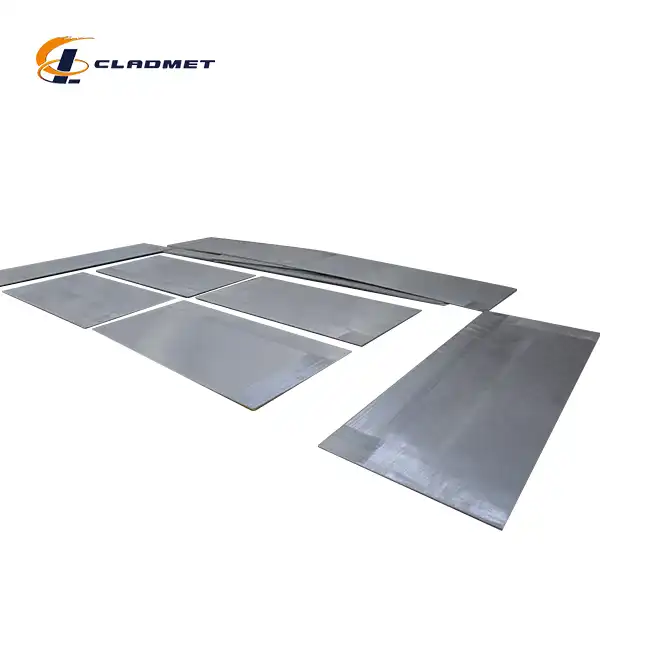

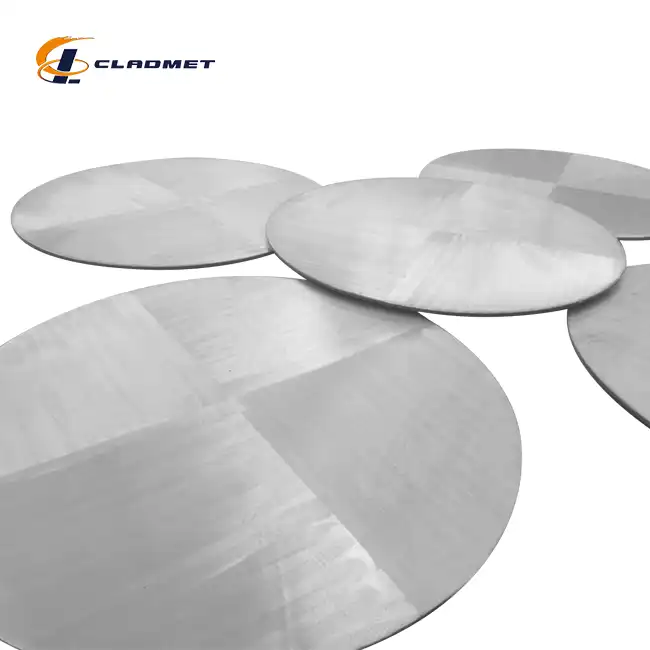

Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

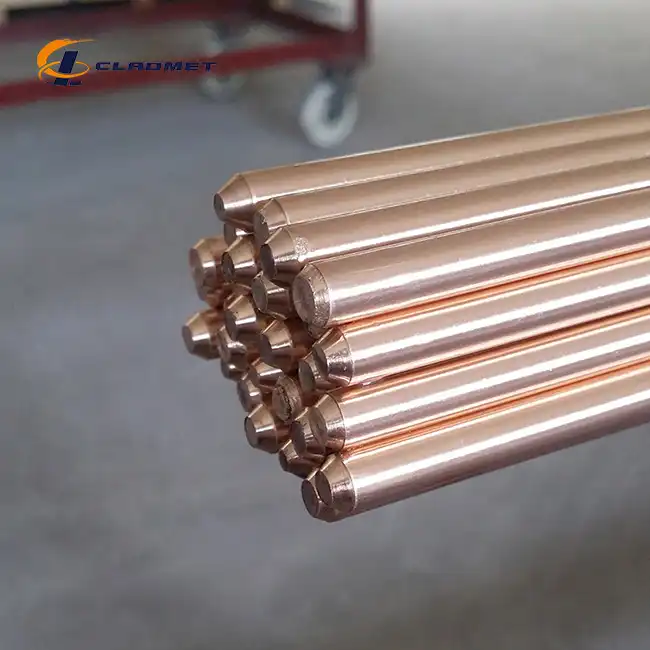

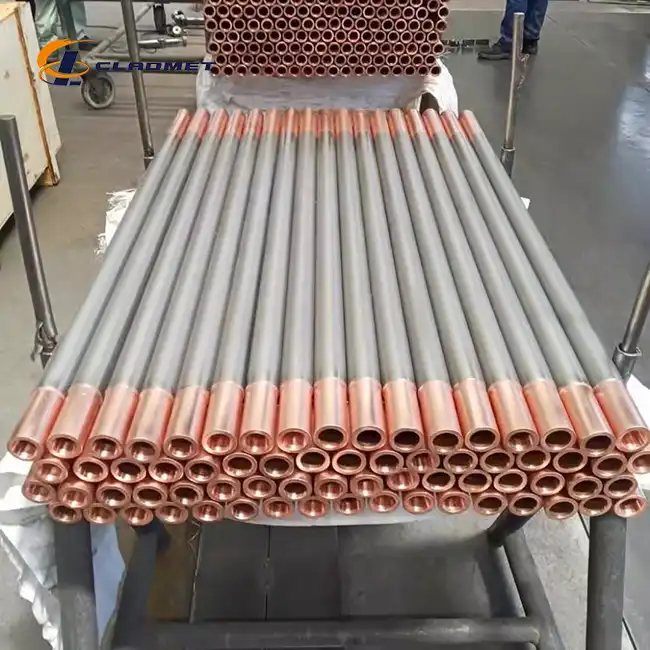

The Copper Aluminum Clad Rod is a high-performance, bi-metallic product designed to combine the best properties of copper and aluminum. Manufactured using advanced explosion welding (EXW) techniques, this product provides excellent electrical conductivity, corrosion resistance, and mechanical strength. Our products are ideal for applications where weight reduction and cost efficiency are critical without compromising on performance, particularly in industries like electrical power, automotive, and construction.

Whether you're looking for superior conductivity or lightweight strength, the product offers a solution that enhances the performance and longevity of your applications. With stringent adherence to ISO, ASTM, and ASME standards, Baoji JL Clad Metals Materials Co., Ltd. ensures you receive high-quality materials that meet international compliance.

Product Specifications

| Attribute | Details |

|---|---|

| Cladding Material | Copper (Cu) |

| Base Material | Aluminum (Al) |

| Cladding Technology | Explosion Welding (EXW) |

| Cladding Thickness | Customizable based on application requirements |

| Diameter Range | 8mm – 100mm |

| Length | Up to 12 meters |

| Surface Treatment | Pickling, Polishing, or Custom Surface Finish |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Packaging Method | Wooden boxes or as per customer specifications |

| Transportation | Air, Sea, or Rail Transport, with global delivery |

| Delivery Cycle | 3–6 months, negotiable based on order size |

| Application Industries | Electrical Power, Automotive, Construction, Renewable Energy |

|

|

|

|

Manufacturing Techniques

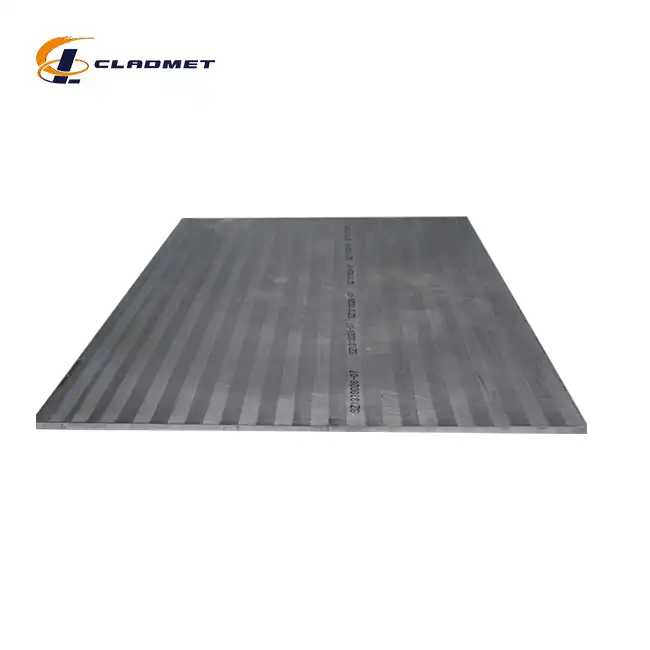

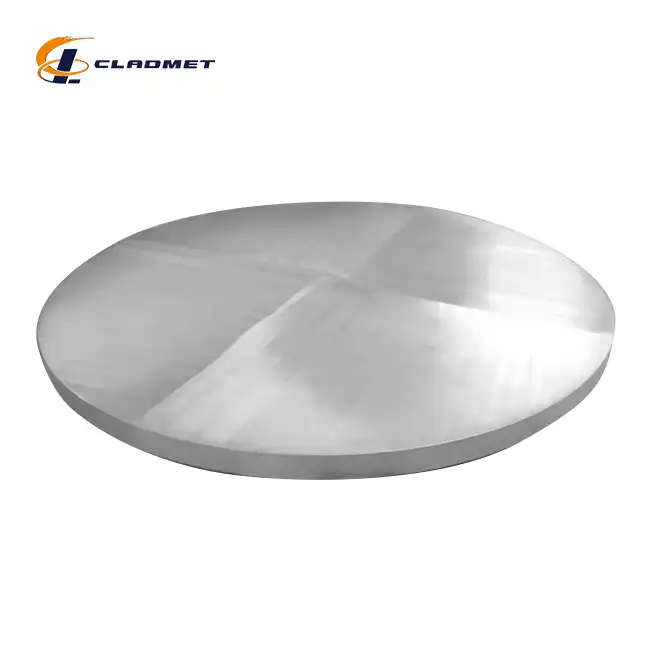

Explosive Bonding

Explosive bonding is a dynamic process that involves using controlled explosives to rapidly fuse titanium and copper into a solid bond. This process begins with preparing the two layers of material, then positioning an explosive charge between them. When detonated, the explosion forces the two metals together at high velocity, creating a strong metallurgical bond. This technique is ideal for producing components where high strength and reliability are critical, such as in heat exchangers, reactors, and pressure vessels.

Roll Bonding

Roll bonding is a mechanical process where titanium and copper are passed through rollers under immense pressure. This pressure causes the materials to bond, forming a tight, strong bond. The process may require several passes through the rollers to ensure an effective fusion. Roll bonding is particularly suited for manufacturing clad rods and plates that need to withstand mechanical stresses in industries such as chemical processing and offshore structures.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a method where titanium and copper layers are placed into a sealed chamber and subjected to both high heat and pressure. This process allows for atomic diffusion between the two materials, ensuring a uniform, solid bond that enhances the material’s overall performance. HIP is commonly used in applications where bond integrity and precision are essential, including aerospace components and parts used in the energy sector.

Key Features and Benefits

Corrosion Resistance

The titanium cladding offers superior corrosion resistance, making these rods an ideal solution for environments prone to moisture, chemical exposure, or extreme weather conditions. The copper core further enhances the rods' durability, particularly in marine and offshore applications where materials are exposed to seawater.

Electrical Conductivity

Copper is renowned for its excellent electrical conductivity, making these rods particularly valuable in applications requiring efficient current flow. The copper core provides optimal performance for electrical systems, while the titanium cladding ensures protection from corrosion and wear, improving the longevity of the product.

Enhanced Strength-to-Weight Ratio

Titanium provides significant strength without adding excessive weight, which is crucial in industries such as aerospace and transportation. This strength-to-weight ratio allows these rods to perform well under mechanical stress while maintaining an efficient overall design.

Long-Term Durability

The combination of copper and titanium ensures that these rods can endure challenging environmental conditions. The titanium layer naturally resists corrosion, while the copper core’s conductivity ensures high performance over an extended period. This durability leads to longer lifespans of equipment and reduced maintenance costs.

Customization Options

Titanium copper clad rods can be customized in terms of size, thickness, and surface treatments to meet specific industry requirements. This flexibility allows manufacturers to produce tailored solutions for various applications, ensuring that each rod performs optimally for its intended use.

Cost-Effectiveness

By combining the properties of two materials, titanium copper clad rods offer a cost-effective solution. The copper core reduces the need for expensive pure titanium products, while the titanium cladding ensures long-lasting performance and resistance to corrosion, minimizing the need for frequent replacements.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Baoji JL Clad Metals Materials Co., Ltd. offers OEM services for our products. We provide custom solutions to meet your exact needs, including specific sizes, surface treatments, and packaging options. Our team of engineers will work closely with you to ensure that the final product aligns with your project requirements and industry standards.

FAQ

1,.What are the typical applications of our products?

Copper aluminum clad rods are used primarily in electrical power systems, automotive components, and renewable energy projects, where high conductivity and lightweight materials are crucial.

2.How do you ensure the quality of the products?

Our products are manufactured under stringent international standards (GB/GBT, ASME/ASTM, JIS), and we follow ISO9001-2000 certification protocols. Each batch is rigorously tested for durability and performance.

3.Can you provide custom sizes for specific applications?

Yes, we offer customizable sizes and specifications for all our clad rods to suit your unique application requirements.

4.What is the typical delivery time?

The standard delivery time is 3–6 months, depending on the order size and customization needs. This can be negotiated for larger projects.

Contact Us

For more information about copper aluminum clad rod or to place an order, please get in touch with us:

- Tel: +86-917-3372918

- WhatsApp: +86 135 3017 0059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)

_1737612858536.webp)

_1737612862251.webp)

_1737612861583.webp)

_1737612858808.webp)

_1737611764680.webp)

_1737612205322.webp)