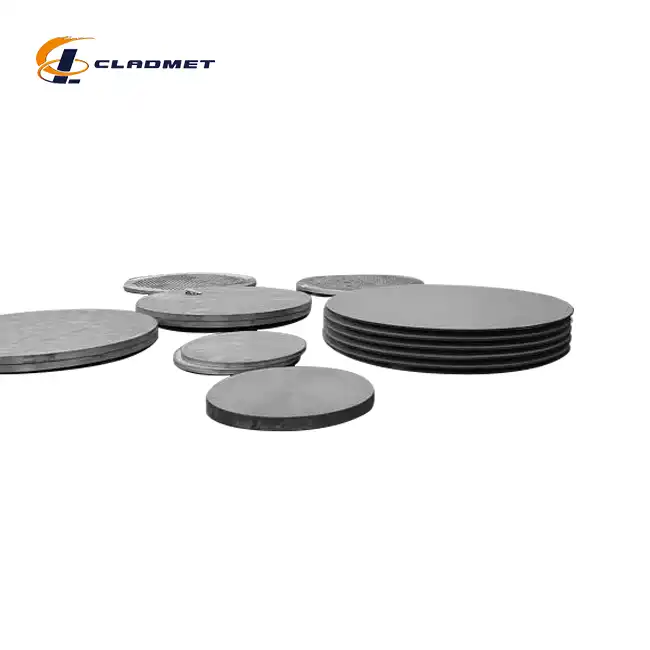

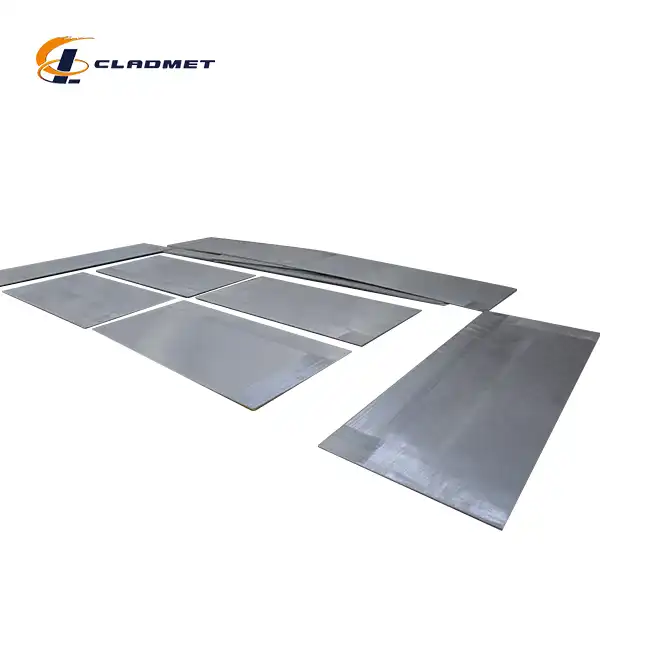

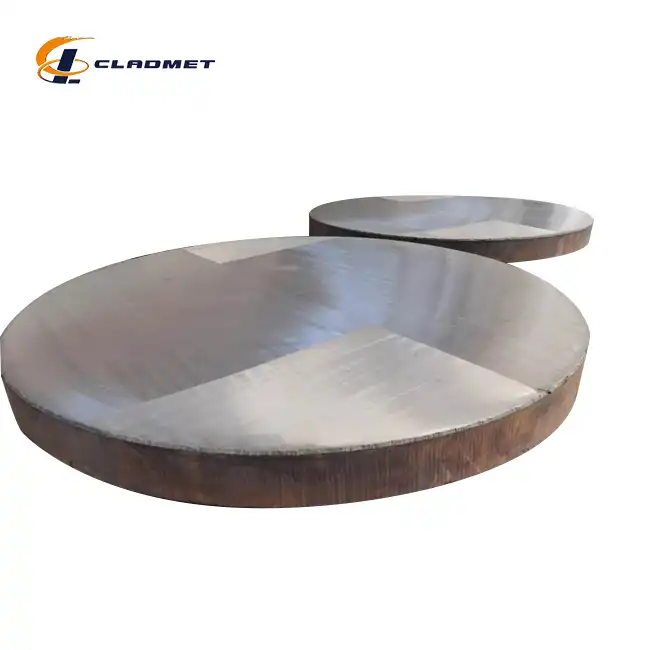

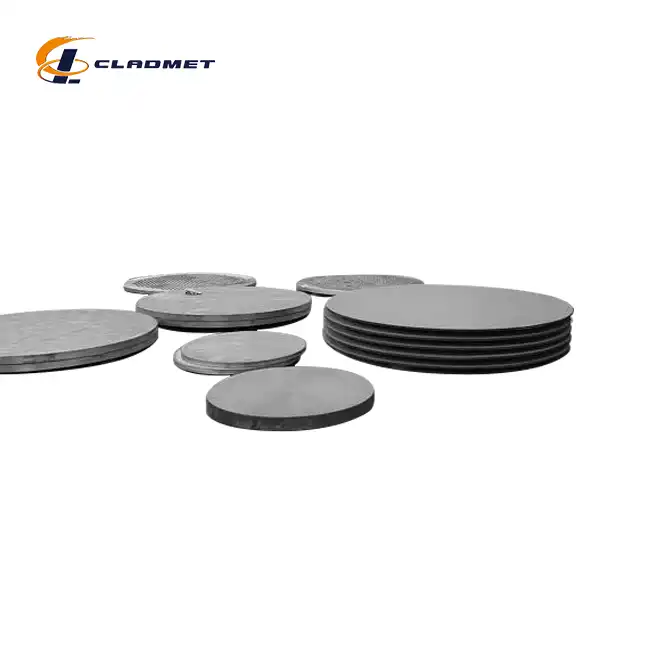

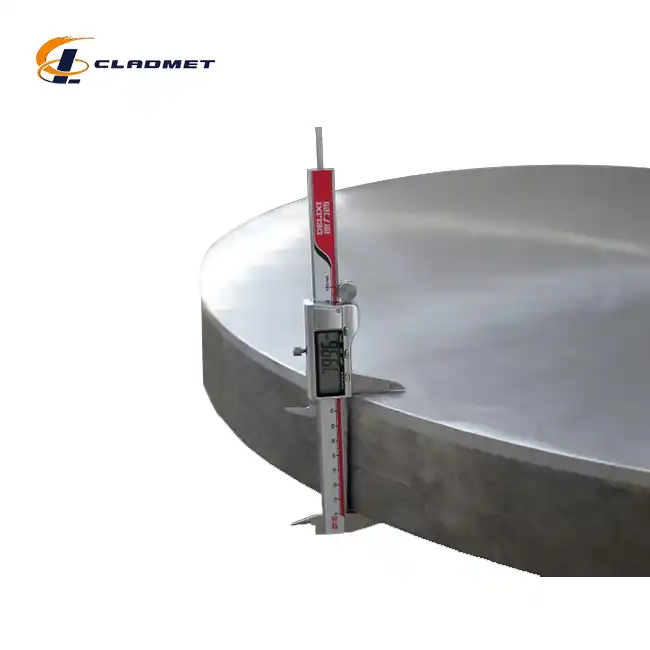

2. Available Sizes & Customization: Standard sizes available; supports custom dimensions upon request.

3. Product Applications: Used in chemical, marine, and aerospace industries.

4. Processing Technology: Explosive welding process for superior material bonding.

5. Quality Control & Testing: Stringent tests ensure durability and high-quality standards.

6. Implementation Standards: Meets ASME, ASTM, JIS standards; ISO9001-2000, PED, ABS certified.

7. Delivery: Global shipping available; flexible delivery options.

8. Packaging: Protective steel frames and moisture-proof wraps.

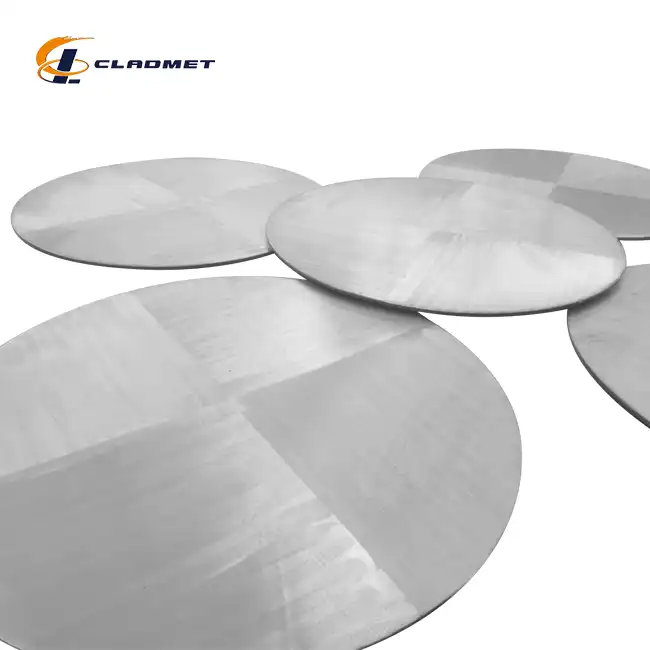

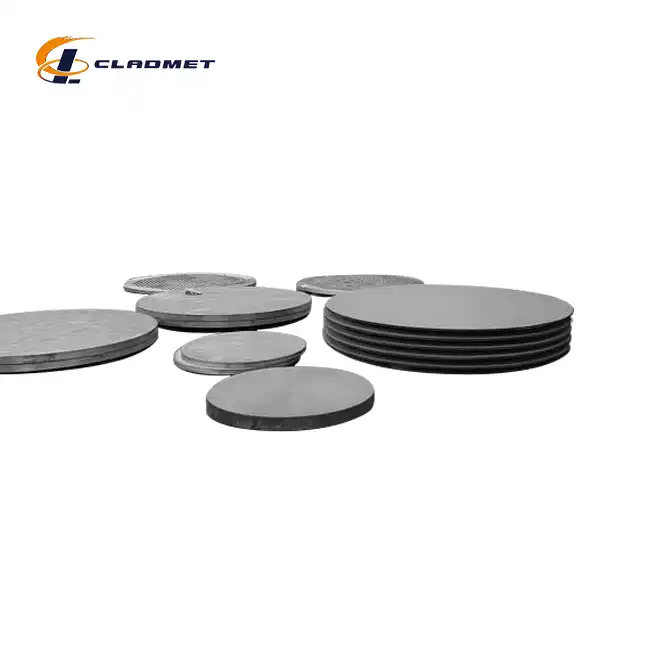

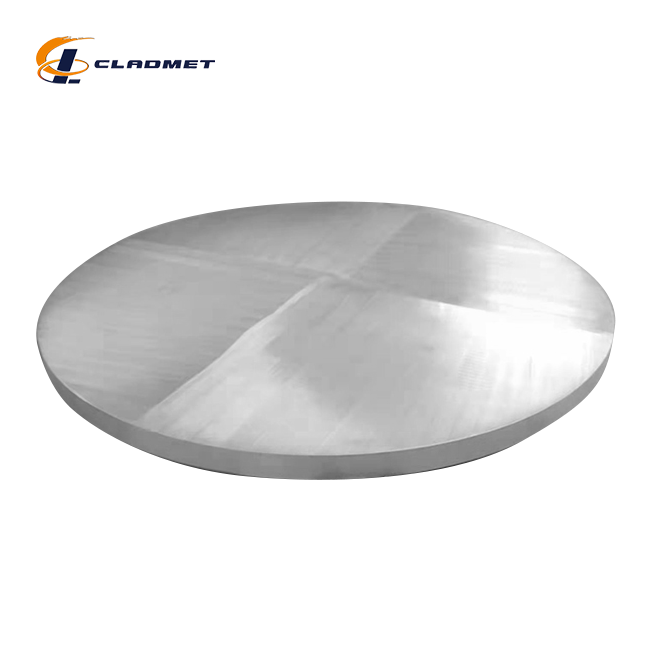

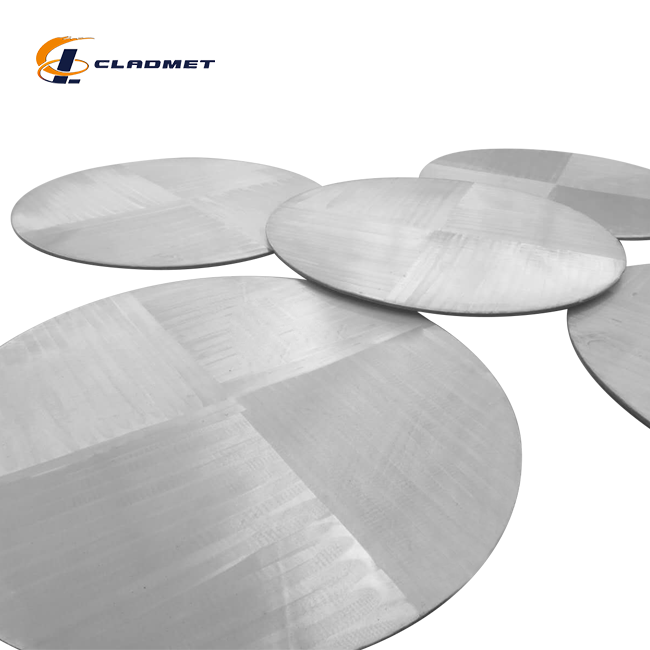

Titanium Clad Aluminum Plates – High-Performance Solutions for Diverse Industries

Baoji JL Clad Metals Materials Co., Ltd.'s Titanium Clad Aluminum Plates offer the ideal balance of titanium's superior strength and aluminum's light weight, making them ideal for a variety of industrial applications. A high-quality product that meets the requirements of even the most demanding industries is guaranteed by our expertise in the production of EXW clad metal and our strict adherence to international standards. Our products are a great option if you need better thermal conductivity or resistance to corrosion.

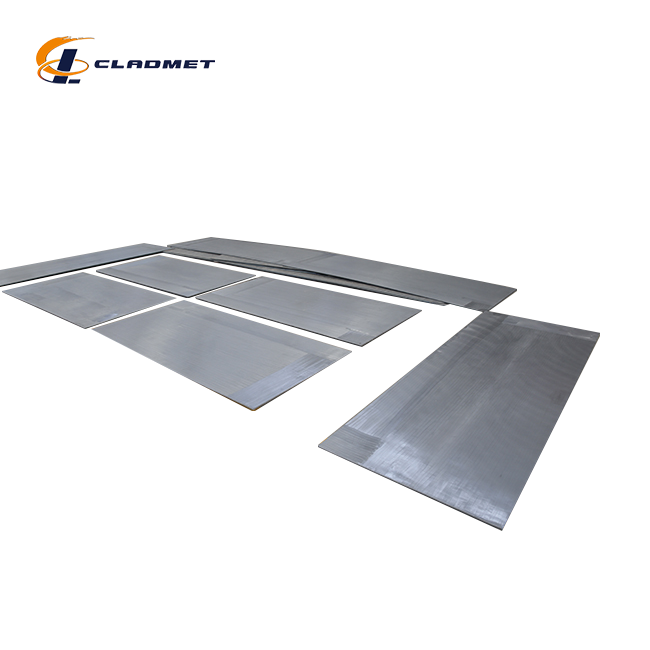

Product Specifications

| Parameter | Details |

|---|---|

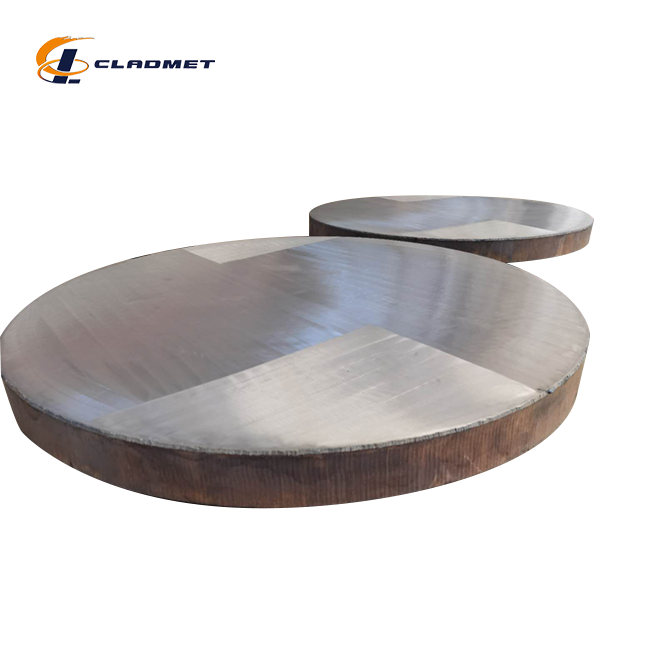

| Cladding Material Range | Pure Titanium, Titanium Alloy (Gr.1, Gr.2) |

| Base Metal Range | Aluminum 6061, 7075 |

| Cladding Size | Thickness: 1mm-20mm; Length: Up to 12m; Width: 1000-2500mm |

| Cladding Technology | Explosion Bonding |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

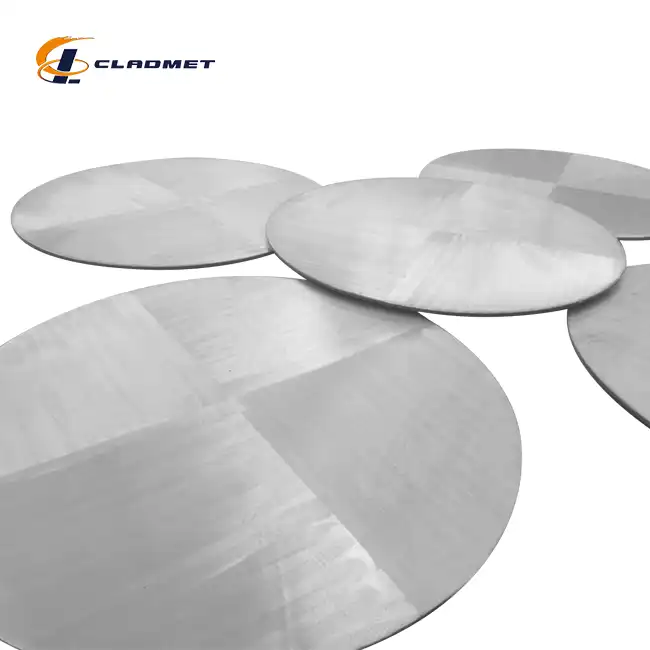

| Surface Treatment | Polished, Sandblasted, Brushed |

| Application Industries | Aerospace, Chemical, Oil & Gas, Marine, Nuclear |

| Packaging Method | Wooden crate with anti-rust wrapping |

| Transportation | Global shipping, air, or sea |

| Delivery Cycle | 3-6 months (negotiable) |

|

|

|

|

|

|

|

|

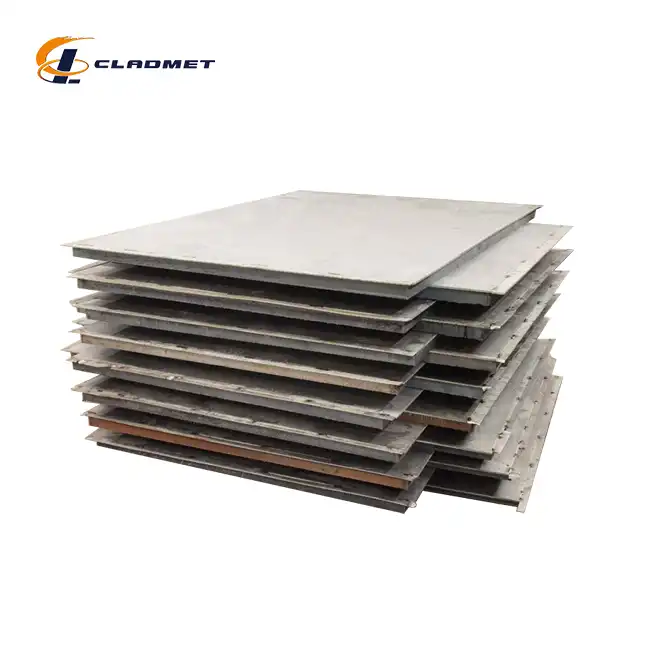

Advanced Manufacturing Techniques for Titanium Clad Aluminum Plates

The process of creating titanium clad aluminum plates involves precise engineering and innovative bonding technologies to achieve a durable and high-performance material. Key methods include:

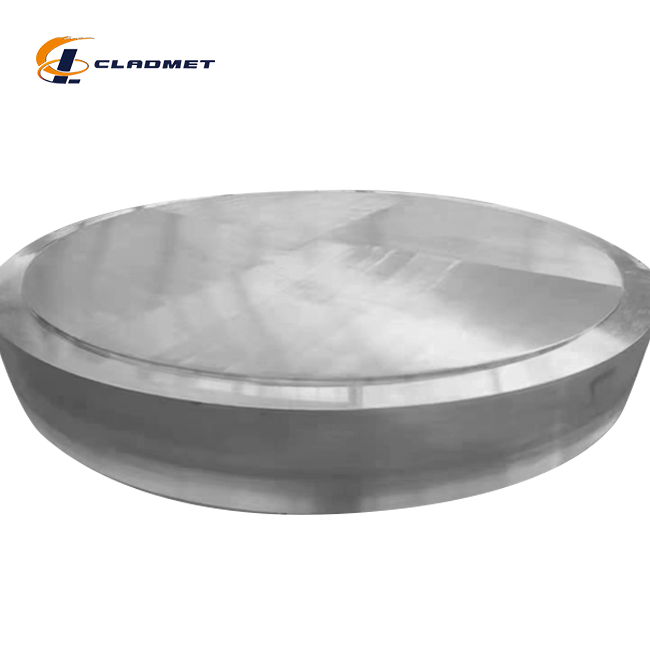

Explosive Bonding

This method utilizes controlled explosions to generate intense pressure, creating a solid metallurgical bond between titanium and aluminum. The steps include:

Preparation and Alignment: Both materials are meticulously cleaned and arranged in a specific layout to ensure uniform bonding.

Explosive Placement: Explosives are carefully positioned to provide a controlled and focused impact.

Dynamic Fusion: The explosion propels the titanium layer into the aluminum substrate, forming a robust, seamless bond.

This technique is particularly effective for manufacturing components that demand exceptional strength and durability, such as in marine and defense applications.

Cold Rolling Bonding

A mechanical process that relies on the application of pressure through rollers to join the titanium and aluminum layers. The main steps are:

Surface Conditioning: Cleaning and texturing of both surfaces to enhance adhesion.

Pressure Application: The materials are passed through high-pressure rollers multiple times until a uniform bond is achieved.

Cold rolling is widely used for lightweight, corrosion-resistant products in industries such as transportation and construction.

High-Temperature Diffusion Bonding

This technique combines heat and pressure to enable atomic-level bonding between titanium and aluminum. The process includes:

Sealing in an Inert Atmosphere: The materials are encapsulated to prevent oxidation during the bonding process.

Thermal Treatment: High temperatures and pressures are applied, resulting in a homogenous diffusion bond.

Diffusion bonding is ideal for producing materials used in critical environments, such as aerospace and electronics.

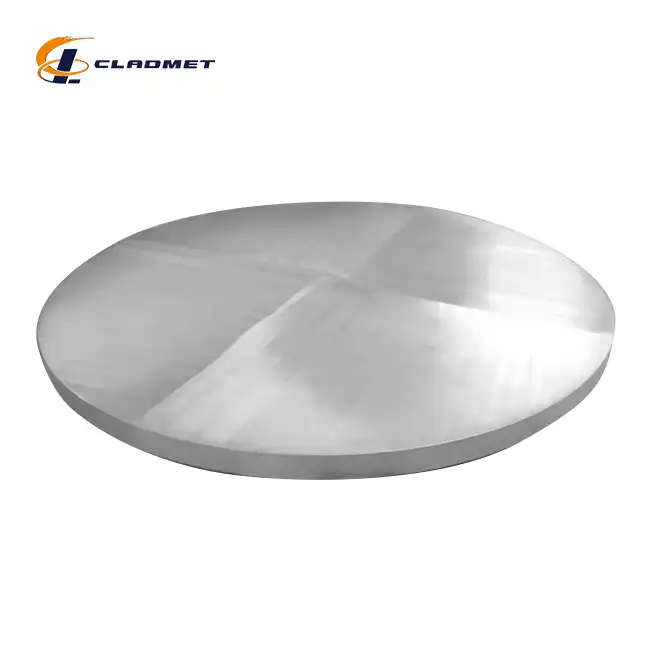

Key Features and Advantages of Titanium Clad Aluminum Plates

Superior Corrosion Resistance: Titanium's inherent resistance to corrosion enhances the material's lifespan in chemically aggressive and marine environments.

Optimized Strength-to-Weight Ratio: The combination of lightweight aluminum and strong titanium offers exceptional structural efficiency.

Thermal and Electrical Efficiency: Aluminum provides excellent heat and electrical conductivity, making these plates ideal for energy systems and heat exchangers.

Design Flexibility: Plates can be customized in terms of size, thickness, and surface finishes to suit specific project requirements.

Durability: The unique combination of materials results in a product capable of withstanding extreme conditions, including high temperatures and mechanical stress.

Cost Efficiency: By combining the benefits of both materials, titanium clad aluminum plates provide a cost-effective alternative to pure titanium while maintaining high performance.

Eco-Friendly Characteristics: Both titanium and aluminum are recyclable, making this material choice environmentally sustainable.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Baoji JL Clad Metals provides comprehensive OEM services, which include customized surface treatments, packaging options, and options for size and thickness. We're ready to work with you on your project, from the initial design to the final delivery, to make sure the finished product meets your exact specifications.

FAQs

Q1: What is the delivery time for Titanium Clad Aluminum Plates?

A1: Our typical delivery cycle is 3-6 months, but we can adjust it based on your project needs.

Q2: How do you ensure the quality of the product?

A2: We strictly adhere to international standards such as GB/GBT, ASME/ASTM, and JIS during the manufacturing process, and our products undergo rigorous testing to ensure quality and durability.

Q3: Can you produce custom sizes?

A3: Yes, we offer fully customizable sizes to meet your specific project requirements, ensuring optimal performance for your applications.

Q4: Do you offer global shipping?

A4: Yes, we ship worldwide, using air, sea, or other modes of transportation based on your preference.

Contact Us

For more information or to place an order, please contact us:

Tel: +86-917-3372918

WhatsApp: 8613530170059

Email: sales@cladmet.com

Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China 721013

_1737007724117.webp)