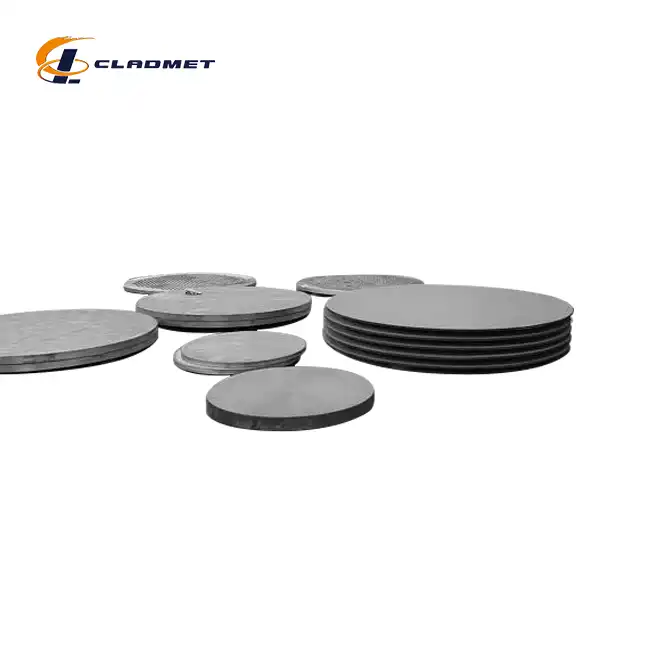

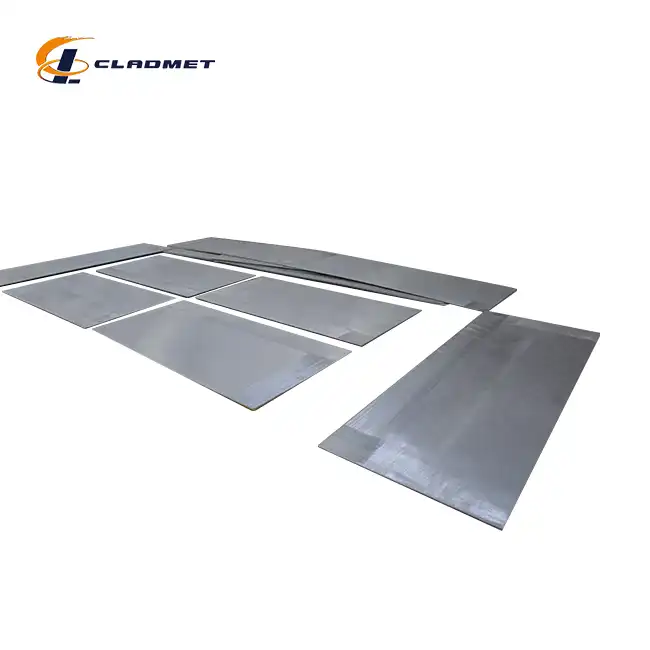

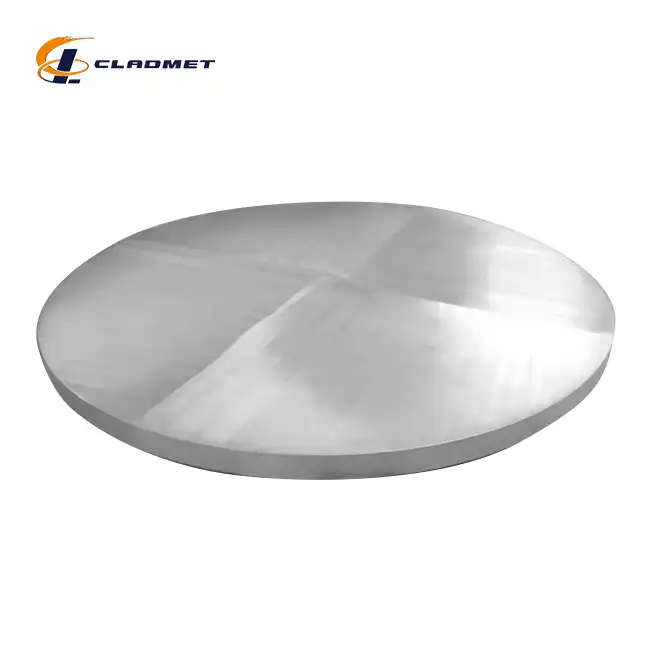

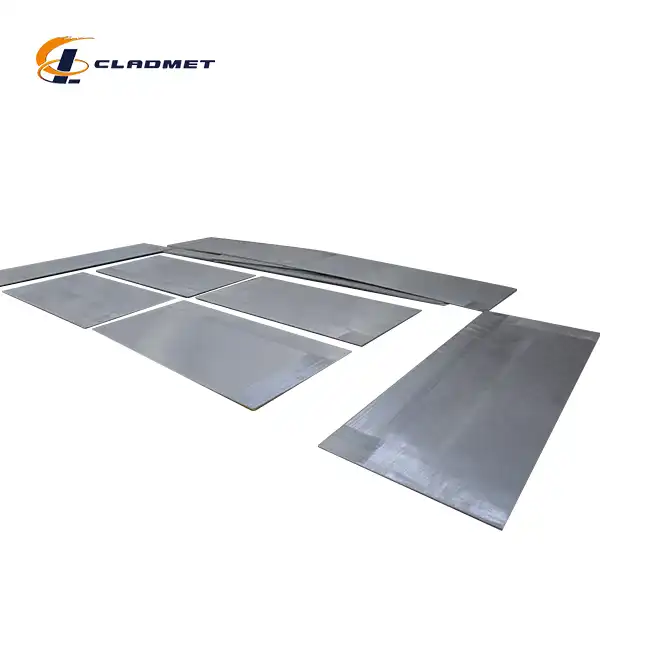

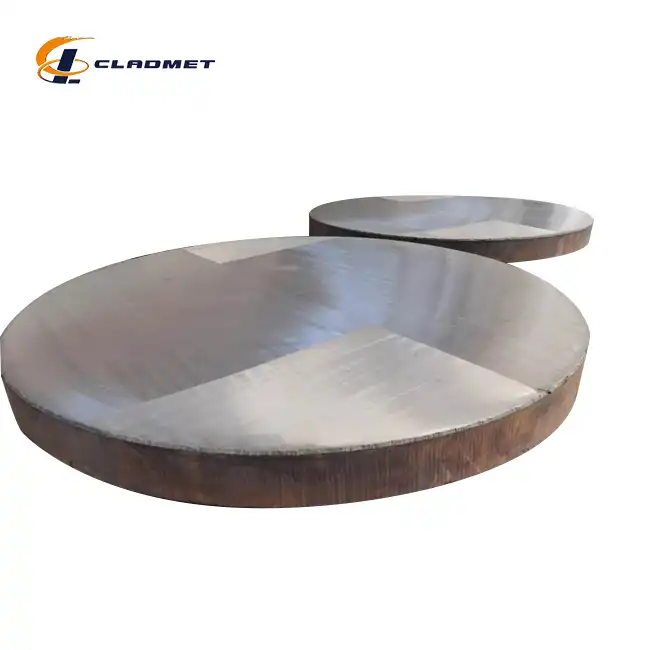

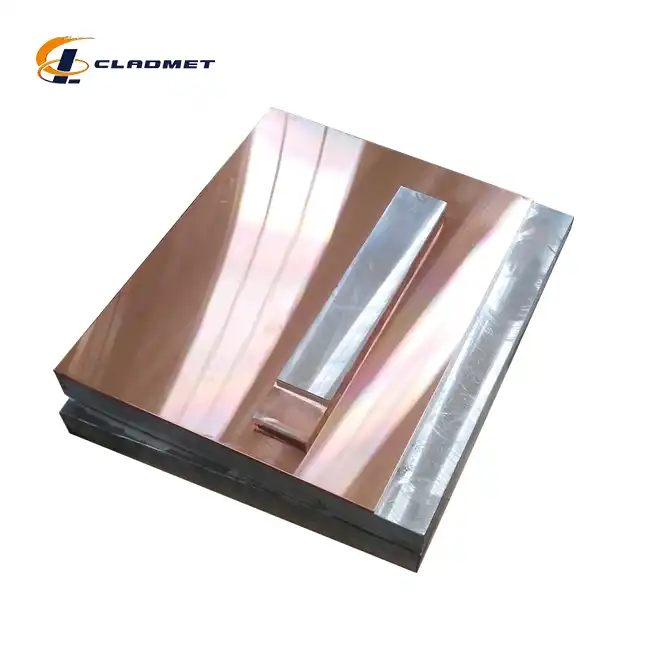

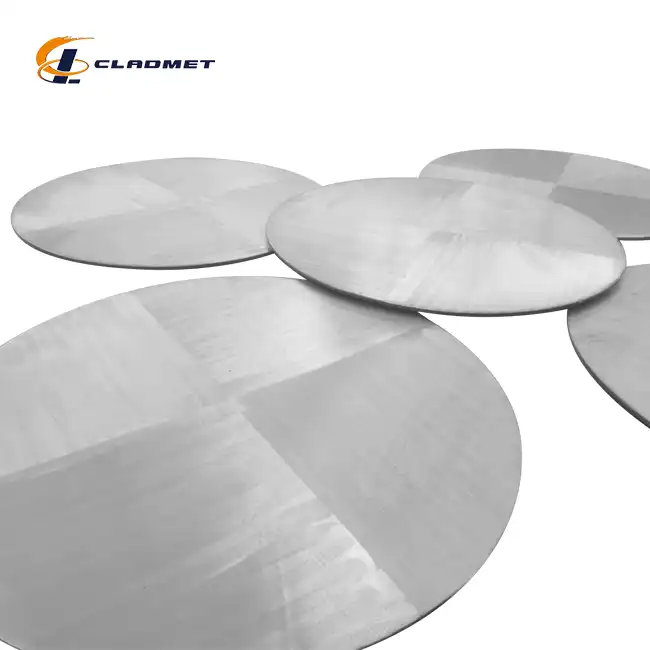

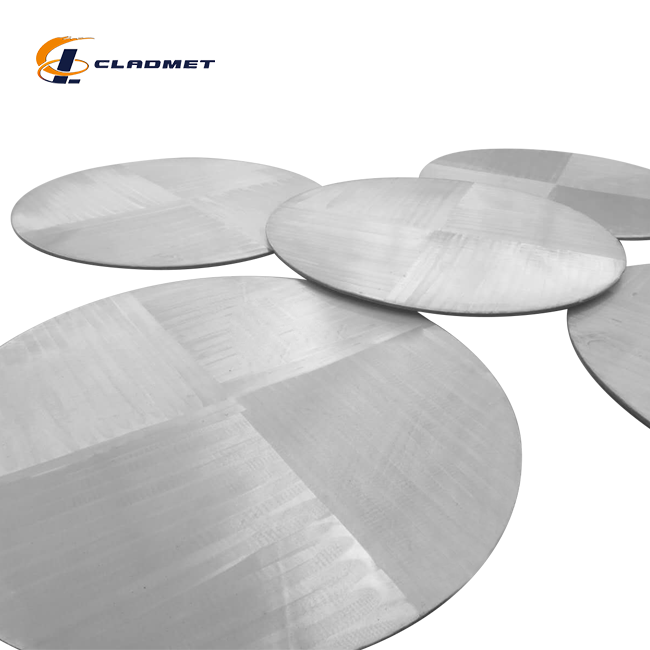

Product Substrate and Cover Materials: Titanium-clad aluminum plate with durable, corrosion-resistant layers.

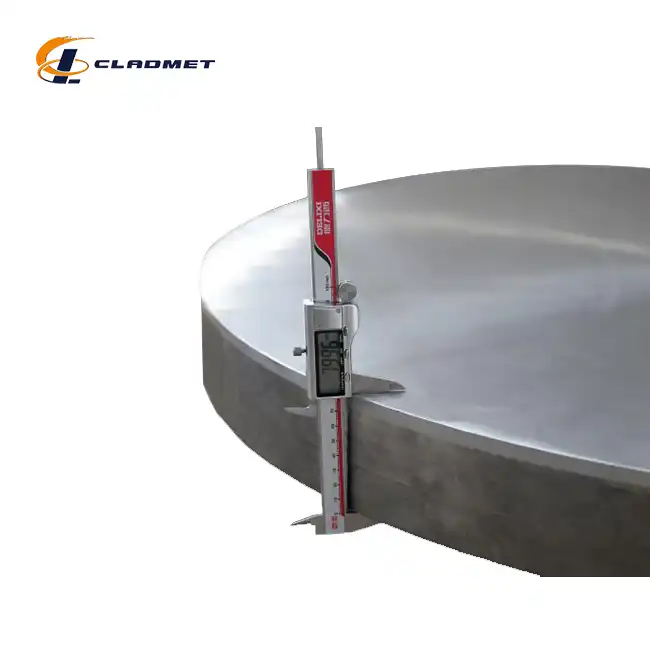

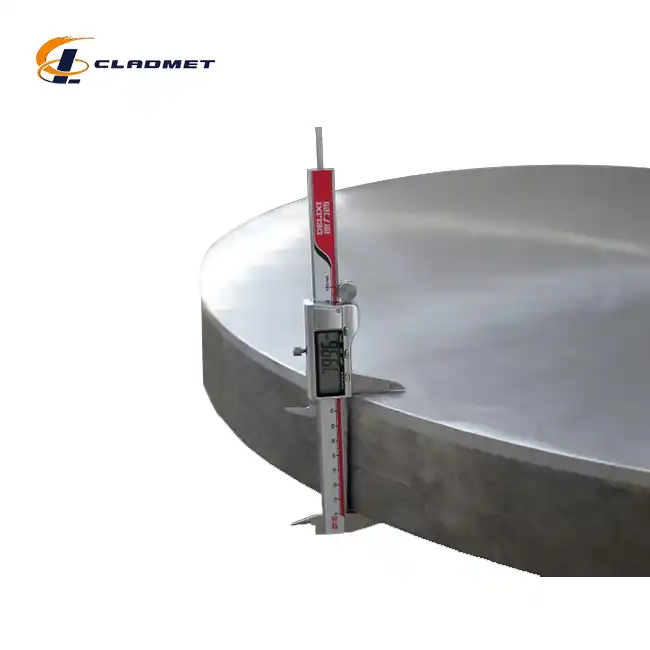

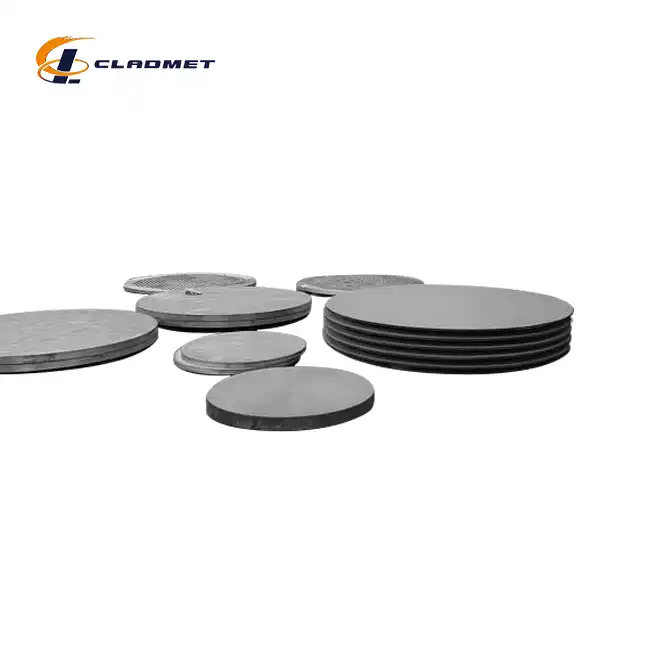

Available Sizes and Customization: Standard sizes from 2mm to 50mm, customized dimensions available.

Product Applications: Widely used in chemical, marine, and aerospace industries.

Processing Technology: Explosive welding and hot-rolled bonding for strong adhesion.

Quality Control and Testing: 100% inspection, ultrasonic testing, and defect-free guarantees.

Product Implementation Standards: Certified by ASME, ASTM, JIS, ISO9001-2000, PED, ABS in 2024.

Delivery: Delivered globally by air, sea, or express shipping.

Packaging: Sturdy wooden cases with protective internal layers.

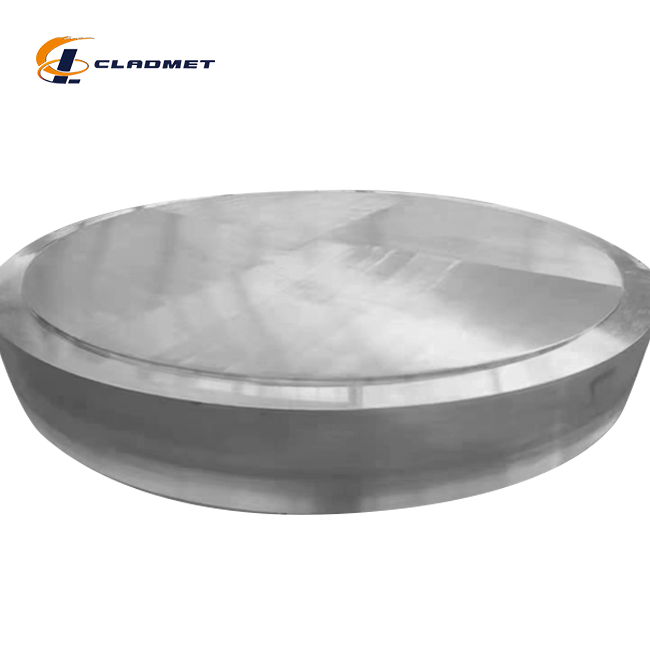

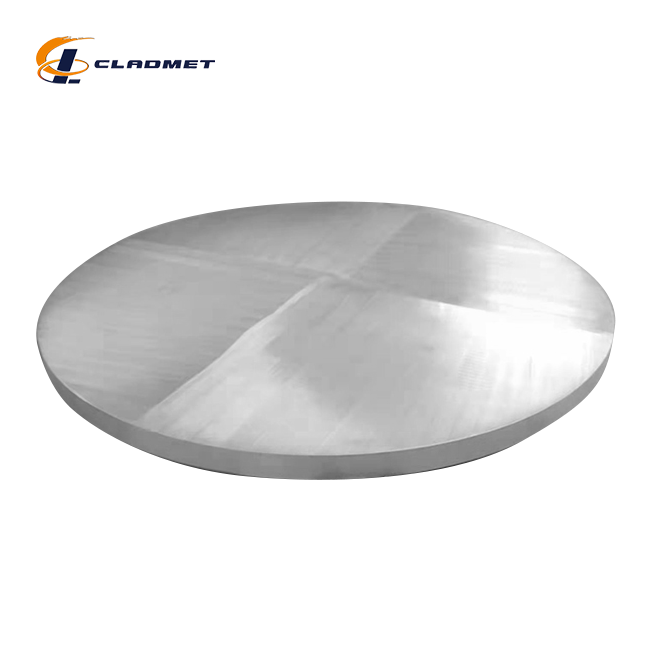

Titanium aluminum clad plate Overview

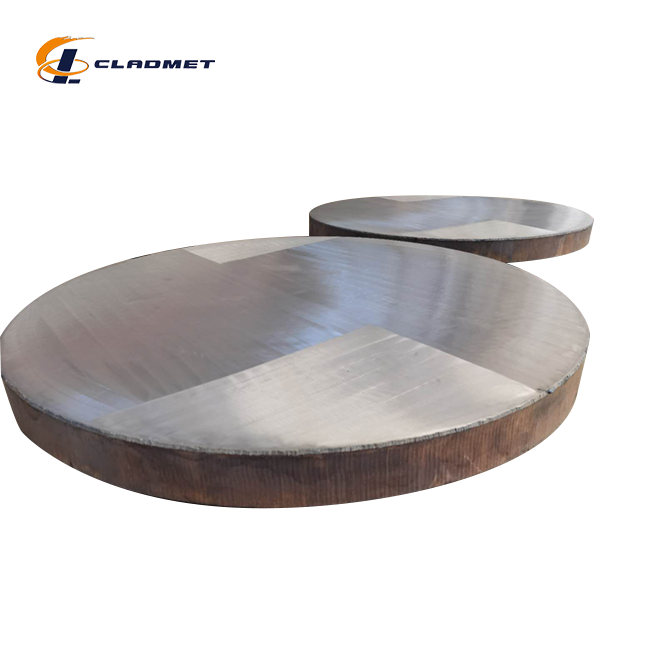

Titanium Aluminum Clad Material refers to a composite material composed of two layers: a core layer of titanium and an outside layer of aluminum. These two metallic layers are bonded together through hot rolling or explosive welding.

The purpose of Titanium Aluminum Clad Material is to take advantage of the individual properties of titanium and aluminum. Titanium provides excellent strength, light weight, and resistance to corrosion, while aluminum offers good conductivity, low density, and ductility. Combining these two metals, the created clad material can benefit from the good characteristics of both.

Titanium Aluminum Clad Material is commonly apply to various industries, such as aerospace, marine, automotive, and building construction. It can be used in fields that require a combination of strength, lightweight, corrosion resistance, and thermal conductivity. Some typical uses of this material include aircraft fuselages, marine structures, heat exchangers, and automobile components.

Titanium aluminum clad plate Specifications

|

Specification |

Details |

|

Cladding Material Range |

Titanium (Gr1, Gr2, Gr5), Aluminum (T6061) |

|

Base Metal Range |

Aluminum, Carbon Steel, Stainless Steel |

|

Cladding Size |

Customizable (Thickness: 0.5mm – 300mm) |

|

Cladding Technology |

Explosion Bonding |

|

Product Standards |

GB/GBT, ASME/ASTM, JIS |

|

Surface Treatment |

Polished, Sandblasted |

|

Thickness |

2mm – 300mm |

|

Length |

Up to 12m |

|

Width |

Up to 3m |

|

Packaging Method |

Wooden crates, steel strapping for protection |

|

Delivery Cycle |

3–6 months (Negotiable) |

|

|

|

|

|

|

|

|

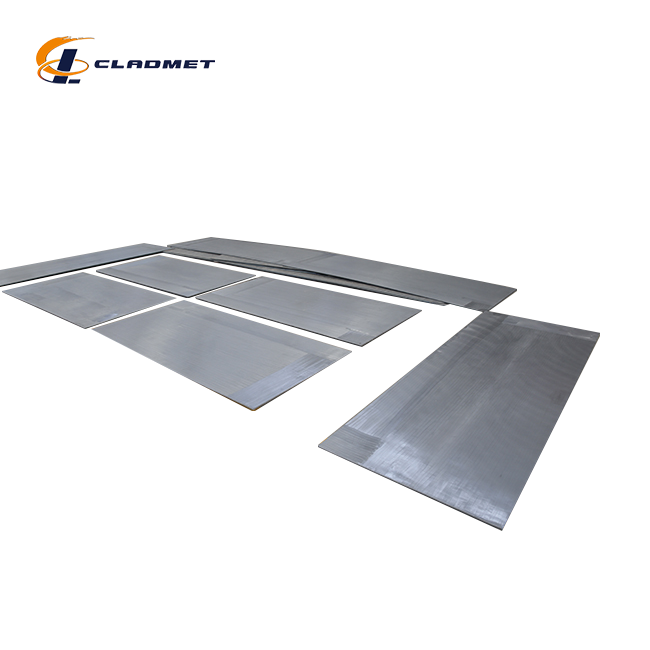

Titanium Aluminum Cladding Techniques

The production of titanium aluminum clad plates utilizes innovative techniques to create a strong and durable bond between titanium and aluminum. The primary methods include:

Explosive Bonding

This high-energy process leverages controlled explosions to achieve an instantaneous and robust bond between the two materials. Key steps include:

Preparation: Both titanium and aluminum layers are thoroughly cleaned and aligned in a precise configuration to ensure a successful bond.

Explosive Loading: An explosive material is strategically placed between the layers.

Dynamic Bonding: Detonation generates a high-velocity impact, fusing the materials together at a metallurgical level.

Explosive bonding is particularly suited for applications where superior mechanical strength and corrosion resistance are required, such as in marine and aerospace engineering.

Cold Roll Bonding

In this mechanical bonding process, titanium and aluminum layers are joined through rolling under intense pressure. The procedure involves:

Surface Preparation: Cleaning and surface texturing to promote adhesion.

Pressure Rolling: Passing the layers through high-pressure rollers, which creates a solid bond. Multiple rolling stages may be necessary for optimal results.

This technique is commonly employed for applications requiring lightweight and corrosion-resistant materials in industries like transportation and chemical processing.

Thermal Diffusion Bonding

This method combines heat and pressure to achieve atomic diffusion between the titanium and aluminum layers, resulting in a seamless bond. The steps include:

Material Encapsulation: Placing the layers in a vacuum-sealed chamber to avoid contamination.

Heat and Pressure Application: Using controlled thermal and mechanical energy to form a homogeneous bond.

Thermal diffusion bonding is preferred for applications where consistent quality and high durability are critical, such as structural components in aerospace and automotive industries.

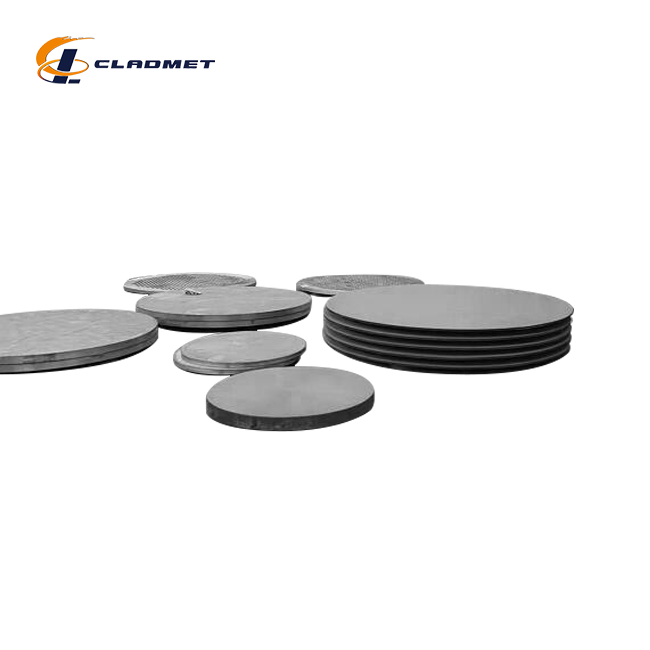

Key Features and Benefits of Titanium Aluminum Clad Plates

Corrosion Resistance: Titanium's exceptional resistance to oxidation and corrosion enhances durability in challenging environments.

Lightweight and Strong: Combining aluminum's lightweight properties with titanium's strength creates a material that optimizes performance in weight-sensitive applications.

Thermal and Electrical Conductivity: Aluminum contributes excellent thermal and electrical properties, making these plates suitable for heat transfer and electrical systems.

Customizable Dimensions: Plates can be tailored to specific thicknesses, sizes, and surface finishes to meet various industrial requirements.

Enhanced Longevity: The durable bond between titanium and aluminum ensures extended service life, reducing maintenance and replacement costs.

Cost-Effective Solutions: Using aluminum as the base material minimizes costs while retaining the functional benefits of titanium.

Eco-Friendly Material: The recyclable nature of both titanium and aluminum aligns with sustainability goals in various industries.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

Why Jl Metal can provide professional solutions for your projects

With more than 40 years of experience in non-ferrous metal cladding technology and production, we provide high quality explosive composite titanium aluminum plates according to ASTM, ASME, JIS, DIN, ISO other standards. More than 20 items of inventory or practical new-type patents also provide us with strong research and technical supports for us.

How we carry on the quality management:

- Technical clarification with customer

- Attend / organize pre-inspection meeting

- In-process inspection, including Material inspection, Test witness, Visual & dimensional inspection, Welding inspection, NDE inspection, Coating inspection

- Final inspection on finished products

- Packing inspection

- Progress report and schedule expediting

- Other inspection might be requested by the customer

OEM Service

We at Baoji JL Clad Metals offer bespoke manufacturing solutions that are tailored to your particular requirements. Our team will collaborate closely with you to find the best solution for your project, whether you need unique dimensions, surface treatments, or material combinations.

FAQs

1:What are the key benefits of using the products?

R:The primary benefits include excellent corrosion resistance, high strength-to-weight ratio, cost savings, and durability.

2:What industries are Titanium Aluminum Clad Plates best suited for?

R:They are commonly used in aerospace, chemical processing, automotive, and power generation industries.

3:What is the typical delivery time?

R:The delivery cycle is typically 3–6 months but can be negotiated depending on the project requirements.

4:Can you customize the size of the clad plates?

R:Yes, we offer customizable sizes to fit your specific project needs.

Contact Us

For more information or to place an order, please contact us at:

· Tel: +86-917-3372918

· WhatsApp: 8613530170059

· Email: sales@cladmet.com

· Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)