Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

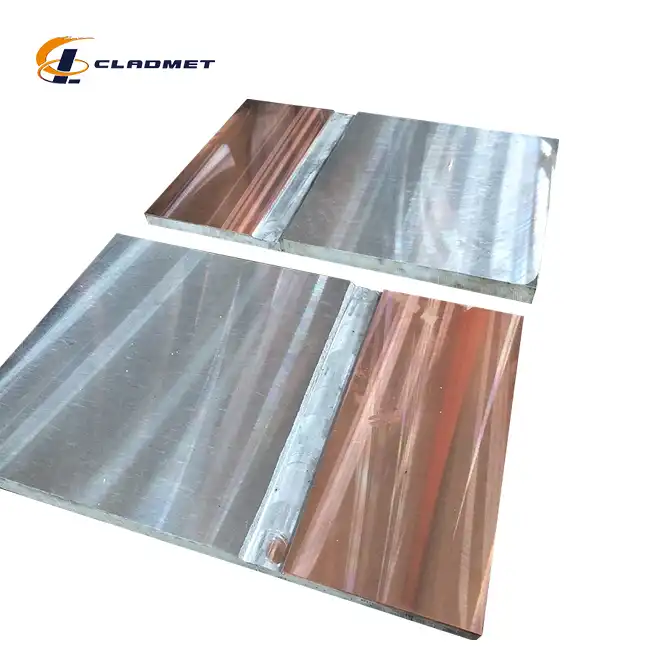

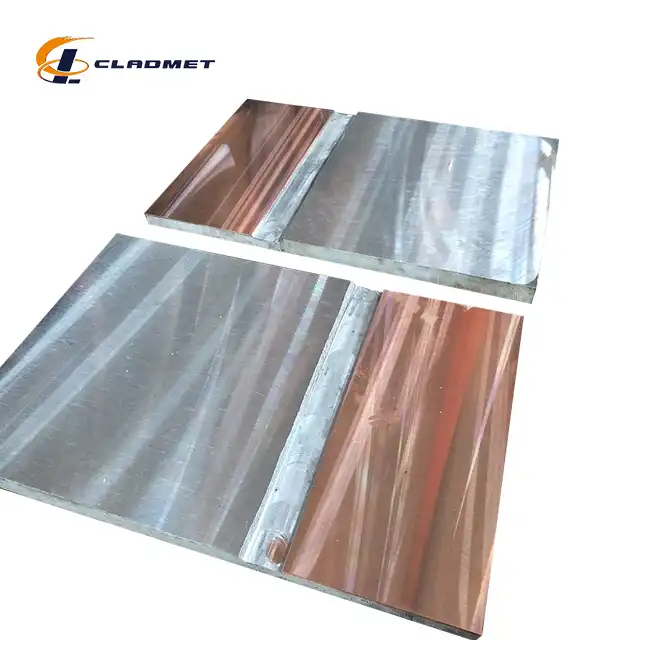

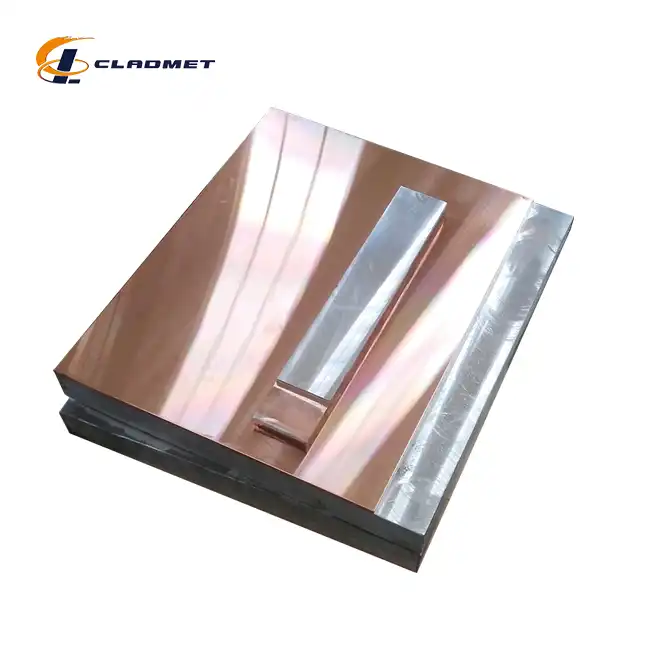

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Product Overview

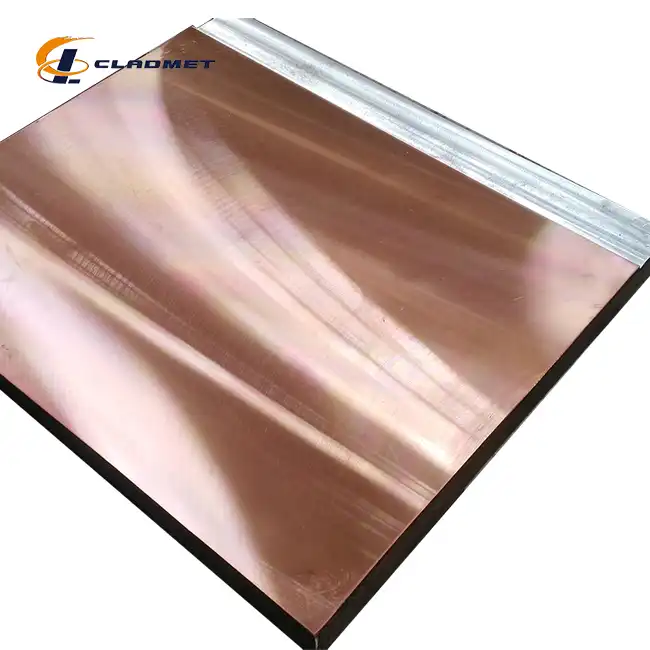

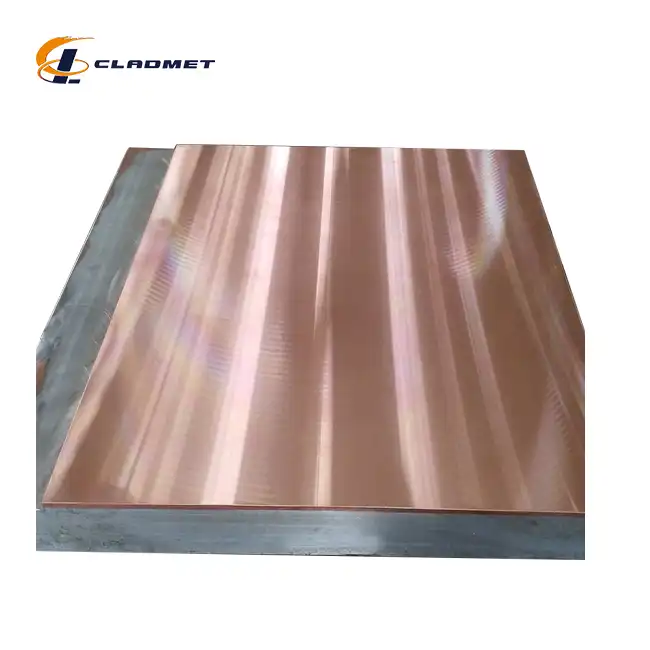

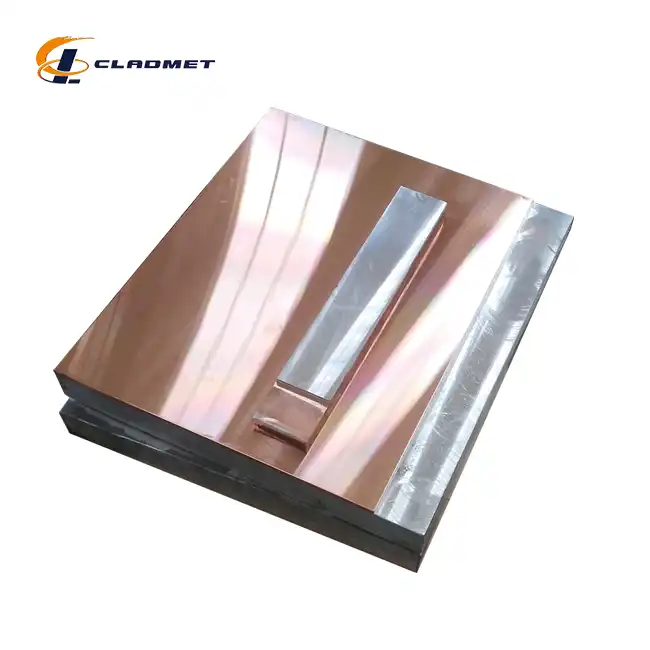

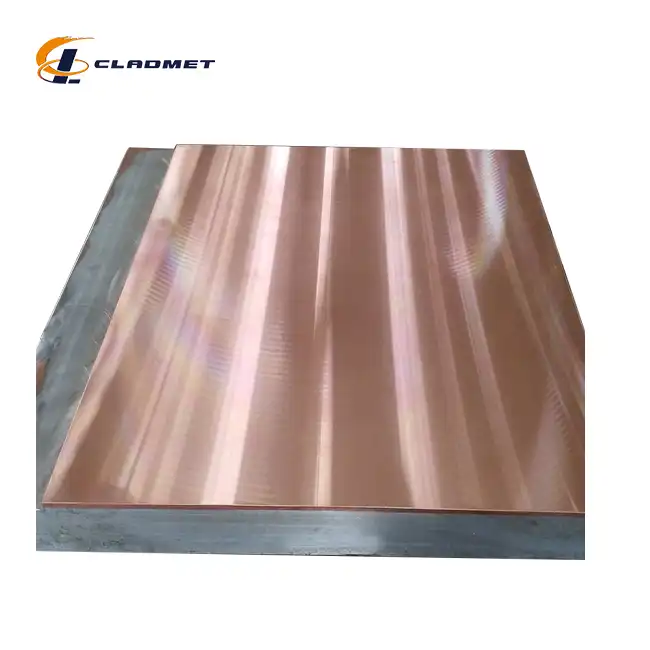

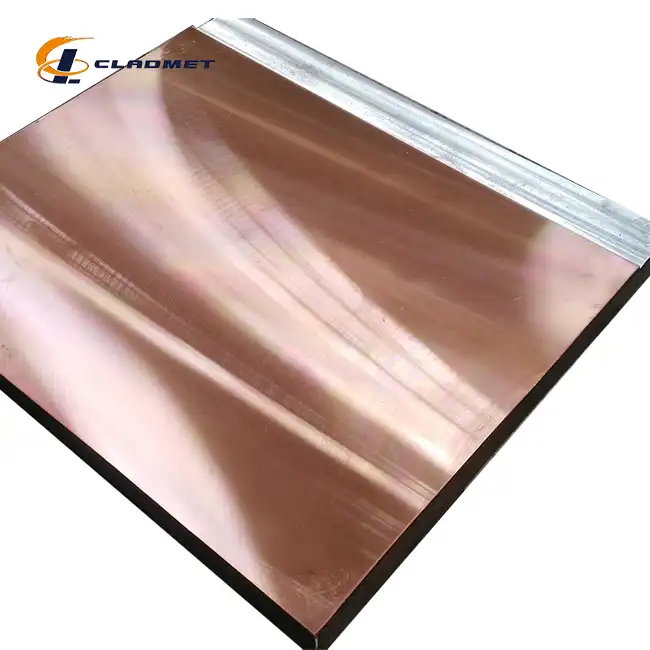

Titanium Copper Clad Plate is a high-performance bi-metal material that combines high-purity titanium (Gr1, Gr2) with high-conductivity copper (T2, C11000) through explosive welding or hot rolling cladding. The material combines the corrosion resistance of titanium and the high conductivity of copper, and is widely used in electrolysis, electroplating, chemical industry, marine engineering, aerospace and other fields.

Performance advantage

✅ Excellent corrosion resistance: titanium layer provides strong acid, alkali, salt corrosion ability, especially suitable for strong acid and alkali environment, such as electrolysis industry and chemical equipment.

✅ High Conductivity & Low Contact Resistance: The copper substrate ensures good conductivity, reduces energy consumption and improves production efficiency, especially for the electroplating industry.

✅ High strength bonding, peeling resistance & impact resistance: the use of explosive welding or hot rolling process to ensure the metallurgical bonding between titanium and copper, high bonding strength, no delamination phenomenon, suitable for high load environment.

✅ Lightweight & cost optimization: Compared with pure copper materials, titanium-copper composite plates not only reduce the amount of copper used, but also improve the service life and improve the overall cost performance.

✅ Good processing performance: can be shearing, bending, stamping, welding and other mechanical processing, suitable for different product manufacturing needs.

Technical parameters

|

Project |

Numerical value |

Test standard |

|

Titanium layer thickness |

0.5mm - 5mm |

ASTM B898, GB/T 8547-2013 |

|

Copper layer thickness |

1mm - 50mm |

ASTM B152, GB/T 5231-2012 |

|

Bond strength |

130 - 160 MPa |

ASTM B898, GB/T 8547-2013 |

|

Conductivity |

≥58 MS/m |

ASTM B193 |

|

Tensile strength |

≥250 MPa |

ASTM E8 |

|

Hardness (HB) |

80-120 (titanium layer), 85-110 (copper layer) |

ASTM E18 |

|

Corrosion resistance |

Acid and alkali corrosion resistance, salt spray resistance > 1000h |

ASTM G85 |

|

Maximum size |

2000mm x 6000mm |

Customization optional |

|

Processing method |

Shearing, bending, stamping, welding |

Suitable for different needs |

|

|

|

|

Production technology

1️⃣ Explosive Welding

• Through the impact of high-energy explosives, titanium and copper can form a metallurgical bonding layer in a very short time, with extremely high bonding strength.

• Suitable for the manufacture of large-area titanium-copper composite plates, with uniform interface and no pores, no need for additional welding of filler metals.

2️⃣ Hot Rolling Cladding

• Rolling titanium and copper layers into one under high temperature and high pressure, the bonding surface is dense and the metal streamline is complete.

• Suitable for mass production, with better surface quality and uniform thickness.

Application industry

Electrolysis industry: electrolytic cell anode support plate, electrolytic electrode, cathode conductive plate

Electroplating industry: electroplating anode bracket, electroplating fixture, electroplating bath liner

Marine engineering: seawater desalination equipment, electrode plates, marine anti-corrosion engineering

New energy industry: hydrogen fuel cell bipolar plate, energy storage system conductive components

Aerospace: Lightweight Corrosion Resistant Structures

Frequently Asked Procurement Questions (FAQ)

❓ 1. Can the thickness of the titanium layer of the titanium-copper composite plate be customized?

✅ Yes, we can provide 0.5mm-5mm titanium layer thickness, and customize the overall specifications according to customer needs.

❓ 2. What is the bonding strength of the titanium copper composite plate?

✅ Bonding strength can reach 130-160 MPa, in line with ASTM B898, GB/T 8547-2013 standards, to ensure long-term use without peeling.

❓ 3. Which electroplating solutions are suitable for titanium copper composite plates?

✅ Suitable for high corrosive electroplating environments such as gold plating, silver plating, chrome plating, nickel plating, etc., significantly prolonging the electrode life.

❓ 4. How is the conductivity of the titanium-copper composite plate?

The conductivity of the ✅ copper layer can reach ≥ 58 MS/m, and the contact resistance is low, which reduces energy consumption and improves production efficiency.

❓ 5. Do you provide a test report?

✅ Yes,we provide SGS, TÜV, BV certified third-party test reports to ensure that the quality meets industry standards.

Why choose us?

More than 20 years of industry experience, strength guarantee

We focus on the research and development and production of metal composites, with more than 20 years of industry experience, and have accumulated rich manufacturing process and technological innovation capabilities. The company continuously optimizes the production process to ensure stable and reliable product quality and meet the strict requirements of the global market.

Advanced compounding process to ensure high quality bonding

We use two core technologies, Explosive Welding and Hot Rolling Cladding, to ensure the formation of a high-strength metallurgical bonding layer between titanium and copper. Compared with ordinary bonding or mechanical bonding, our products have higher peel resistance and longer service life, and can operate stably even in extreme environments.

Perfect quality control system, international certification guarantee

We strictly implement the ISO 9001 quality management system and have obtained certifications from SGS, TÜV, BV and other international authorities. All products undergo rigorous physical, chemical and performance tests, including:

• Ultrasonic flaw detection (UT): ensure no gaps, no delamination

• Metallographic Analysis: Verifying the effect of metallurgical bonding

• Tensile test: check whether the bonding strength meets the standard

• Corrosion Resistance Test: Ensure stable operation in acid-base environments

A variety of customized services to meet different application needs

We offer a variety of customization options for the size, thickness, alloy grade, and surface treatment of titanium-copper composite plates to meet the specific needs of customers in different industries. Whether it is electrolysis, electroplating, new energy, or marine engineering, we can provide suitable solutions.

Global supply chain advantages, fast delivery

The company has established a stable supply chain system around the world and established long-term cooperative relationships with partners in many countries and regions. Whether it is small batch samples or large-scale procurement, we can provide flexible delivery cycles and fast logistics solutions to ensure that customers receive products in a timely manner and reduce downtime costs.

Successful stories are globally recognized

Our titanium-copper composite plates have been exported to South East Asia, Europe, America, the Middle East and other countries and regions, and are widely used in electrolytic plating, chemical equipment, marine engineering, aerospace, new energy and other fields, and have been highly praised by many customers.

Contact Us

Phone: +86-917-3372918

WhatsApp: 8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

_1737007724117.webp)