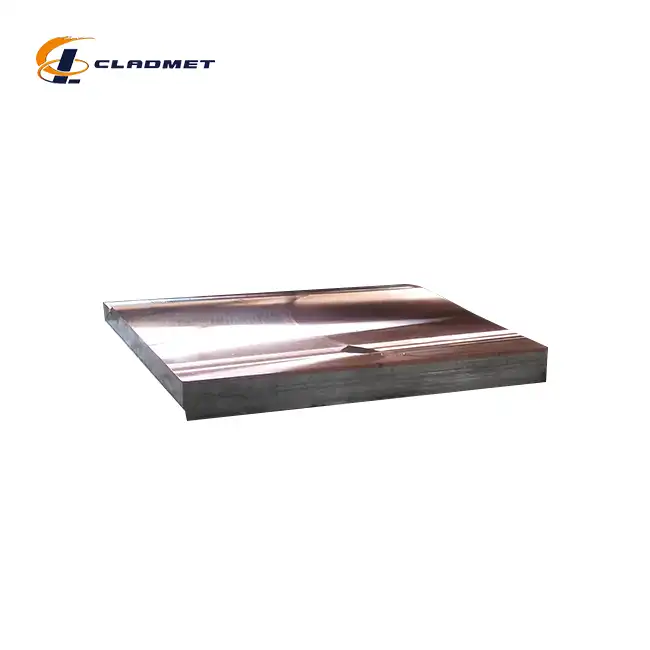

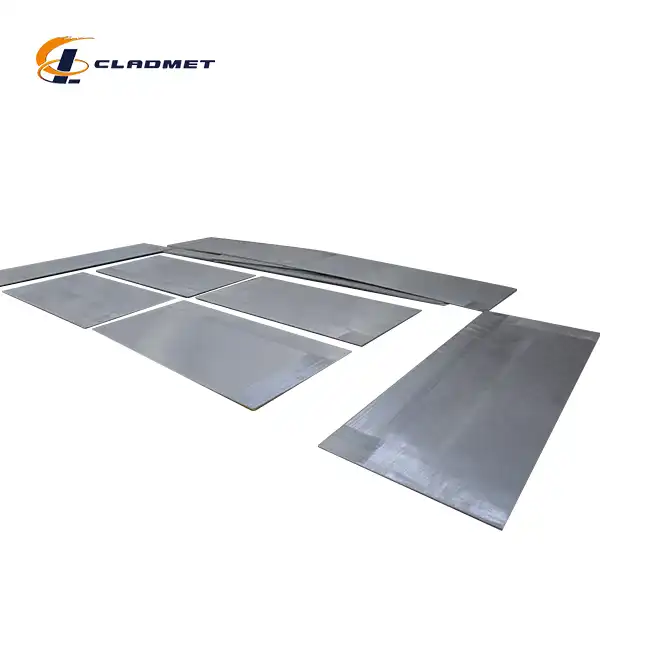

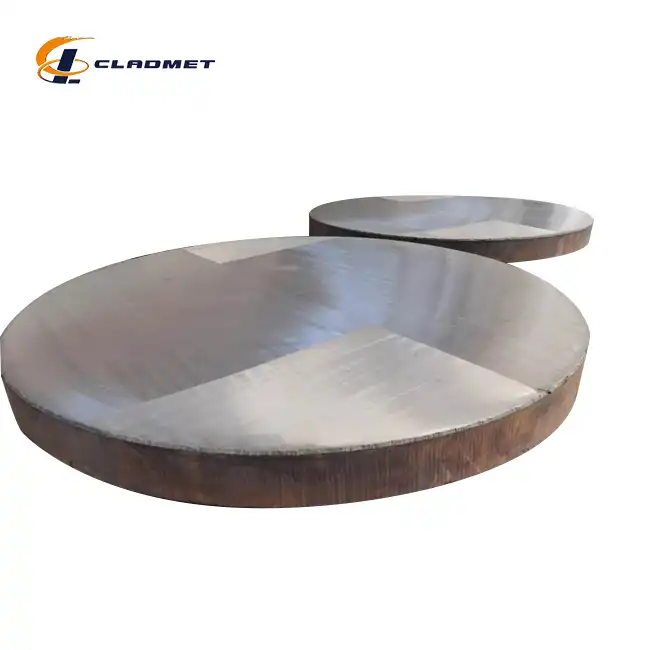

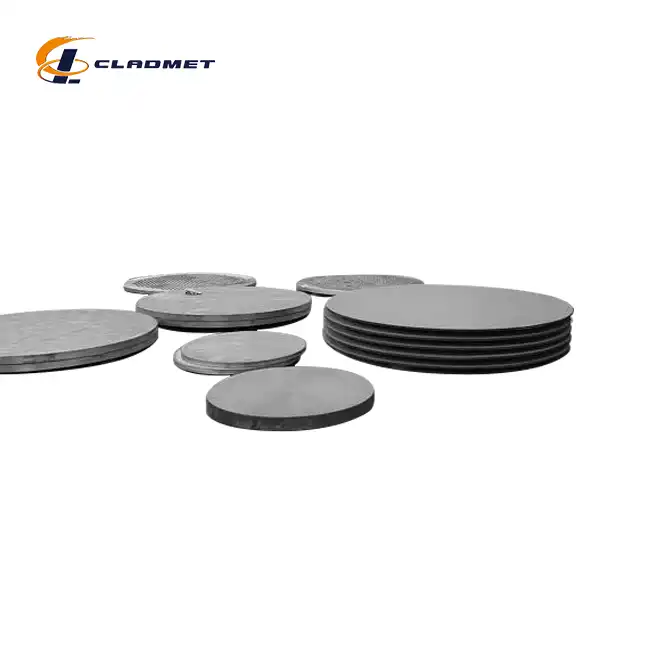

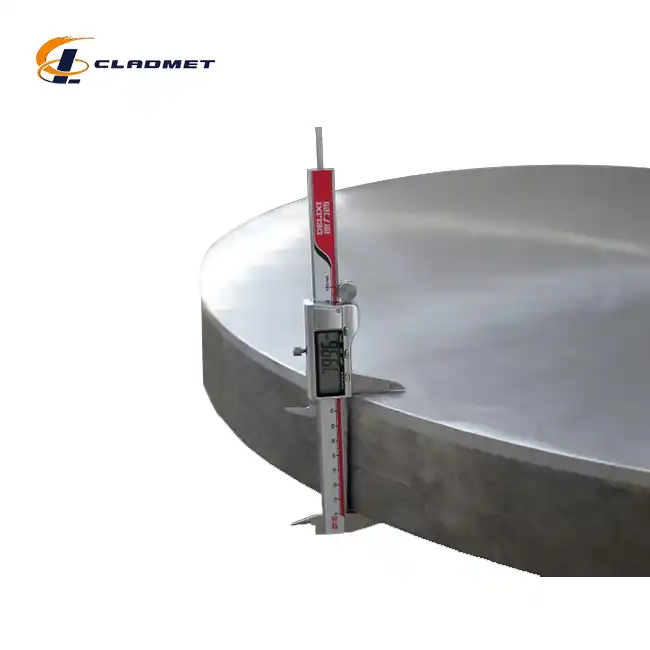

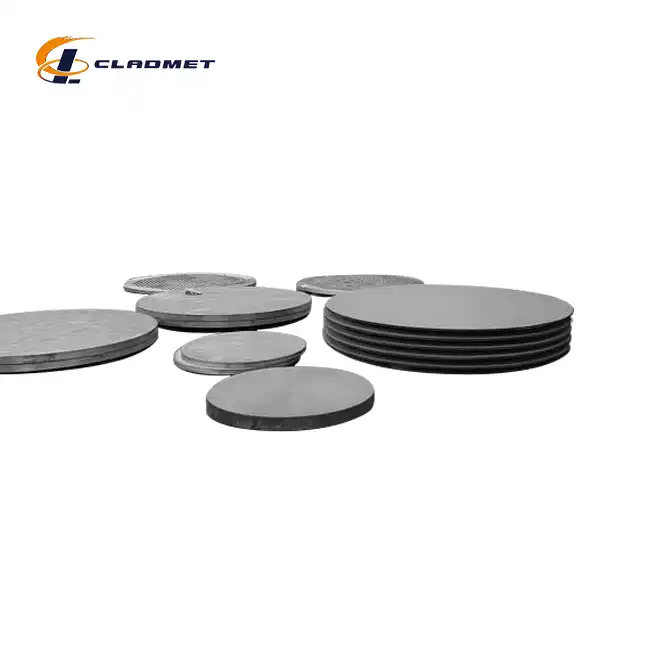

Available Sizes and Customization: Thickness: 10-100mm, Width: 500-2000mm. Custom sizes available.

Product Applications: Used in chemical, shipbuilding, and power industries.

Processing Technology: Explosive welding ensures durable bond strength.

Quality Control and Testing: Strict testing, ISO9001-2000 certified, PED, ABS audits passed in 2024.

Product Implementation Standards: Compliant with ASME, ASTM, JIS standards.ABS &PED qualification.

Delivery: Ships via sea, air, or land transport.

Packaging: Wooden crate packaging for safe transport.

Overview

JL Ti Clad Copper has excellent conductivity and is fully ductile for shaping and forming. Ti Clad Copper also has good weldability for connecting, capping and joining.

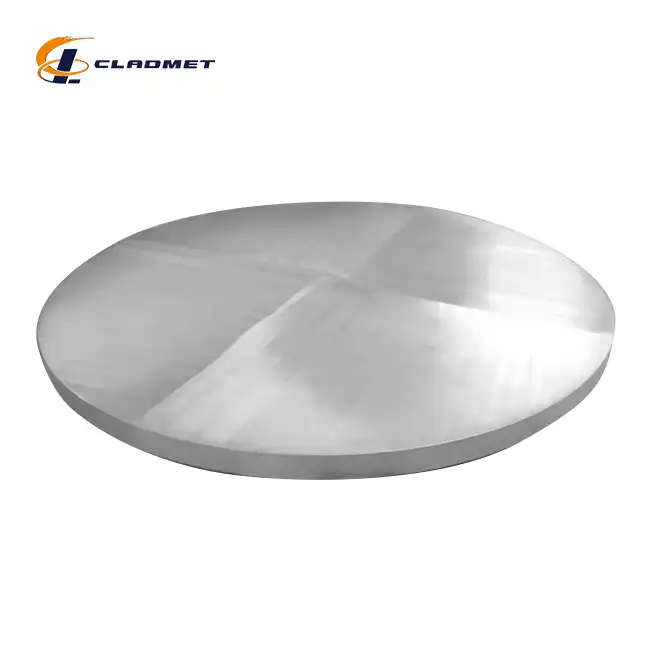

Jl Ti Clad Copper can be cut to length and packaged to customer requirements. JL clad metals also offers complete metallurgical services for testing and quality control.

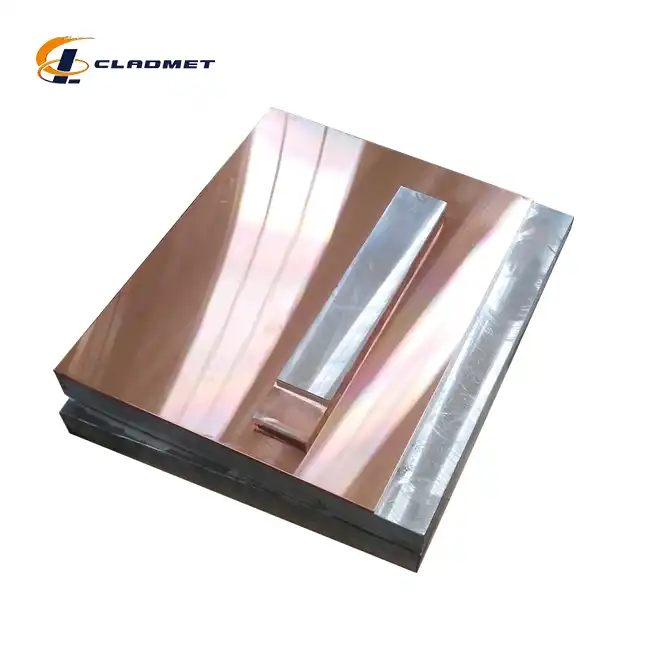

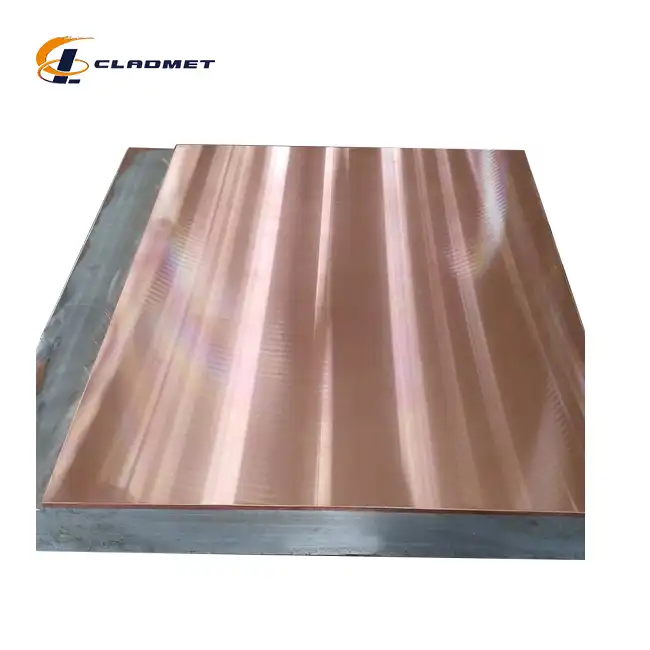

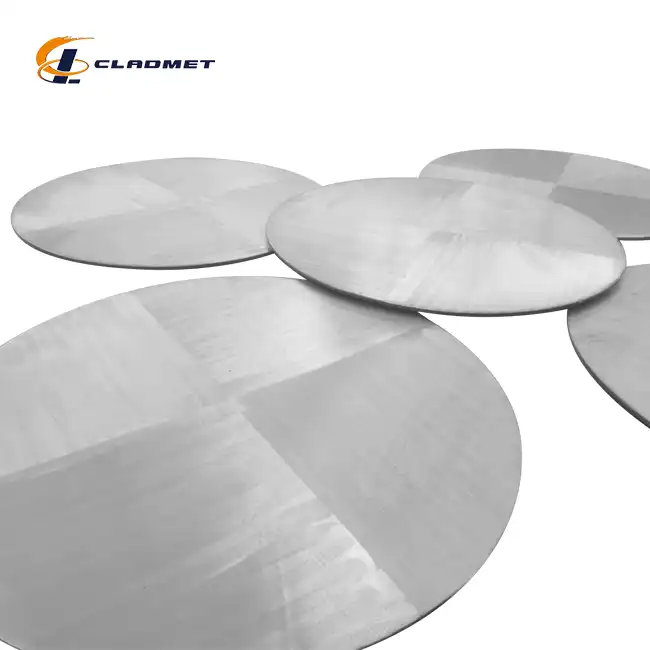

Titanium clad copper plates are a highly versatile and durable material created by bonding a layer of titanium onto a copper base. This process enhances the properties of both metals, providing exceptional corrosion resistance and electrical conductivity. These plates are widely used in industries that require superior performance in extreme environments, such as electroplating, chemical processing, and marine engineering.

Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in the clad metals industry, specializes in producing high-quality titanium clad copper plates using advanced technologies such as explosion bonding. With decades of expertise, we ensure that our products meet international standards, including GB/GBT, ASME/ASTM, and JIS, providing superior quality and reliability.

Product Specifications:

|

Copper sheet,Copper plate |

||

|

Material |

C10100,C10200,C10300,C10400,C10500,C10700,C10800, C10910,C10920, C10930,C11000,C11300,C11400,C11500,C11600,C12000, C12200,C12300, C12500,C14200,C14420,C14500,C14510,C14520,C14530, C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000, C33200,C37000 C44300,C44400,C44500,C60800,C63020,C65500,C68700, C70400,C70600, C70620,C71000,C71500,C71520,C71640,C72200,etc. |

|

|

Specifications |

Thickness |

0.1mm-200mm |

|

Width |

10mm-2500mm |

|

|

Length |

10mm~12000mm,or as required |

|

|

Price Term |

Ex-work,FOB,CFR,CIF,etc. |

|

|

Payment Term |

T/T,L/C,Western Union,etc. |

|

|

Transportation |

Road, Air, Sea with wooden crates or as per customer requirements |

|

|

MOQ |

100Kgs. |

|

|

Export To |

Singapore,Indonesia,Korea,Thailand,Egypt,India,Dubai,Oman, Russia,Malaysia,etc. |

|

Key attributes

Industry-specific attributes

|

Material |

Bronze |

|

Cu (Min) |

80%-90% |

|

Alloy Or Not |

Non-Alloy |

|

UItimate Strength (≥MPa) |

205 |

|

Elongation (≥%) |

40 |

Methods of Titanium Cladding

Titanium cladding can be completed through many methods, further details as below:

Explosive Welding

Explosive welding is a process of creating a high-energy impact between the base material and the titanium layer. This impact results in a metallurgical bond between these two materials.

The process including:

Assembly: Cleaning the preparing the base material and titanium layer are meticulously then assembling them together in a specific configuration.

Explosive Charge: Placing an explosive material between these two layers then detonating it.

High-Speed Impact: The explosion generates a high-speed impact, causing the materials to collide. This impact leads to the formation of a strong, metallurgical bond.

Explosive welding is often used in applications where a high bond strength required, such as the manufacture of heat exchangers and pressure vessels.

Roll Bonding

Roll bonding is a cold-welding process that involves passing the base material and titanium layer through a set of rollers. The pressure exerted by the rollers creates a bond between the two materials. The key procedures in roll bonding including as below:

Surface Preparation: Clearing both the base material and titanium layer are thoroughly to ensure a strong bond.

Rolling Process: The materials are fed through rollers under high pressure, causing them to bond together. Multiple passes may be required for a complete bond.

Roll bonding is often used in the production of clad plates and sheets for various applications, including chemical processing equipment and offshore structures.

Hot Isostatic Pressing (HIP)

It is a method that involves subjecting the base material and titanium layer to high temperature and pressure in a sealed container. This process results in a diffusion bond between the materials.

The procedure includs as below:

Assembly and Encapsulation: Assemly the base material and titanium layer and place them in a container and seal.

Heating and Pressurization: Place the sealed container in high temperatures and pressures, bond the materials together through atomic diffusion.

HIP is often used in applications requiring a high level of bonding integrity, such as aerospace components and critical parts for the oil and gas industry.

Product Features&Advantages

l Corrosion Resistance: The titanium layer provides outstanding resistance to corrosion, especially in environments with strong acids and alkaline solutions.

High Electrical Conductivity: The copper base ensures excellent electrical conductivity, making these plates ideal for electroplating and other electrical applications.

Strong Bonding: Advanced bonding techniques like explosion and roll bonding ensure a durable and reliable bond between the titanium and copper layers.

Lightweight and Flexible: Titanium clad copper plates are lighter than solid copper or titanium plates, allowing for easier handling and installation without compromising on strength.

Cost-Effective: By using a copper base with a titanium surface, these clad plates offer the advantages of titanium at a fraction of the cost of solid titanium plates.

Durability: Titanium’s exceptional resistance to wear and corrosion significantly extends the lifespan of the plates, reducing maintenance costs.

Customizable: Our plates can be customized to specific thicknesses and sizes, making them suitable for a variety of industrial applications.

Compliance: JL Clad Metals adheres to rigorous manufacturing standards, ensuring consistent quality and safety in every product.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service:

Baoji JL Clad Metals offers OEM services for custom orders. Whether you need specific dimensions, surface treatments, or additional features, our team will work with you to design and manufacture titanium clad copper plates that meet your exact specifications.

FAQ:

Q: What are the advantages of using titanium clad copper plates over solid titanium plates?

A: Titanium clad copper plates provide the same corrosion resistance and durability as solid titanium at a lower cost, with added benefits of copper’s conductivity.

Q: What is the typical delivery time for orders?

A: Our standard delivery cycle is 3-6 months, depending on order size and customization requirements.

Q: Can you provide certifications for your products?

A: Yes, we can provide certifications such as GB/GBT, ASME/ASTM, and JIS upon request.

As well as international qualification such as ABS and GTP.

Contact Us:

For inquiries or to place an order, please contact us:

Tel: +86-917-3372918

WhatsApp: 8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

By focusing on quality, compliance, and customization, Baoji JL Clad Metals ensures that our titanium clad copper plates meet the needs of industries requiring superior performance and durability.

_1737007724117.webp)