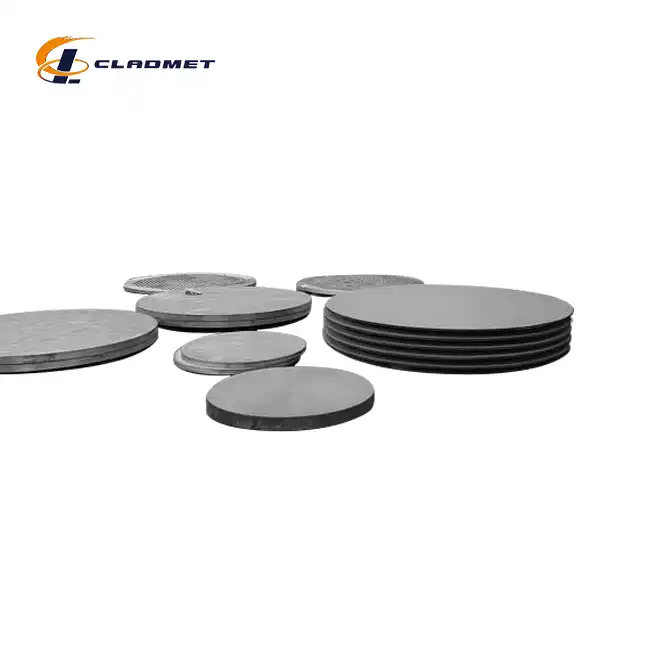

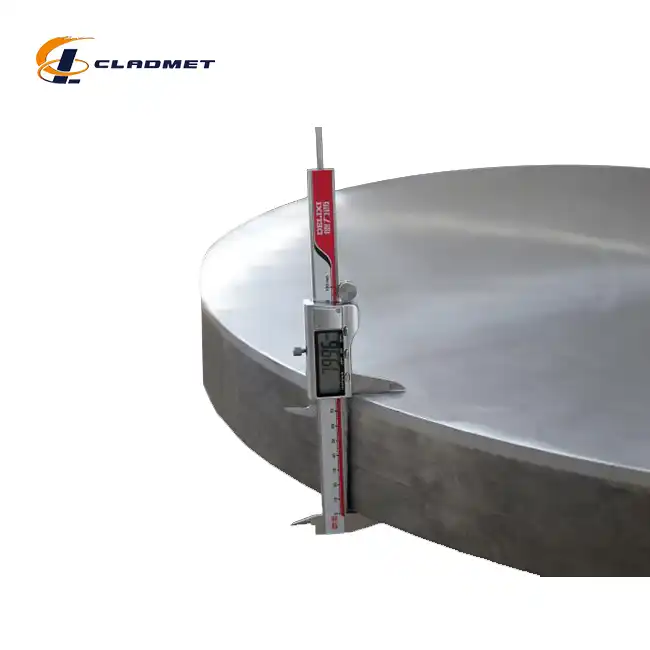

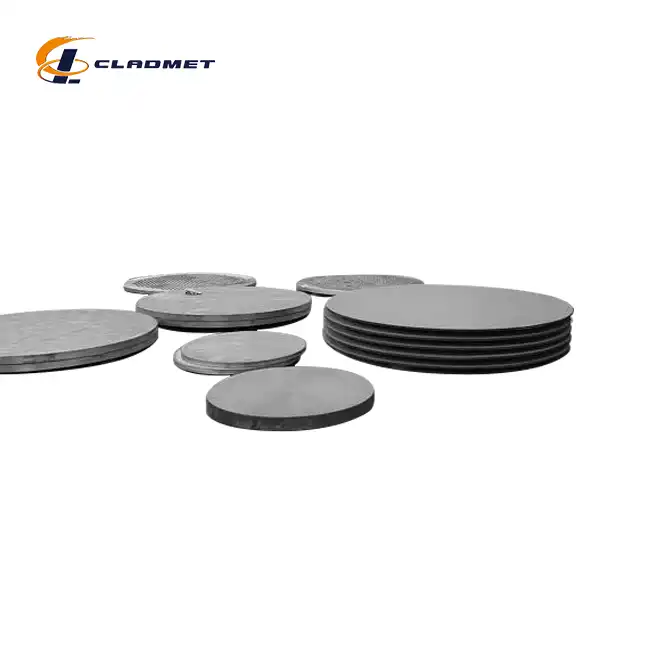

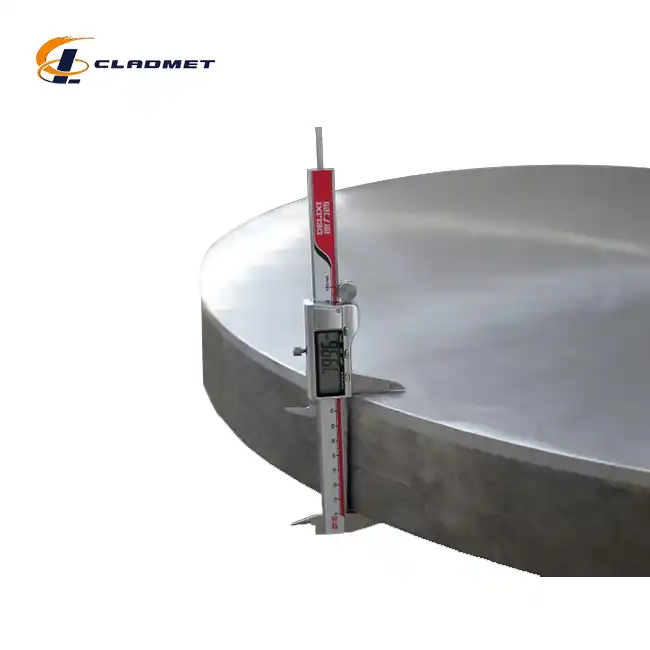

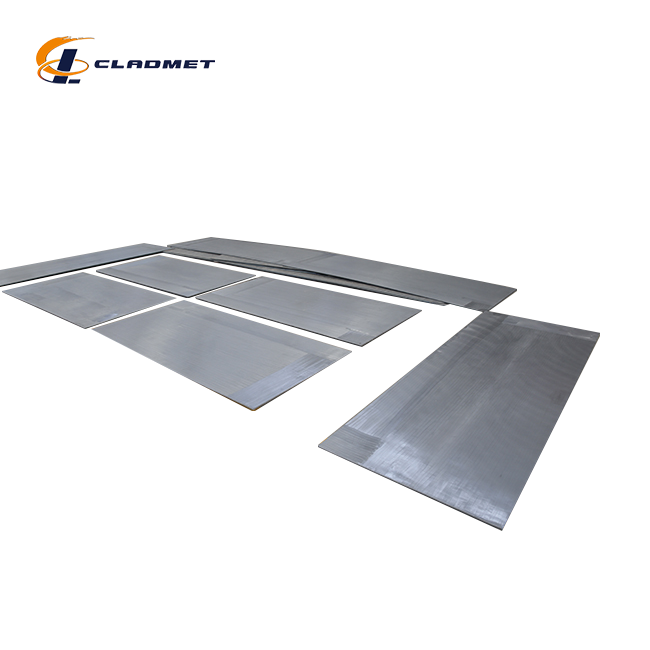

2. Available Sizes and Customization: Thickness: 1-50mm, width: 1000-3000mm, custom sizes supported.

3. Applications: Used in aerospace, chemical, marine, and oil industries.

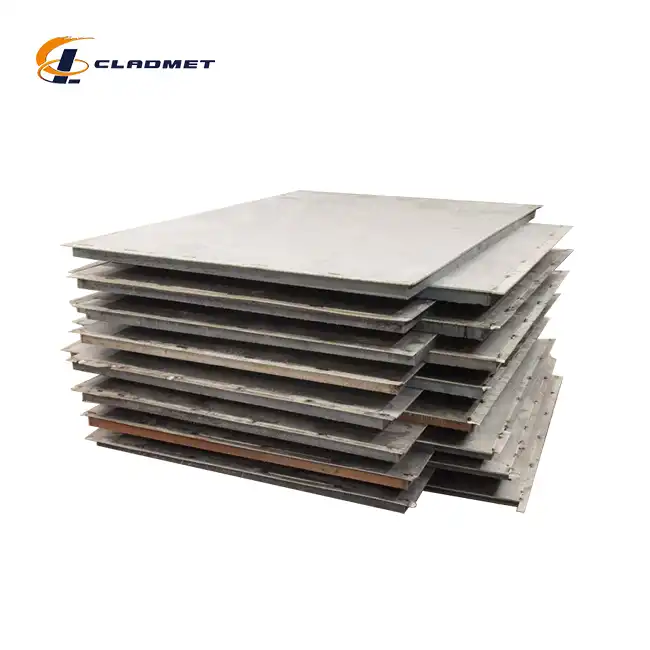

4. Processing Technology: Explosive bonding technology for strong metallurgical bonding.

5. Quality Control and Testing: Strict non-destructive testing, ultrasonic and X-ray inspections.

6. Product Standards and Certifications: Complies with ASME, ASTM, JIS, ISO9001-2000, PED, and ABS.

7.Delivery:Global shipping by sea or air, flexible delivery options.

8. Packaging: Export wooden crates or custom protective packaging.

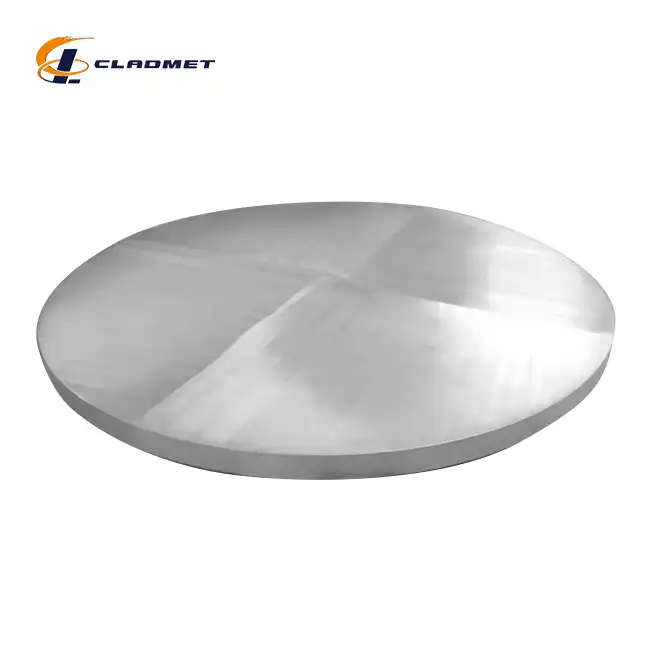

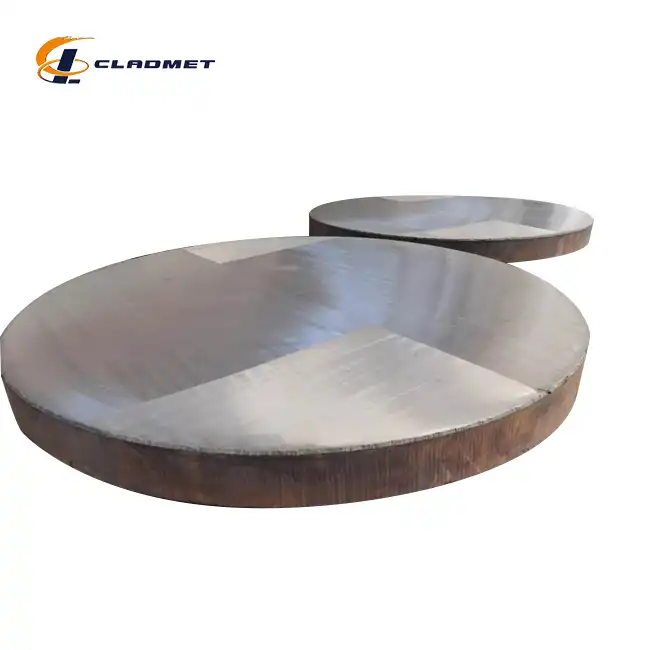

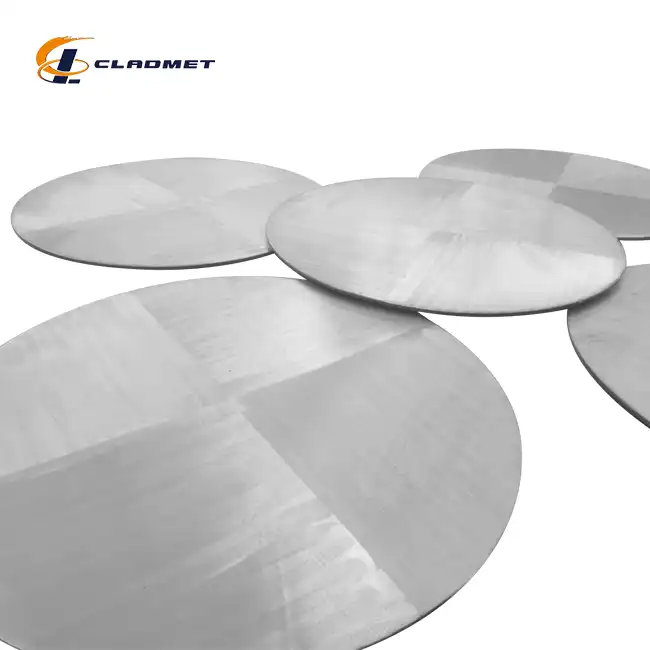

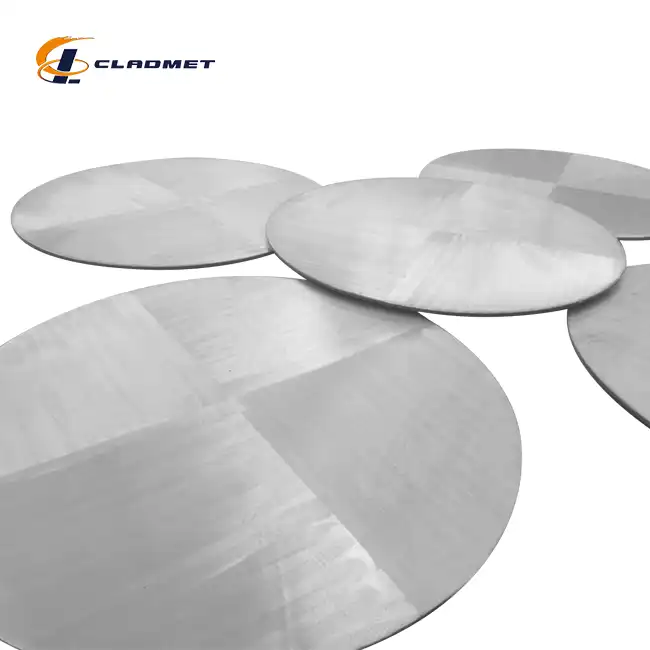

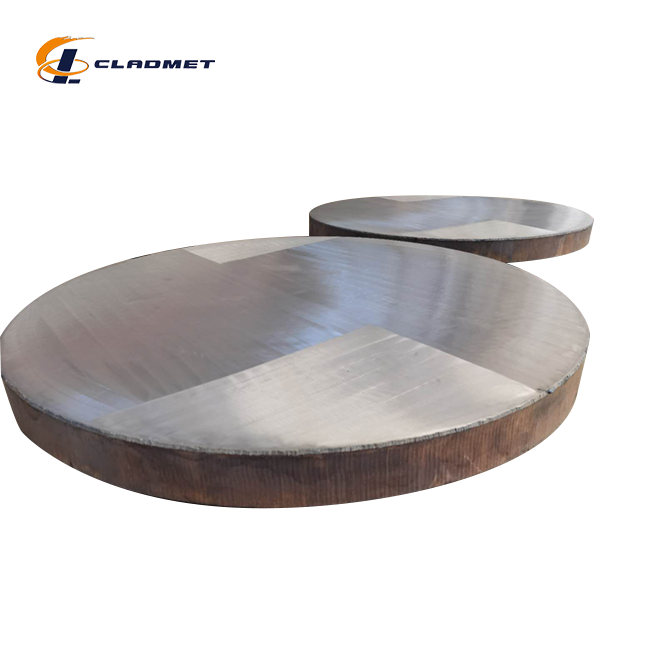

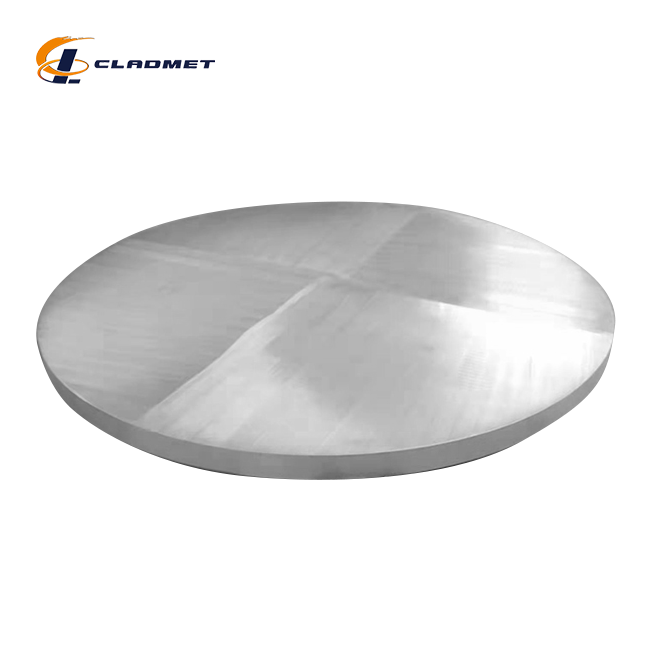

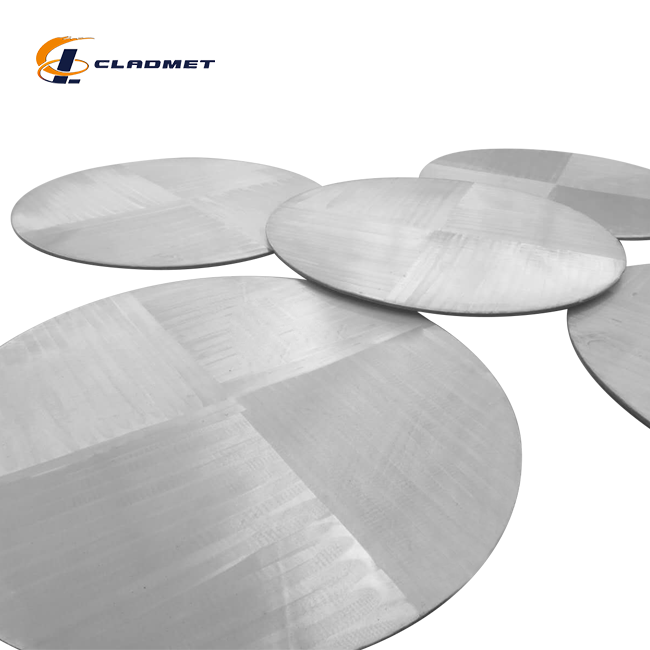

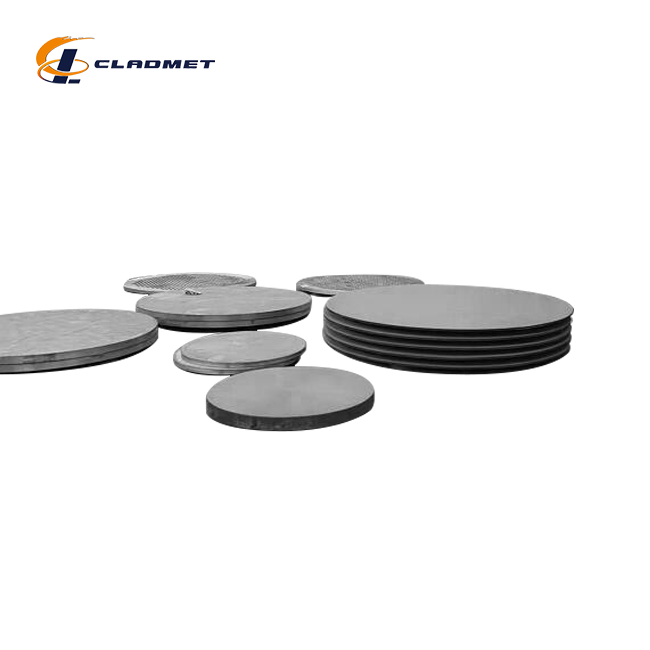

Titanium Clad Steel Plates are high-performance composites that combine the corrosion resistance of titanium with the strength of steel. Roll or explosion bonding is used to join steel and titanium to create these plates with improved mechanical properties and durability. The products are a cost-effective solution that improves functional productivity while also extending the life of equipment, making them ideal for industries like synthetic handling, petrochemicals, and marine design where primary uprightness and consumption opposition are essential.

Product Specifications

| Category | Details |

|---|---|

| Cladding Material | Titanium, Titanium Alloy |

| Base Metal | Carbon Steel, Stainless Steel |

| Cladding Size | Customized (as per client’s requirement) |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Thickness | 3mm to 200mm |

| Length | Up to 12,000mm |

| Width | Up to 3,000mm |

| Surface Treatment | Polished, Sandblasted, Acid Pickling |

| Packaging | Wooden cases, Custom packaging available |

| Transportation | Sea freight, Air freight, Road transport |

| Delivery Cycle | 3-6 months (negotiable) |

|

|

|

|

|

|

|

|

Cladding Techniques for Titanium and Steel

Explosive Welding Method

Explosive welding is a specialized technique that forms a metallurgical bond between titanium and steel through controlled, high-energy impact. Key steps include:

Surface Preparation: The steel and titanium are thoroughly cleaned to remove contaminants and improve bond quality.

Explosive Setup: A calculated amount of explosive material is positioned to create the required energy for bonding.

Impact and Bonding: The detonation creates a powerful impact, forcing the materials to join at the atomic level.

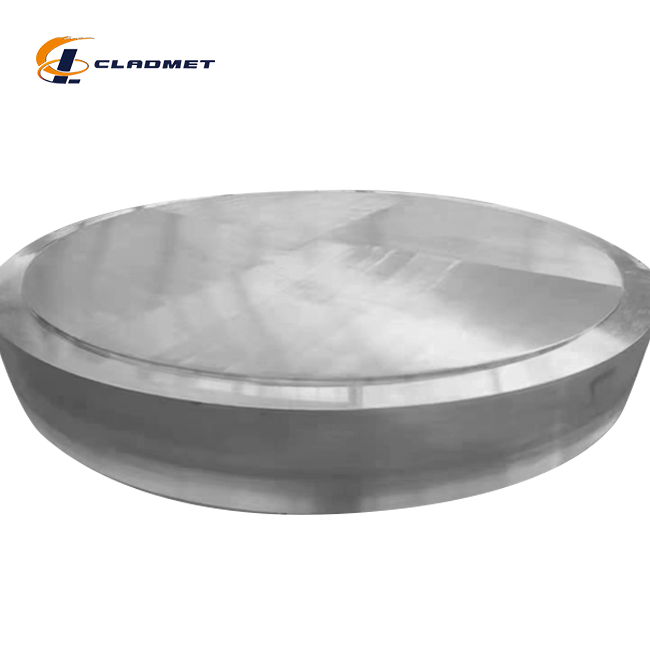

This technique is ideal for manufacturing pressure vessels and heat exchanger plates where high bonding strength is critical.

Cold Roll Bonding Process

This process uses mechanical pressure to join titanium and steel without significant heat. The procedure includes:

Surface Treatment: Cleaning and roughening the material surfaces to enhance bonding.

Pressurized Rolling: The materials are passed through rollers that apply high force, bonding them into a composite plate.

Post-Treatment: Additional heat treatments or finishing may follow to improve material performance.

Cold roll bonding is widely used in the production of plates for chemical processing and desalination equipment.

Diffusion Bonding via Hot Isostatic Pressing (HIP)

HIP ensures a seamless bond through the application of heat and pressure in a vacuum-sealed environment. The key stages are:

Encapsulation: Titanium and steel layers are enclosed in a sealed container to maintain a controlled atmosphere.

Thermal-Pressure Application: High temperature and uniform pressure facilitate atomic diffusion, creating a durable bond.

This method is preferred for applications requiring high structural integrity, such as aerospace and high-pressure environments.

Features and Advantages of Titanium Clad Steel Plates

Unmatched Corrosion Resistance: The titanium layer protects the steel core from corrosion caused by seawater, chemicals, and acidic environments.

Enhanced Strength and Stiffness: The steel base provides structural integrity, enabling the plates to withstand high pressures and mechanical loads.

Weight Optimization: Combining titanium's lightweight nature with steel’s robustness ensures optimal strength-to-weight performance.

Extended Lifespan: The corrosion-resistant properties of titanium reduce material degradation, prolonging equipment life and lowering maintenance costs.

Tailored Solutions: Plates can be customized in size, thickness, and finish to suit specific industrial needs.

Thermal Efficiency: These plates are well-suited for heat transfer applications due to titanium’s thermal conductivity and resistance to scaling.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive OEM services, allowing you to modify the products to meet your specific project requirements. We customize solutions for everything from thickness and size to surface treatments in close collaboration with our customers.

FAQ

Q1: What is the lead time for The products?

A: The delivery cycle is typically 3-6 months, but this can be negotiated based on order volume and specifications.

Q2: Can I request custom dimensions for the clad plates?

A: Yes, we offer full customization services to meet your specific needs in terms of size, thickness, and surface treatments.

Q3: How do you ensure product quality?

A: We adhere to strict national and international standards (GB/GBT, ASME/ASTM, JIS) during production and conduct rigorous quality checks to ensure all products meet or exceed expectations.

Q4: What industries typically use Titanium Clad Steel Plates?

A: Common applications include the oil and gas industry, chemical processing, marine engineering, aerospace, and power generation.

Contact Us

We welcome you to reach out for any inquiries or product consultations. Our team is ready to assist with your specific project needs.

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)