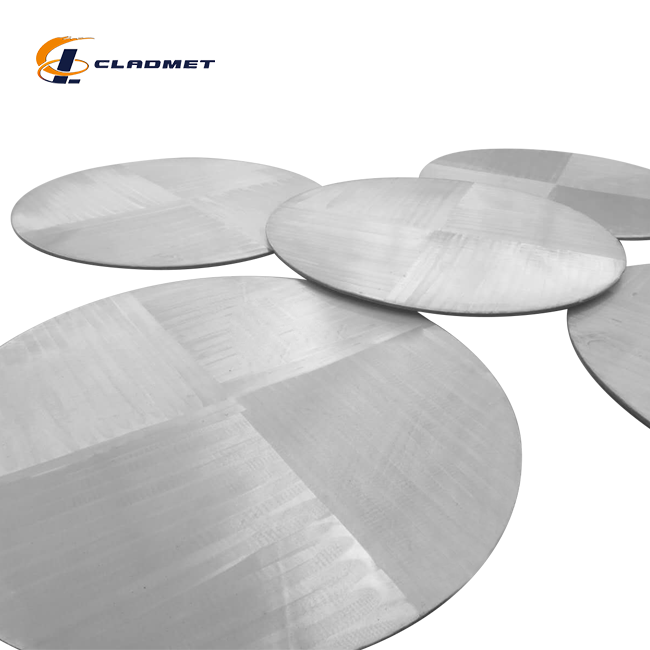

Product Applications:Used in electroplating, chemical, and marine industries

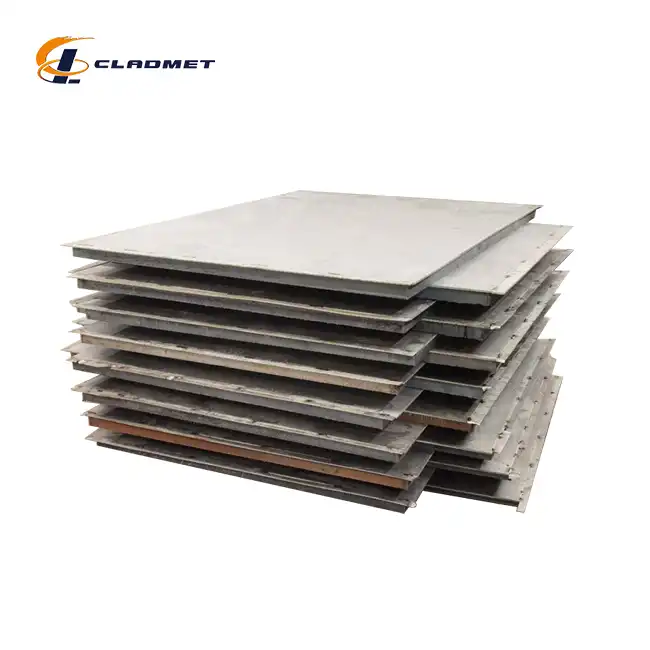

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

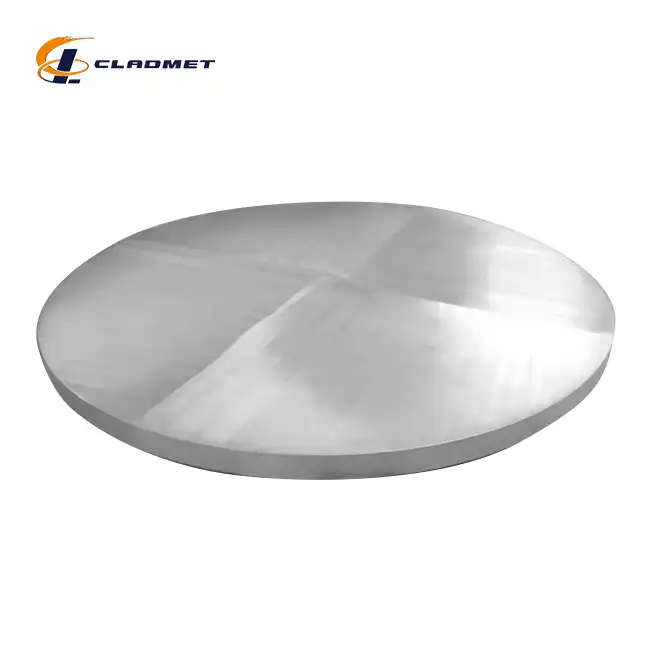

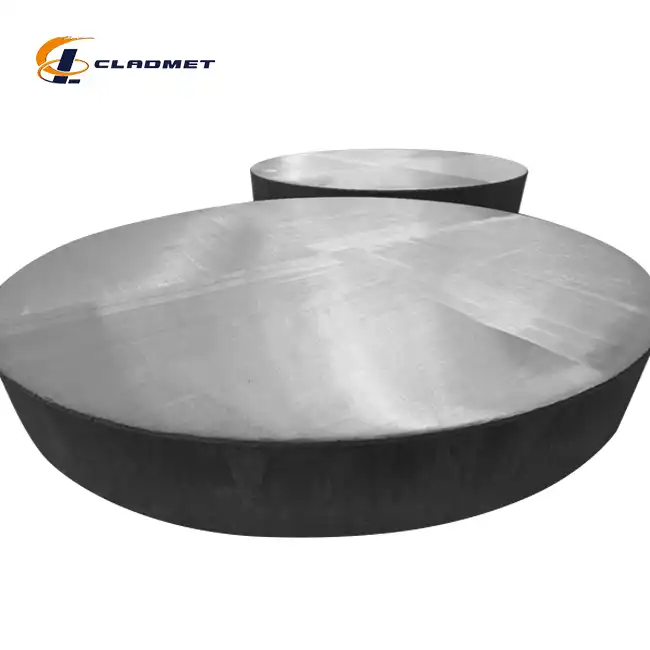

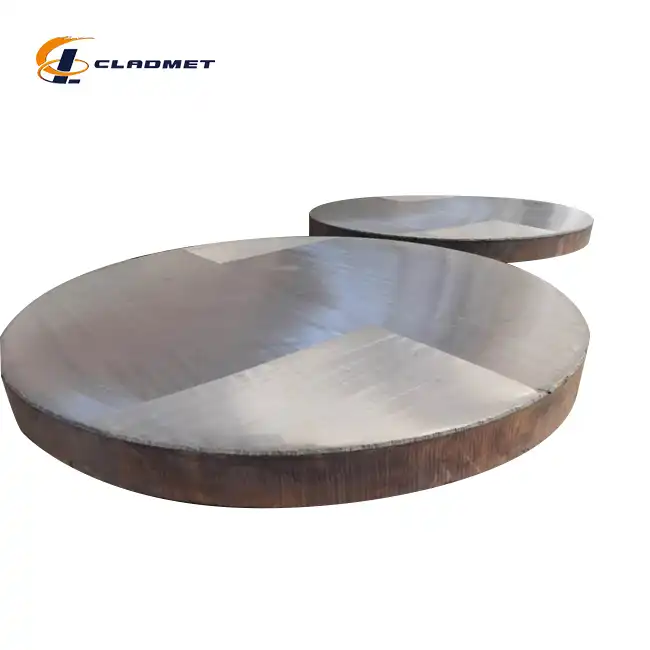

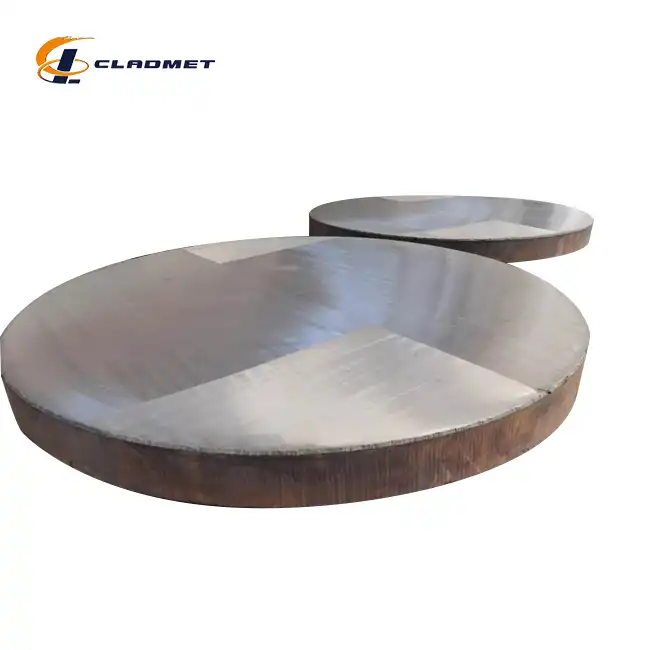

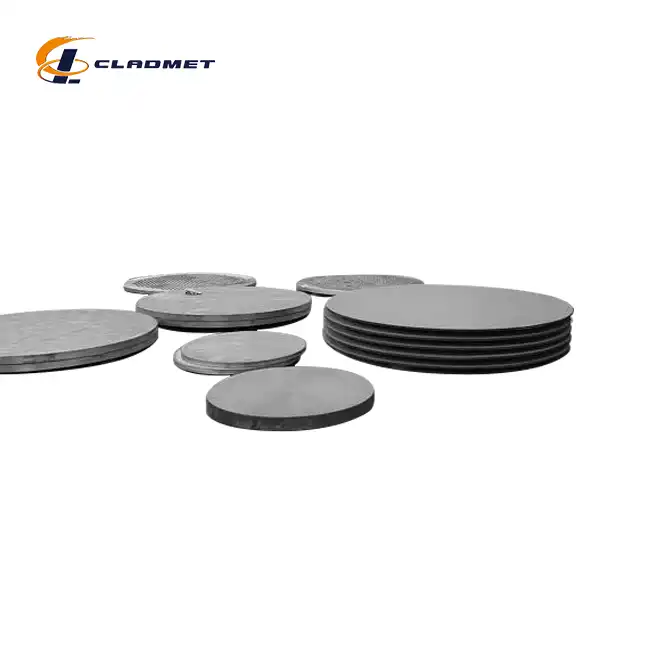

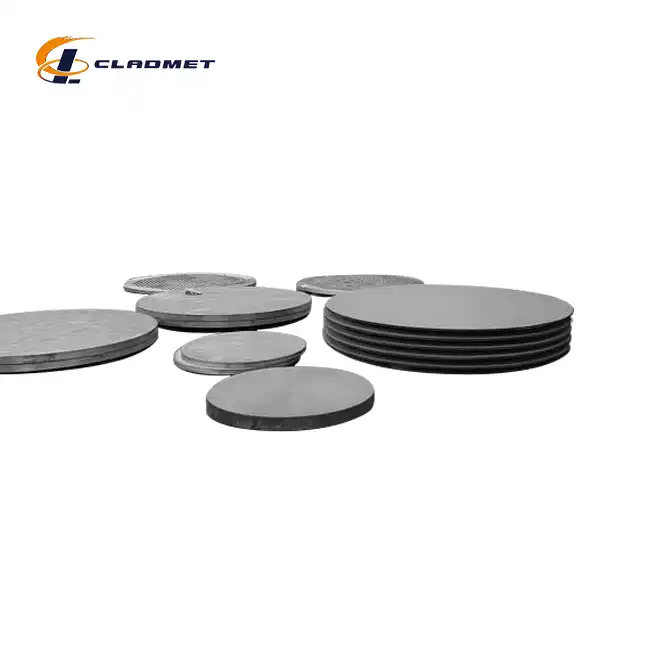

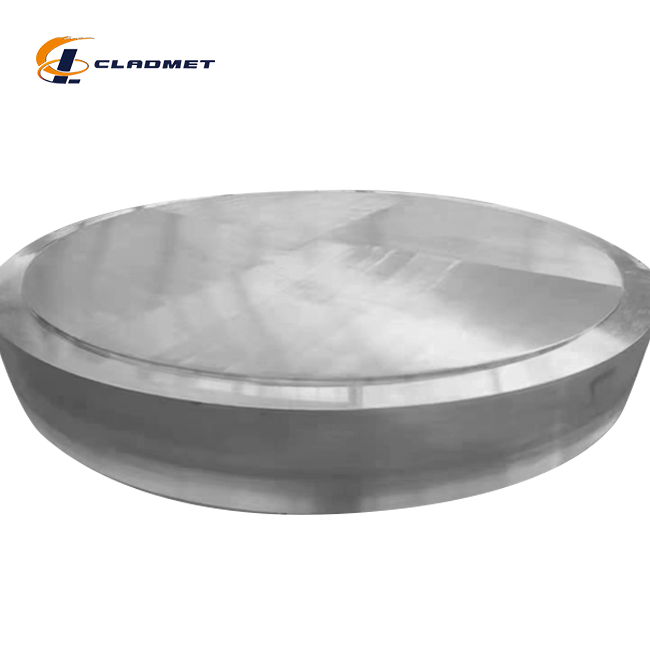

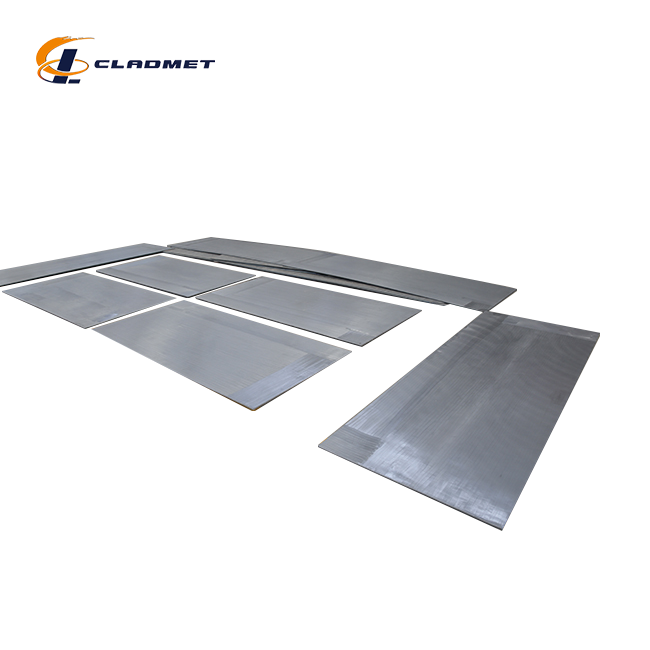

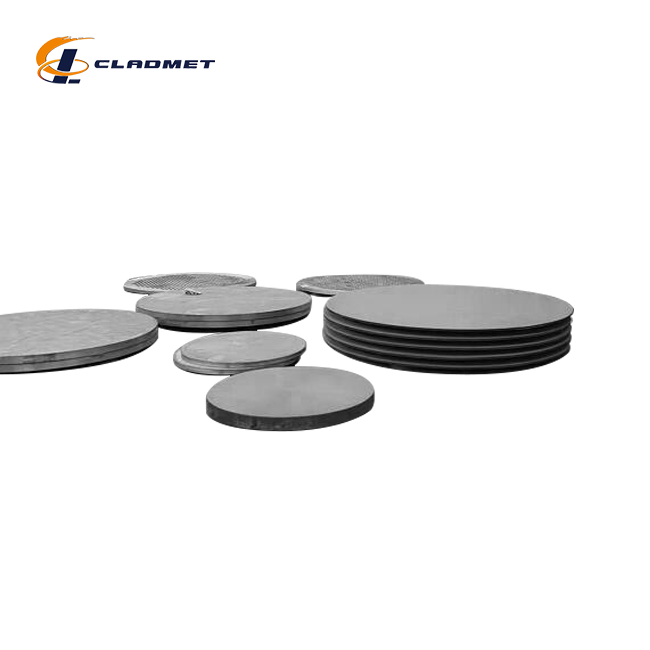

Titanium clad plates Overview

Titanium clad plates are our speciality at Baoji JL Clad Metals Materials Co., Ltd. because of their exceptional strength, resistance to corrosion, and longevity in industrial applications. Our products provide customrized solutions for many industries appllication requirements, high-performance materials by bonding titanium with various base metals through roll-bonding or explosion-bonding processes. We are a reliable partner of companies in the chemical processing, oil and gas, aerospace, and other industries.

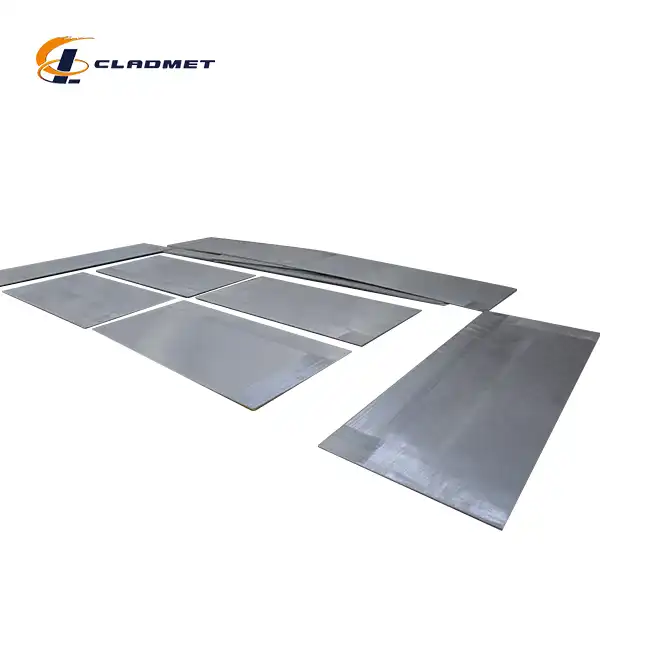

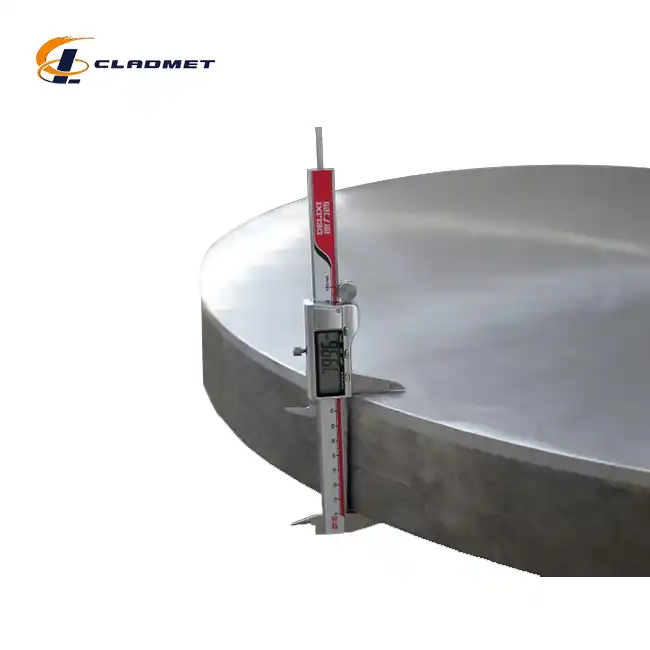

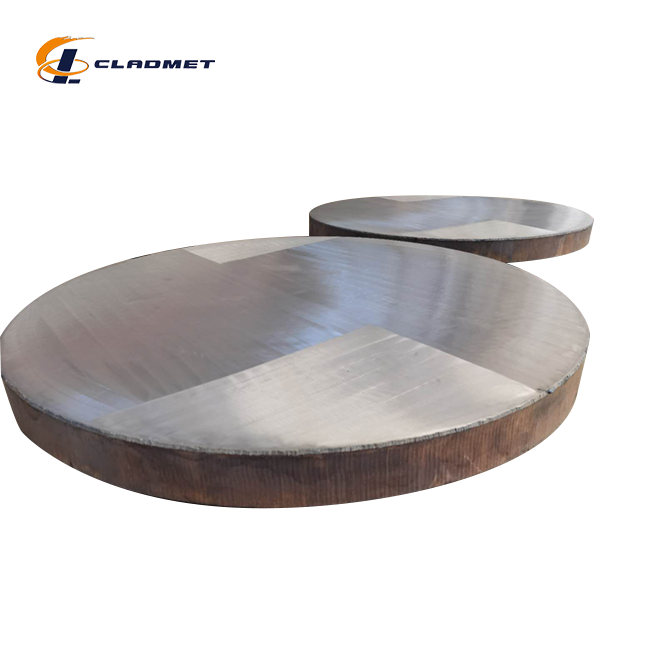

Product Specifications

|

Parameter |

Specification |

|

Base Material |

Carbon Steel, Stainless Steel, Copper, etc. |

|

Clad Material |

Titanium (Grade 1, Grade 2,etc.) |

|

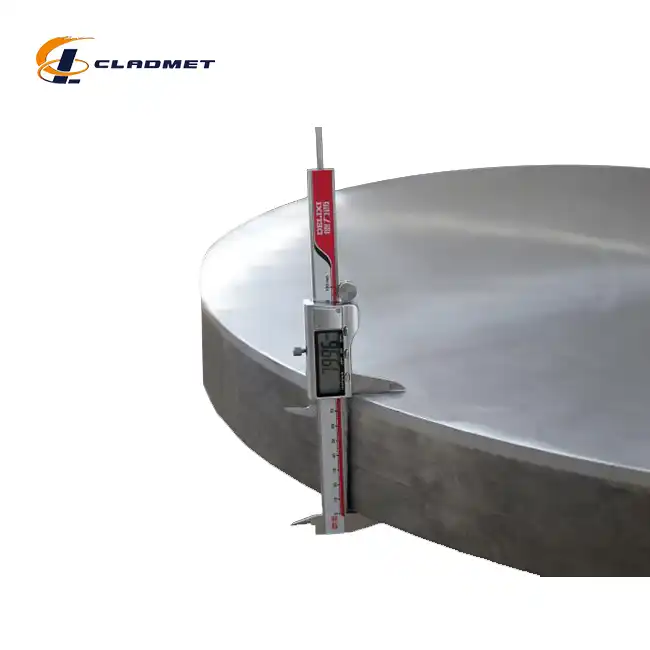

Clad Thickness |

1.0 mm - 20.0 mm |

|

Base Thickness |

5.0 mm - 200 mm |

|

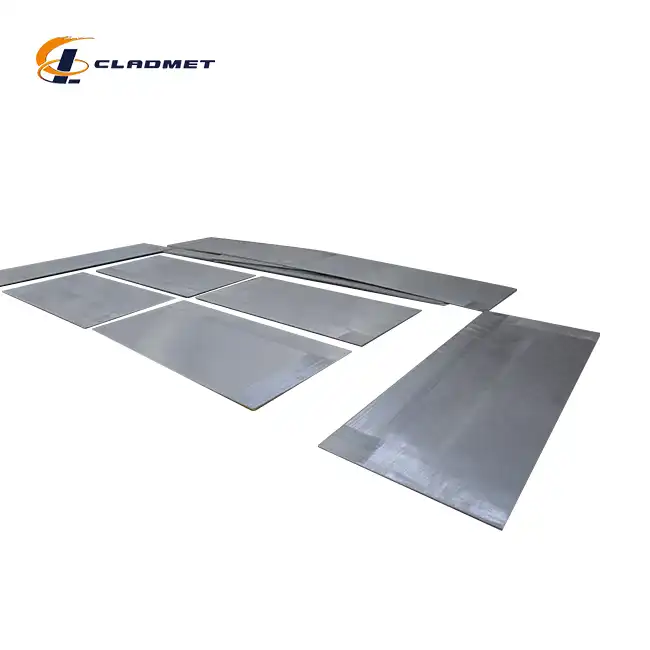

Width |

500 mm - 3000 mm |

|

Length |

1000 mm - 12000 mm |

|

Bonding Type |

Explosive Bonding, Roll Bonding |

|

Tensile Strength |

≥ 320 MPa (varies by material grade) |

|

Shear Strength |

≥ 140 MPa |

|

Elongation |

≥ 20% |

|

Corrosion Resistance |

Excellent (varies with environment) |

|

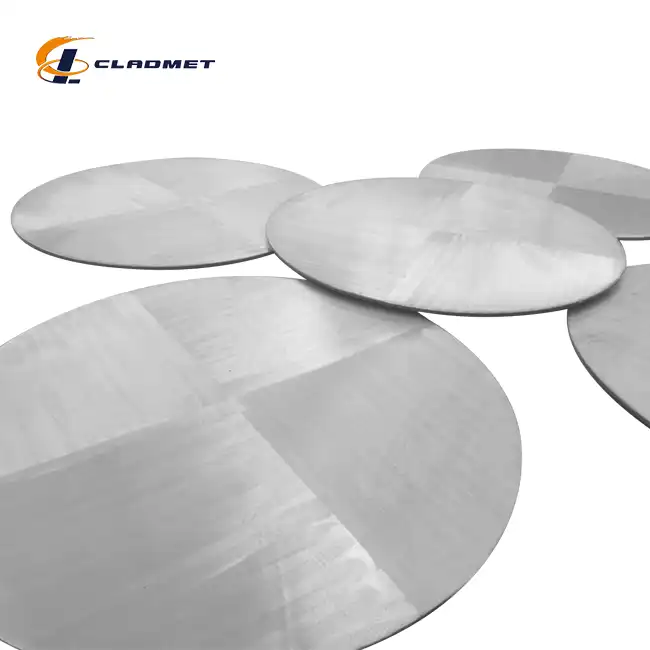

Surface Finish |

Polished, Pickled, Sand Blasted |

|

Industry Standards |

ASTM B898, ASME SB-898, GB/T 8547 |

|

Applications |

Chemical, Marine, Medical, Aerospace, etc. |

|

|

|

|

|

|

|

|

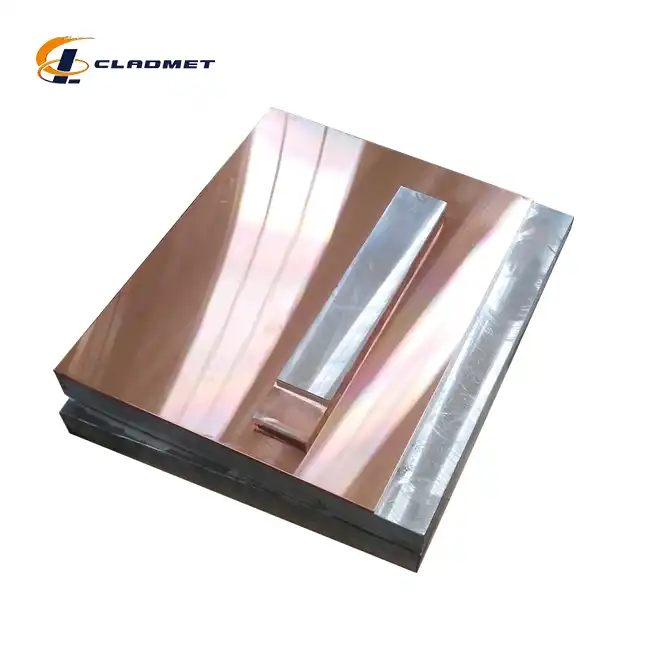

Methods of Titanium Cladding

Titanium cladding can be completed through many methods, further details as below:

Explosive Welding

Explosive welding is a process of creating a high-energy impact between the base material and the titanium layer. This impact results in a metallurgical bond between these two materials.

The process including:

Assembly: Cleaning the preparing the base material and titanium layer are meticulously then assembling them together in a specific configuration.

Explosive Charge: Placing an explosive material between these two layers then detonating it.

High-Speed Impact: The explosion generates a high-speed impact, causing the materials to collide. This impact leads to the formation of a strong, metallurgical bond.

Explosive welding is often used in applications where a high bond strength required, such as the manufacture of heat exchangers and pressure vessels.

Roll Bonding

Roll bonding is a cold-welding process that involves passing the base material and titanium layer through a set of rollers. The pressure exerted by the rollers creates a bond between the two materials. The key procedures in roll bonding including as below:

Surface Preparation: Clearing both the base material and titanium layer are thoroughly to ensure a strong bond.

Rolling Process: The materials are fed through rollers under high pressure, causing them to bond together. Multiple passes may be required for a complete bond.

Roll bonding is often used in the production of clad plates and sheets for various applications, including chemical processing equipment and offshore structures.

Hot Isostatic Pressing (HIP)

It is a method that involves subjecting the base material and titanium layer to high temperature and pressure in a sealed container. This process results in a diffusion bond between the materials.

The procedure includs as below:

Assembly and Encapsulation: Assemly the base material and titanium layer and place them in a container and seal.

Heating and Pressurization: Place the sealed container in high temperatures and pressures, bond the materials together through atomic diffusion.

HIP is often used in applications requiring a high level of bonding integrity, such as aerospace components and critical parts for the oil and gas industry.

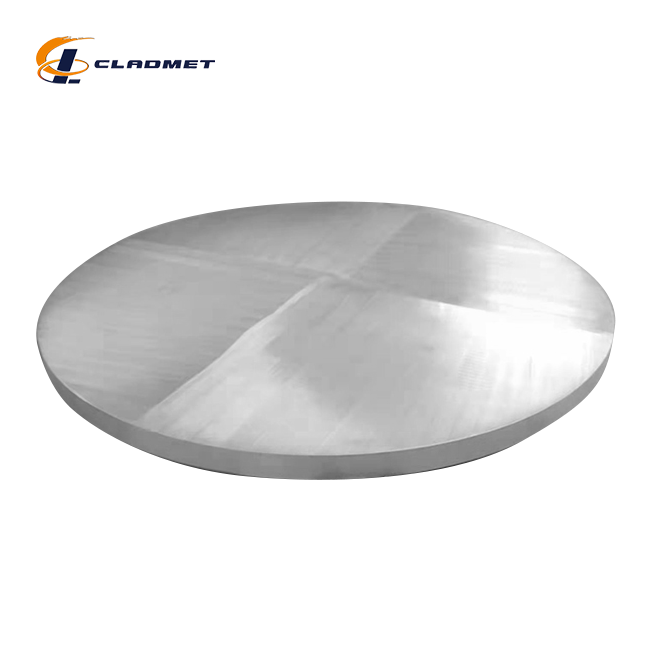

Product Features&Advantages

Corrosion Resistance: Titanium’s exceptional corrosion resistance extends the life of the equipment, making it ideal for harsh environments.

High Strength: Our advanced bonding techniques ensure superior strength, suitable for heavy-duty applications.

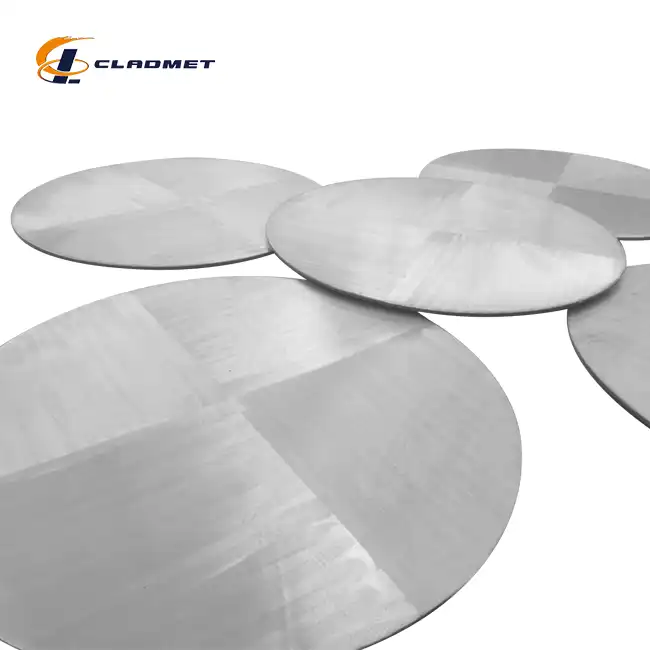

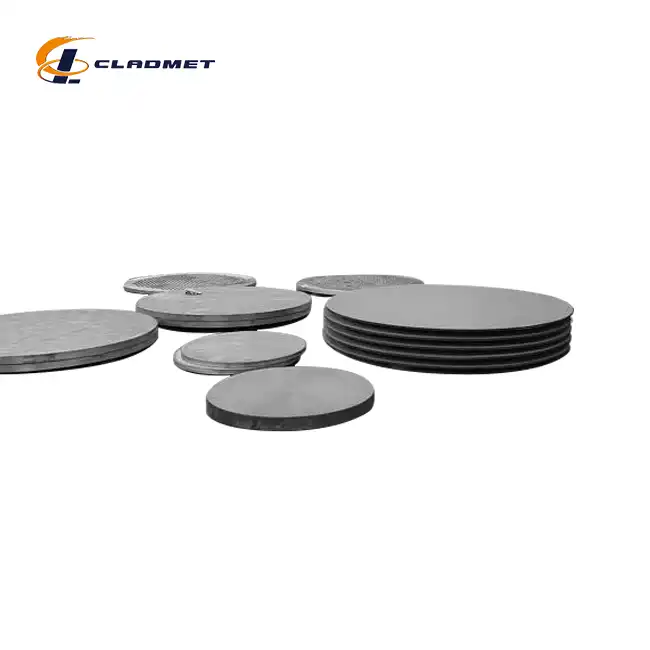

Customizable: We offer tailor-made solutions, including various sizes and material combinations to meet specific industrial needs and applications.

Cost Efficiency: With an excellent strength-to-weight ratio, titanium clad plates reduce overall project costs while maintaining performance.

Durability: Enhanced resistance to corrosion and wear, ensuring longevity even in extreme conditions.

Reduced Maintenance: Low maintenance costs due to the material’s durability and resistance to wear and corrosion.

Global Standards: Manufactured to meet international standards (GB, ASME, JIS), ensuring high quality and compliance.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

JL CLAD offer individualized OEM services, supplying clients with industry-specific solutions. From material selection to final production, our technical team can assist with product development.

FAQs

Q: What is the delivery time for the titanium clad plates?

A: The standard delivery cycle is between 3-6 months, depending on the order size and specifications. Negotiable for urgent projects.

Q: Can I request custom dimensions for my products?

A: Yes, we offer fully customizable sizing options to meet your project’s needs.

Q: What industries benefit most from the products?

A: The products are widely used in oil and gas, chemical processing, aerospace, marine engineering, and pharmaceuticals.

Why Choose Us – Baoji JL Clad Metals Materials Co., Ltd.

Extensive Experience

Established in 1988, JL Clad Metals boasts 36 years of expertise in clad metal manufacturing. Our long history reflects a deep understanding of the industry and a proven track record of excellence.

Strong R&D Capabilities

We collaborate with leading research institutes and enterprises, including Kunming Technology University, China Northwest Industrial University, Baoti Group, and others. This ensures that our products benefit from cutting-edge research and innovation.

Strict Quality Standards

JL Clad Metals adheres to the most rigorous quality standards, including GB/GBT, ASME/ASTM, and JIS. We are ISO 9001-2000 certified and have achieved PED and ABS international qualifications, guaranteeing the reliability and safety of our products.

Comprehensive Product Range

Our portfolio includes a wide variety of clad metal materials such as titanium, nickel, stainless steel, aluminum, tantalum, zirconium, and columbium. We also provide deep processing services, offering finished products for chemical equipment and other industrial applications.

Global Reach

JL Clad Metals serves clients worldwide, with our products widely used in industries like petroleum, chemical, pharmacy, metallurgy, electric power, and environmental protection. Our strong domestic and international presence ensures trusted solutions across the globe.

High-Tech Facilities

Located in a High-Tech Development District, we leverage state-of-the-art technology and modern production techniques to deliver superior products efficiently and sustainably.

Customized Solutions

We specialize in creating tailored solutions to meet the specific needs of our clients, ensuring optimal performance and satisfaction in every project.

Exceptional Customer Service

Our dedicated team is committed to providing prompt support and expert guidance, ensuring a seamless experience from inquiry to delivery.

Choose Baoji JL Clad Metals for reliable, high-quality clad metal materials and services that empower your business with industry-leading solutions.

Contact Us

For more information on our titanium clad plates or to request a quote, contact us today!

· Phone: +86-917-3372918

· WhatsApp: +8613530170059

· Email: sales@cladmet.com

· Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)