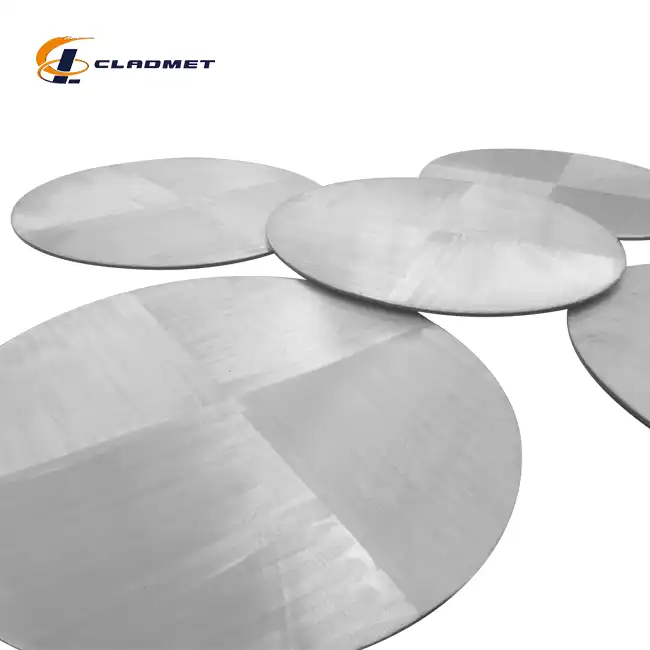

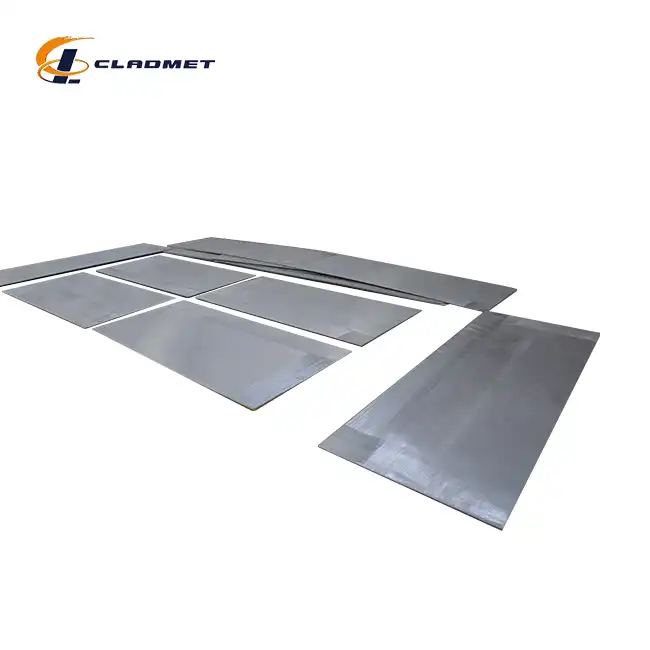

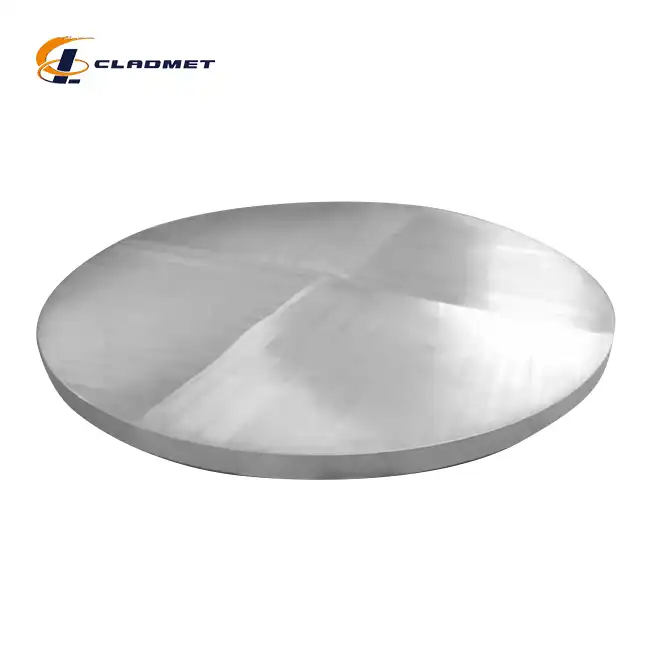

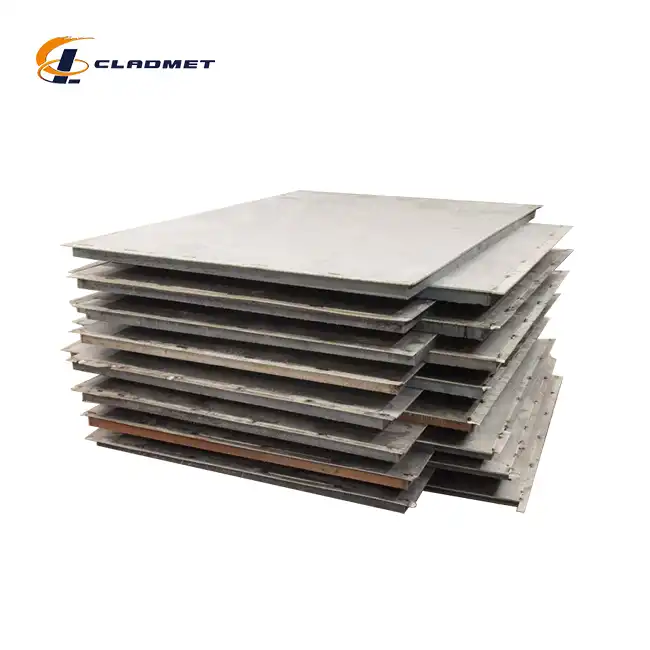

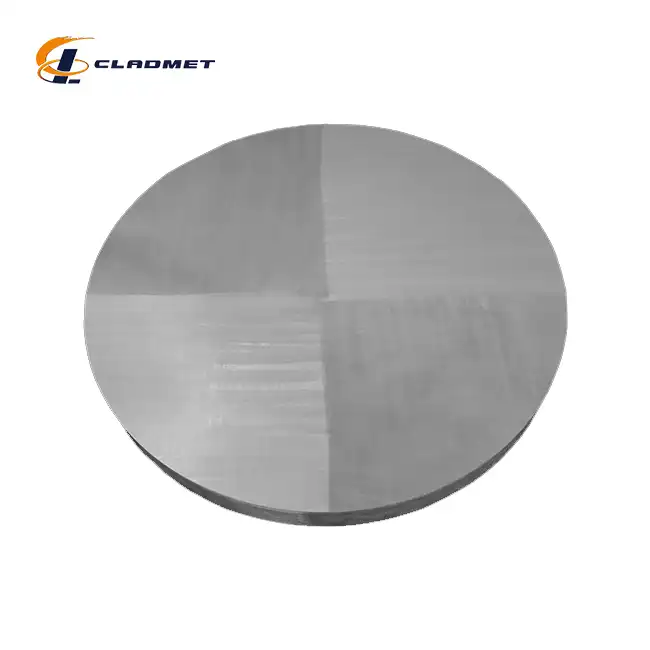

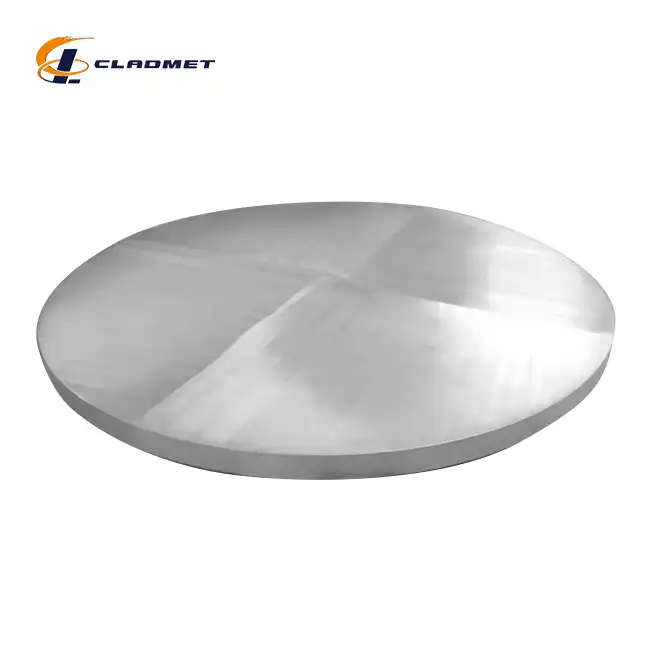

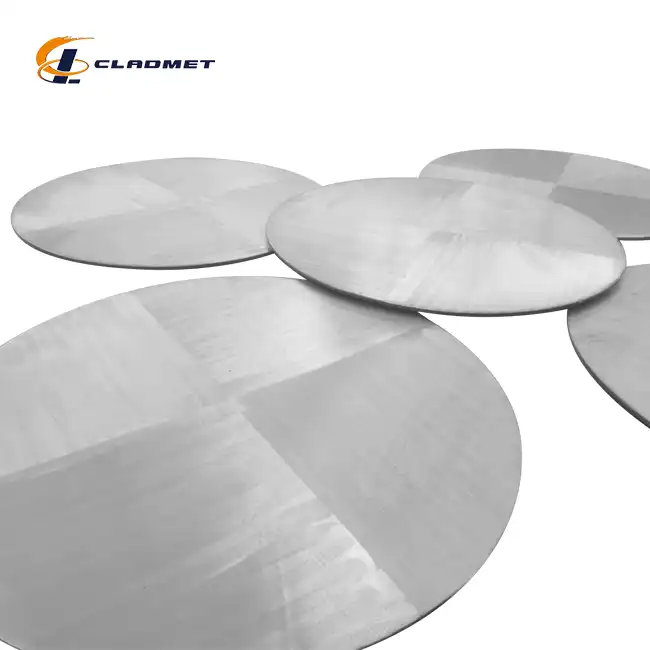

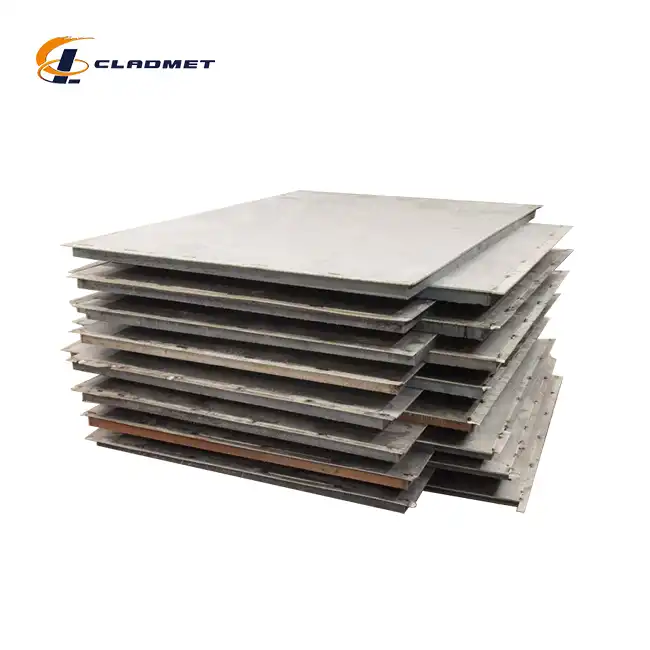

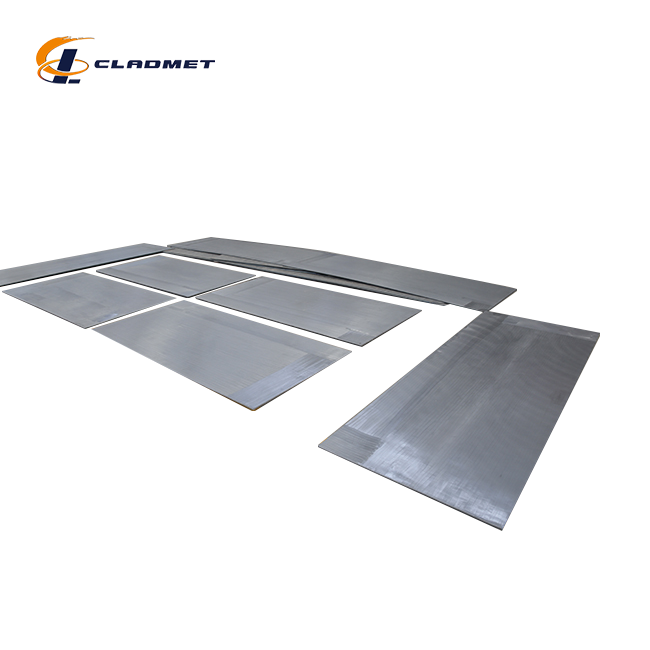

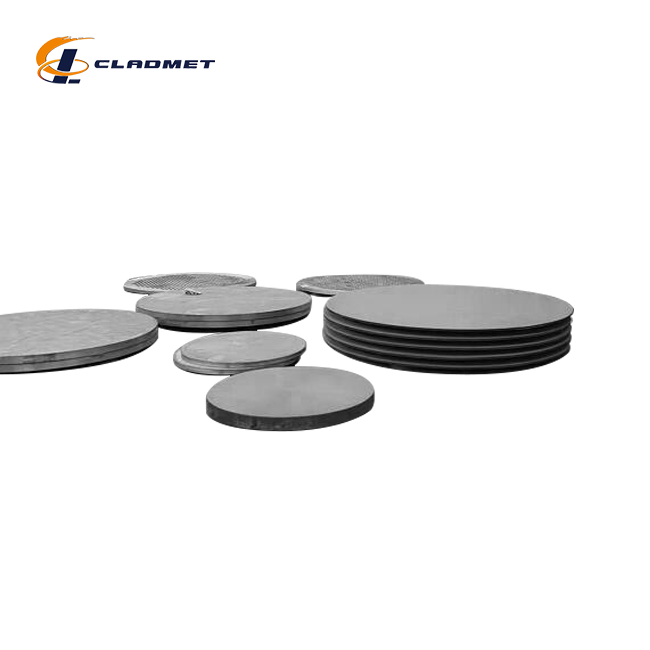

- Titanium and carbon steel clad plate.

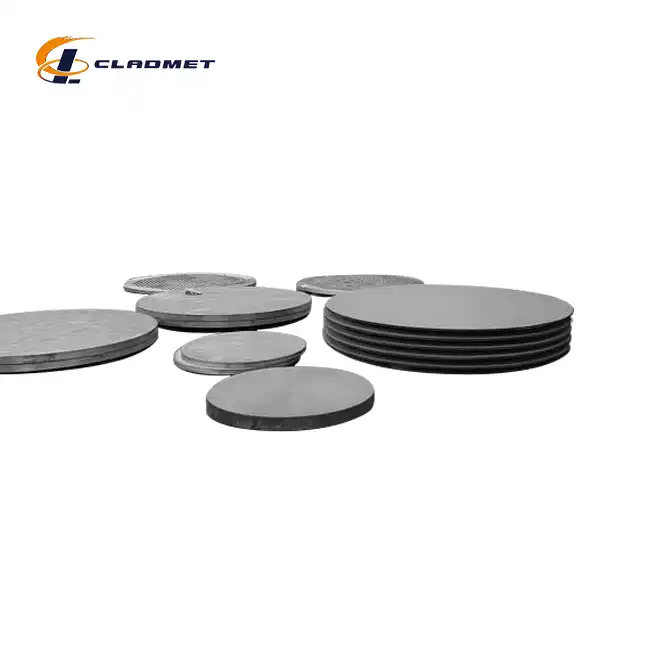

- Available in various material combinations.

Available Sizes and Customization:

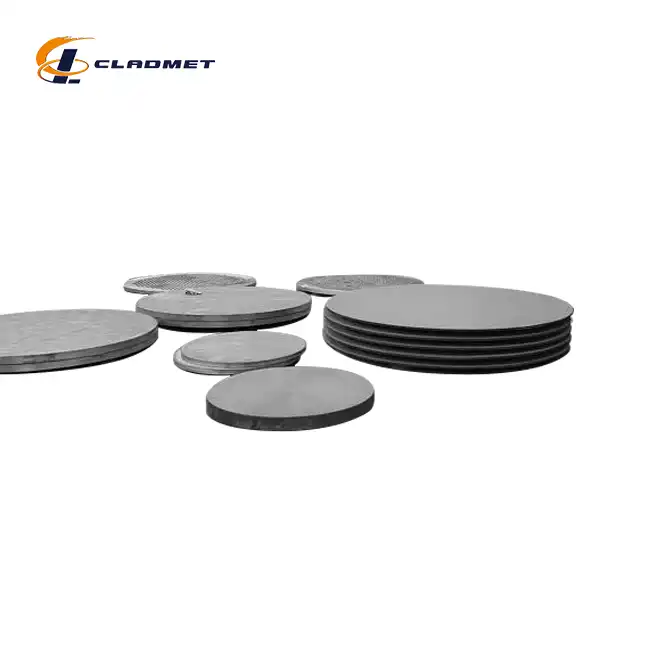

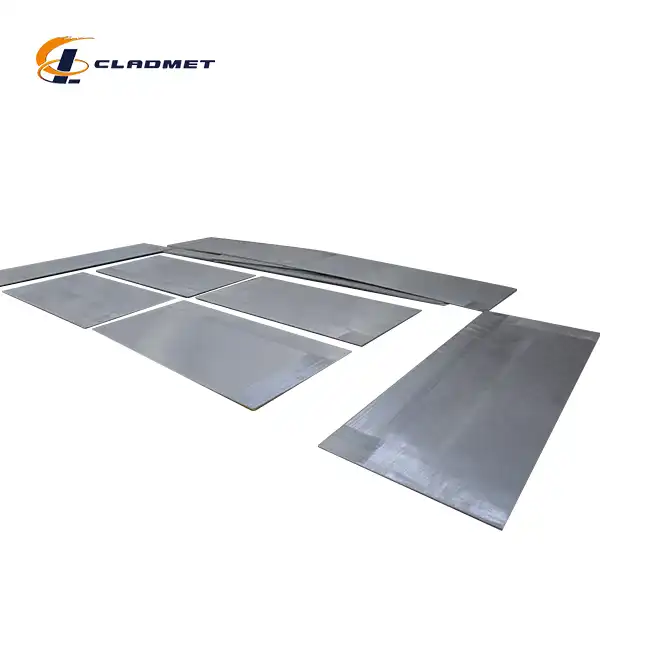

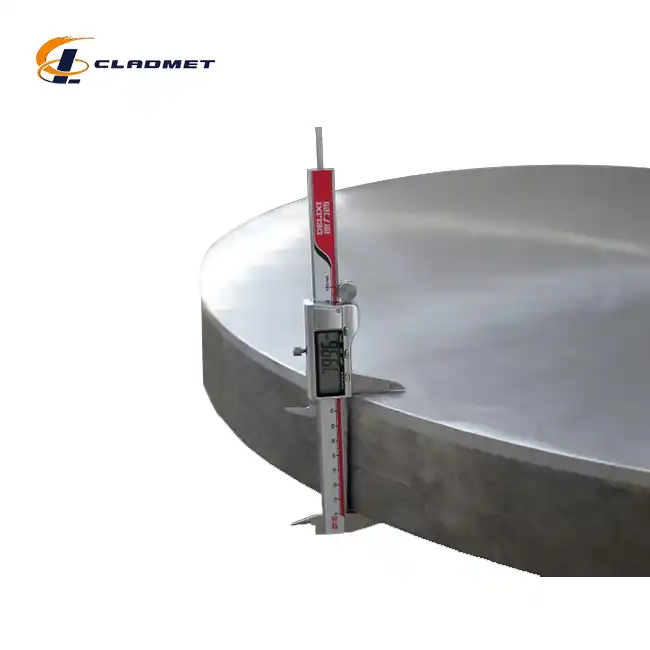

- Standard and custom sizes available.

- Thickness range: 1mm to 100mm.

Product Implementation Standards:

- ASME, ASTM, JIS certified.

- ISO9001-2000, PED, ABS qualified in 2024.

Delivery:

- Global shipping via sea, air, or express courier.

- Fast turnaround for custom orders.

Packaging:

- Wooden crates and protective film packaging.

- Ensures safe and secure transportation.

What is Titanium Clad Nickel Plates

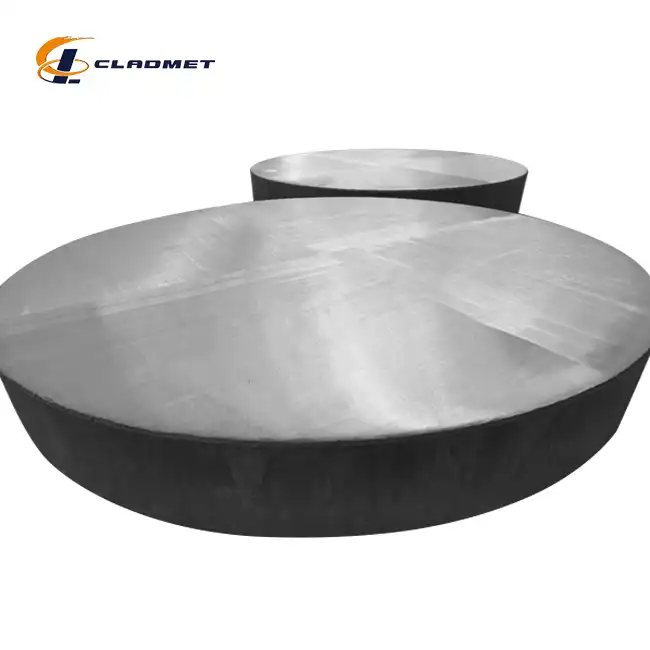

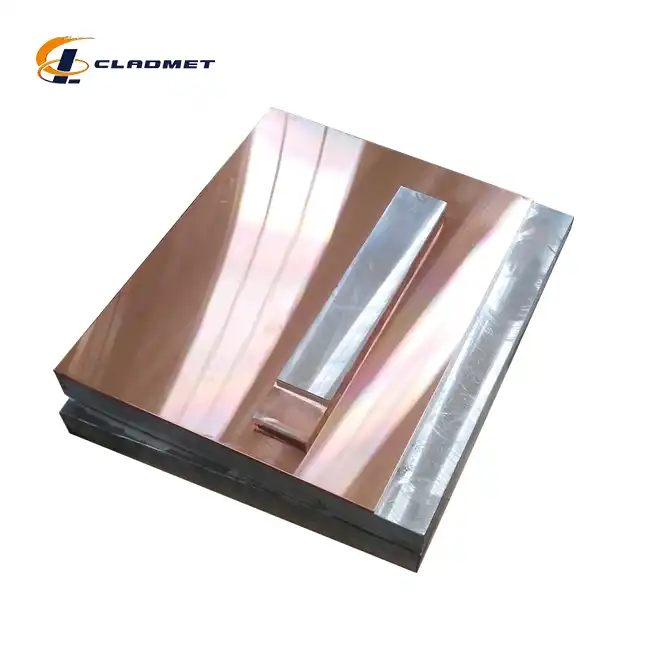

Titanium Clad Nickel Plates are high-performance materials that combine the best qualities of nickel and titanium. Due to their superior strength, durability, and resistance to corrosion, these plates are ideal for demanding applications in chemical processing, marine engineering, and aerospace. The bonding of titanium and nickel improves the material's overall properties, making it a cost-effective option for businesses that need durable, dependable materials.

Product Specifications

|

Specification |

Details |

|

Cladding Material |

Titanium (Grade 1, Grade 2, etc.) |

|

Base Material |

Nickel (Nickel 200, Nickel 201) |

|

Cladding Technology |

Explosion Bonding, Roll Bonding |

|

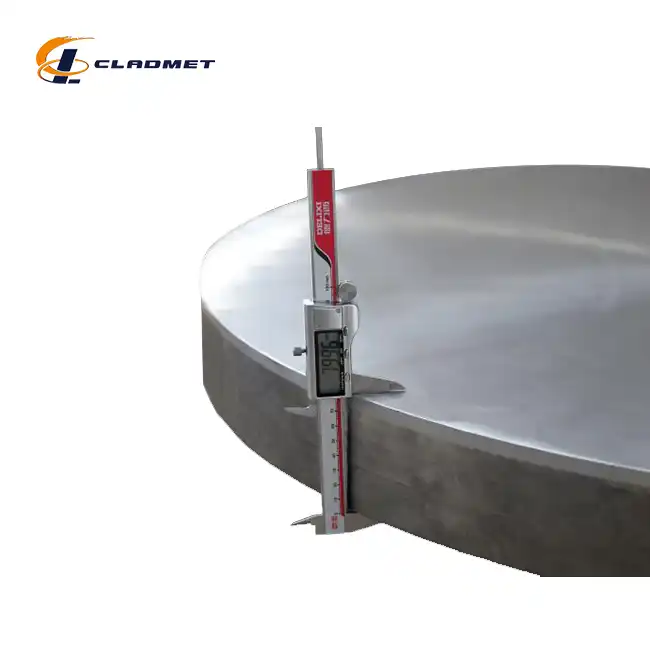

Thickness |

Customizable (Cladding: 1-10mm, Base Metal: 2-50mm) |

|

Length |

Up to 6000mm |

|

Width |

Up to 2500mm |

|

Surface Treatment |

Polished, Matte, Brushed, Custom |

|

Product Standards |

GB/GBT, ASME/ASTM, JIS |

|

Delivery Cycle |

3-6 months (Negotiable) |

|

Packaging Method |

Wooden cases or as per customer requirement |

|

Transportation |

By sea, air, or land, depending on customer location |

|

Applications |

Petrochemical, Marine Engineering, Aerospace, and more |

|

|

|

|

|

|

|

|

Innovative Bonding Techniques

Titanium clad nickel plates are produced using state-of-the-art methods that ensure a robust fusion of titanium's lightweight strength and nickel's durability. Here are the key processes employed:

Explosive Bonding

Explosive bonding is a high-energy technique that utilizes shock waves to weld titanium and nickel into a cohesive unit. The steps include:

Preparation: Meticulous cleaning and arrangement of titanium and nickel layers in a precise assembly.

Controlled Detonation: Explosive material is strategically placed to create a rapid energy release.

Instantaneous Fusion: The collision caused by the explosion produces a strong metallurgical bond.

This method is highly effective in creating materials for industries that demand durability under extreme pressure, such as pressure vessels and heat transfer systems.

Cold Roll Bonding

Cold roll bonding involves mechanical pressure to forge a bond between titanium and nickel. The procedure includes:

Surface Treatment: Ensuring both metals are free from impurities for optimal adhesion.

Compression: Applying significant rolling pressure to form a stable bond, often requiring multiple passes.

This approach is ideal for creating clad sheets with consistent thickness, widely used in structural components and industrial equipment.

Diffusion Bonding through High-Temperature Pressing

This method relies on simultaneous heat and pressure to achieve atomic-level integration between titanium and nickel. Key steps:

Sealing and Encapsulation: Aligning the materials in an airtight container to eliminate contamination.

Thermal and Pressure Application: Sustained heat and force create a uniform, long-lasting bond.

This technique is particularly suitable for high-precision components in aerospace and marine engineering.

Key Attributes and Advantages

Exceptional Corrosion Resistance: The titanium layer protects against chemical attacks, while nickel provides added resilience in harsh environments.

Thermal Conductivity: Nickel enhances heat transfer efficiency, making these plates suitable for energy-intensive applications.

High Mechanical Strength: The unique combination of materials ensures excellent tensile strength while maintaining a lightweight profile.

Custom Configurations: Available in tailored dimensions and surface finishes to meet diverse industrial requirements.

Enhanced Durability: Titanium's resistance to wear and nickel's toughness make these plates ideal for long-term use in demanding conditions.

Eco-Friendly Design: Both materials are recyclable, reducing environmental impact.

Cost-Effective Solution: Combining titanium and nickel reduces the need for frequent replacements, offering long-term savings.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Based on the particular requirements of each customer, we provide services for customization. Thicknesses, sizes, and surface treatments can be customized through our OEM services. We can meet your needs, whether you need specific nickel or titanium grades.

FAQs

What is the typical lead time for Titanium Clad Nickel Plates? The delivery cycle is usually 3-6 months, but it can be negotiated based on order size and customer needs.

Can you customize the plate dimensions? Yes, we can customize the length, width, thickness, and surface treatment to match your exact specifications.

What industries are these plates best suited for? The products are ideal for petrochemical, marine, aerospace, pharmaceutical, and nuclear industries.

What is the bonding technology used? We primarily use explosion bonding and roll bonding technologies to create a strong metallurgical bond between titanium and nickel.

Contact Us

· Phone: +86-917-3372918

· WhatsApp: +8613530170059

· Email: sales@cladmet.com

· Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

For Titanium Clad Nickel Plates or to discuss your specific requirements, feel free to reach out to us!

_1737007724117.webp)