Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

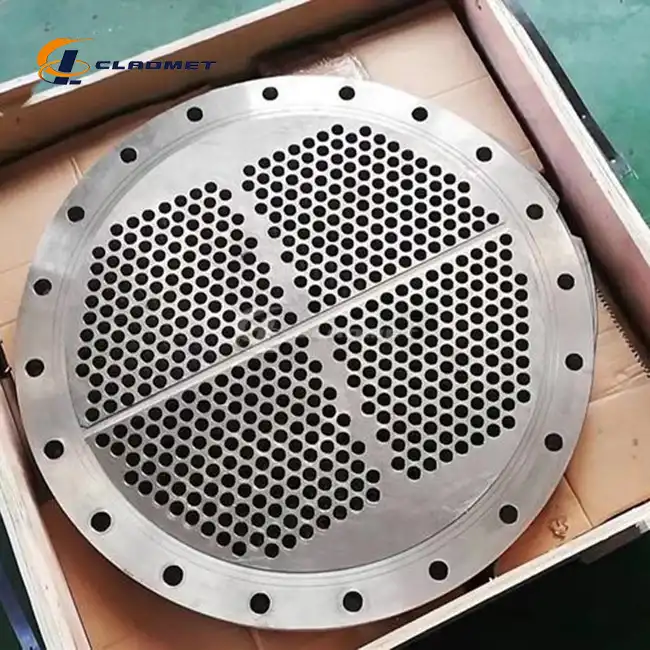

Secure wooden crate packaging for international shipping.

At Baoji JL Clad Metals Materials Co., Ltd, we offer premium clad plates for tube sheets, providing industry-leading strength, corrosion resistance, and cost-efficiency. With over 20 years of expertise, we specialize in creating advanced clad materials for critical industrial applications, ensuring performance, longevity, and reliability.

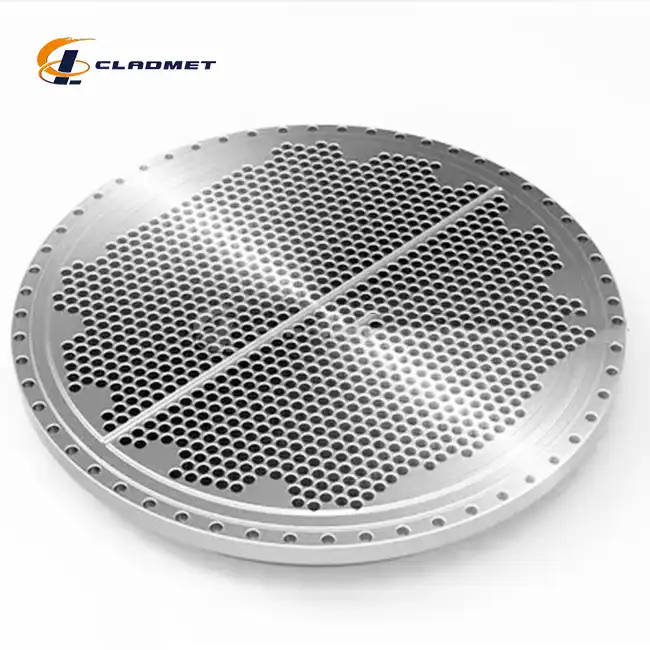

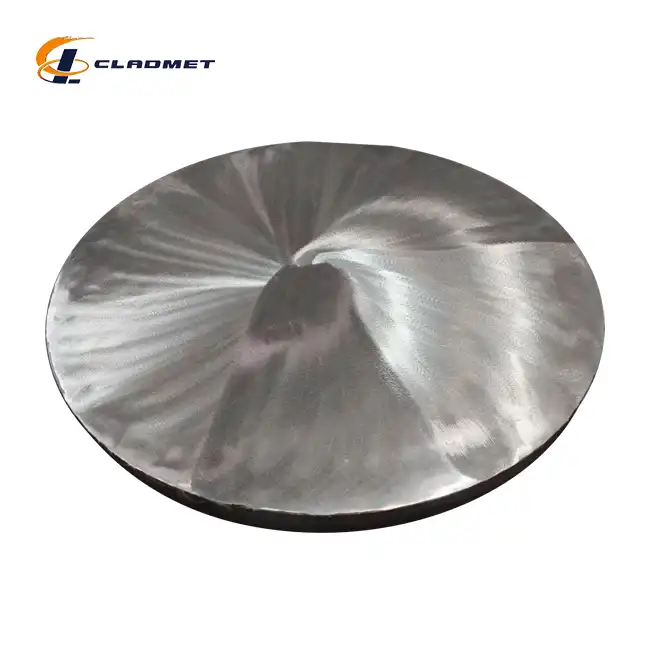

What are Clad Plates for Tube Sheets?

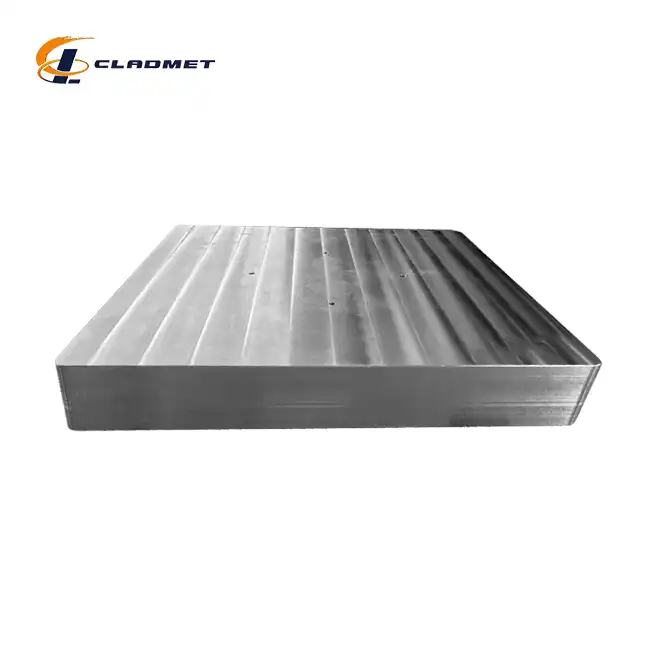

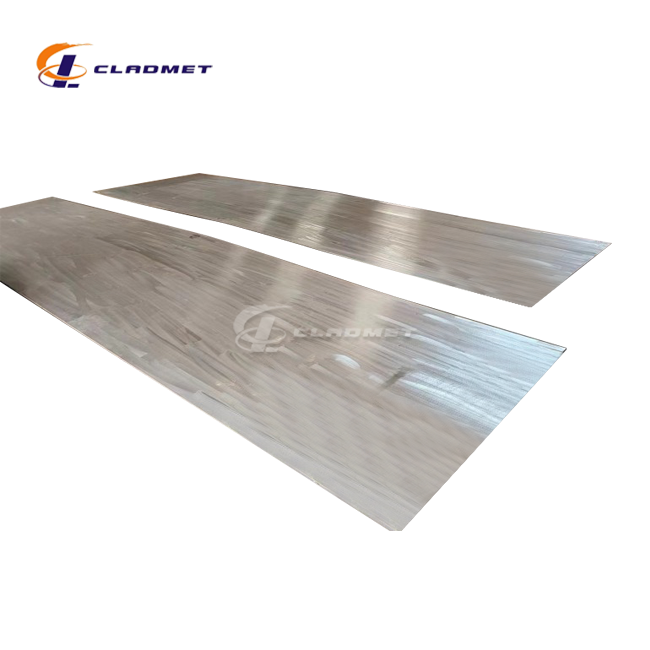

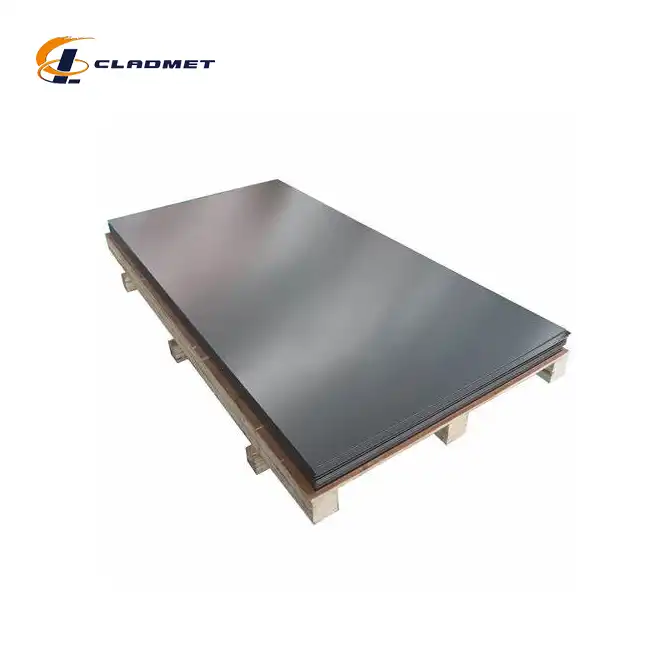

Clad plates are composite metal materials where two or more metals are bonded together, either through roll-bonding or explosion-bonding techniques. This combination enhances the mechanical properties of the materials, offering superior strength, durability, and resistance to wear and corrosion—ideal for tube sheets in heat exchangers, boilers, and pressure vessels.

Product Specifications

| Category | Details |

|---|---|

| Cladding Material | Titanium, Nickel, Stainless Steel, Aluminium, Tantalum, Zirconium |

| Base Metal | Carbon Steel, Stainless Steel, Aluminum |

| Cladding Technology | Explosion-bonding, Roll-bonding |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Thickness Range | 3mm - 300mm |

| Width & Length | Up to 5,000mm width; custom length options available |

| Surface Treatment | Polishing, Sandblasting, Corrosion-resistant coatings |

| Applications | Oil & Gas, Chemical, Nuclear, Aerospace, Marine |

| Packaging | Wooden cases, Steel frames |

| Delivery Cycle | 3-6 months or negotiable |

|

|

|

Manufacturing Techniques

Explosive Welding

Explosive welding is a key method for manufacturing clad plates for tube sheets. It involves the precise alignment of two materials, followed by the controlled detonation of an explosive charge placed between them. The shockwave generated from the explosion causes the materials to collide at high speed, creating a metallurgical bond that ensures a strong, permanent fusion. This method is particularly beneficial for creating clad plates that need to endure harsh conditions, such as high-pressure environments in chemical and oil processing plants.

Roll Bonding

Roll bonding is another common technique for manufacturing clad plates for tube sheets. This cold-working process involves passing the base material and the cladding layer through a set of rollers under high pressure. The materials bond together through the mechanical force of the rollers, creating a solid interface. Multiple passes may be necessary to ensure the materials are fully bonded. This method is commonly used in the production of clad plates for applications in heat exchangers and other systems where uniformity and precision are essential.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a high-temperature, high-pressure method used to form a diffusion bond between the base material and the cladding layer. In this process, the materials are placed inside a sealed container and exposed to both heat and pressure. The combination of these factors promotes atomic diffusion, ensuring a strong bond between the materials at the molecular level. HIP is especially useful for producing high-performance clad plates used in industries such as aerospace, oil and gas, and chemical processing, where bond integrity and long-term durability are critical.

Key Features and Benefits

Superior Corrosion Resistance

One of the standout features of clad plates for tube sheets is their exceptional corrosion resistance. The outer cladding layer, often made of titanium, stainless steel, or other corrosion-resistant materials, protects the base material from aggressive chemicals, acids, and seawater. This makes the plates ideal for use in environments where exposure to corrosive substances is a concern, such as chemical plants, offshore platforms, and desalination facilities.

Thermal Conductivity

The cladding materials used in tube sheet plates often exhibit excellent thermal conductivity, allowing efficient heat transfer in heat exchangers and other systems requiring temperature regulation. This property ensures that these plates can withstand the thermal stresses that come with industrial applications, providing reliable performance over extended periods.

Enhanced Strength-to-Weight Ratio

Clad plates are designed to offer excellent strength without a significant increase in weight. The combination of a lightweight base material, such as carbon steel or aluminum, with a strong, durable cladding layer creates a high-strength, low-weight product. This is particularly valuable in industries like aerospace and power generation, where minimizing weight is a key factor in improving operational efficiency.

Customization Options

Clad plates for tube sheets can be customized in terms of size, thickness, and the specific metals used for both the base and cladding layers. This versatility makes them suitable for a wide range of applications, ensuring that each product can be tailored to meet the precise requirements of different industries.

Cost-Effective Solution

The combination of high-performance materials like titanium with more cost-effective base metals such as carbon steel results in a product that delivers both strength and durability at a lower cost. This cost-efficiency makes clad plates an attractive option for industries looking to balance performance with budget constraints.

Durability and Longevity

Clad plates are designed to withstand extreme conditions, including high temperatures, corrosive environments, and heavy mechanical stresses. Their durability ensures a long service life, reducing the need for frequent replacements and minimizing downtime in industrial operations.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Services

We offer comprehensive OEM services, providing custom-designed clad plates tailored to your exact specifications. From initial design consultation to final delivery, our team ensures that your product meets all industrial standards and performance requirements.

FAQ

Q1: What metals can be used for cladding?

A1: We offer a range of metals including titanium, nickel, stainless steel, aluminum, tantalum, and zirconium for cladding.

Q2: How long is the delivery cycle?

A2: Typically, the delivery cycle is 3-6 months, but this can be negotiated based on your project needs.

Q3: Do you offer custom sizes?

A3: Yes, we provide custom sizing and thicknesses based on your specifications.

Contact Us

For more information or to request a quote for our clad plates for tube sheets, reach out to us:

- Phone: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

At Baoji JL Clad Metals, we pride ourselves on delivering high-quality, durable solutions that meet the unique demands of industries worldwide. Let us help you improve the performance and lifespan of your equipment with our advanced clad plates for tube sheets!

_1737007724117.webp)