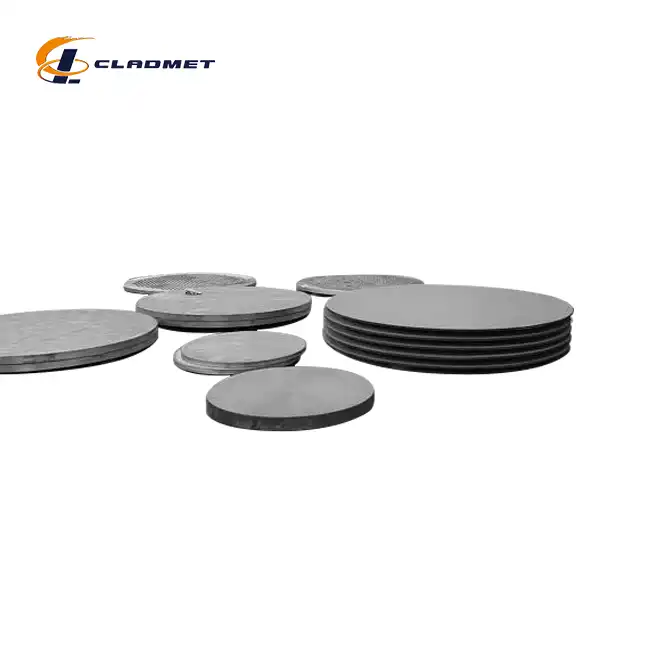

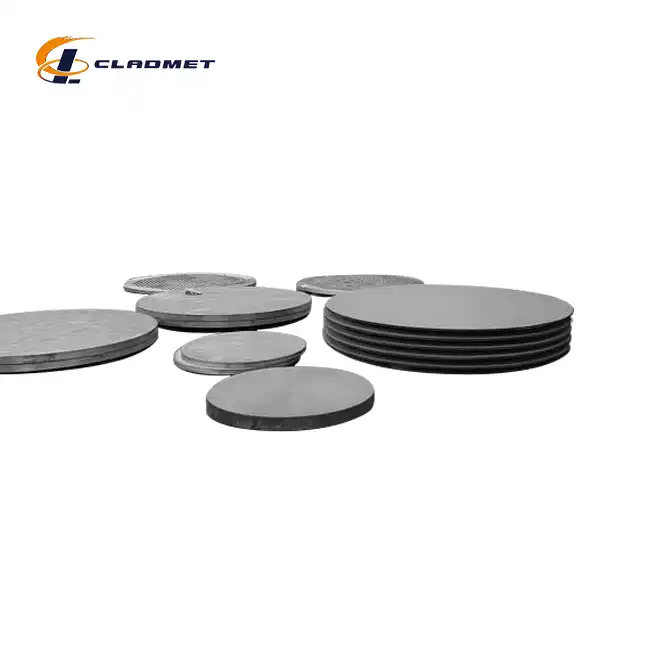

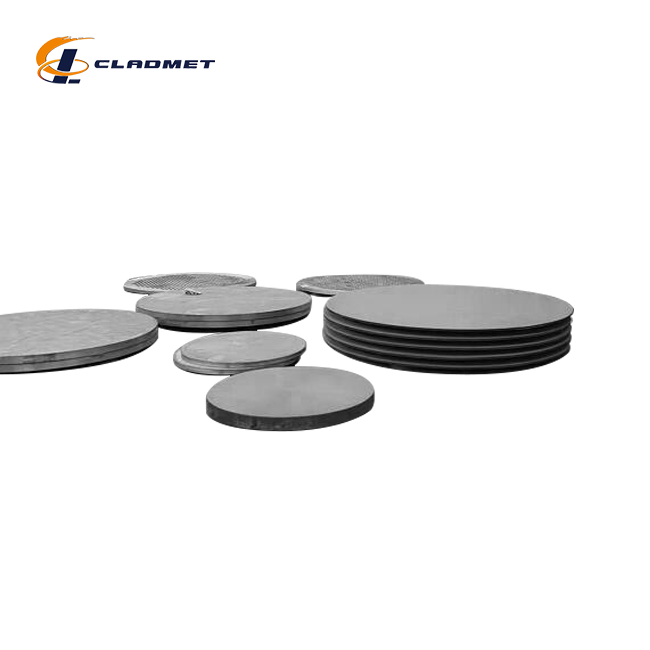

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

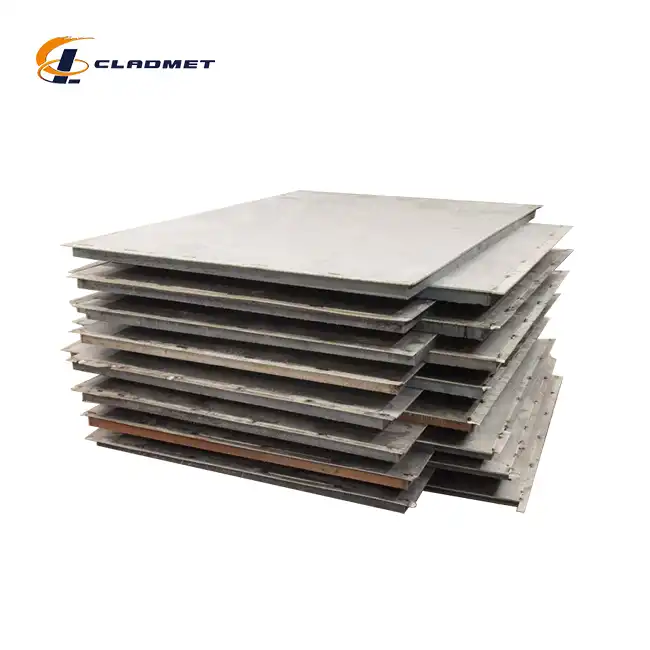

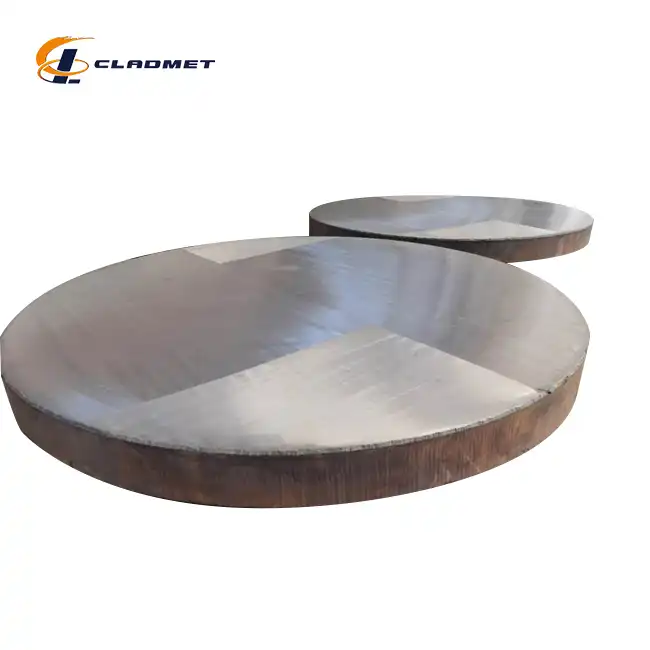

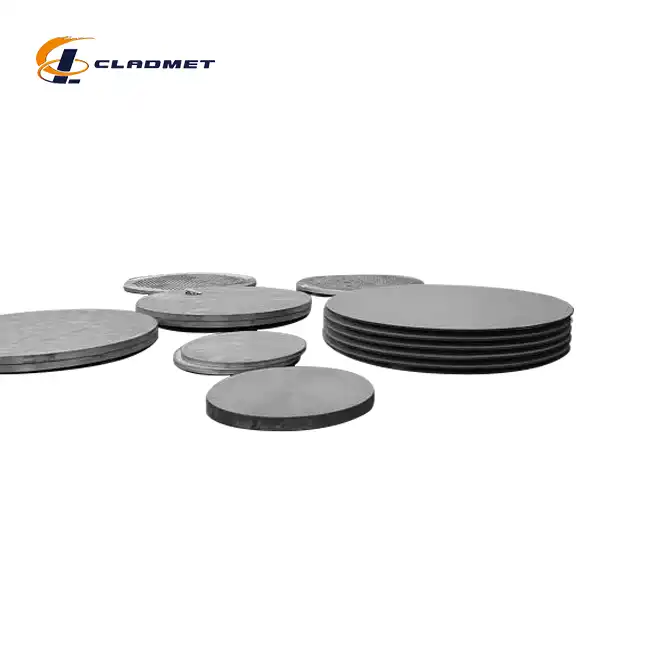

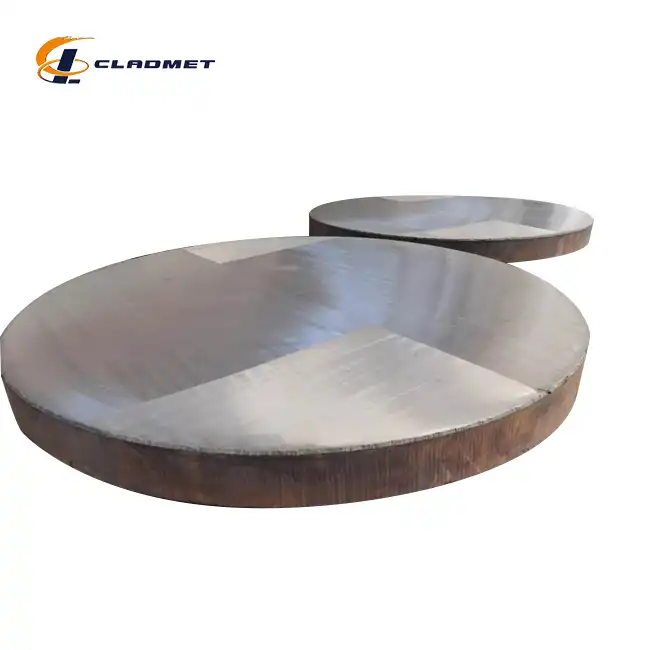

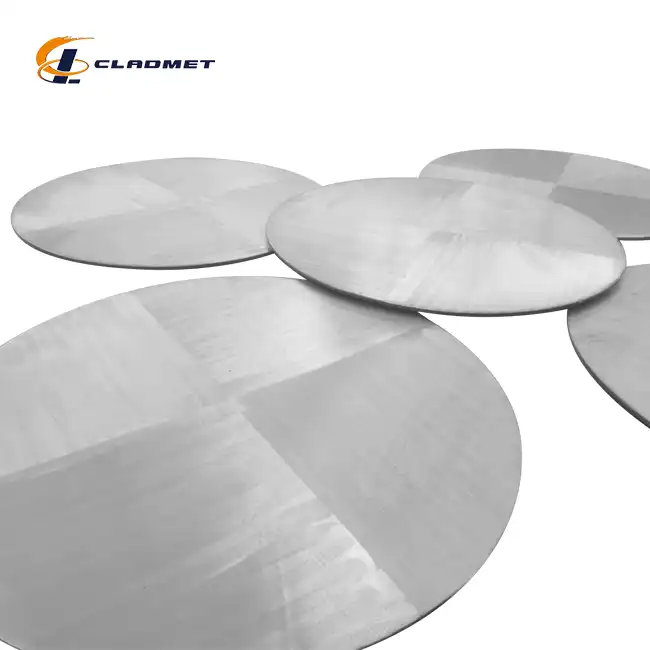

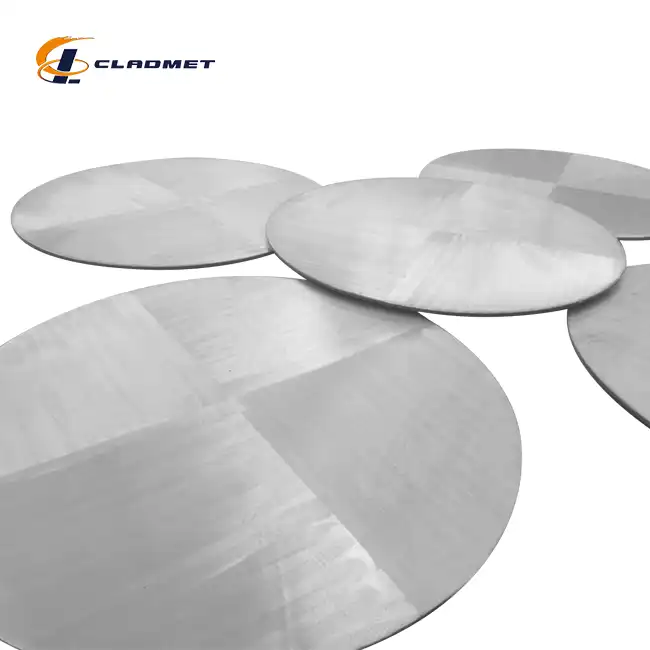

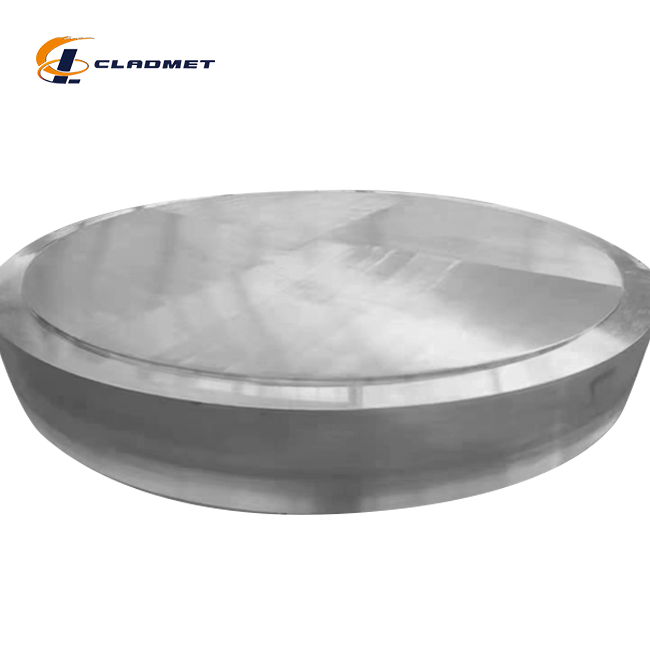

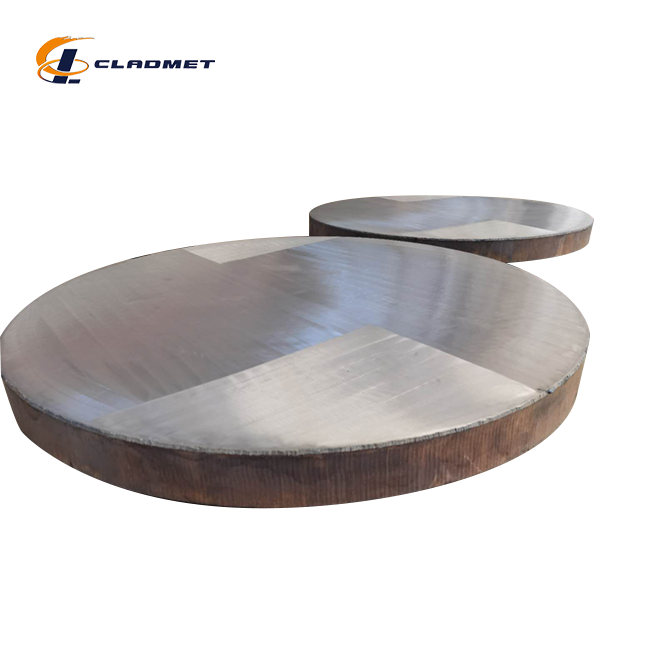

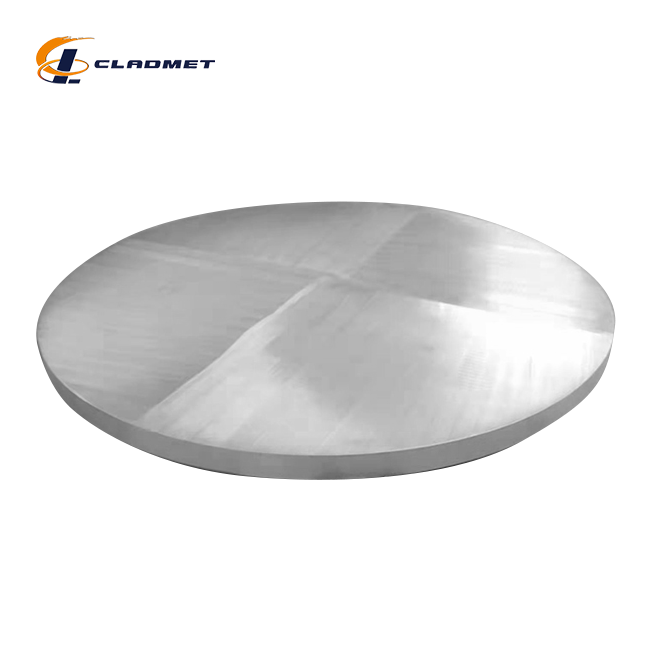

Titanium Clad Carbon Steel Plate: High-Performance, Cost-Effective Solution

Titanium clad carbon steel plate combine carbon steel's strength with titanium's superior resistance to corrosion and lightweight characteristics. Using advanced methods like roll bonding or explosion bonding, a titanium layer is bonded to a carbon steel base to make these plates. Industries that require high-strength and corrosion-resistant materials can benefit greatly from this combination, which also results in lower overall production costs. Baoji JL Clad Metals Materials Co., Ltd. is the preferred supplier for demanding applications in industries like chemical processing, marine engineering, and power generation due to its expertise in the production of high-quality products that meet international standards.

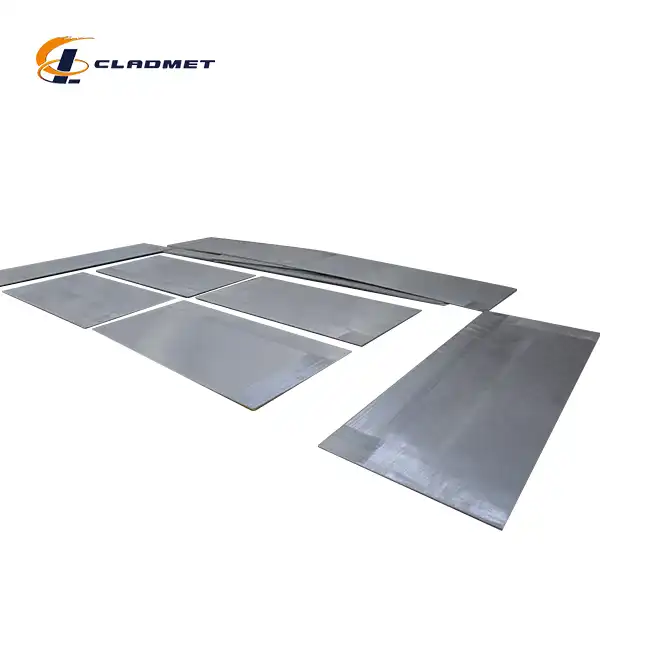

Product Specifications

Below are the specifications for the titanium clad carbon steel plate offered by Baoji JL Clad Metals Materials Co., Ltd.

| Specification | Details |

|---|---|

| Cladding Material | Titanium (Gr1, Gr2, Gr5) |

| Base Material | Carbon Steel (Q235, Q345, SA516 Gr.60/70) |

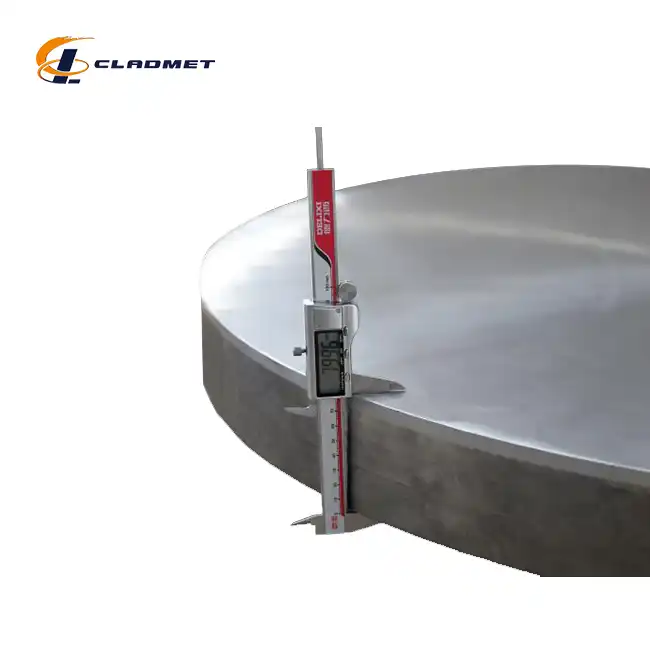

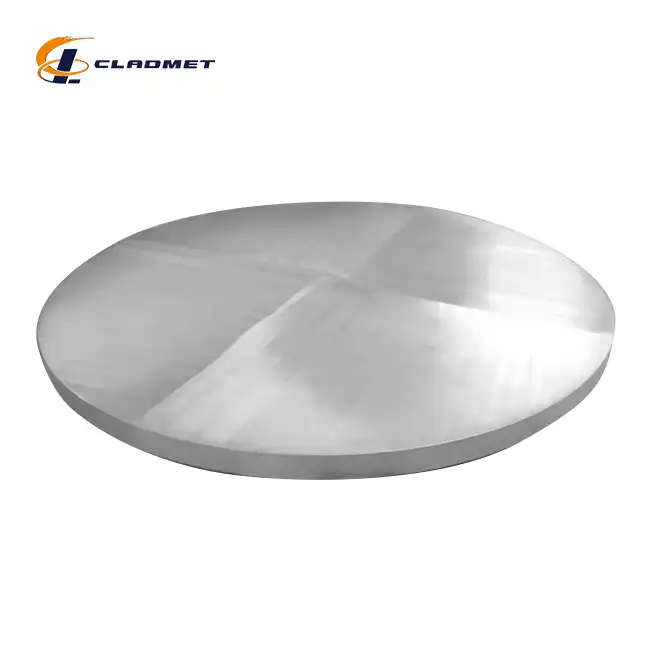

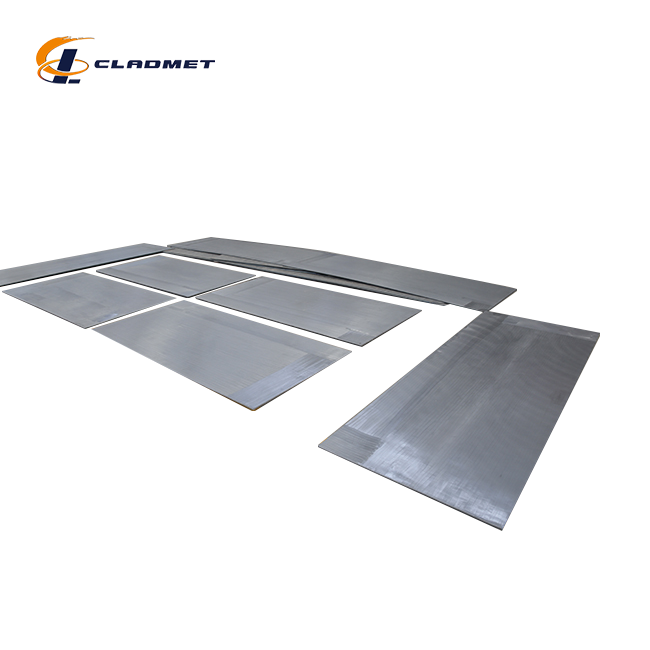

| Cladding Thickness | 1.0 mm - 20 mm |

| Base Thickness | 5.0 mm - 200 mm |

| Standard | GB, GBT, ASME, ASTM, JIS |

| Max Length | 12,000 mm |

| Max Width | 3,000 mm |

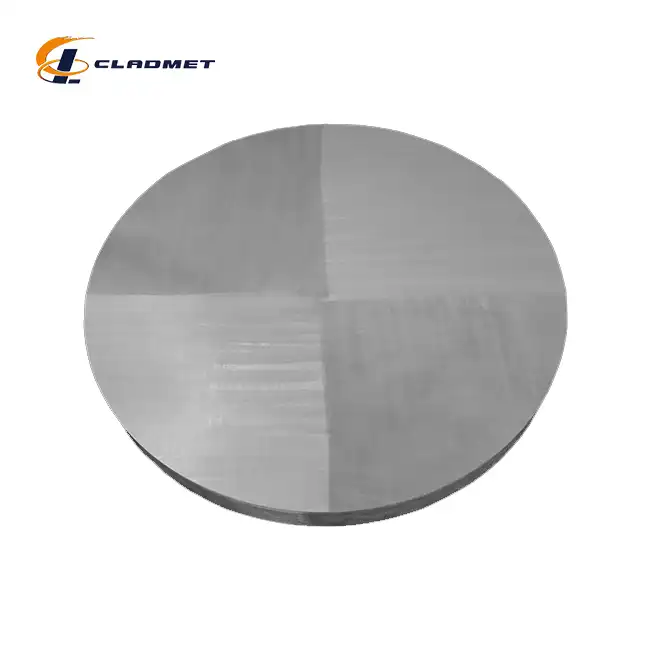

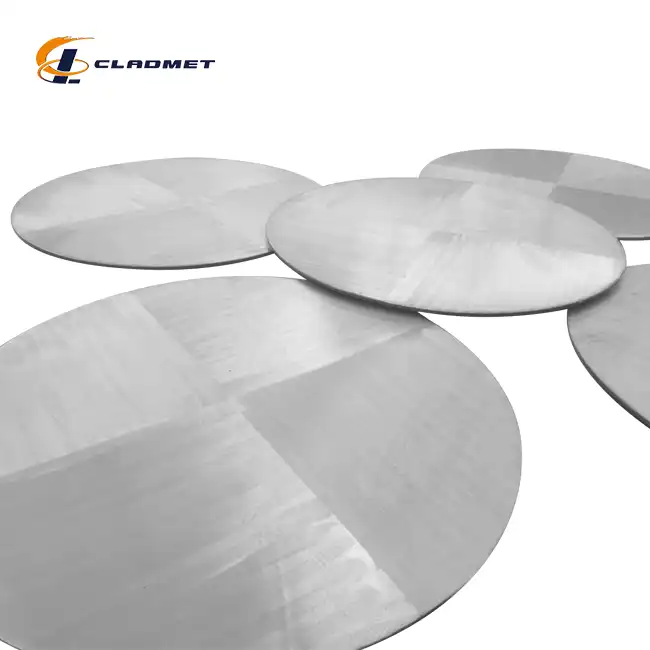

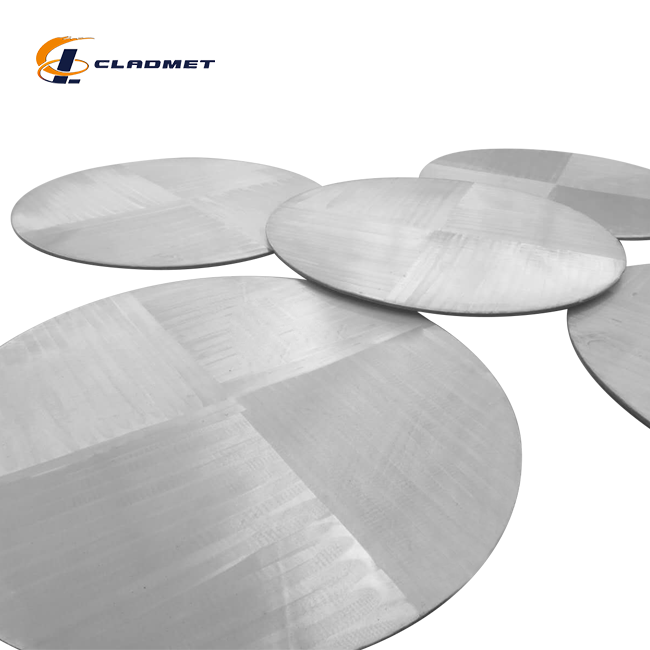

| Surface Treatment | Polished, Brushed, or Customized |

| Industry Applications | Chemical, Oil & Gas, Power Generation, Marine Engineering, etc. |

| Packaging | Wooden cases, steel frames, or as per customer requirements |

| Delivery Time | 3-6 months (negotiable) |

|

|

|

|

|

|

|

|

Titanium Cladding Techniques

The production of titanium clad carbon steel plates relies on specialized processes designed to bond titanium and carbon steel seamlessly. These methods include:

Explosive Cladding

This technique uses controlled explosions to achieve a high-energy bond between titanium and carbon steel. The process steps are:

Preparation and Alignment: The carbon steel and titanium layers are thoroughly cleaned and arranged in a specific configuration.

Placement of Explosives: Explosive material is carefully positioned between the layers.

Impact and Bond Formation: The explosion generates a high-speed collision, creating a strong metallurgical bond through pressure and heat.

Explosive cladding is preferred for high-performance applications where exceptional bond strength is critical, such as in the construction of reactors and pressure vessels.

Pressure Rolling

Pressure rolling, a cold welding technique, combines titanium and carbon steel by passing them through high-pressure rollers. Key stages include:

Surface Cleaning: Both layers undergo rigorous cleaning to eliminate impurities and enhance bonding potential.

Rolling Process: The materials are fed through rollers under significant force, ensuring a consistent bond. Multiple rolling passes may be necessary to complete the process.

This method is commonly used for producing clad plates designed for industrial applications requiring uniform thickness and large dimensions.

Diffusion Bonding via HIP

Hot isostatic pressing (HIP) involves applying heat and pressure in a controlled atmosphere to achieve atomic-level bonding between titanium and carbon steel. The process includes:

Material Encapsulation: The layers are sealed in a vacuum container to prevent contamination.

Heat and Pressure Application: Uniform heating and pressurization result in diffusion bonding, creating a strong and durable composite.

This approach is ideal for aerospace components and other industries requiring precise and robust material bonding.

Features and Benefits of Titanium Clad Carbon Steel Plates

Exceptional Corrosion Resistance: Titanium’s inherent resistance to corrosion makes these plates well-suited for aggressive chemical and marine environments.

High Mechanical Strength: Carbon steel provides structural integrity, while titanium enhances durability, ensuring a robust composite material.

Thermal Stability: The plates maintain their performance even under extreme temperature variations, making them suitable for thermal cycling applications.

Reduced Weight: Titanium’s lightweight properties contribute to reducing the overall weight of equipment without compromising strength.

Cost Optimization: By using titanium only as a cladding layer, material costs are minimized while maintaining the desired corrosion resistance and strength.

Custom Manufacturing: Plates can be customized in terms of size, thickness, and surface finishes to meet specific industry requirements.

Longevity: The combination of titanium and carbon steel significantly extends the service life of equipment, reducing maintenance costs.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Baoji JL Clad Metals provides full OEM services, including custom sizes, thicknesses, and surface treatments to meet your project's specific needs. In addition, we offer technical support to assist you in incorporating the titanium-clad carbon steel plates into your particular application to guarantee maximum performance.

FAQ

-

Q1: What is the typical lead time for the products?

A1: Our standard lead time is 3-6 months, but this can be adjusted based on the complexity and volume of your order. -

Q2: Can you customize the dimensions of the plates?

A2: Yes, we offer fully customizable solutions based on your specific needs, including thickness, length, and surface finish. -

Q3: What standards do your products meet?

A3: Our products comply with GB, GBT, ASME, ASTM, and JIS standards, ensuring high quality and reliability. -

Q4: How is the product packaged for delivery?

A4: The plates are securely packed in wooden cases or steel frames, depending on the size and quantity, to ensure safe delivery.

Contact Us

- Tel: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

Enhance your industrial applications with the superior performance and cost savings of Baoji JL Clad Metals' titanium clad carbon steel plate. Reach out to us today for a consultation!

_1737007724117.webp)