs of various industries. Whether it involves adjusting the diameter, length, surface finish, or adding special coatings, customization ensures the rods meet the unique demands of each application. This adaptability enhances the versatility and effectiveness of these rods in a wide range of sectors.

Improved Performance in Challenging Conditions

Copper carbon steel clad rods offer a remarkable balance of mechanical strength and electrical performance. Their resilience in extreme conditions such as high temperatures, pressure, and corrosive environments makes them ideal for applications in industries such as aerospace, energy, and marine technology.

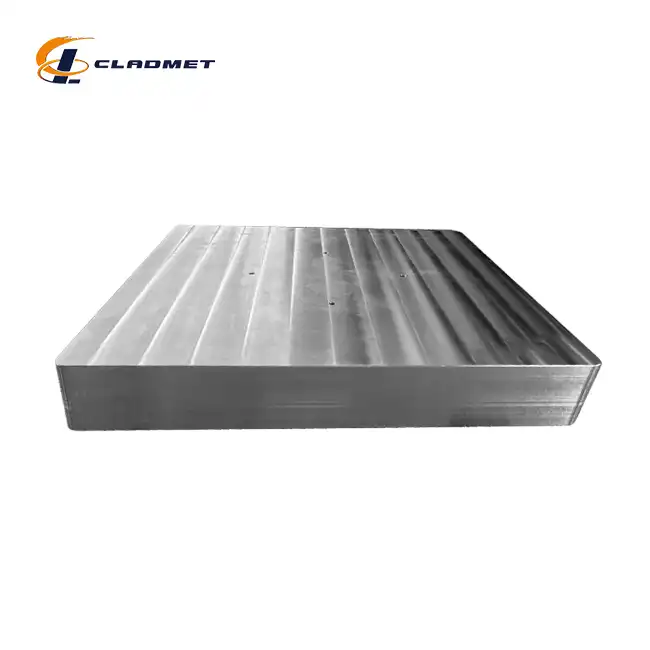

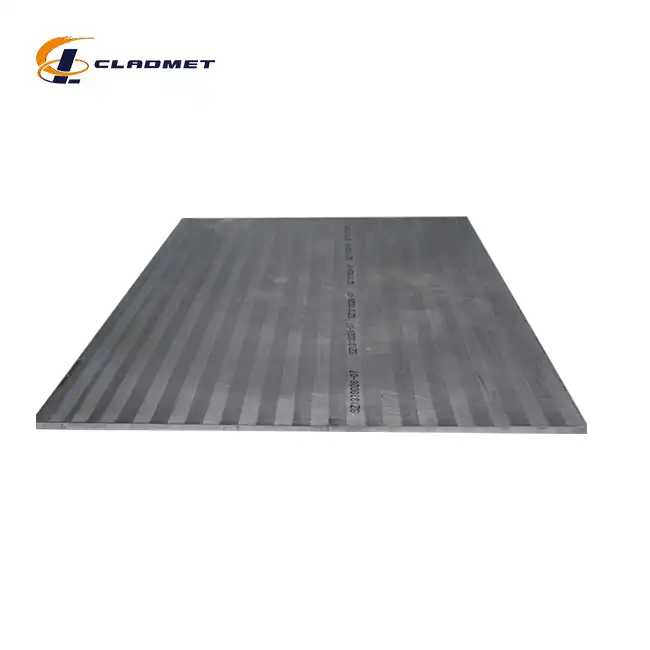

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Baoji JL Clad Metals Materials Co., Ltd. offers OEM services for customers requiring specific dimensions, shapes, or finishing for the Copper Carbon Steel Clad Rod. Our expert team works closely with clients to develop tailored solutions that meet their exact industry standards and requirements.

FAQs

1.What is the minimum order quantity for our products?

The minimum order quantity is negotiable based on your specific project requirements.

2.What is the delivery timeline?

The standard delivery timeline ranges from 3 to 6 months, depending on order size and customization needs.

3.Can the rods be customized in terms of length and diameter?

Yes, we offer full customization based on your project specifications.

4.What testing standards do the products adhere to?

Our priducts adhere to ASME, ASTM, GB/T, and JIS standards.

Contact Us

For mors informations about Copper Carbon Steel Clad Rods and to place an order, please contact us at:

Phone: +86-917-3372918

WhatsApp: 8613530170059

Email: sales@cladmet.com

Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China 721013

_1737007724117.webp)

_1737612205322.webp)

_1737612204932.webp)

_1737612204966.webp)

_1737612206009.webp)

_1737611764680.webp)

_1737612858536.webp)