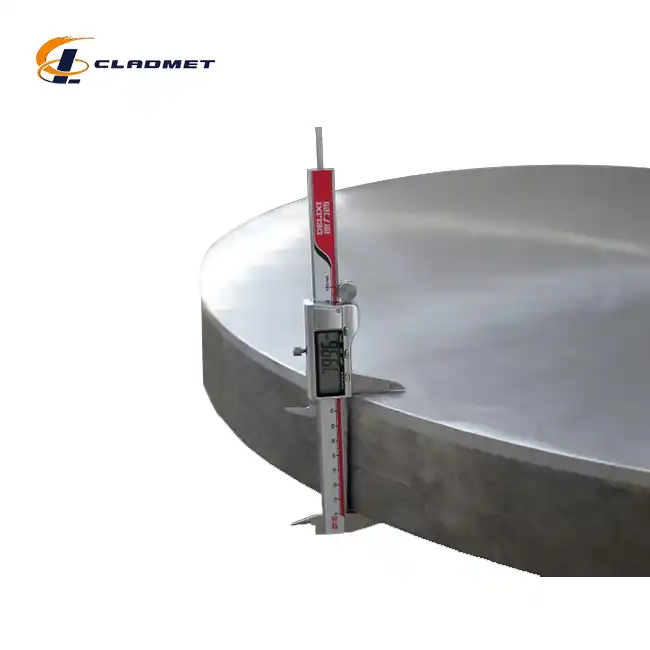

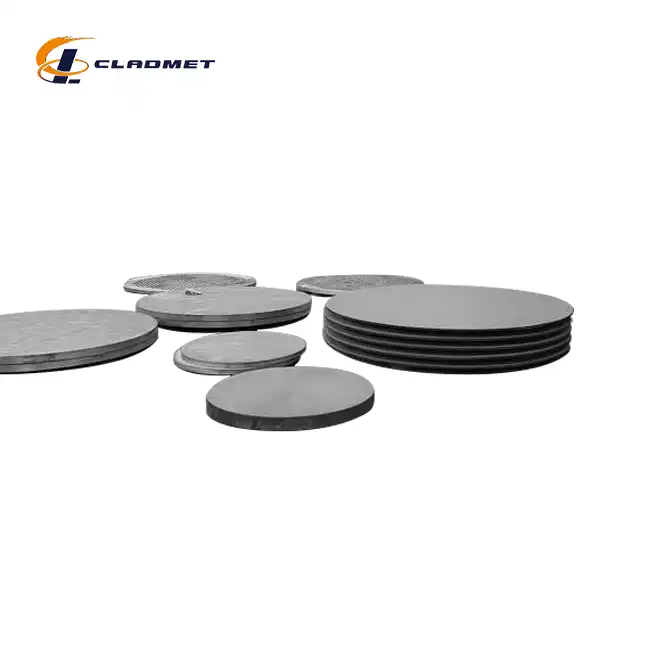

2. Sizes: Custom sizes supported, standard thicknesses available.

3. Applications: Ideal for chemical, marine, and aerospace industries.

4. Technology: Explosive welding ensures strong bond integrity.

5. Quality Control: Stringent testing for strength, corrosion, and durability.

6. Standards: ASME, ASTM, JIS; ISO9001-2000, PED, ABS certified in 2024.

7.Delivery: Global shipping by air, sea, or express courier.

8. Packaging: Wooden crates with protective wrapping.

Titanium Stainless Steel Clad Plate Overview:

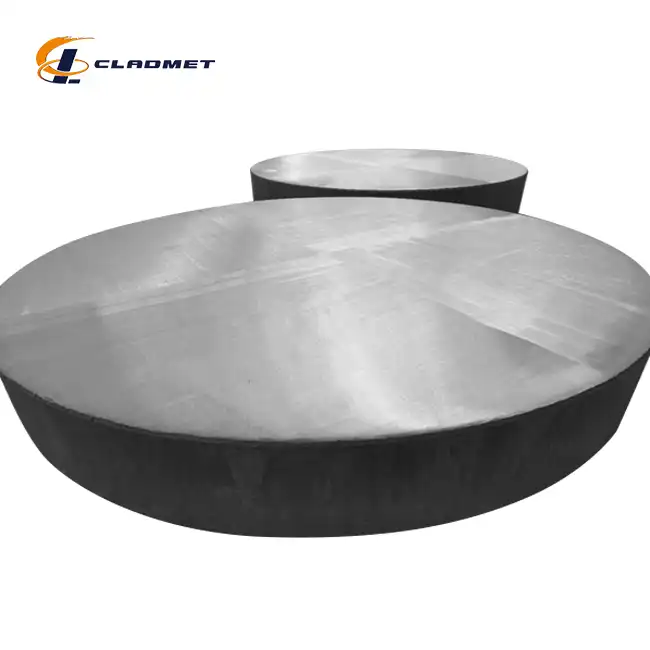

Titanium Stainless Steel Clad Plate is a composite plate made by bonding a layer of titanium to one or both sides of a stainless steel plate using a high-temperature explosion process. This kind of material combines the strength, corrosion resistance, and durability of stainless steel with the light weight and high-temperature resistance of titanium.

The titanium layer in the clad plate is usually pure titanium, while the stainless steel layer can be of various grades of stainless steel, such as 304 or 316. The thickness of the titanium layer can vary depending on the specific application and requirements.

Titanium Clad Stainless Steel Plates join the best properties of titanium and tempered steel through a high level holding process. Because of their superior durability, mechanical strength, and resistance to corrosion, these plates are an excellent option for industries that demand both performance and cost-effectiveness. JL titanium-clad plates are produced utilizing blast holding, guaranteeing a consistent and great connection between the materials, reasonable for the most requesting applications.

Product Specifications

| Parameter | Details |

|---|---|

| Cladding Material | Titanium (Grade 1, Grade 2, Grade 5) |

| Base Material | Stainless Steel (304, 316, etc.) |

| Cladding Size | Customized |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Thickness (mm) | 1mm - 100mm |

| Length (mm) | Up to 12,000mm |

| Width (mm) | Up to 3,000mm |

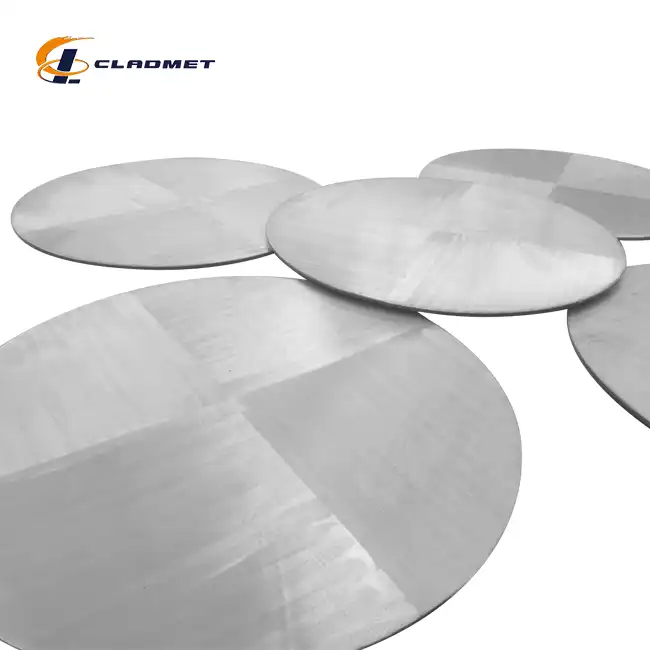

| Surface Treatment | Polished, Sandblasted, Custom Finishing |

| Application Industry | Oil & Gas, Chemical Processing, Pharmaceuticals |

| Packaging Method | Wooden crates with protective layers |

| Transportation | By sea, air, or land transport |

| Delivery Cycle | 3-6 months (negotiable based on quantity and complexity) |

Techniques for Titanium Cladding

The production of titanium clad stainless steel plates involves several advanced techniques, each tailored to achieve a high-quality bond between titanium and stainless steel. Key methods are as follows:

Explosive Bonding

This method utilizes controlled explosive energy to forge a metallurgical bond between titanium and stainless steel. The process comprises:

Preparation: Cleaning and arranging the titanium and stainless steel layers to ensure optimal contact.

Explosive Setup: Placing explosive material strategically between the layers.

Impact Bonding: Detonating the charge creates an intense, high-velocity collision, forming a durable bond.

Explosive bonding is widely chosen for its ability to produce strong, reliable bonds, particularly suitable for manufacturing pressure vessels and heat exchangers used in demanding environments.

Cold Rolling Process

This technique employs mechanical pressure to achieve adhesion between titanium and stainless steel layers. The process steps include:

Surface Preparation: Both materials are meticulously cleaned and prepared to enhance bonding efficiency.

Rolling: The layers are passed through rollers under significant pressure, ensuring a solid union. Multiple passes may be required to finalize the process.

Cold rolling is often applied in producing thin clad plates for use in chemical processing and offshore industries.

Hot Isostatic Pressing (HIP)

HIP technology involves high heat and isostatic pressure in a sealed environment, enabling atomic diffusion between the titanium and stainless steel. The main steps are:

Encapsulation: Placing the materials within a sealed container to maintain the desired atmosphere.

Heating and Pressurization: Applying uniform heat and pressure to forge a strong diffusion bond.

This method is particularly suited for aerospace applications and other critical areas requiring exceptional bonding integrity.

Features and Advantages of Titanium Clad Stainless Steel Plates

Superior Corrosion Resistance: Titanium’s remarkable resistance to corrosion enhances the longevity of the plates in chemically aggressive or saline environments.

Enhanced Durability: The fusion of titanium’s strength and stainless steel’s resilience ensures durability under extreme conditions.

Improved Electrical and Thermal Conductivity: Stainless steel contributes to thermal and electrical performance, making these plates suitable for specialized applications.

Customizability: Tailored dimensions, thicknesses, and finishes are available to meet industry-specific needs.

Cost Efficiency: Combining titanium and stainless steel reduces material costs while maintaining superior performance, minimizing replacement frequency and long-term expenses.

High Strength-to-Weight Ratio: Lightweight titanium enhances the plates’ mechanical properties without adding unnecessary weight.

Product Manufacturing Process

An explosion bonding process is used to produce JLClad Metals Ti/SS Plates. In this method, controlled explosions are used to weld the metals together at the molecular level. The bonding will be strong, seamless, and long-lasting as a result of this procedure. We likewise utilize roll holding for explicit applications, offering high adaptability in the development of custom fitted clad plates. With strict adherence to international standards like GB/GBT, ASME/ASTM, and JIS, quality control is an essential component.

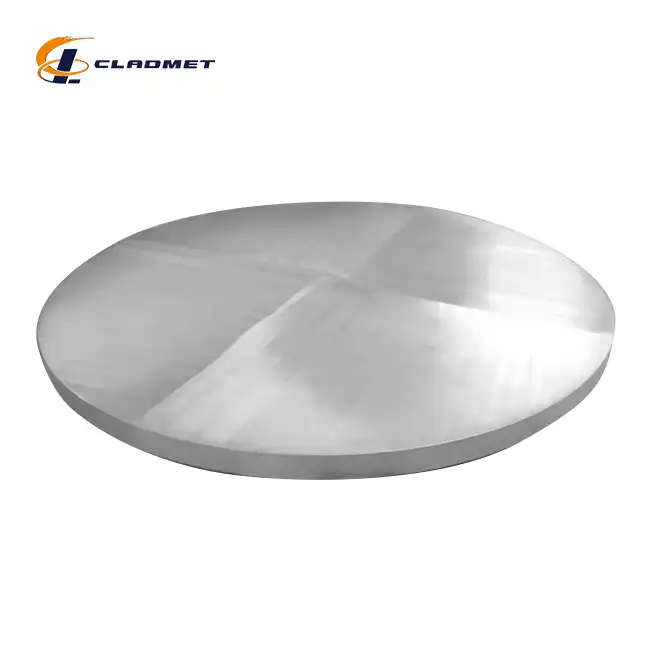

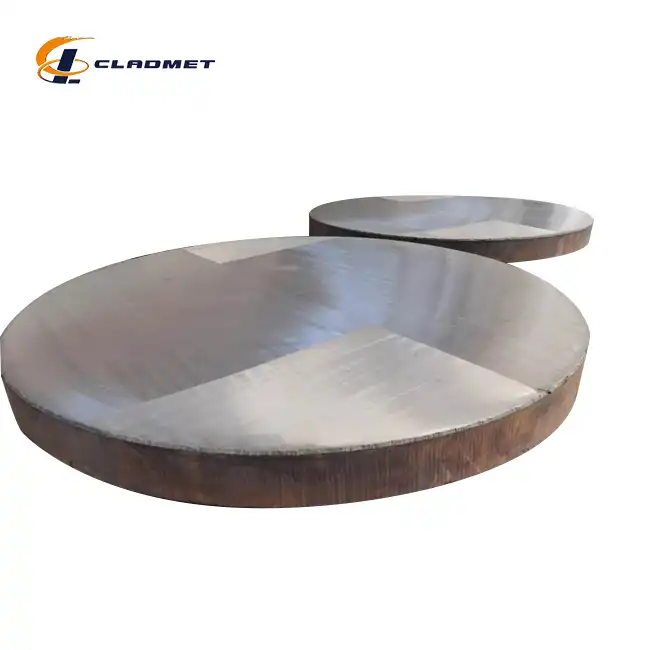

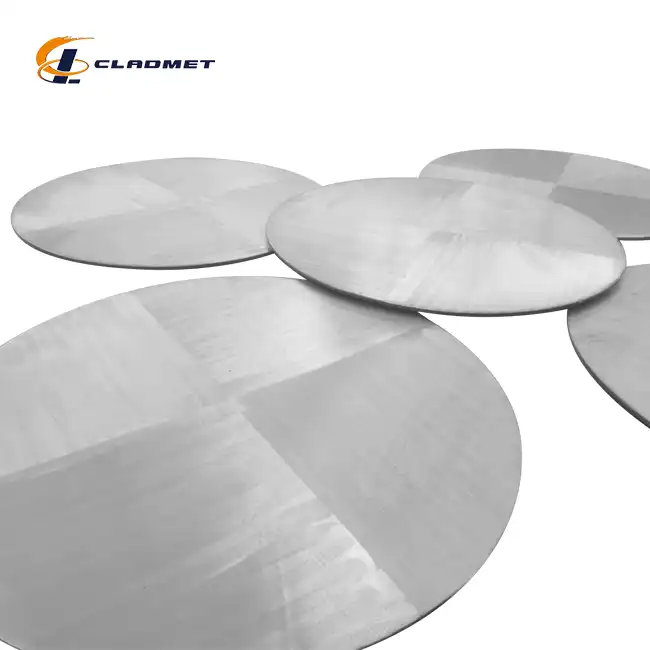

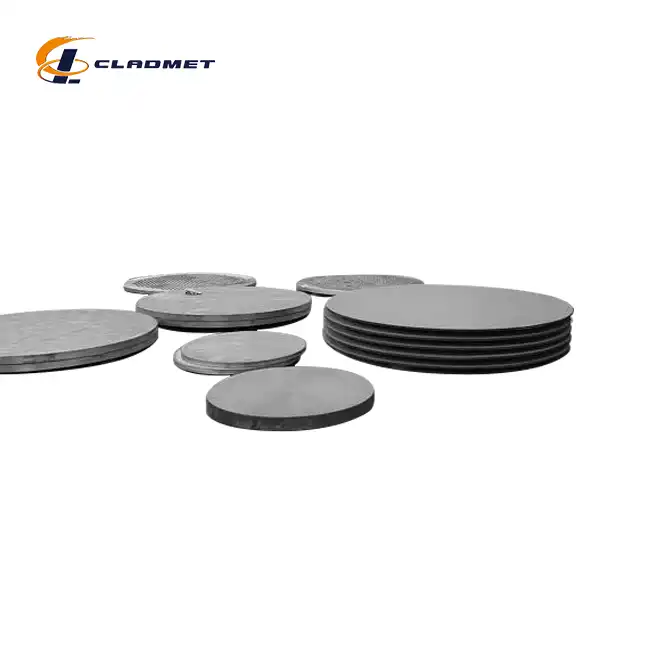

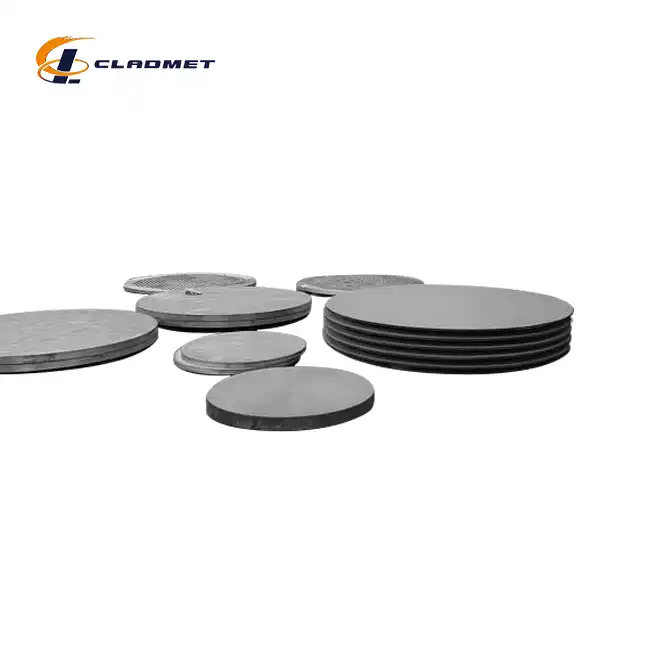

After grinding and polishing titanium stainless steel composite plate

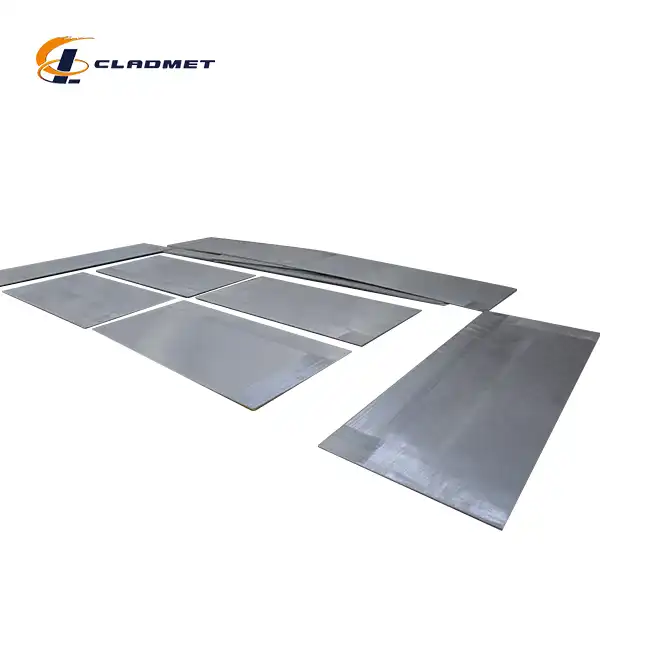

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

For our products, we provide comprehensive OEM services. Whether you require explicit sizes, gets done, or customized arrangements, our group of specialists is prepared to help. We team up with clients to meet their interesting necessities, guaranteeing that each item is planned and produced to the best expectations.

FAQ

1. What are the benefits of using Titanium Clad Stainless Steel Plates over solid titanium?

Using clad plates offers the same corrosion resistance as solid titanium at a lower cost, with added strength from the stainless steel base.

2. Can I order custom sizes and thicknesses?

Yes, we provide custom solutions to meet the specific dimensions and requirements of your project.

3. What is the typical delivery cycle?

Our delivery cycle ranges from 3 to 6 months, depending on order quantity and complexity.

4. How are the plates packaged?

Our plates are securely packed in wooden crates with protective layers to prevent damage during transport.

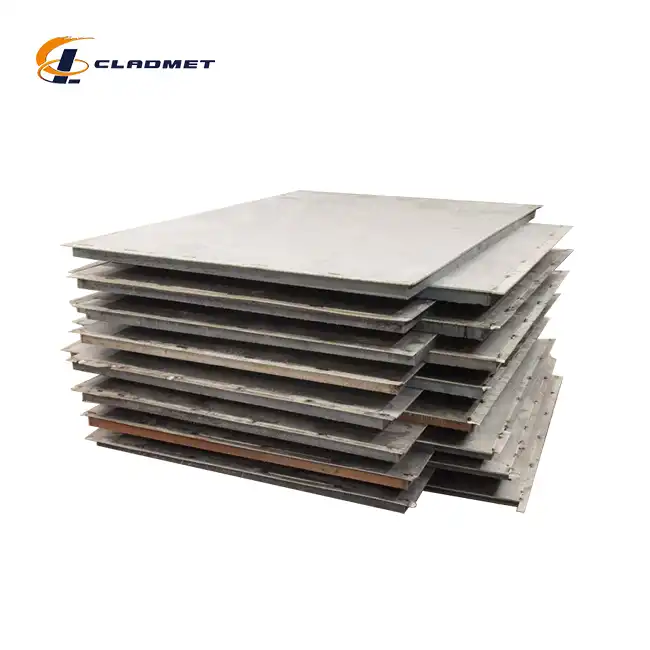

Packing and ready to ship titanium stainless steel composite plate image as above

Contact Us

For more information or to place an order, please contact us:

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)