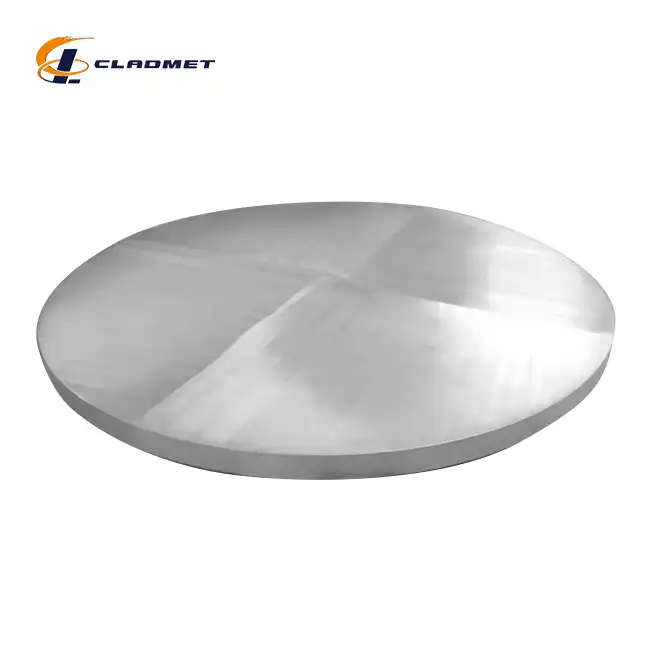

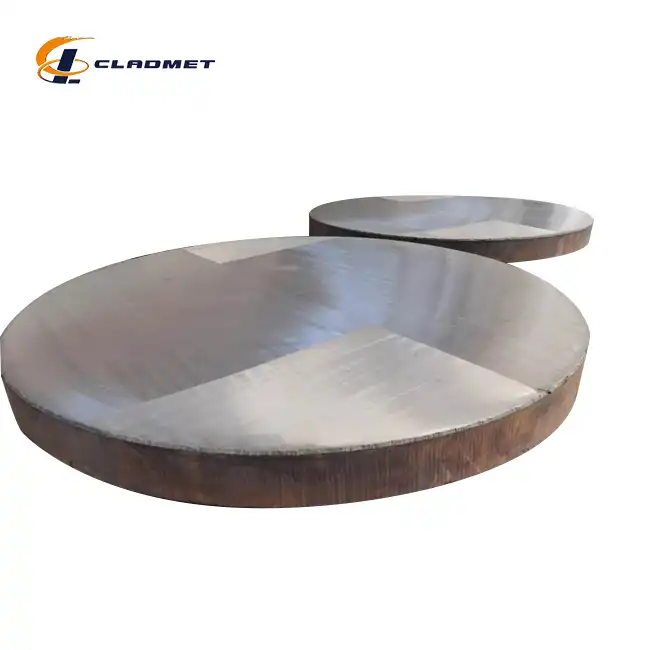

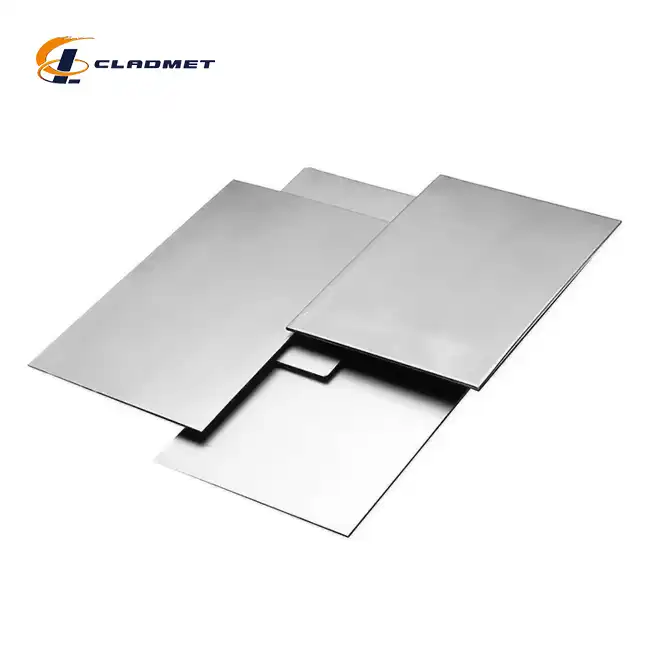

Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

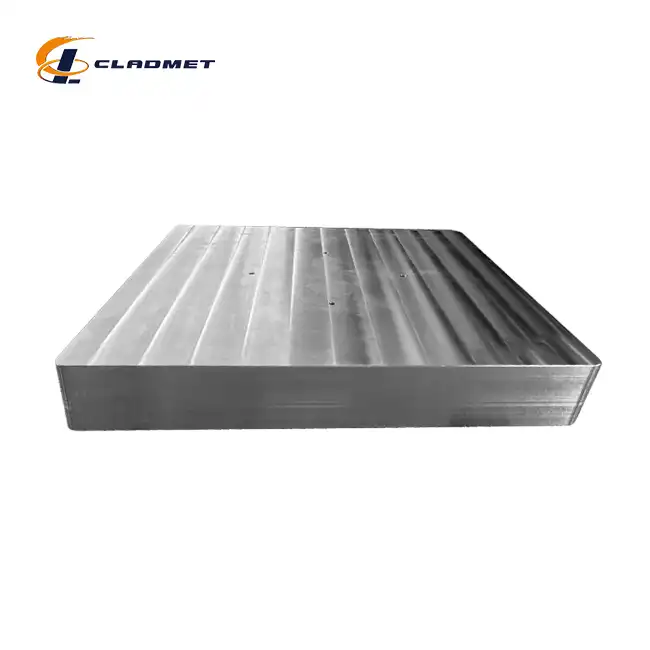

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

Titanium copper clad rods are innovative composite materials that combine the excellent properties of both titanium and copper. These rods are designed to offer high strength, superior corrosion resistance, and enhanced electrical conductivity, making them ideal for industries requiring advanced materials that can withstand harsh environments. At Baoji JL Clad Metals Materials Co., Ltd., we specialize in manufacturing top-quality products that meet international standards like ASME/ASTM, JIS, and GB/GBT. Our product is widely used in various industries, such as electronics, petrochemical, marine engineering, and power generation.

Product Specifications

| Specification | Details |

|---|---|

| Cladding Material Range | Pure titanium (Grade 1, 2) |

| Base Metal Range | Pure copper (T2) |

| Cladding Size | Diameter: 10-150mm |

| Cladding Technology | Explosion bonding, Roll bonding |

| Product Standards | GB/GBT, ASTM, ASME, JIS |

| Thickness | Customizable |

| Length | 500mm - 6000mm |

| Surface Treatment | Polishing, Sandblasting |

| Packaging Method | Wooden crates, Steel frames |

| Delivery Cycle | 3-6 months (negotiable) |

| Application Industries | Electronics, Marine engineering, etc. |

| Transportation | Sea freight, Air freight |

|

|

|

|

Manufacturing Techniques for Titanium-Copper Clad Rods

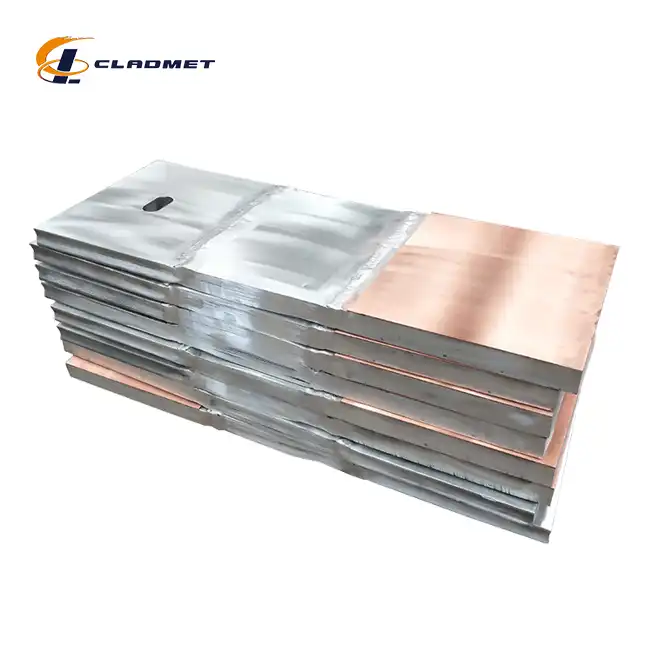

Explosive Bonding

Explosive bonding is a dynamic process used to create a high-strength bond between titanium and copper. In this method, an explosive charge is detonated between the two metal layers, generating a powerful force that causes the metals to fuse together at high speed. This results in a solid, metallurgical bond. The explosive bonding technique is often chosen for applications where the strength of the bond is of paramount importance, such as in the manufacturing of industrial components exposed to extreme environments.

Roll Bonding

Roll bonding is a cold-welding technique in which the base material (titanium) and copper are passed through rollers under high pressure. This pressure forces the two layers to bond together, forming a strong composite material. The method is effective for producing large quantities of clad rods and is commonly used in the creation of components for industries such as aerospace, marine engineering, and power generation.

Hot Isostatic Pressing (HIP)

In Hot Isostatic Pressing (HIP), the titanium and copper materials are sealed in a container and subjected to high pressure and temperature. This process allows the materials to bond at the atomic level through diffusion, resulting in a homogeneous and highly durable product. HIP is especially effective for applications where material integrity and high-performance standards are critical, such as in aerospace and defense industries.

Key Features and Advantages of Titanium-Copper Clad Rods

Corrosion Resistance

The titanium cladding offers exceptional resistance to corrosion, particularly in aggressive environments like seawater, chemicals, and industrial fluids. This makes titanium-copper clad rods highly effective in applications where exposure to harsh conditions is common.

Superior Electrical Conductivity

The copper core ensures high electrical conductivity, making these rods ideal for applications in electrical systems that require efficient current transmission. The combination of titanium’s strength and copper’s conductivity offers a unique solution for demanding electrical and electronic applications.

Strength-to-Weight Ratio

Titanium’s lightweight nature combined with its high strength ensures that the clad rods maintain structural integrity without adding unnecessary weight. This is particularly important in industries such as aerospace and automotive, where reducing weight can lead to improved performance and fuel efficiency.

Customization Options

These rods can be tailored to meet specific industry requirements, such as varying sizes, lengths, diameters, and surface treatments. This flexibility ensures that the titanium-copper clad rods are suitable for a broad range of applications.

Long-Term Durability

Thanks to the corrosion-resistant properties of titanium, the rods have an extended service life, even in challenging environments. This reduces the need for frequent replacements, making them a cost-effective option over time.

Enhanced Performance

The combination of titanium’s strength and copper’s conductivity ensures that the rods are not only durable but also highly efficient. This makes them ideal for industries where both material strength and electrical efficiency are essential.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer customizable OEM services for our titanium copper clad rods to meet the specific needs of your project. Whether you need a unique size, shape, or surface finish, our experienced R&D team can develop a tailored solution for you. Contact us to discuss your custom requirements, and we’ll work with you to design a product that meets your specifications.

FAQ

Q: What is the delivery time for the product?

A: The standard delivery cycle is 3-6 months, depending on the order size and customization requirements.

Q: Can the rods be customized for specific applications?

A: Yes, we offer a range of customization options, including size, thickness, and surface treatments.

Q: What industries use our products?

A: These Titanium Copper Clad Rods are widely used in electronics, marine engineering, petrochemical, aerospace, and power generation industries.

Q: How are the rods shipped?

A: We package the rods securely in wooden crates or steel frames, and they can be shipped via sea or air freight.

Contact Us

For more information about our Titanium Copper Clad Rod or to place an order, please contact us at:

- Tel: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)

_1737611894905.webp)

_1737611894462.webp)

_1737611894952.webp)

_1737611894498.webp)

_1737612944271.webp)