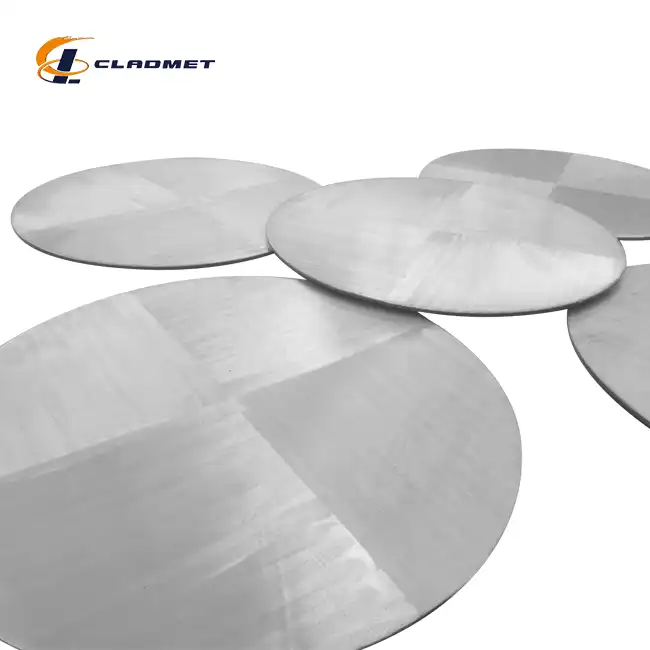

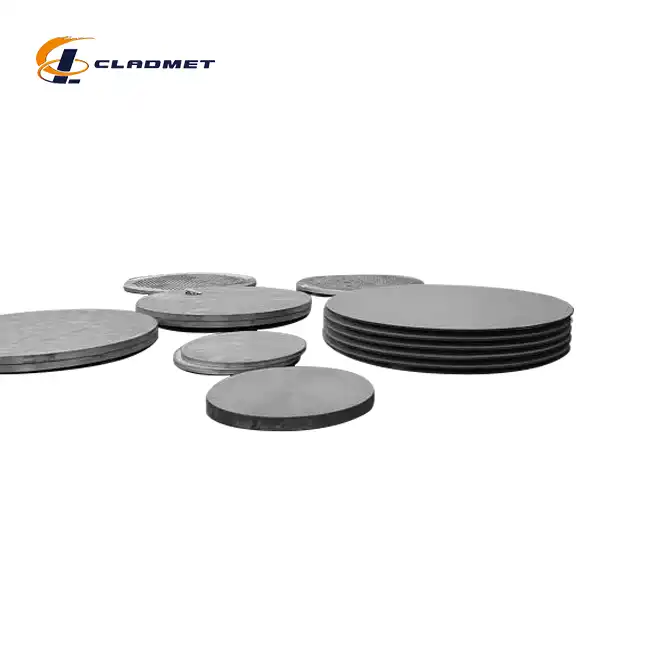

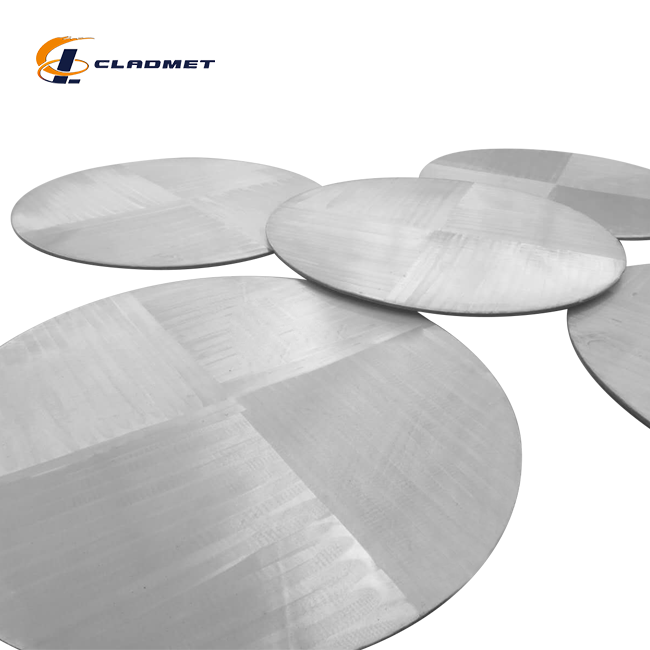

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

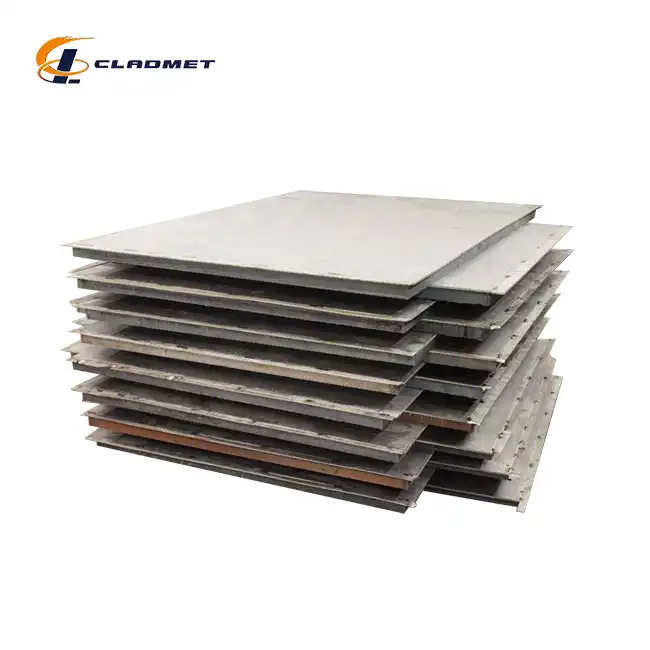

Packaging:Secure wooden crates for international transport

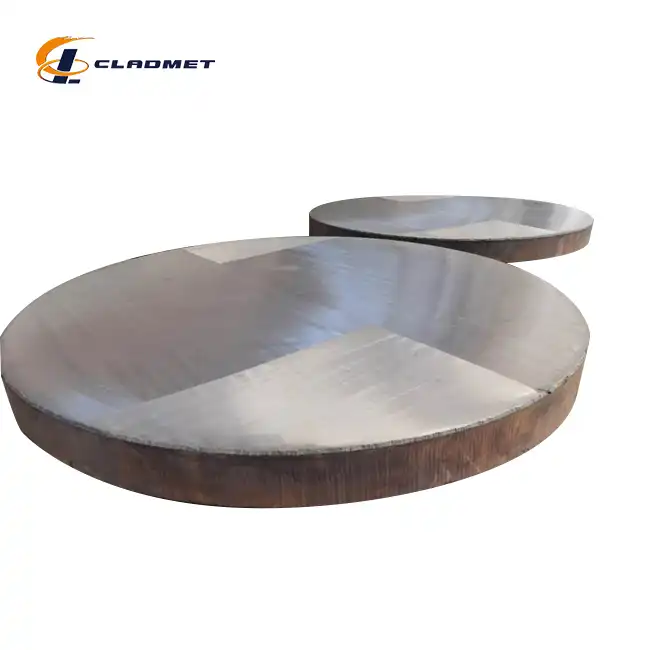

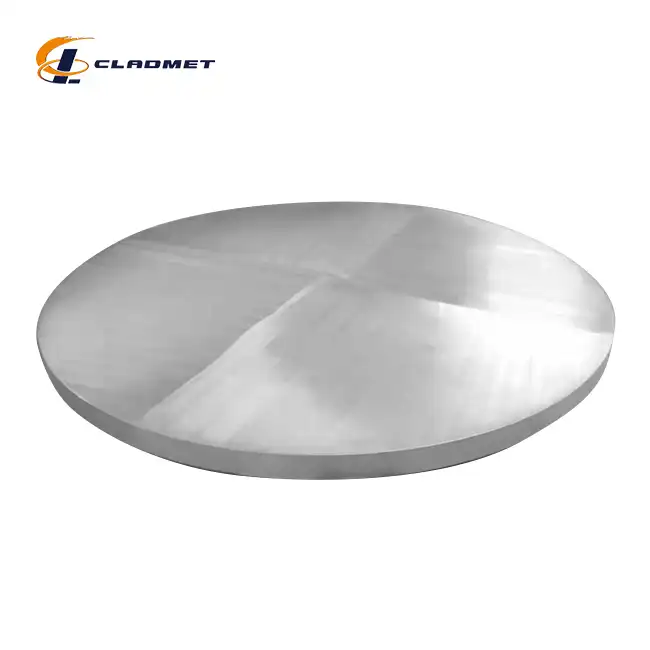

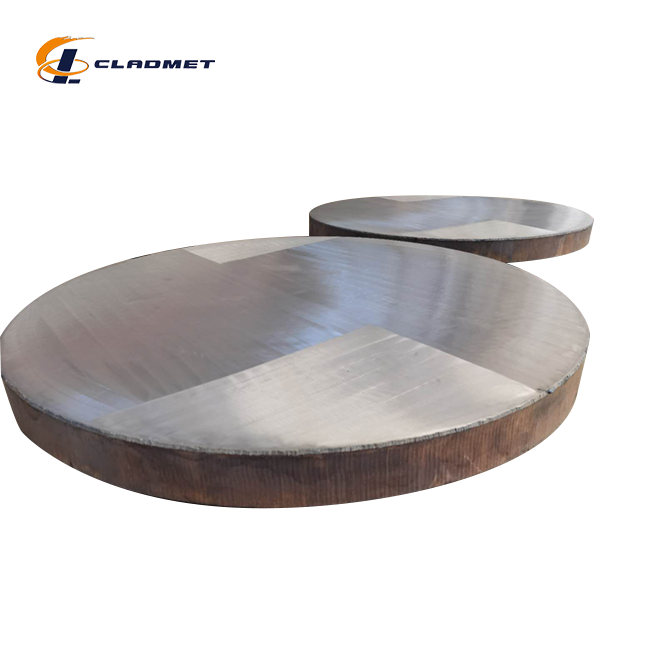

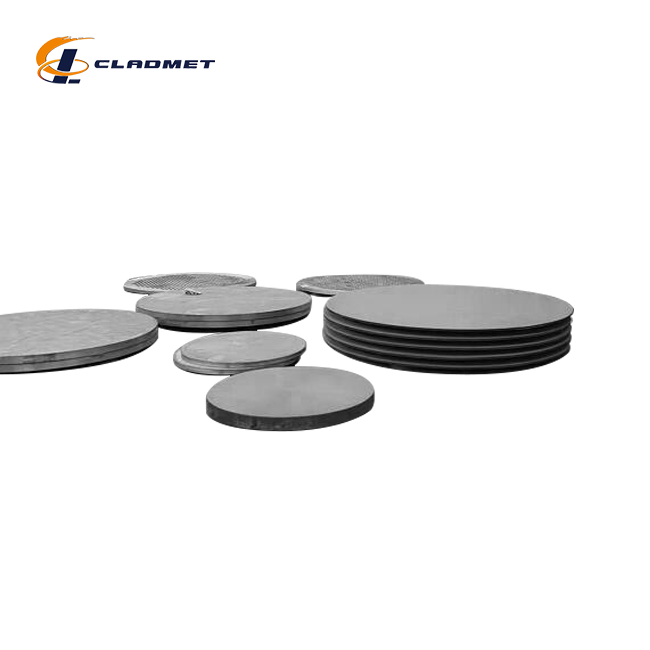

Introduction To Titanium Carbon Steel Clad Plate

Baoji JL Clad Metals Materials Co., Ltd. produces our high-performance Titanium Carbon Steel Clad Plate to meet the ever-evolving requirements of industries that demand superior strength, corrosion resistance, and longevity. These clad plates are an extraordinary material for rock solid applications in oil and gas, substance handling, and marine designing since they join the strength of carbon steel with the exceptional characteristics of titanium.

To produce products that meet or exceed customer expectations, we employ cutting-edge bonding methods like explosion welding (EXW) and roll bonding and adhere to stringent quality standards. Our Titanium Carbon Steel Clad Plate offer the ideal balance of lightweight, high strength, and exceptional durability, making them suitable for use in even the most demanding industrial settings.

Product Specifications

| ||

|---|---|---|

| Base Material | Carbon Steel (e.g., Q235B, Q345B, etc.) | |

| Cladding Material | Titanium (e.g., TA1, TA2, Gr1, Gr2, etc.) | |

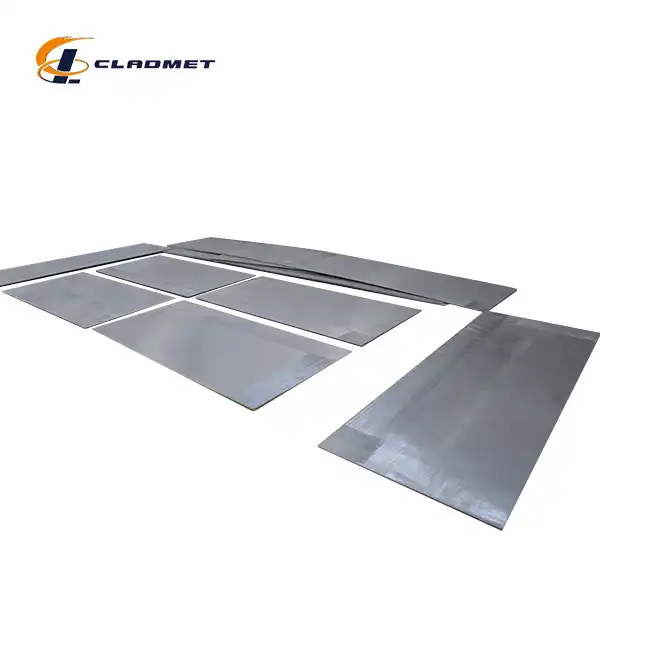

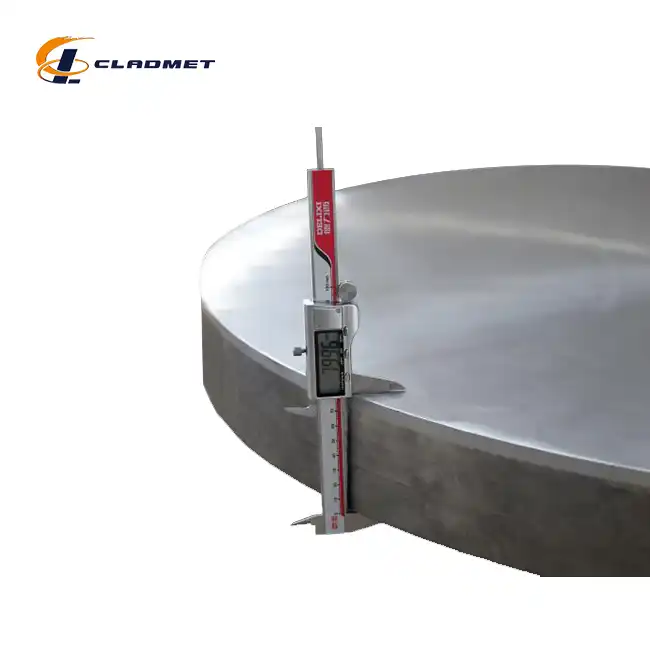

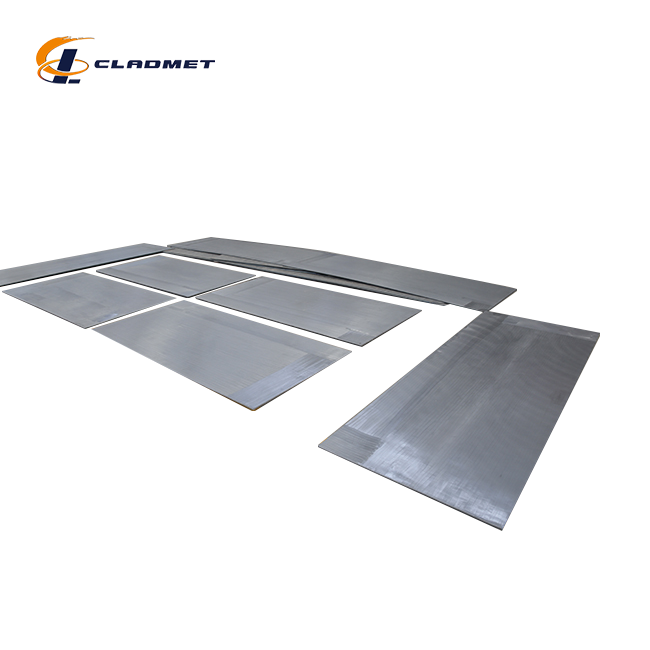

| Thickness Range | Total: 5 mm - 200 mm (e.g., 2 mm Titanium + 8 mm Carbon Steel) | |

| Clad Layer Thickness | 1 mm - 20 mm (customizable) | |

| Base Layer Thickness | 3 mm - 180 mm (customizable) | |

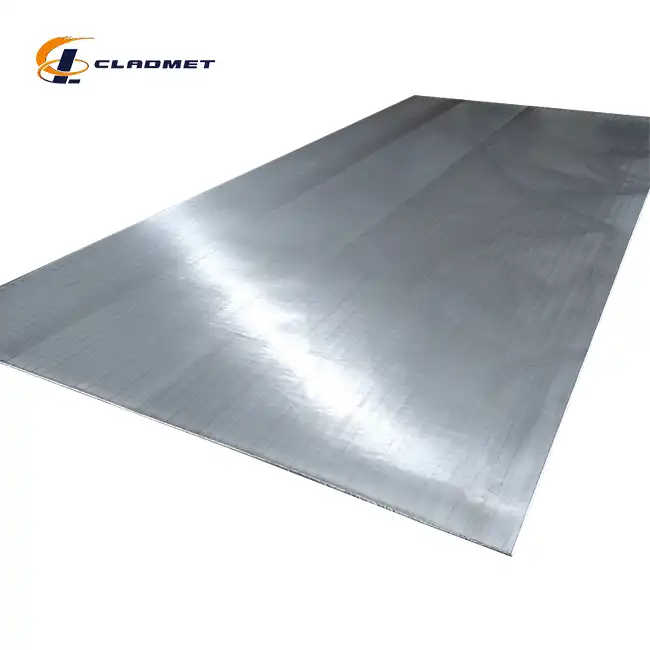

| Width Range | Up to 3000 mm | |

| Length Range | Up to 12000 mm | |

| Bonding Technology | Explosion Bonding or Hot Rolling | |

| Bonding Strength | ≥ 140 MPa | |

| Shear Strength | ≥ 105 MPa | |

| Corrosion Resistance | Excellent resistance to corrosion in various environments (acid, alkali, and salt) | |

| Application Industries | Chemical, Marine, Aerospace, Medical, Power Generation, Desalination Plants, etc. | |

| Standards Compliance | ASTM B898, ASME SB-898, GB/T 8165, etc. | |

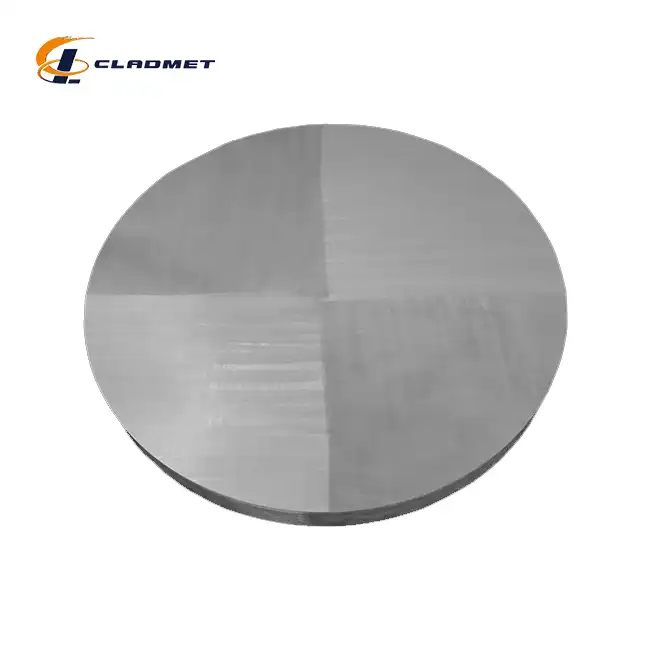

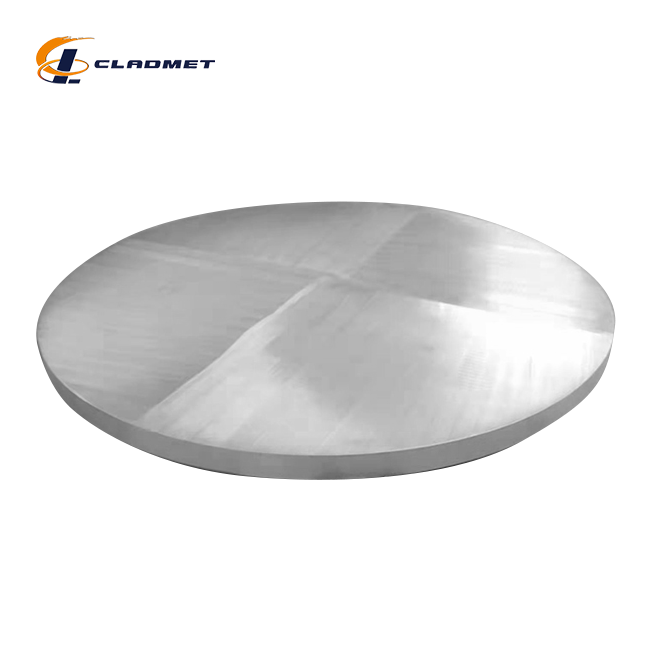

| Surface Finish | Polished, Sandblasted, or Customized | |

| Customizations Available | Size, Material Grade, Thickness Ratio, and More |

|

|

|

|

|

|

|

|

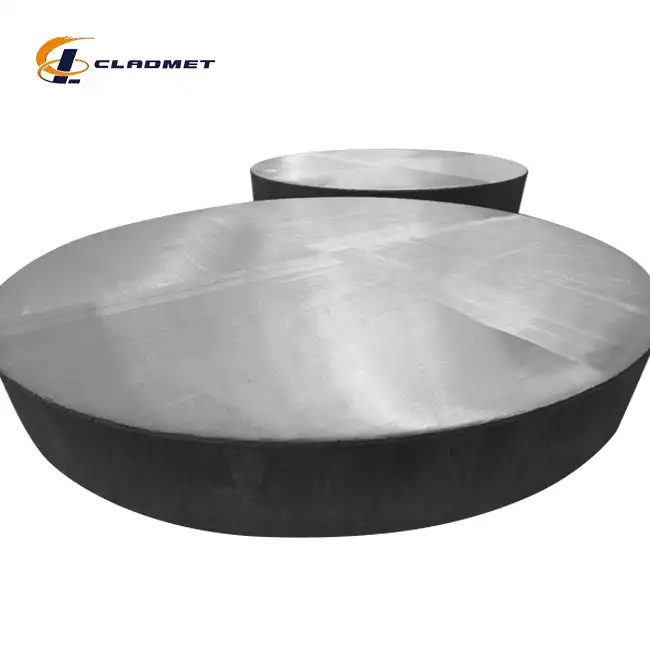

Advanced Manufacturing Techniques

Titanium carbon steel clad plates are manufactured using specialized processes that ensure a robust and durable bond between titanium and carbon steel. These methods are designed to combine the anti-corrosion properties of titanium with the strength and affordability of carbon steel. The primary manufacturing techniques include:

Explosive Bonding

This innovative process creates a high-energy collision between titanium and carbon steel, resulting in a strong metallurgical connection. The steps are:

Material Preparation: Titanium and carbon steel are thoroughly cleaned and aligned in a precise configuration.

Explosive Arrangement: A carefully measured explosive charge is placed to achieve the desired impact force.

Energy Transfer: The detonation produces an intense collision, forming a seamless bond.

This method is ideal for producing clad plates for high-pressure environments like pressure vessels and heat exchangers.

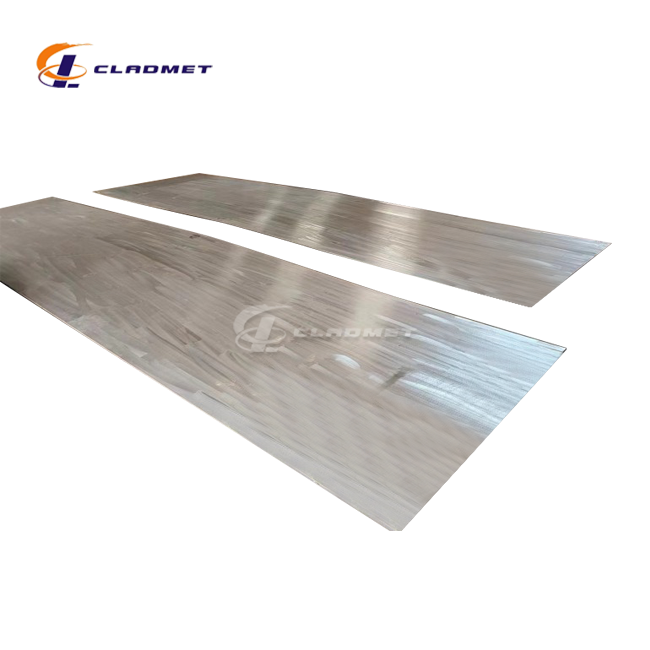

Cold Roll Cladding

Cold roll cladding involves compressing titanium and carbon steel through a series of rollers to create a unified plate. The process includes:

Pre-Cladding Preparation: Ensuring clean and smooth surfaces for optimal adhesion.

High-Pressure Rolling: Repeated passes through rollers to ensure a uniform bond.

This method is widely adopted for creating large sheets and plates for structural and industrial applications.

Diffusion Bonding at Elevated Conditions

By applying controlled heat and pressure in a vacuum chamber, diffusion bonding achieves an atomic-level connection between the layers. Key steps include:

Encapsulation and Sealing: The materials are encased to prevent contamination.

Controlled Heating and Compression: Elevated temperature and pressure facilitate diffusion.

This method is preferred for applications demanding precision and high integrity, such as chemical and marine industries.

Product Features and Benefits

Exceptional Corrosion Resistance: Titanium provides superior resistance to rust and chemical degradation, especially in harsh or corrosive settings.

Enhanced Mechanical Strength: The carbon steel core ensures excellent structural integrity, supporting heavy loads and high-pressure applications.

Optimized Cost-Performance Ratio: Combining titanium's high performance with carbon steel's cost-effectiveness makes these plates an economical choice for many industries.

Thermal and Electrical Efficiency: Ideal for systems requiring heat or electrical conductivity due to their tailored material properties.

Versatile Customization: Available in a wide range of thicknesses, sizes, and configurations to meet diverse operational needs.

Extended Service Life: Resistance to wear, corrosion, and mechanical stresses contributes to longer operational lifespan, reducing replacement costs.

Environmentally Friendly: Durable construction minimizes material waste and reduces environmental impact over time.

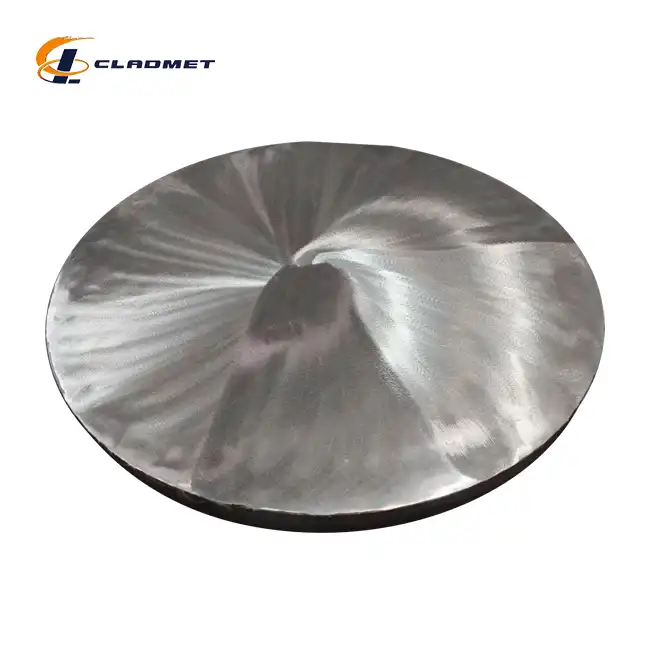

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

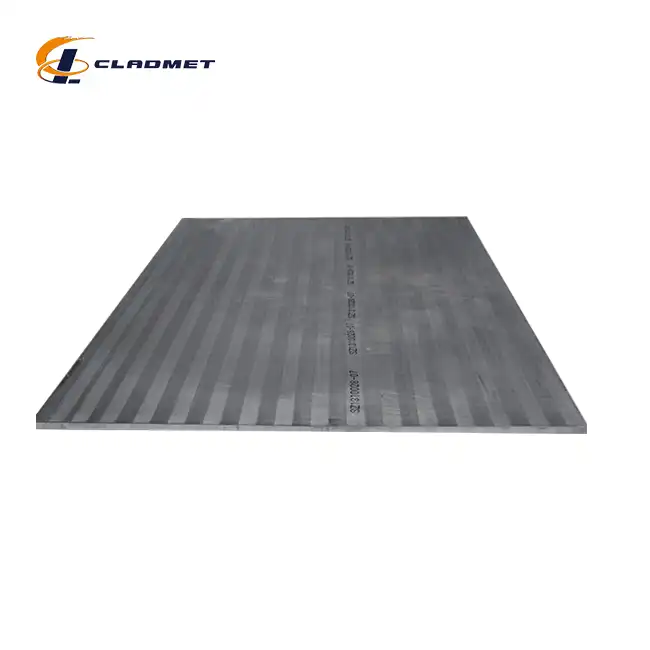

Hot Rolling

Hot Rolling

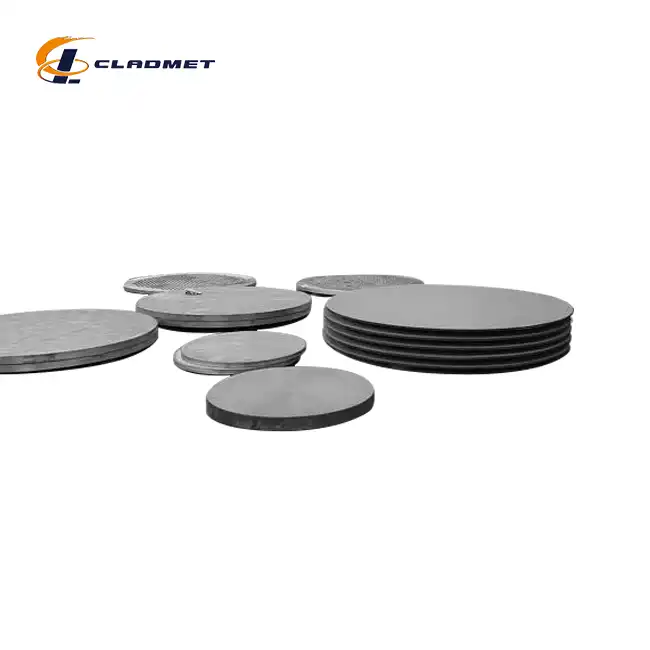

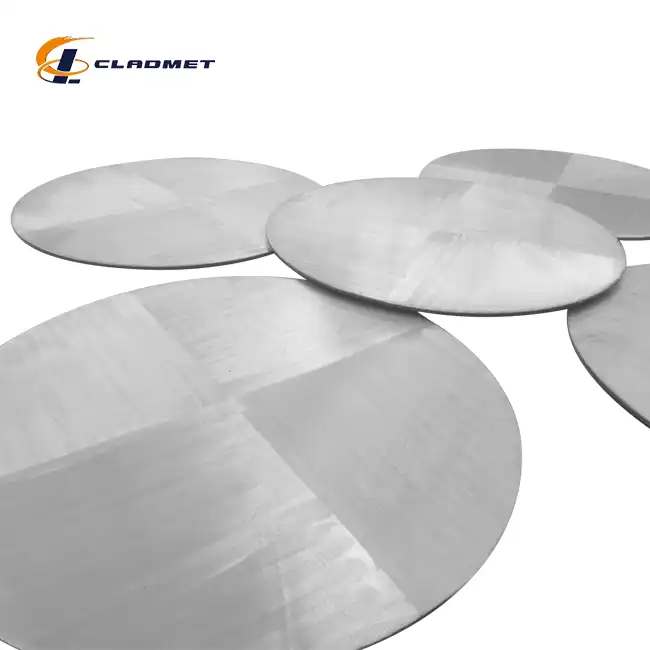

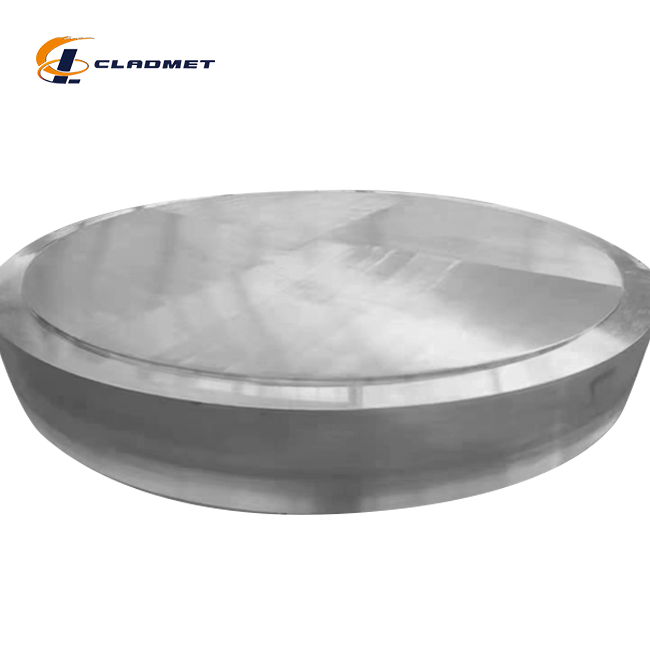

Main Products

Main Application Industries

OEM Service

We provide individualized OEM services to meet the requirements of your project. Our team is ready to work with you to create custom solutions, no matter what your requirements are—unique dimensions, surface finishes, or unique technical requirements. Contact us right away to talk about your bespoke order.

FAQ

1. What is the delivery time for Titanium Carbon Steel Clad Plates?

Our standard delivery cycle is 3-6 months, but we offer negotiable delivery times based on your project needs.

2. Can you provide technical support for product applications?

Yes, our technical team is available to assist with product applications and offer guidance on the best use of our clad plates in your projects.

3. What are the packaging methods for clad plates?

We ensure safe and secure packaging, using wooden pallets or customized solutions depending on the size and quantity of the order.

4. Do you provide samples for testing?

Yes, we offer sample testing for clients before full-scale production to ensure product quality and suitability.

Contact Us

For more information on our Titanium Carbon Steel Clad Plate or to place an order, feel free to contact us:

- Tel: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)