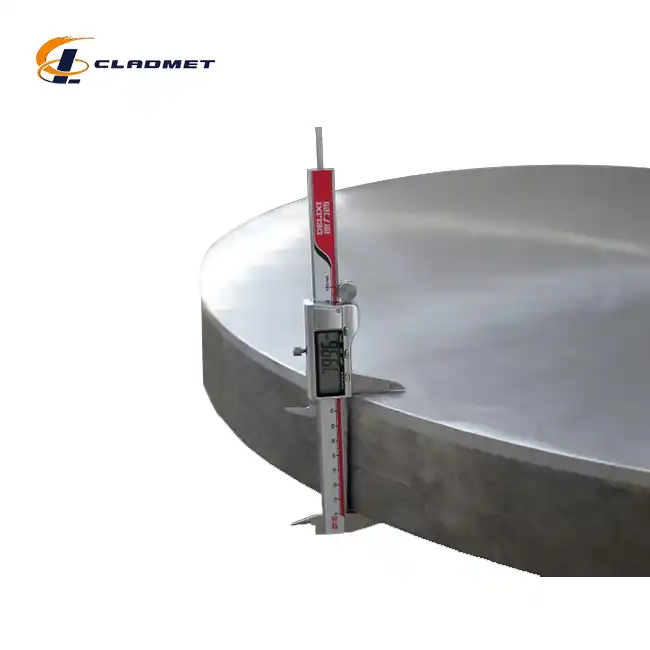

Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

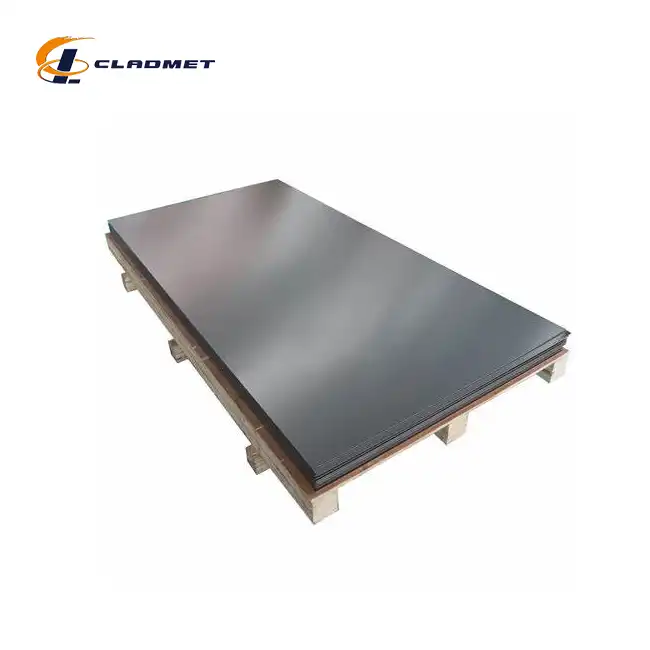

Packaging

Secure wooden crate packaging for international shipping.

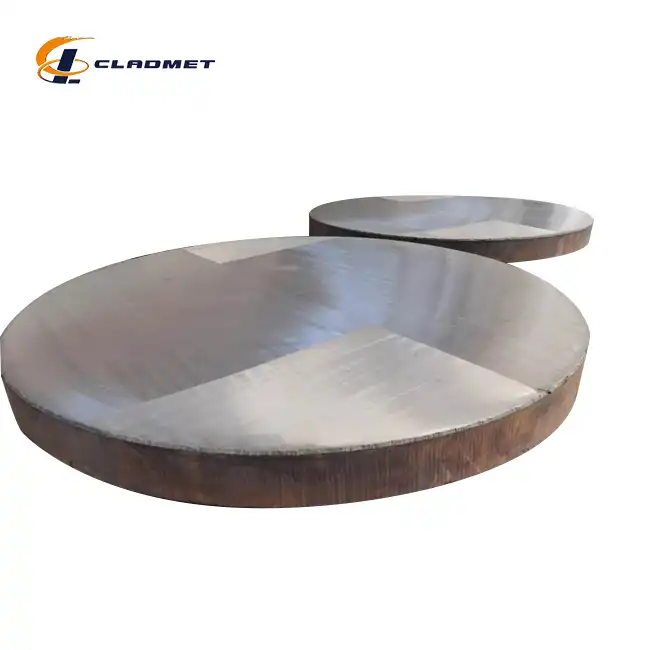

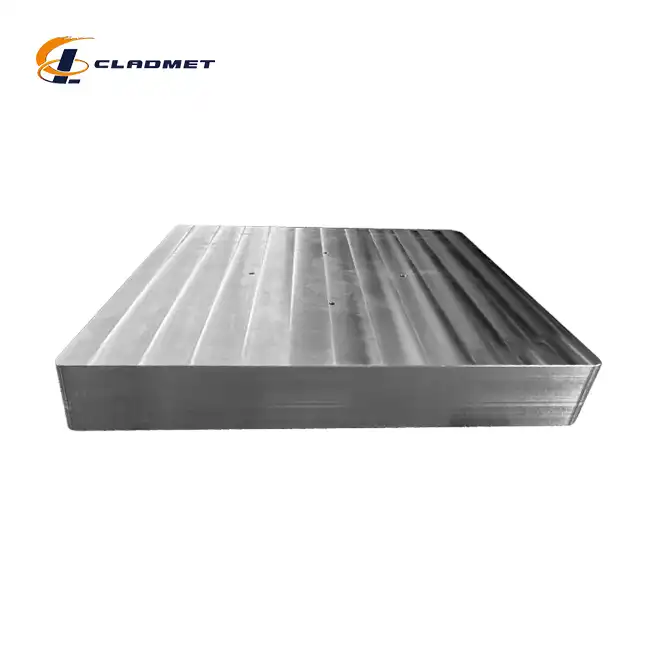

Introduction to Clad Tube Sheet

At Baoji JL Clad Metals Materials Co., Ltd, we are experts in manufacturing high-performance the product that are designed to meet the most demanding industrial needs. Our clad tube sheets are produced by bonding multiple layers of different metals to create a product with enhanced durability, corrosion resistance, and strength. These sheets are widely used in industries such as petrochemicals, pharmaceuticals, energy production, and more.

Whether you need a solution for high-temperature environments or harsh chemical processes, our product provide unmatched reliability and performance. Made with precision and adhering to international standards, our products are trusted by clients worldwide for their quality and longevity.

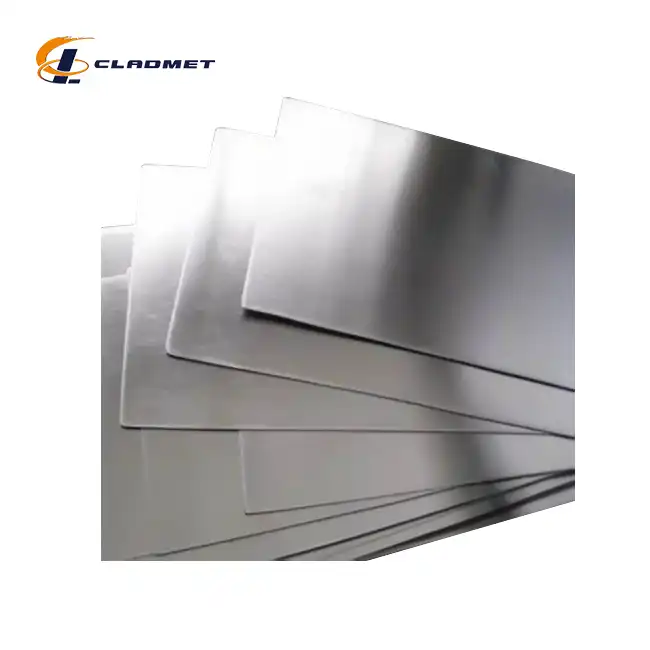

Product Specifications

| Specification | Details |

|---|---|

| Cladding Material Range | Titanium, Nickel, Stainless Steel, Aluminum |

| Base Metal Range | Carbon Steel, Stainless Steel |

| Cladding Size | Customizable according to client requirements |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Product Standards | ASME/ASTM, JIS, GB/GBT |

| Thickness | 5mm to 100mm |

| Length | Up to 6 meters |

| Width | Up to 3 meters |

| Surface Treatment | Polished, Sandblasted, Anti-corrosion Coating |

| Product Application Industry | Chemical, Petrochemical, Pharmaceutical, Power Generation |

| Packaging Method | Wooden Crates, Custom Packaging Available |

| Transportation | Air, Sea, Road (as per client requirements) |

| Delivery Cycle | 3-6 months or negotiable |

|

|

|

Manufacturing Methods

Explosive Bonding

Explosive bonding is a highly effective method for producing clad tube plates. This process involves positioning the base metal and the cladding material in a specific arrangement, then applying a controlled explosive charge between the two. The detonation generates a shockwave that forces the metals to bond together at high velocity, resulting in a strong, metallurgical bond. This method is particularly useful for applications that require a robust connection between the materials, such as those in offshore platforms, refineries, and chemical plants.

Roll Bonding

Roll bonding is a cold-forming technique used to produce clad tube plates by passing the materials through a set of rollers under high pressure. The mechanical force exerted by the rollers causes the materials to fuse at their interfaces, creating a strong, unified bond. This process may require multiple passes through the rollers to achieve a complete and uniform bond. Roll bonding is commonly used for producing tube plates for heat exchangers, especially when a smooth, consistent surface is needed for effective heat transfer.

Hot Isostatic Pressing (HIP)

In HIP, the base metal and cladding layer are placed inside a sealed container and exposed to high temperatures and pressures. This process promotes atomic diffusion, resulting in a diffusion bond between the layers. The bonding strength and uniformity achieved through HIP are critical in applications that demand high levels of reliability and longevity, such as aerospace and critical power generation systems.

Features and Benefits

Corrosion Resistance

Clad tube plates benefit from the inherent corrosion resistance of the cladding material, such as titanium or stainless steel. This makes them ideal for use in environments exposed to aggressive chemicals, seawater, or other corrosive substances. They are commonly used in industries like petrochemical processing, desalination, and offshore oil and gas extraction.

Enhanced Heat Transfer Efficiency

The combination of the cladding material’s durability and the base material’s heat conductivity ensures that clad tube plates maintain high efficiency in heat exchangers and similar applications. The cladding protects the plate from corrosion while the base material efficiently conducts heat, ensuring the proper functioning of thermal systems in demanding environments.

Mechanical Strength

The base material used in clad tube plates provides a solid framework that supports the structure, ensuring the plate can withstand mechanical stresses in high-pressure applications. The cladding layer adds an extra level of protection without compromising the mechanical properties of the plate, making them suitable for high-strength, high-pressure systems.

Customization and Versatility

Clad tube plates can be tailored to specific requirements, including material choices, thickness, and dimensions. This flexibility ensures that they can meet the needs of a wide range of industries and applications, whether in a heat exchanger, a chemical reactor, or a pressure vessel. Customization also extends to surface finishes, allowing for improved performance or aesthetic considerations.

Cost-Effective Solution

By combining a high-performance cladding material with a more affordable base material, clad tube plates offer an economical solution to the challenges of corrosion and mechanical stress. This approach lowers the overall production costs while maintaining long-term reliability, making it a popular choice for industries looking to balance performance and budget.

Longer Service Life

The corrosion-resistant cladding material extends the service life of clad tube plates, reducing the frequency of replacements and minimizing maintenance costs. This longevity is particularly beneficial in industries where downtime is costly, such as power generation, oil and gas, and chemical processing.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We provide OEM services to meet the custom requirements of our clients. From material selection to final product specifications, our team works closely with customers to deliver solutions that align with their production and operational needs. Contact us to discuss your project and receive tailored solutions.

FAQ

Q1: What is the typical delivery time for a clad tube sheet?

A: The delivery cycle is usually 3-6 months, depending on the order size and customization requirements.

Q2: Can I request a specific size or material combination?

A: Yes, we offer fully customizable sizes and material combinations to meet your specific industrial requirements.

Q3: What testing is done on the sheets?

A: All products undergo a range of tests, including corrosion resistance, pressure testing, and adhesion strength testing.

Contact Us

For inquiries or to place an order, please reach out to us via the following:

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

Let us help you find the best clad tube sheet solutions for your industry needs!

_1737007724117.webp)