Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

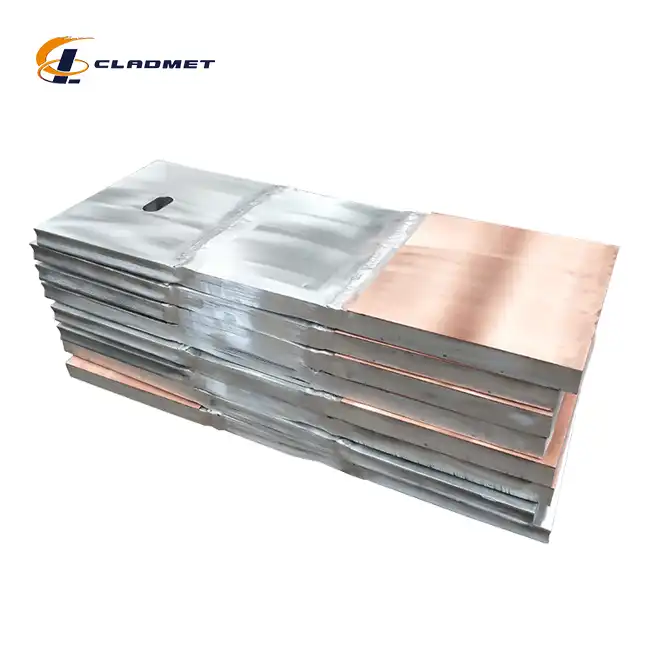

Packaging

Secure wooden crate packaging for international shipping.

Titanium-copper Clad Rod Manufacturer

Welcome to Baoji JL Clad Metals Materials Co., Ltd, your trusted manufacturer for high-quality clad metal solutions. Our Titanium-copper clad rod is designed to provide superior performance in various industrial applications, combining the best properties of both titanium and copper. With over 20 years of experience and industry-leading certifications, we ensure that our products meet the highest standards for quality, reliability, and innovation.

Product Specifications

| Parameter | Description |

|---|---|

| Core Material | Copper (e.g., T2, C11000, C12200, etc.) |

| Cladding Material | Titanium (e.g., TA1, TA2, Gr1, Gr2, etc.) |

| Diameter Range | 10 mm - 200 mm (customizable) |

| Clad Layer Thickness | 0.5 mm - 5 mm (customizable) |

| Rod Length | Up to 6000 mm (customizable) |

| Bonding Technology | Explosion Bonding, Hot Rolling, or Hot Extrusion |

| Bonding Strength | ≥ 130 MPa |

| Shear Strength | ≥ 100 MPa |

| Corrosion Resistance | Excellent resistance to acid, alkali, and seawater environments |

| Electrical Conductivity | Superior conductivity (~99% IACS for copper core) |

| Heat Resistance | Good thermal stability depending on titanium grade |

| Density | ~8.96 g/cm³ (core) + ~4.51 g/cm³ (cladding layer) |

| Application Industries | Electroplating, Electrolysis, Power Transmission, Chemical Processing, Marine Engineering, etc. |

| Standards Compliance | ASTM B551, ASME SB-551, GB/T 8165, and other international standards |

| Surface Finish | Polished, Pickled, or Customized |

| Customizations Available | Diameter, Length, Material Grades, Surface Finish, etc. |

|

|

|

|

Manufacturing Techniques for Titanium-Copper Clad Rods

Titanium-copper clad rods are composite materials that combine the excellent corrosion resistance and durability of titanium with the superior electrical conductivity of copper. This combination is highly beneficial for a wide range of industries, offering both mechanical strength and enhanced performance. The rods are manufactured using advanced bonding techniques that ensure a high-quality, durable bond between the titanium and copper layers.

Explosive Bonding

Explosive bonding is a high-energy process that uses a controlled explosive charge to bond the titanium and copper layers. This technique results in a robust metallurgical bond between the materials.

Preparation: Both the titanium and copper materials are carefully cleaned and aligned before the explosive charge is applied.

Explosion: The explosive charge is placed between the layers, and when detonated, the resulting high-speed impact causes the titanium and copper to fuse together, forming a strong bond.

End Product: The resulting titanium-copper clad rod benefits from the high strength of titanium and the excellent conductivity of copper, making it suitable for a range of applications in both mechanical and electrical industries.

Explosive bonding is particularly useful for applications that require high-strength bonds, such as those in the aerospace and power generation industries.

Roll Bonding

Roll bonding is a cold-welding method where the titanium and copper layers are passed through rollers under high pressure. This process creates a strong bond between the two materials.

Surface Treatment: Both the titanium and copper are thoroughly prepared to ensure the surfaces are free from contaminants, which ensures a good bond.

Rolling Process: The materials are passed through rollers where high pressure forces them to bond together. Multiple passes may be required to achieve a strong and uniform bond.

Final Product: The resulting titanium-copper clad rods have excellent mechanical properties, offering strength and reliability in various demanding environments.

This method is ideal for producing rods that need to be large-scale and cost-effective, especially in industries like marine and chemical processing.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a technique that involves subjecting the titanium and copper layers to high pressure and temperature in a sealed container. This method results in a diffusion bond at the atomic level, ensuring a high-quality bond between the materials.

Encapsulation: The titanium and copper materials are placed in a sealed container that is then heated to high temperatures and pressurized.

Diffusion Bonding: The combination of heat and pressure causes atoms from the titanium and copper to diffuse into one another, creating a uniform bond.

End Product: The titanium-copper clad rods produced using HIP technology exhibit excellent performance characteristics, such as high durability, corrosion resistance, and electrical conductivity.

HIP is particularly suitable for applications that demand high structural integrity and uniform bonding, such as in aerospace or high-performance electronics.

Key Features and Benefits of Titanium-Copper Clad Rods

Superior Corrosion Resistance

The titanium layer provides exceptional resistance to corrosion, particularly in harsh environments such as marine settings, chemical processing plants, and offshore installations. This makes titanium-copper clad rods highly reliable in environments where corrosion could be a significant concern.

Excellent Electrical Conductivity

The copper core ensures excellent electrical conductivity, which is crucial for applications in electrical systems, such as conductors and cables, where the efficient transmission of electricity is required.

Lightweight and Strong

Titanium’s high strength-to-weight ratio makes the clad rods strong without adding excessive weight. This property is particularly valuable in industries like aerospace, where reducing weight is critical to enhancing performance and fuel efficiency.

Customization

Titanium-copper clad rods can be tailored to specific requirements, including size, thickness, and surface finish. This allows for flexibility in design and ensures that the rods can meet the unique needs of various industrial applications.

Enhanced Durability

The natural corrosion resistance of titanium combined with the strength of copper ensures that these rods have a long lifespan. They can withstand wear and tear, even in challenging environments, reducing the need for frequent replacements and maintenance.

Cost-Effectiveness

By combining titanium’s durability and copper’s conductivity, the clad rods offer a cost-effective solution for industries that need both properties. This reduces the overall material costs, while still delivering high performance.

Improved Performance

With both the strength of titanium and the conductivity of copper, these rods are ideal for applications requiring both mechanical durability and high electrical efficiency. Their performance characteristics make them suitable for a wide range of demanding applications.

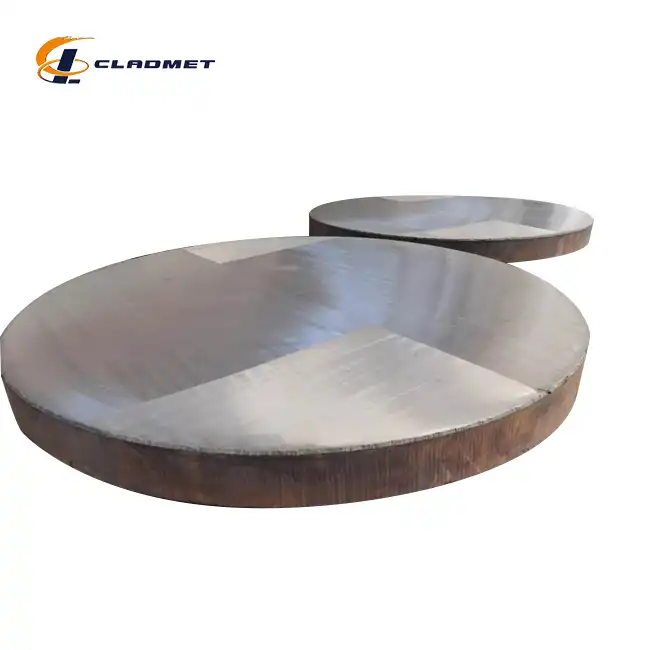

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

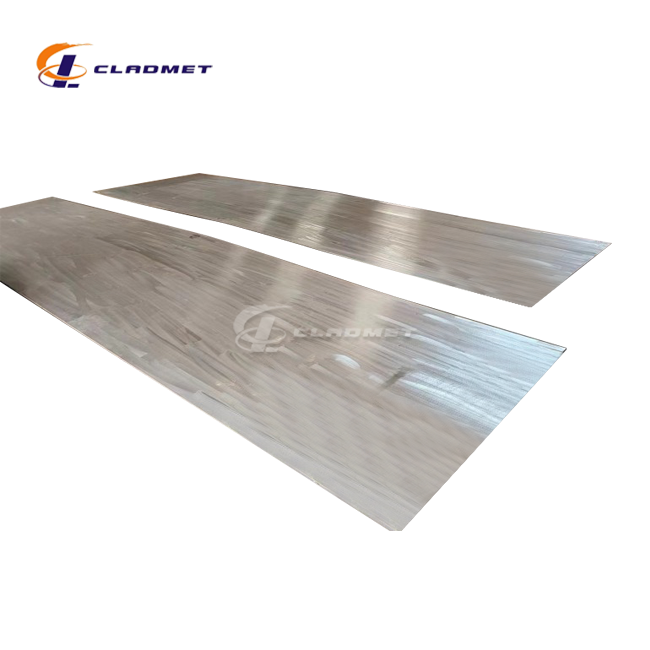

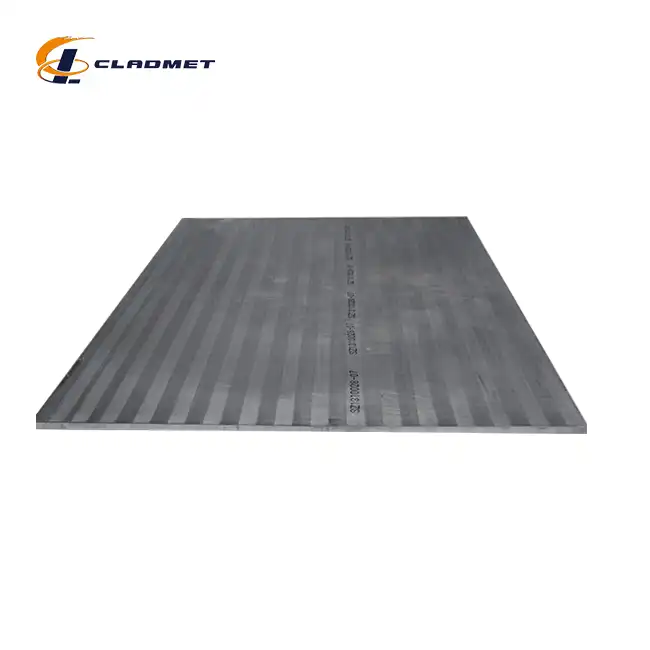

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals Materials Co., Ltd, we offer OEM services tailored to your specific requirements. Whether you need custom sizes, special surface treatments, or unique packaging solutions, our team is ready to work with you to deliver the ideal product for your application.

FAQ

Q1: What is the delivery time for the product?

A1: The typical delivery time is between 3-6 months, depending on the order size and specifications. We also offer flexible delivery schedules based on your project requirements.

Q2: Can the product be customized?

A2: Yes, we offer a range of customization options, including thickness, length, surface treatment, and packaging.

Q3: What standards do your products comply with?

A3: Our products comply with GB/GBT, ASME/ASTM, and JIS standards. We have also passed ISO9001-2000, PED, and ABS certifications.

Q4: What industries are these rods suitable for?

A4: These rods are suitable for the electrical, marine, chemical, aerospace, and power generation industries.

Contact Us

For more information or to place an order, feel free to contact us:

- Phone: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

At Baoji JL Clad Metals Materials Co., Ltd, we pride ourselves on delivering top-quality, high-performance clad metals that meet the needs of today’s industries. Contact us today to learn more about our Titanium-copper clad rod and how we can assist you in achieving your project goals!

_1737007724117.webp)

_1737611764680.webp)

_1737611765298.webp)

_1737611765028.webp)

_1737611764988.webp)

_1737611948854.webp)

_1737612858536.webp)