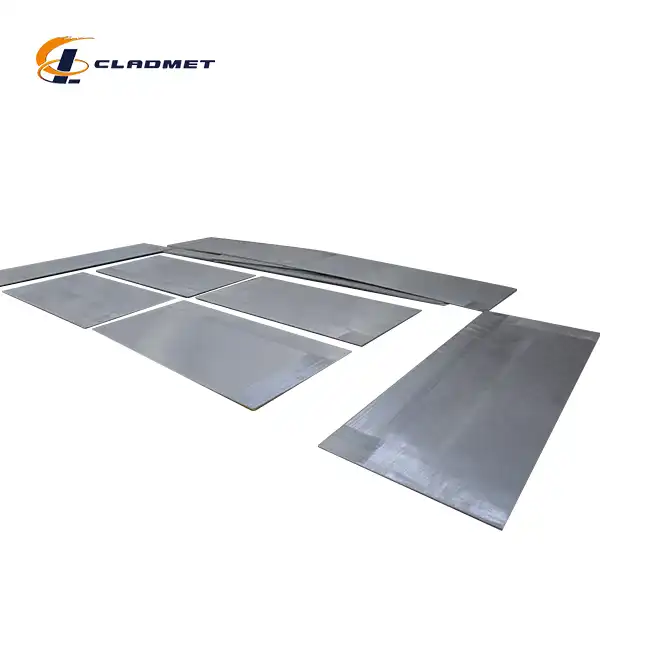

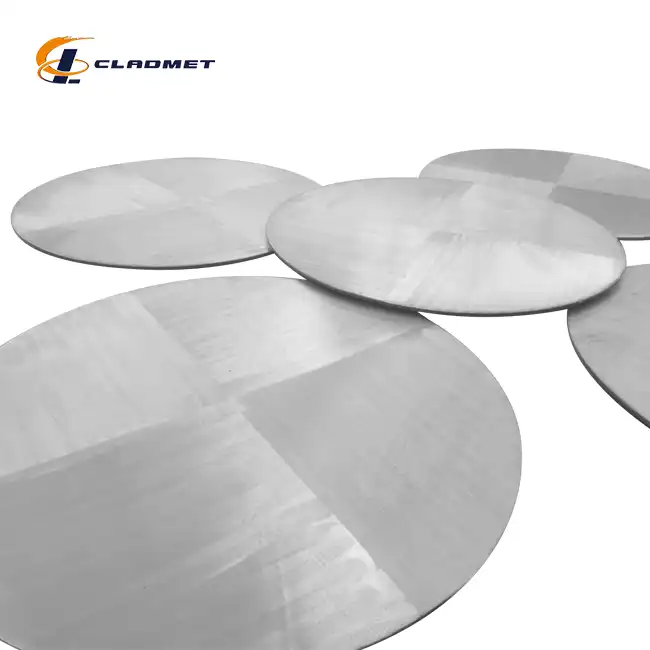

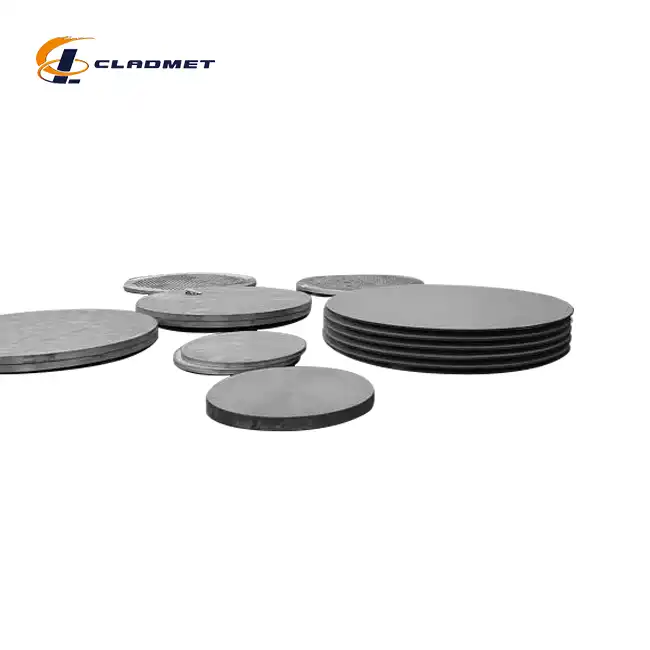

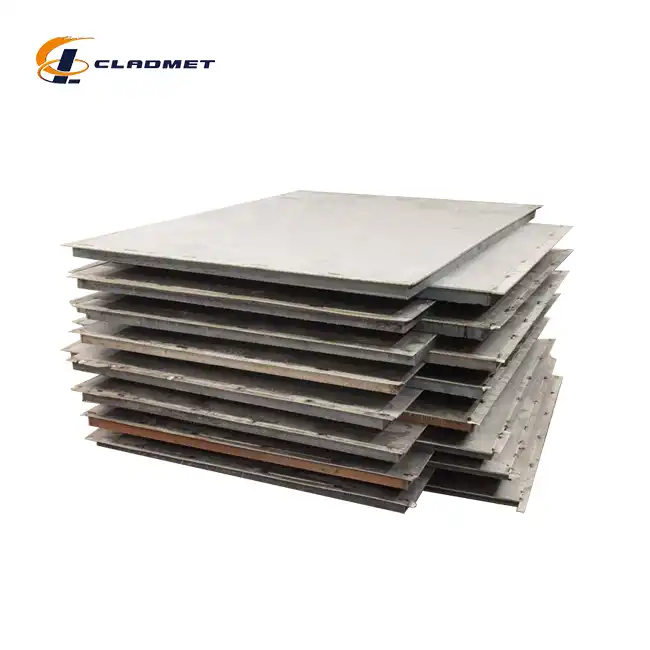

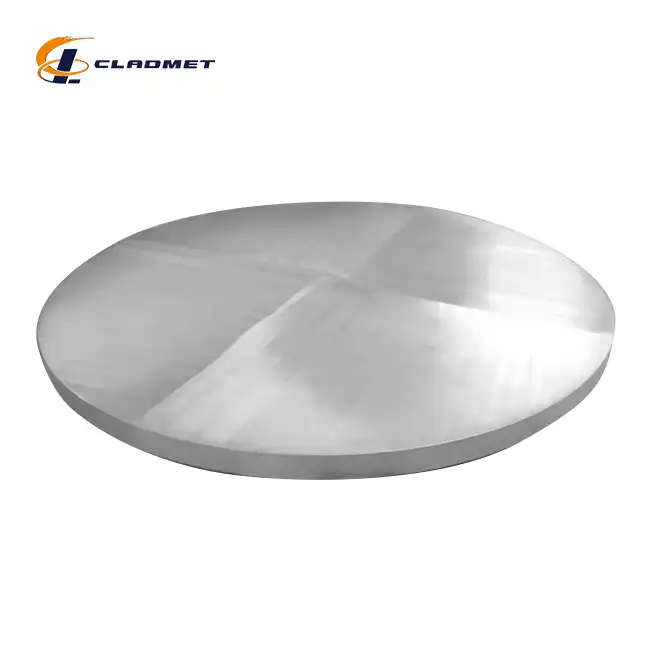

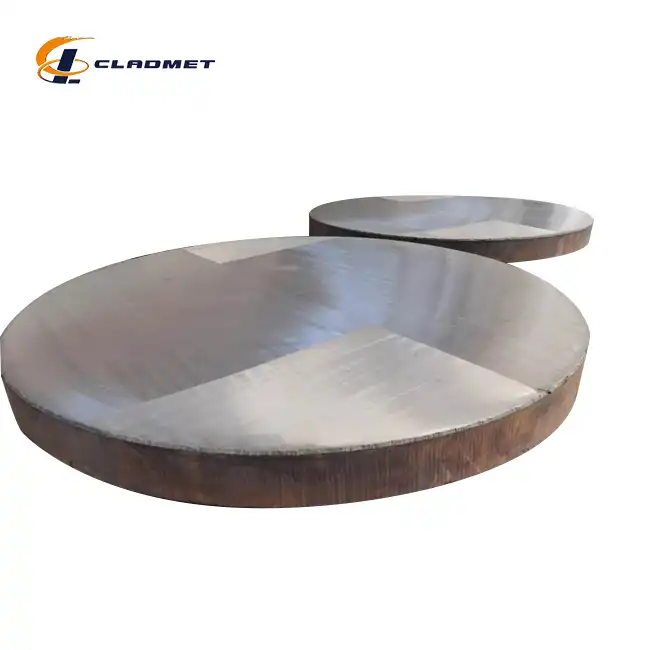

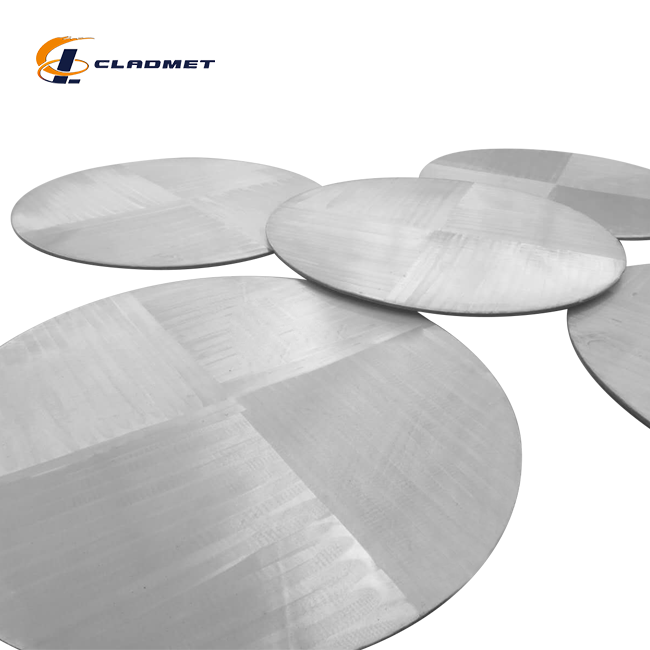

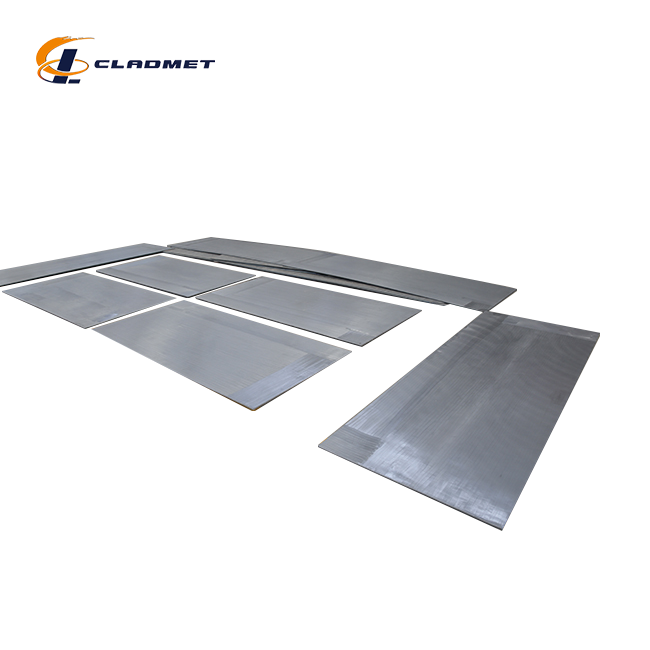

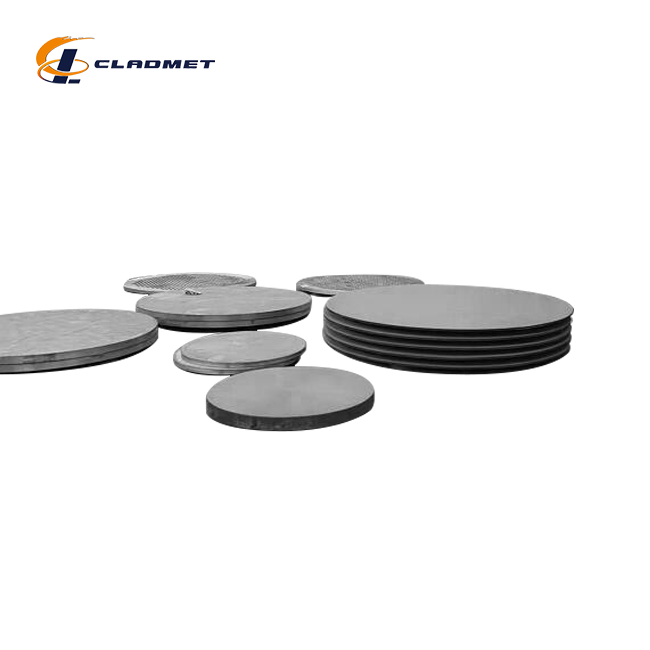

Available Sizes: Standard sizes and fully customizable options.

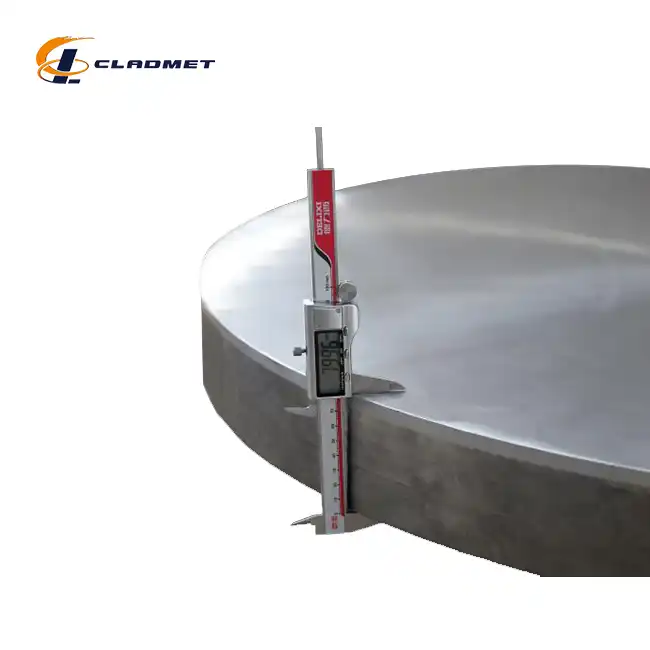

Quality Control and Testing: Strict tests following ASME, ASTM, JIS standards.

Product Standards: ISO9001-2000 certified. Passed PED and ABS audits in 2024.

Delivery: Worldwide shipping by sea, air, or express.

Packaging: Secure wooden crates and protective layers.

Overview

Titanium clad zirconium plate from JL clad metals are used in a wide range of applications, where corrosion resistance, low weight, strength or human body compatibility are important product properties.

Excellent Capacity due to titanium and zirconium material special virtus as following:

Titanium is highly resistant to chloride-containing media, practically all salt solutions, seawater, a range of acids, organic and inorganic chemicals and gases. The high environmental resistance is primarily based on a very thin, tenacious and highly protective surface oxide film. The oxide film provides high resistance to erosion in high velocity process streams.

This corrosion and erosion resistance makes titanium a preferred heat transfer material for tube/shell heat exchangers since it permits the use of thin heat transfer walls and high fluid flow rates. In addition, titanium has only half the weight of steel. It is non-magnetic and characterized by a high melting point, high strength-to-weight ratio and a low modulus of elasticity.

Zirconium is highly resistant to a wide range of acids and bases, both organic and inorganic, which makes it an interesting and exceptional long-life alternative to other materials in highly demanding applications. The seamless tube zirconium grade, produced for heat exchanger applications, is Sandvik Zr 702*, which offers the process industry a high quality and competitive product concept.

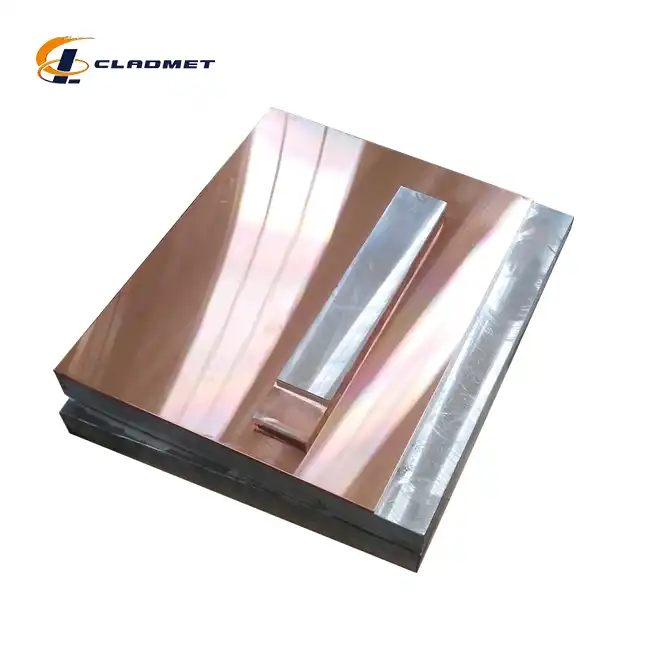

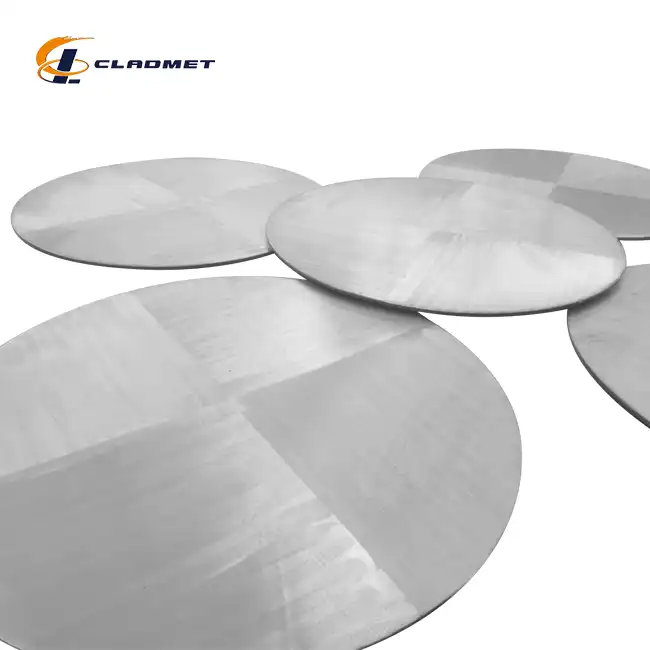

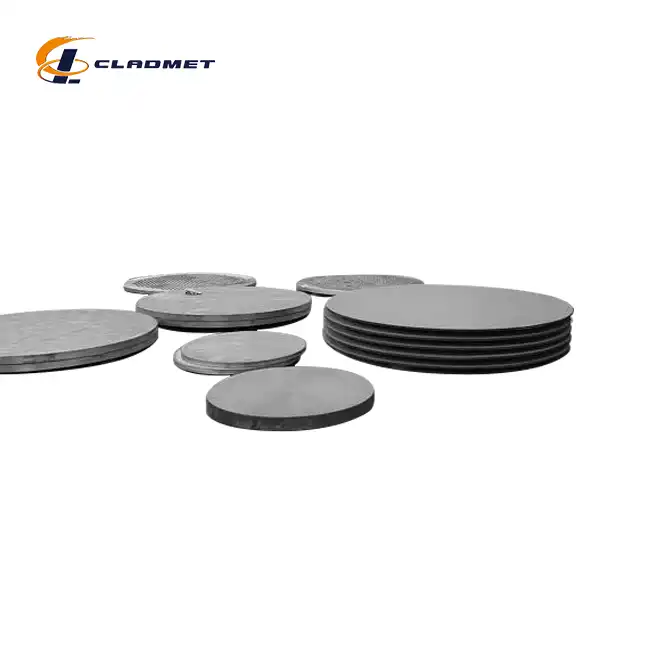

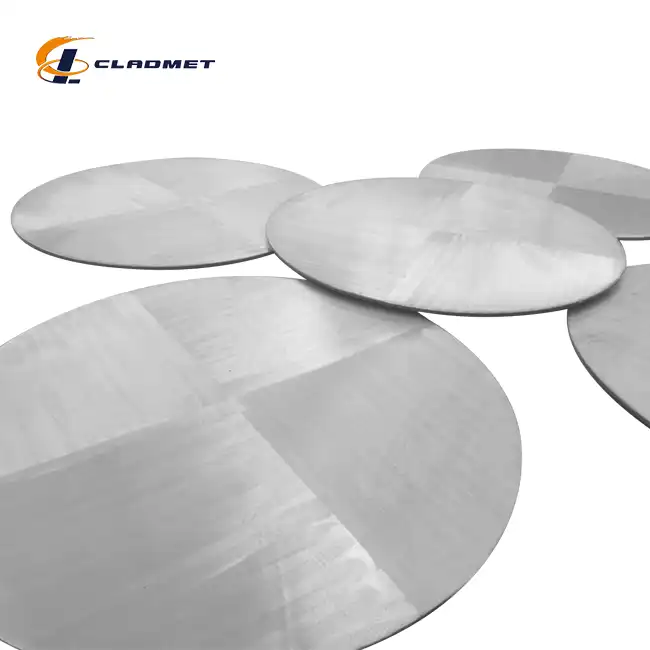

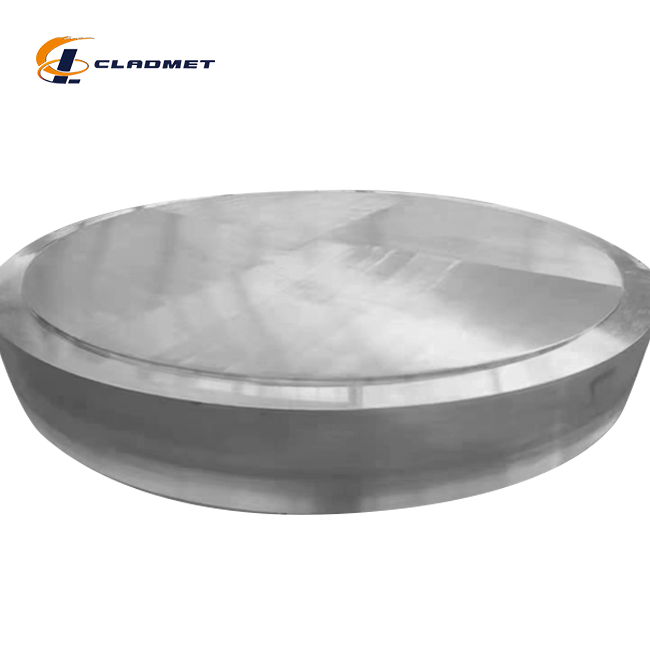

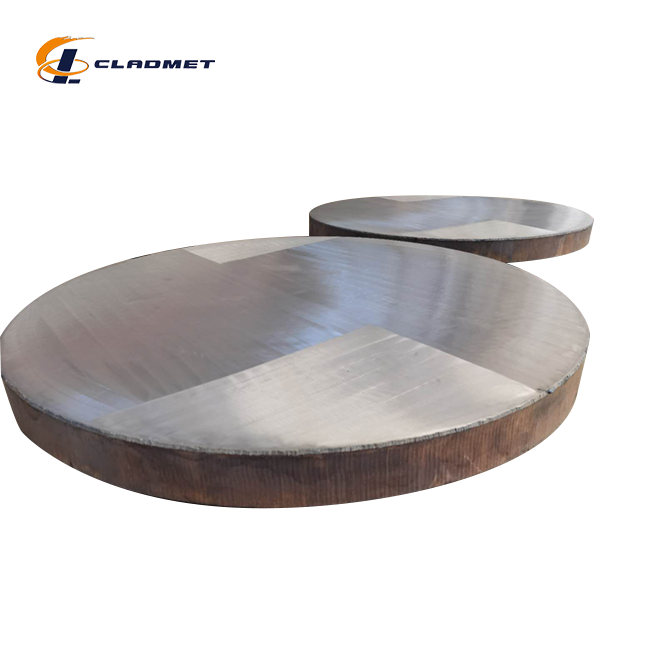

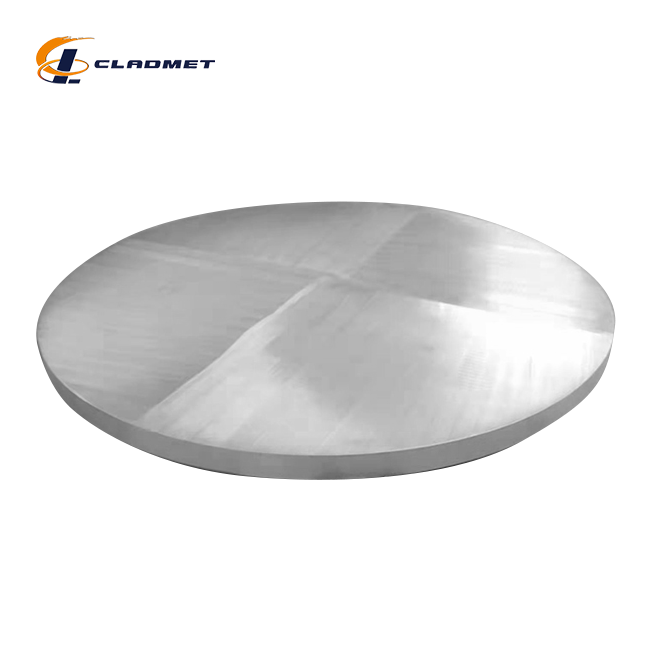

Titanium Clad Zirconium Plates are cutting-edge, high-performance materials made to be strong, durable, and resistant to corrosion. For chemical processing, oil and gas, and nuclear power, these plates combine the advantages of titanium and zirconium, making them an excellent choice. At Baoji JL Clad Metals Materials Co., Ltd., we spend significant time in creating top-quality products through cutting edge blast welding (EXW) methods, guaranteeing consistent holding and predominant material uprightness.

Including GB/GBT, ASME/ASTM, and JIS, our products adhere to the highest international standards. We are dedicated to providing dependable, high-performance clad metals that can satisfy a wide range of industrial requirements thanks to our more than 20 years of experience and ongoing R&D.

Specifications

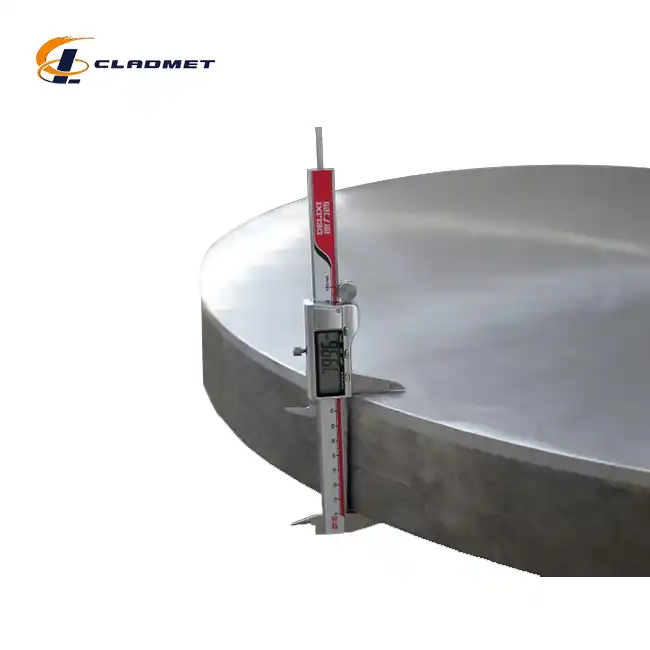

Below is a detailed specification table for our Titanium Clad Zirconium Plates:

|

Cladding Material |

Titanium (Grade 1, 2, 5) |

|

Base Metal |

Zirconium (Grade 702, 705) |

|

Cladding Size |

2mm - 10mm thickness |

|

Cladding Technology |

Explosion welding (EXW) |

|

Product Standards |

GB/GBT, ASME/ASTM, JIS |

|

Thickness Range |

3mm - 200mm (Total thickness) |

|

Length |

Up to 6000mm |

|

Width |

Up to 2500mm |

|

Surface Treatment |

Polished, brushed |

|

Packaging Method |

Wooden crate or customized packaging |

|

Transportation |

Sea, air, or rail |

|

Delivery Cycle |

3-6 months (negotiable) |

|

|

|

|

|

|

|

|

Innovative Manufacturing Processes

Titanium clad zirconium plates are produced using advanced cladding technologies, ensuring a seamless integration of titanium's corrosion resistance with zirconium's chemical stability. Below are the primary techniques utilized:

Dynamic Impact Bonding

This method employs controlled explosions to generate the energy required for bonding titanium and zirconium at a molecular level. Key stages include:

Material Preparation: Comprehensive cleaning and alignment of the titanium and zirconium layers.

Charge Placement: Carefully positioning an explosive charge to achieve a uniform impact.

Bond Formation: The resulting high-speed collision creates a robust metallurgical bond.

Dynamic impact bonding is ideal for applications where strength and durability are critical, such as heat exchangers and reactors.

Cold Rolling Fusion

Cold rolling fusion is a mechanical bonding process performed at ambient temperature. Key steps include:

Surface Conditioning: Meticulous surface cleaning ensures optimal adhesion.

Pressure Application: High-pressure rollers compress the layers, forging a durable bond.

This process is widely used to produce uniform plates for structural and industrial applications.

Diffusion Bonding Under High Pressure

High-pressure diffusion bonding combines heat and pressure to form a seamless integration between titanium and zirconium. Steps include:

Sealed Assembly: Encasing the materials to prevent contamination during bonding.

Thermal Processing: Using elevated temperatures and uniform pressure to enable atomic diffusion.

This technique is particularly suitable for high-performance components in chemical and nuclear industries.

Key Features and Advantages

Outstanding Corrosion Resistance: Titanium’s anti-corrosive properties, coupled with zirconium’s resistance to strong acids, make these plates ideal for harsh environments.

Chemical Compatibility: Zirconium enhances the plates’ ability to withstand aggressive chemicals, ensuring longevity in chemical processing applications.

Superior Thermal Stability: The combination of materials allows for efficient performance at elevated temperatures.

High Strength-to-Weight Ratio: The lightweight nature of titanium, paired with zirconium’s strength, ensures excellent structural performance without added weight.

Customizable Options: Available in various thicknesses, dimensions, and finishes to suit specific industrial needs.

Prolonged Durability: These plates exhibit exceptional wear resistance, ensuring long service life even under extreme conditions.

Economic Efficiency: Reduced maintenance and extended lifespan lower operational costs.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Baoji JL Clad Metals provides comprehensive OEM services to meet the requirements of your particular project. We can make adjustments to the plates' dimensions, thicknesses, and surface treatments to make sure they meet your exact requirements. We collaborate closely with you to develop custom industrial application solutions.

FAQs

Q:What are the typical delivery times?

A:Standard delivery time is 3-6 months, depending on order size and customization. However, timelines can be negotiated based on urgency.

Q:What industries can benefit from Titanium Clad Zirconium Plates?

A:These plates are ideal for industries such as chemical processing, oil and gas, nuclear power, aerospace, and more.

Q:What is the main advantage of using clad plates instead of solid metals?

A:Clad plates provide similar performance to solid metals at a lower cost while offering the flexibility of custom designs.

Contact Us

· Phone: +86-917-3372918

· WhatsApp: +86 13530170059

· Email: sales@cladmet.com

· Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China, 721013

We look forward to working with you to provide high-quality Titanium Clad Zirconium Plates for your industrial needs!

_1737007724117.webp)