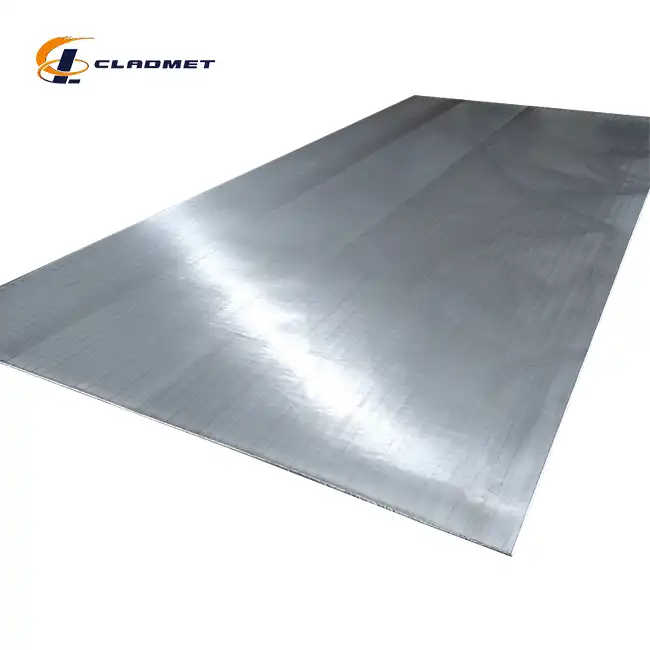

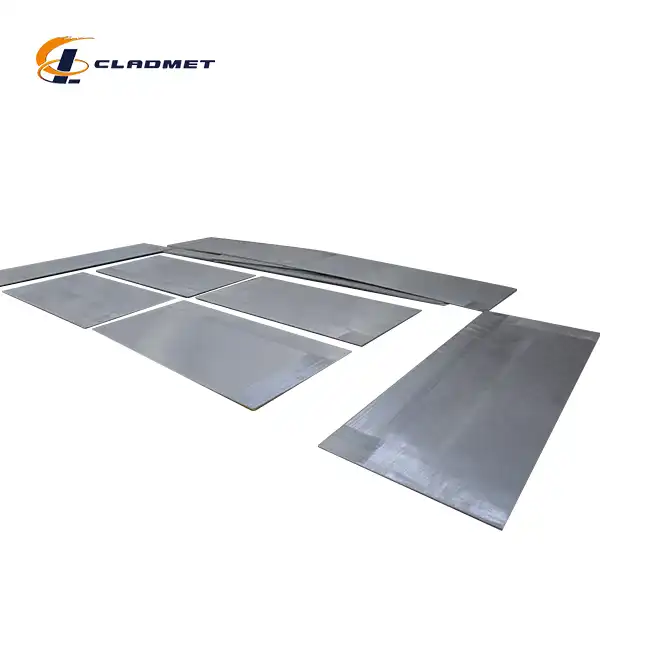

Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

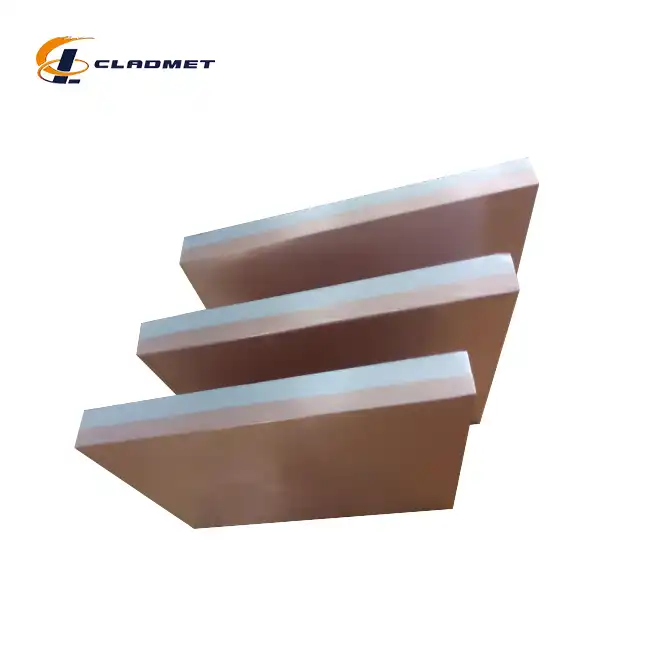

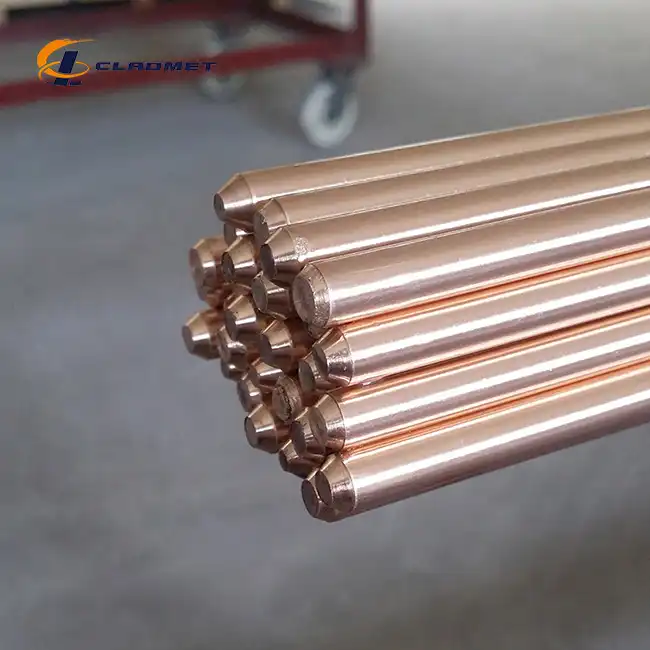

The Aluminum Copper Clad Rod is an advanced material that combines the superior electrical conductivity of copper with the lightweight and cost-effective properties of aluminum. This unique combination provides excellent performance in electrical and thermal conductivity, making it ideal for a wide range of industrial applications. Whether you are looking for a durable, corrosion-resistant material for electrical projects or need a high-strength solution for mechanical structures, the product offers a versatile and efficient option.

With over 20 years of expertise, Baoji JL Clad Metals Materials Co., Ltd. ensures top-quality products that meet international standards such as GB/GBT, ASME/ASTM, and JIS, offering tailored solutions to meet customer needs in industries like electrical, automotive, aerospace, and telecommunications.

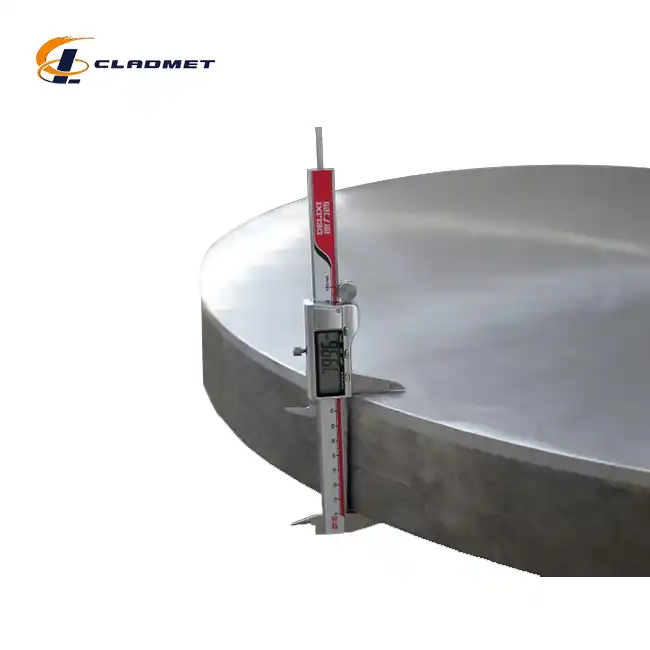

Product Specifications

| Specification | Details |

|---|---|

| Cladding Material Range | Aluminum (various grades) |

| Base Metal Range | Copper (C101, C110) |

| Cladding Technology | Explosion-bonding, Roll-bonding |

| Cladding Size | Customizable according to client needs |

| Thickness | 0.5mm – 200mm |

| Length | Customizable |

| Width | Up to 1500mm |

| Surface Treatment | Polished, anodized, or custom surface treatments available |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Application Industries | Electrical, Automotive, Aerospace, Telecommunications |

| Packaging Method | Wooden crates or customized packaging available |

| Transportation | Shipping via air, sea, or land |

| Delivery Cycle | 3-6 months (negotiable based on order volume) |

|

|

|

|

Manufacturing Techniques

Explosive Welding

Explosive welding, a high-energy impact bonding technique, is employed to fuse aluminum and copper together. The process involves carefully aligning the two materials and placing an explosive charge between them. Once detonated, the explosive force propels the materials toward each other at high velocity, forming a strong metallurgical bond. This bonding method is particularly useful for applications where superior strength and resistance to harsh conditions are required, such as in power generation and heavy-duty industrial equipment.

Roll Bonding

Roll bonding is a cold-welding process that uses pressure to bond aluminum and copper together. During the process, both materials are passed through rollers, which exert intense pressure, causing them to fuse. This method may involve multiple passes to ensure a complete bond, depending on the thickness of the materials. Roll bonding is ideal for producing aluminum copper clad rods used in electrical transmission systems and other structural components, where the efficiency and mechanical strength of the product are paramount.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is another method used to join aluminum and copper at a molecular level. In HIP, the materials are placed inside a sealed container, which is then subjected to high heat and pressure. This process encourages atomic diffusion, resulting in a highly uniform bond between the two metals. HIP is often employed in applications where structural integrity and high-quality bonds are essential, such as in aerospace, automotive, and oil and gas industries.

Features and Advantages

Corrosion Resistance

Aluminum is naturally resistant to corrosion, and when combined with copper, this property is further enhanced. Aluminum copper clad rods are ideal for use in environments where exposure to moisture, chemicals, or harsh weather conditions is common. This corrosion resistance extends the lifespan of components, particularly in marine and offshore applications.

Electrical Conductivity

Copper is known for its superior electrical conductivity, and the copper core in these rods ensures that electrical systems operate efficiently. The combination of aluminum’s lightweight and copper’s conductivity makes these rods highly effective for power transmission and electrical applications.

Lightweight

The use of aluminum as the outer layer provides a lightweight alternative to heavier metal alloys. This characteristic is especially beneficial in industries like aerospace and transportation, where reducing weight is critical for enhancing fuel efficiency and overall performance.

Strength and Durability

Despite its light weight, aluminum copper clad rods retain the strength needed to withstand mechanical stresses. The copper core provides additional strength, making these rods highly durable for a variety of industrial uses. Their resistance to wear and fatigue ensures that they can perform well even under demanding conditions.

Customization Flexibility

Aluminum copper clad rods can be customized to suit specific industrial requirements. Variations in size, thickness, and surface treatments can be tailored, making them suitable for a wide range of applications in electrical systems, structural components, and more.

Cost-Effective Solution

The combination of aluminum and copper offers an economical alternative to using pure copper or other high-cost metals. This cost-effectiveness, along with the material’s durability and long lifespan, makes aluminum copper clad rods an attractive option for industries looking to reduce overall operational costs.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals Materials Co., Ltd., we provide comprehensive OEM services for custom products. From design to production, we collaborate closely with clients to develop tailored solutions that meet their specific application requirements. Our expert technical team is available to offer guidance throughout the entire process.

FAQ

Q1: What is the typical lead time for an order?

The delivery cycle is between 3-6 months, depending on the volume and customization requirements.

Q2: How is the packaged?

We offer custom packaging, with options such as wooden crates to ensure safe transportation.

Q3: Can I request a specific thickness or length?

Yes, we provide fully customizable dimensions to meet your project needs.

Q4: How does this product compare to pure copper rods?

While pure copper rods offer excellent conductivity, the product provides a cost-effective and lightweight alternative with similar electrical performance.

Contact Us

If you have any questions about Aluminum Copper Clad Rod or would like to place an order, feel free to contact us:

- Tel: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

By choosing Baoji JL Clad Metals Materials Co., Ltd., you are assured of high-quality products, competitive prices, and a stable supply chain to meet your production needs.

_1737007724117.webp)

_1737612944271.webp)

_1737612945022.webp)

_1737612944804.webp)

_1737612944666.webp)

_1737611894905.webp)