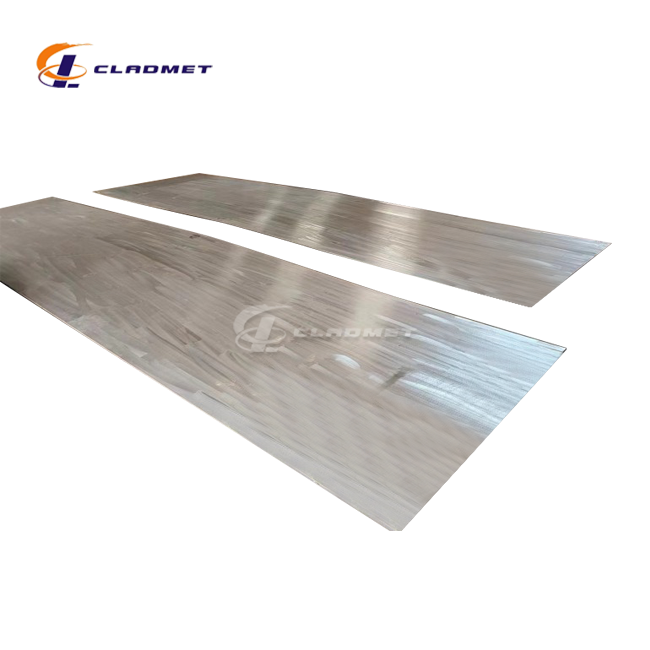

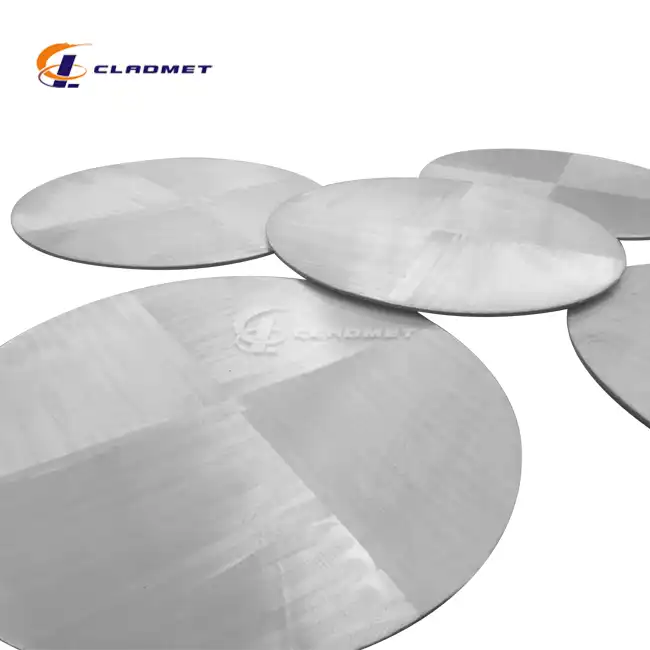

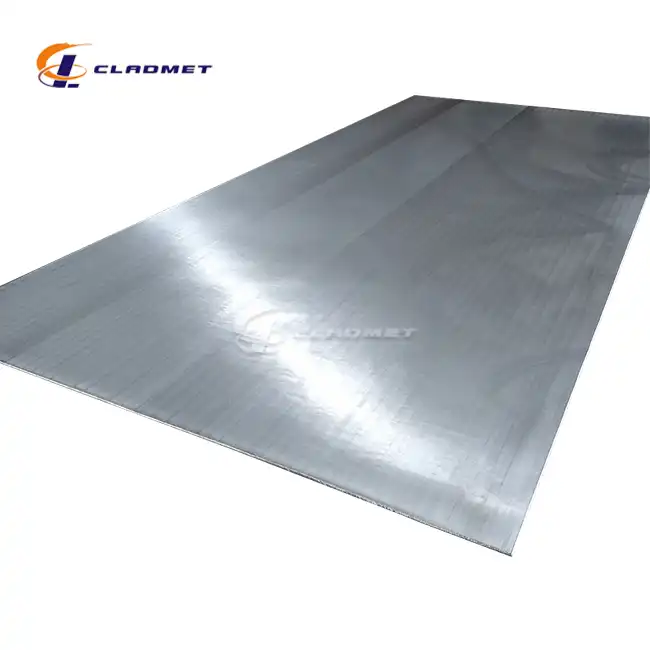

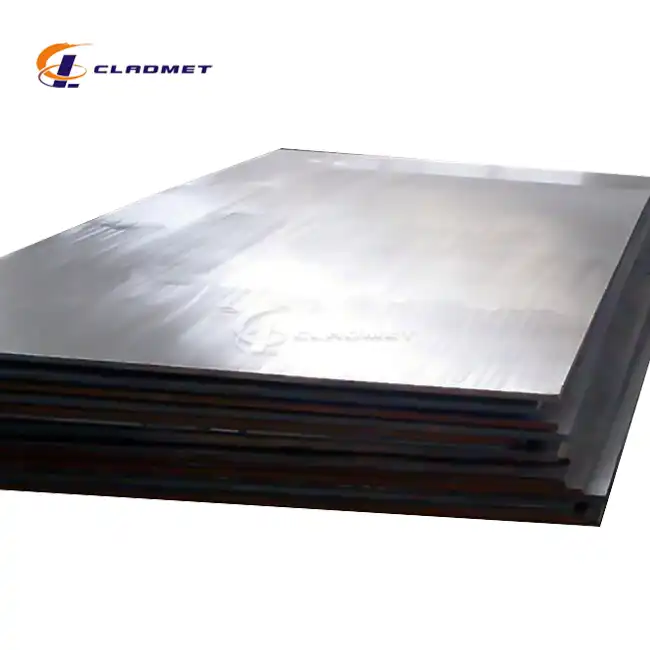

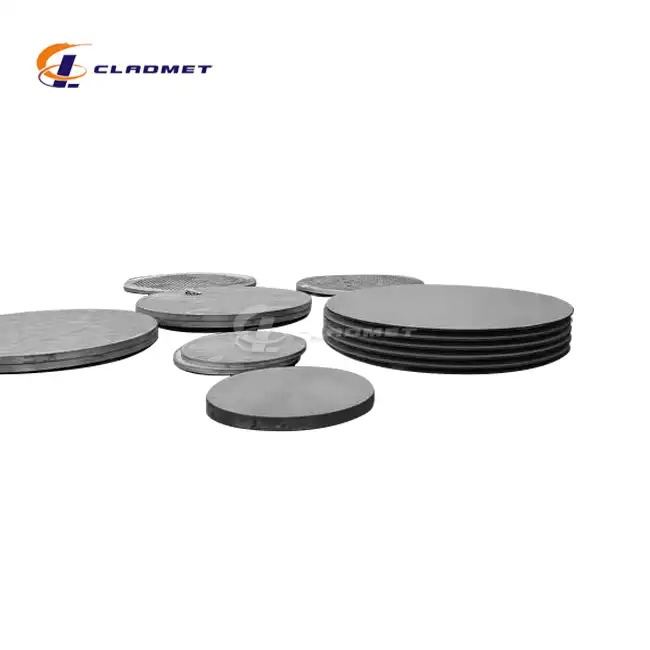

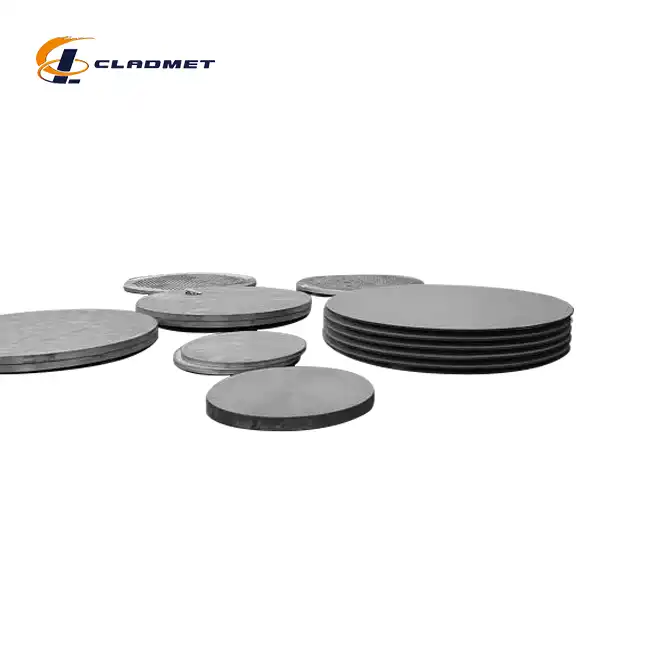

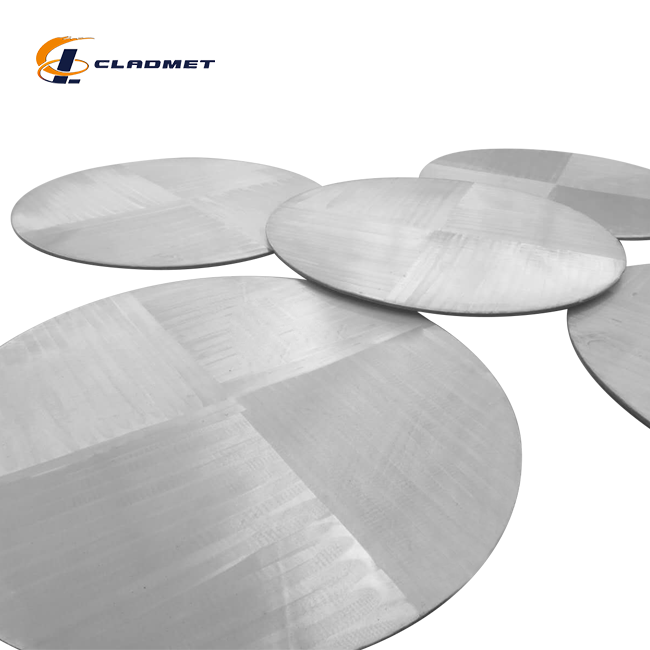

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Product Introduction

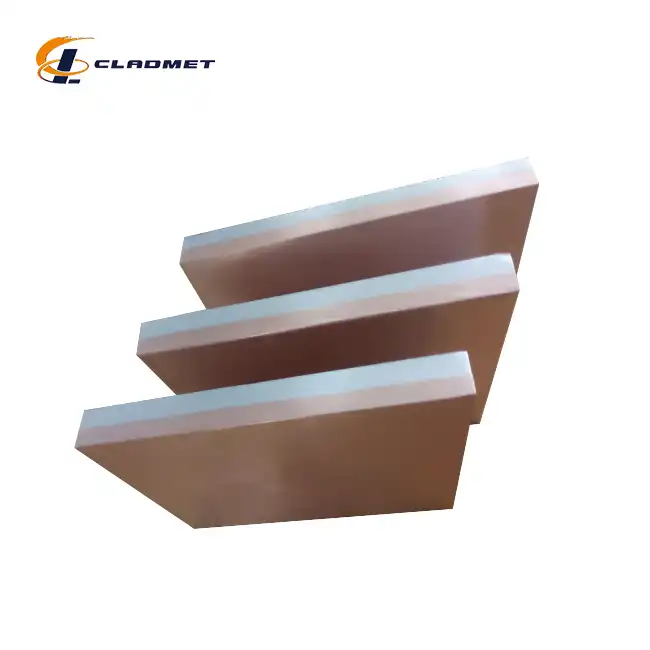

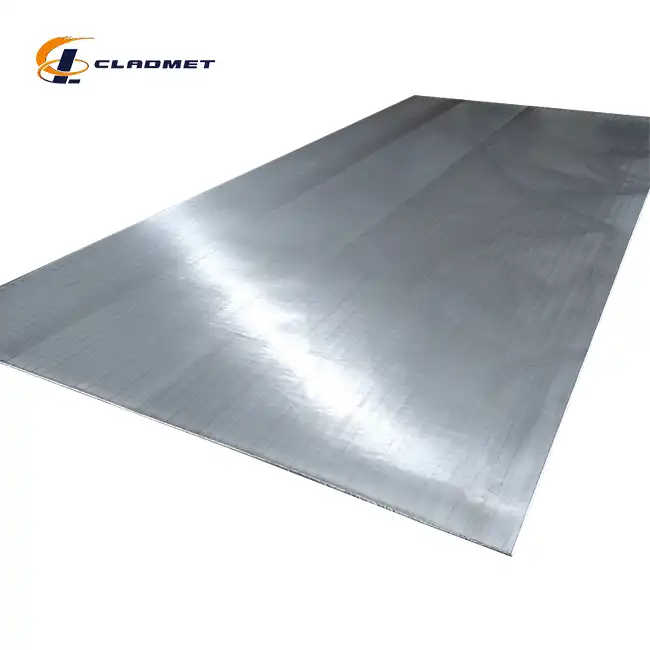

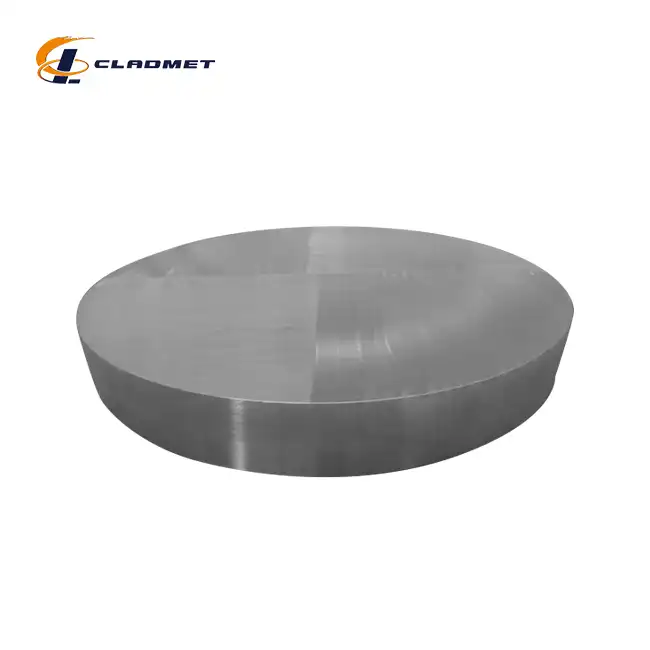

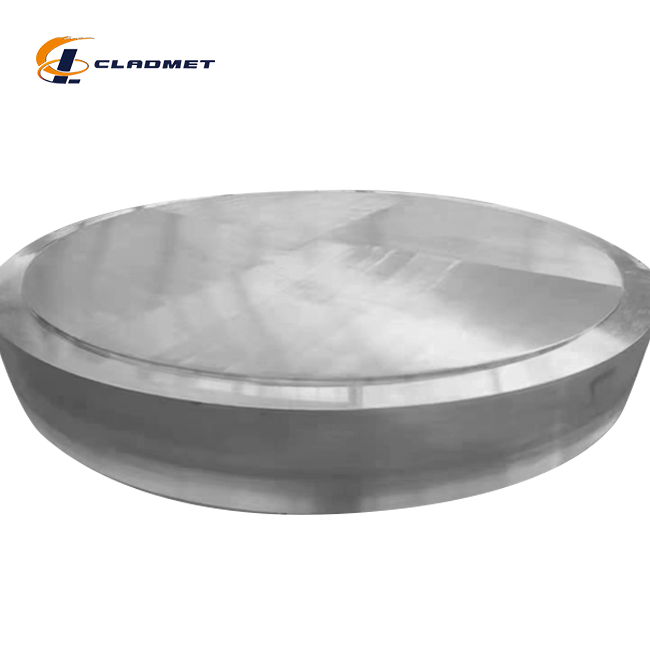

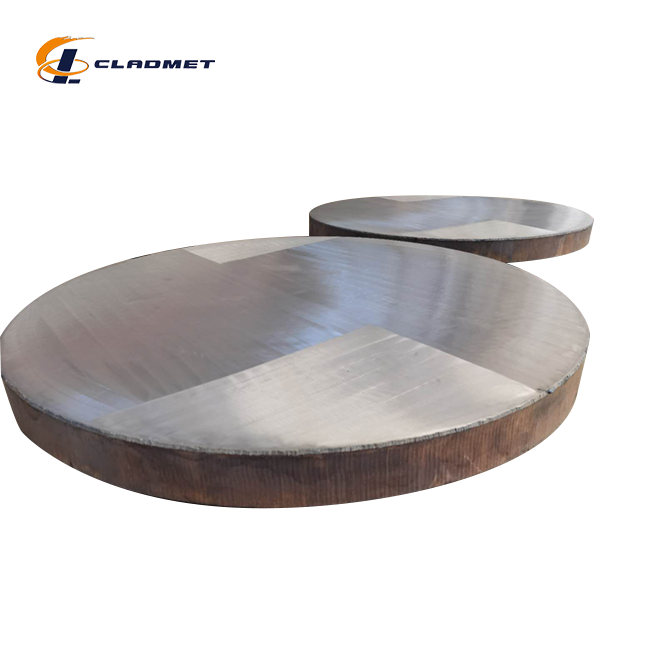

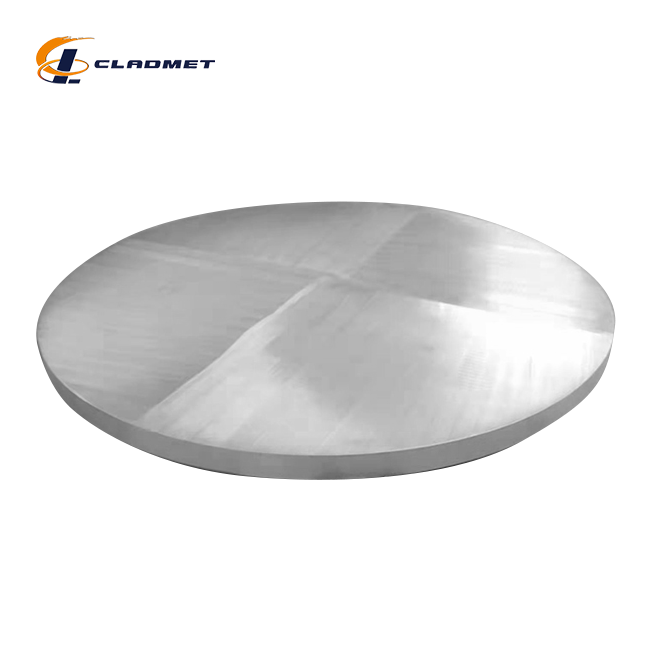

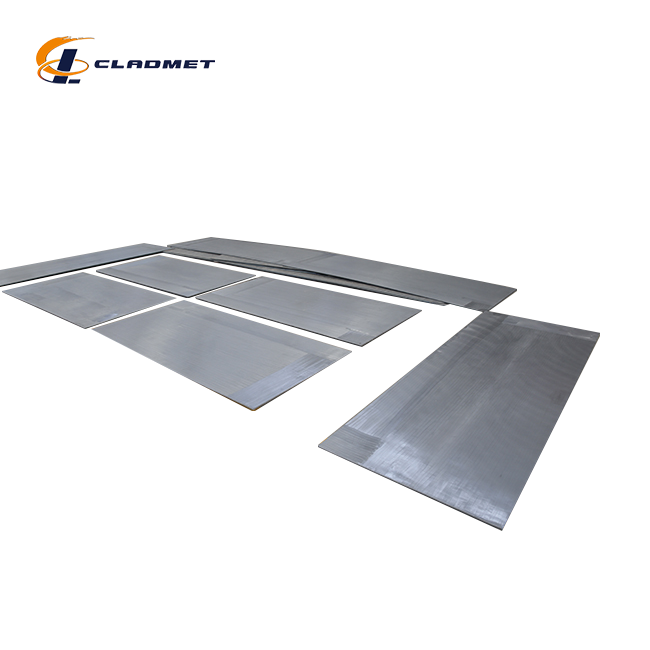

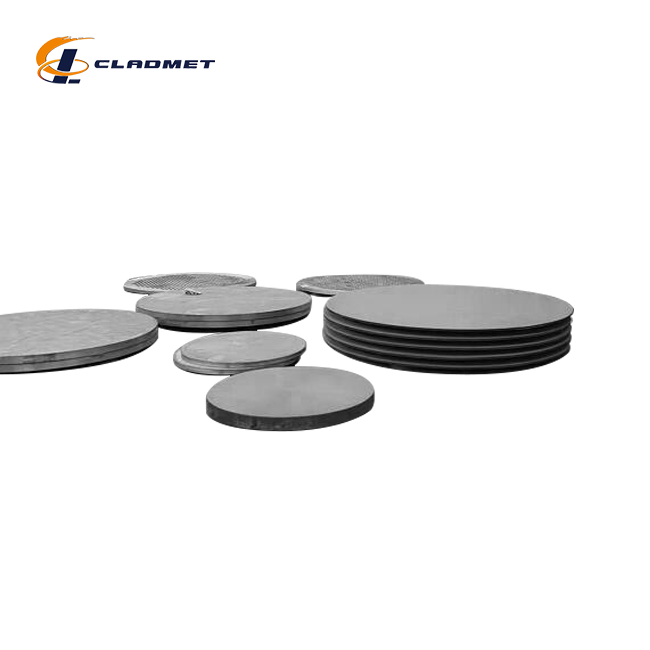

The aluminium clad steel plate is a composite material that combines the strengths of both aluminium and steel. The aluminium layer offers exceptional corrosion resistance, while the steel layer provides strength and durability. This unique combination results in a product with excellent structural performance, making it ideal for applications that demand a high strength-to-weight ratio, corrosion resistance, and long-term durability. Widely used in industries such as marine engineering, aerospace, and chemical processing, the steel plates offer a cost-effective and customizable solution for various industrial needs.

Product Specifications

| Category | Details |

|---|---|

| Cladding Material | Aluminium (T6061) |

| Base Material | Steel (Q355B) |

| Cladding Size | Customizable |

| Thickness Range | 1.5mm to 50mm |

| Length | Up to 12 meters |

| Width | Up to 3 meters |

| Cladding Technology | Explosion bonding, Roll bonding |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Surface Treatment | Custom finishes available |

| Packaging Method | Secure wooden crates |

| Transportation | Sea, Air, Land |

| Delivery Cycle | 3-6 months (negotiable) |

|

|

|

|

|

|

|

|

Manufacturing Methods

Aluminium clad steel plates combine the strength and durability of steel with the corrosion resistance of aluminium. This dual-layer structure offers a solution where both material properties are needed for specific applications. Several methods are employed to bond the aluminium layer to the steel, ensuring a robust and efficient composite material. The primary techniques include:

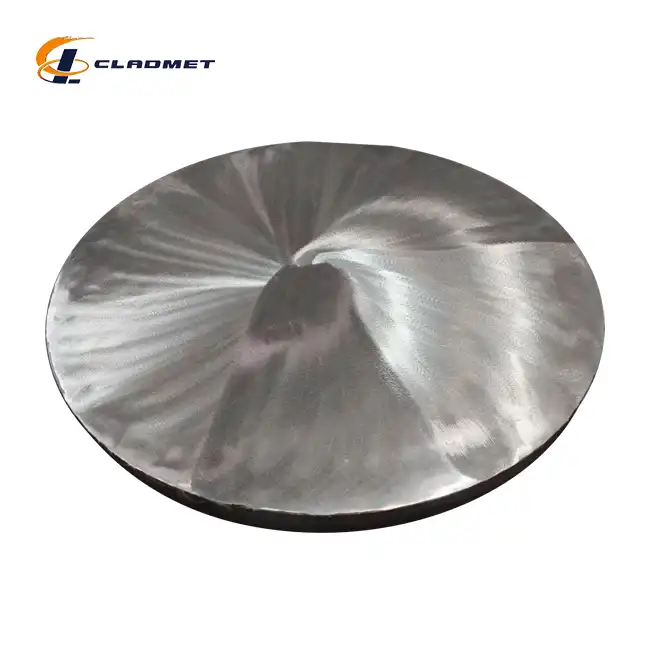

Explosive Bonding

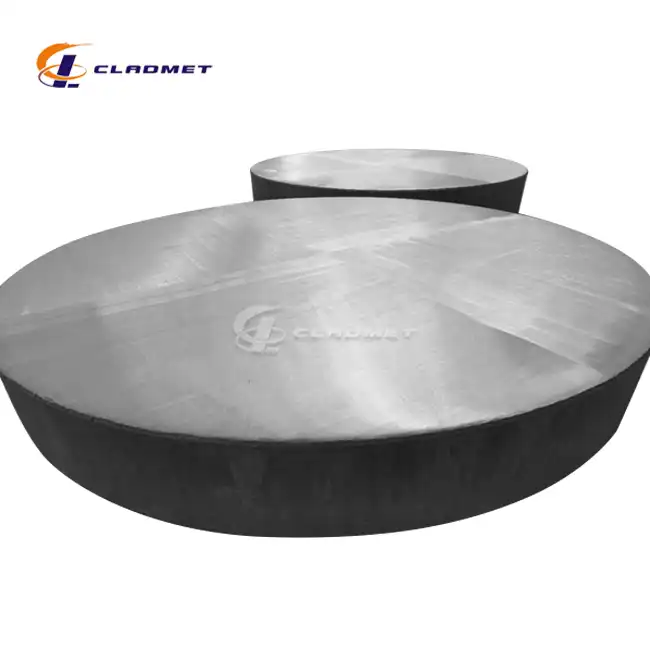

Explosive bonding is a highly effective technique used to join the aluminium layer with the steel base material by utilizing a controlled explosive force. This process ensures a high-strength metallurgical bond that is particularly useful for challenging applications.

Material Preparation: Both aluminium and steel surfaces are cleaned and carefully arranged for the bonding process.

Detonation: Explosives are placed between the two materials, and a detonation initiates the bonding.

Impact and Bonding: The explosion creates a high-speed collision between the aluminium and steel, forming a durable bond between the two materials.

This method is commonly applied when a strong, reliable bond is required for demanding industries such as aerospace, chemical processing, and heavy machinery manufacturing.

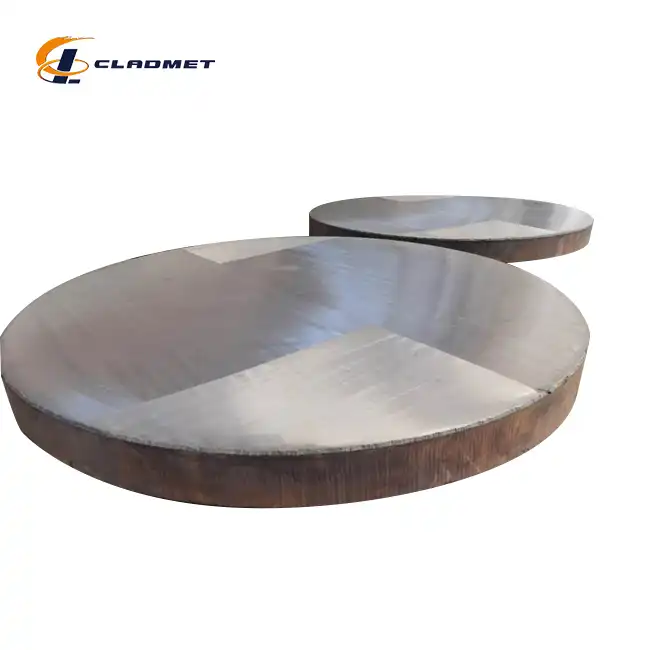

Roll Bonding

Roll bonding is a cold-rolling process in which the aluminium and steel are passed through rollers under intense pressure. This creates a strong connection between the materials through mechanical deformation.

Surface Cleaning: Both materials undergo thorough cleaning to ensure a secure bond.

Pressing Process: The materials are rolled through high-pressure rollers, forcing the aluminium to adhere to the steel.

Multiple Passes: Depending on the thickness of the materials, multiple passes through the rollers may be required to ensure a solid and uniform bond.

This process is often used for manufacturing large sheets and plates, making it ideal for use in construction, transportation, and marine industries.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing involves applying high pressure and temperature in a sealed chamber to bond the aluminium to the steel through atomic diffusion. The process ensures a high-quality and uniform bond, suitable for applications requiring exceptional durability.

Preparation: The materials are assembled and sealed in a high-pressure chamber.

Heating and Pressurization: The chamber is subjected to elevated temperatures and high-pressure conditions, allowing atomic diffusion to create a strong bond between the two metals.

Bond Formation: This process results in a strong diffusion bond that is resistant to mechanical and environmental stresses.

HIP is commonly used for high-performance applications in aerospace, defense, and other industries that require precision and integrity in material bonding.

Key Benefits of Aluminium Clad Steel Plates

Superior Corrosion Resistance: The aluminium cladding provides excellent resistance to corrosion, making these plates ideal for applications in environments exposed to moisture, chemicals, and extreme weather conditions.

Strength and Durability: While the aluminium layer offers corrosion protection, the steel core provides exceptional structural strength, ensuring that the material is both robust and long-lasting.

Lightweight: Aluminium’s relatively low density means that aluminium-clad steel plates are lighter than solid steel plates, improving efficiency in applications where weight is a critical factor.

Cost-Effective Solution: Combining the durability of steel with the protective properties of aluminium reduces the need for frequent replacements, making it a cost-effective solution for various industries.

Thermal Conductivity: Aluminium is an excellent conductor of heat, making these plates ideal for applications requiring efficient heat transfer.

Customization: Aluminium-clad steel plates can be tailored in terms of thickness, surface finishes, and bonding methods to meet specific industry requirements.

Impact Resistance: The combination of materials ensures high impact resistance, which is important for industries where mechanical stress or physical wear is a concern.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals Materials Co., Ltd., we offer comprehensive OEM services. Our technical team collaborates with customers to design and manufacture the steel plates tailored to your specific requirements, ensuring top-notch quality and timely delivery.

FAQ

- Q: What is the delivery time for aluminium clad steel plates?

- A: Delivery typically takes 3-6 months, but it can be negotiated based on project needs.

- Q: Are custom sizes available?

- A: Yes, we offer customizable sizes to suit your project’s specifications.

- Q: What industries use the steel plates?

- A: Common applications include marine, aerospace, chemical processing, and petroleum industries.

- Q: How do I place an order?

- A: You can place an order through our website, email, or by contacting our sales team directly.

Contact Us

- Phone: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)