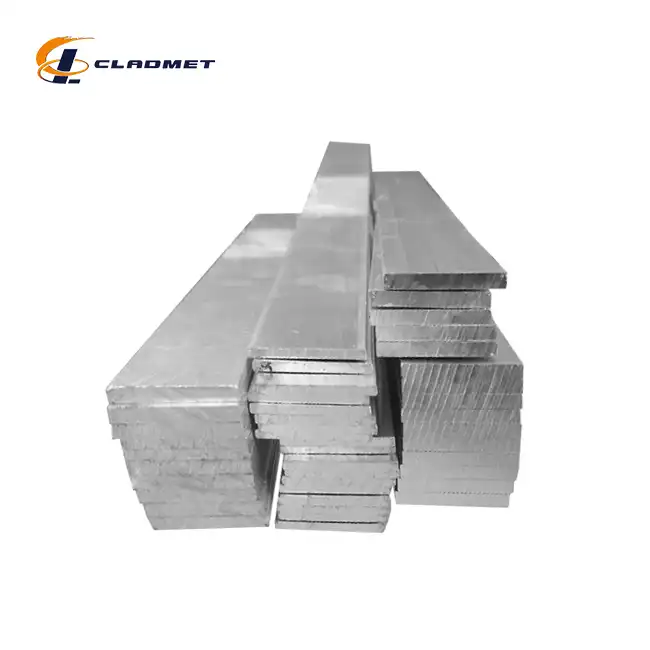

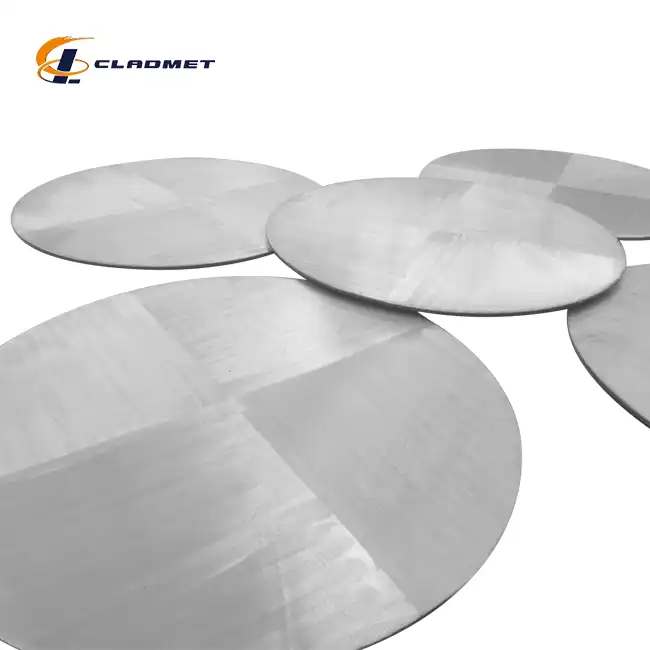

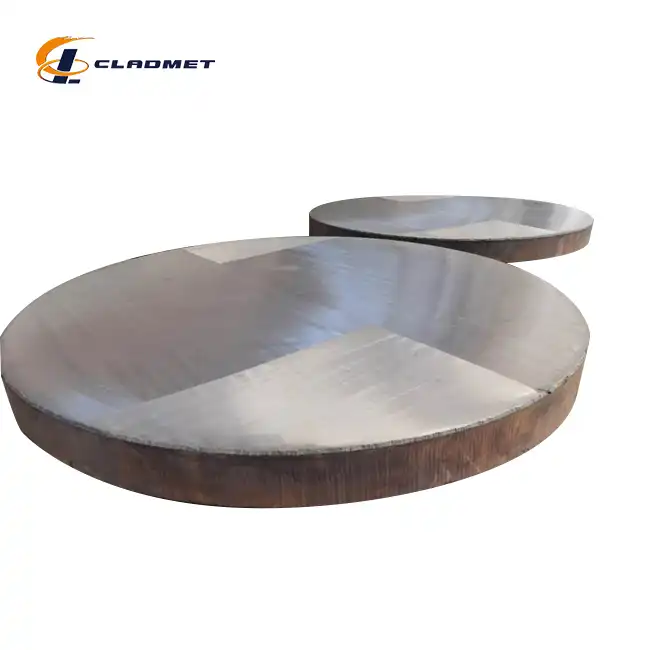

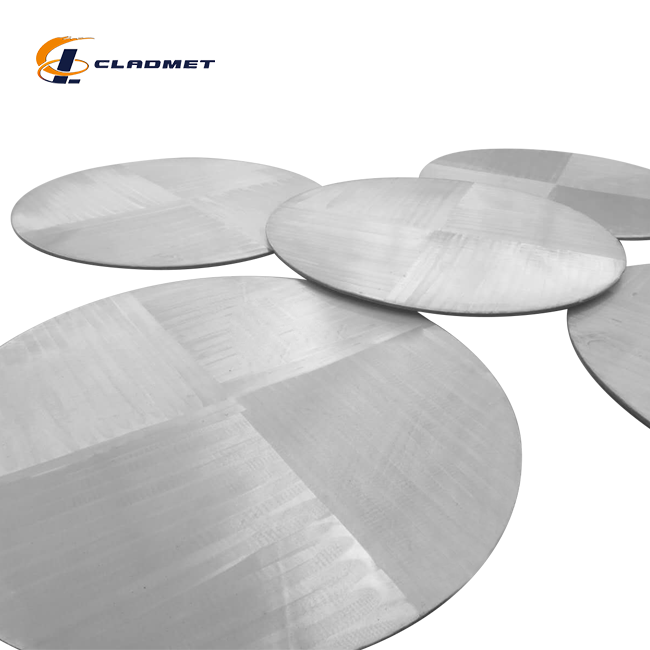

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

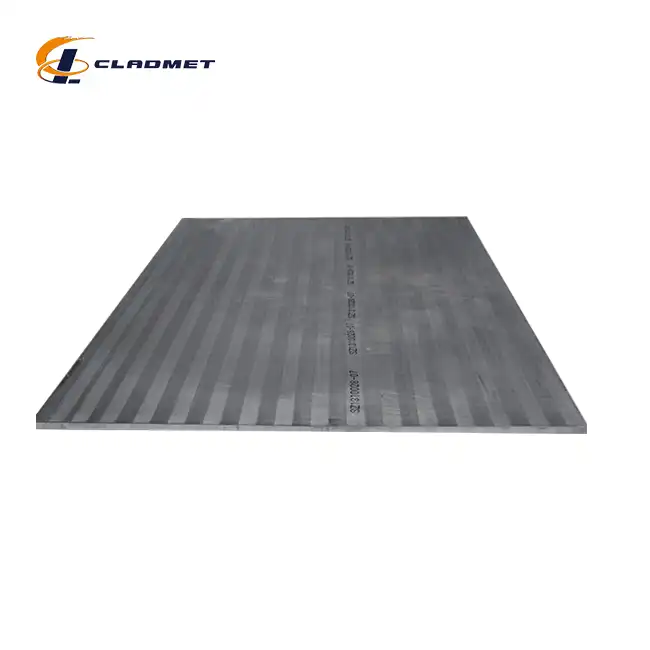

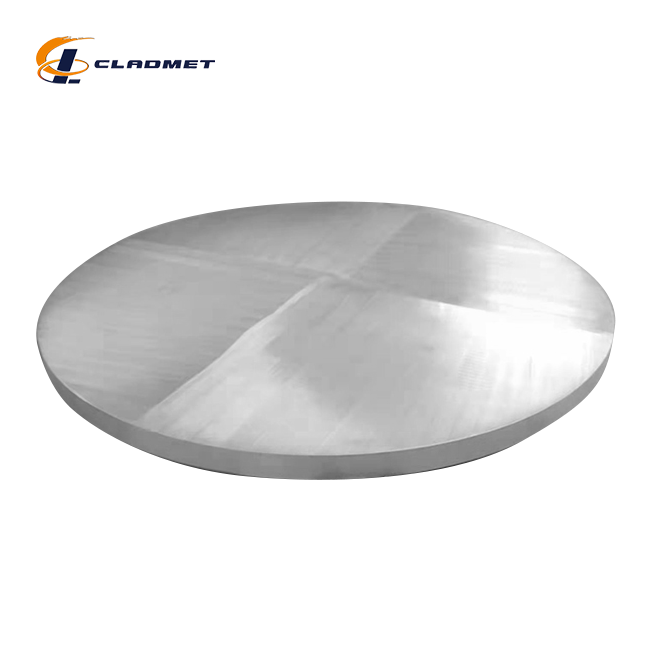

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

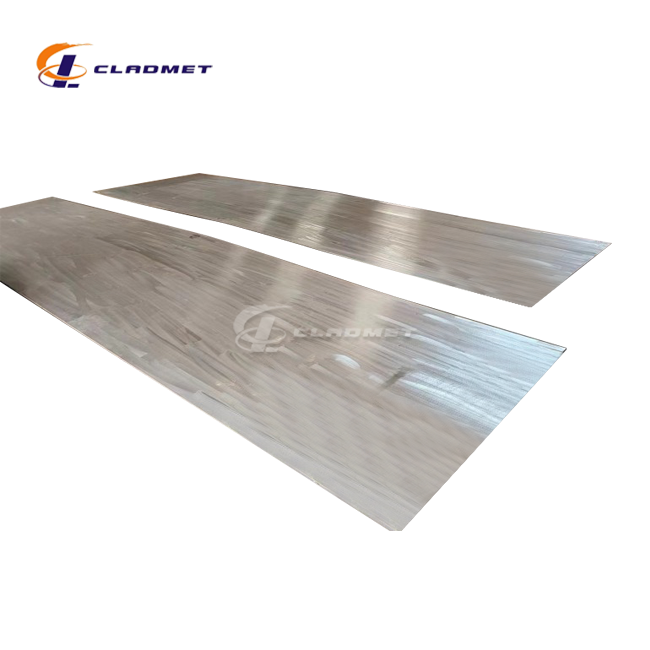

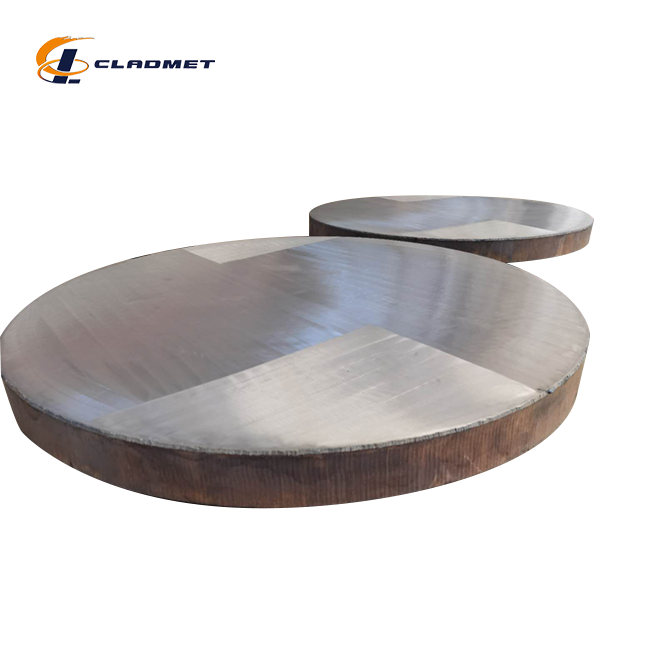

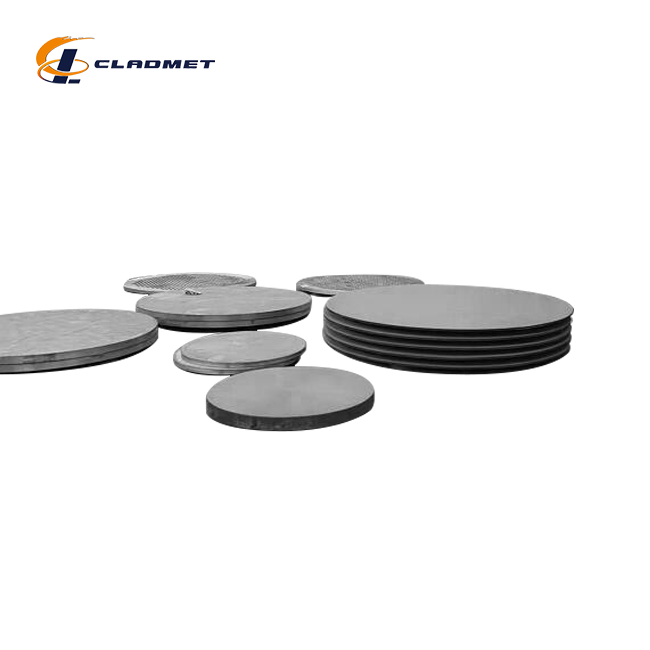

Introduction To Nickel-Stainless Steel Clad Plate

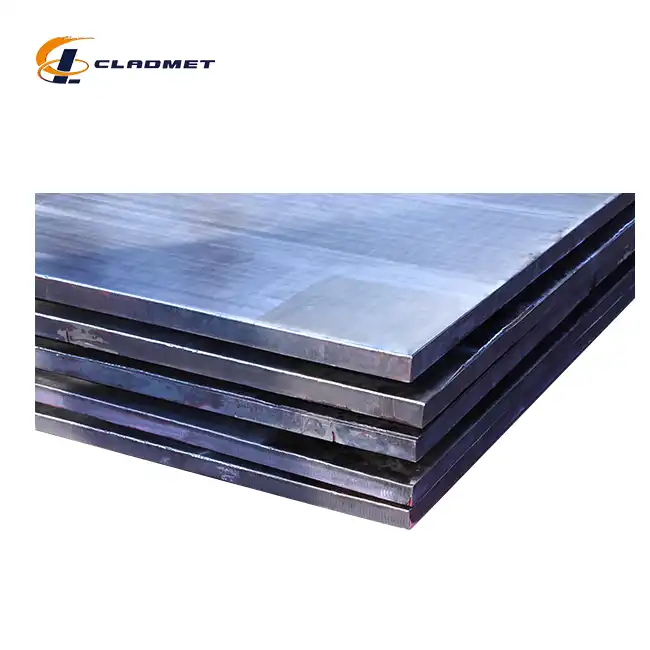

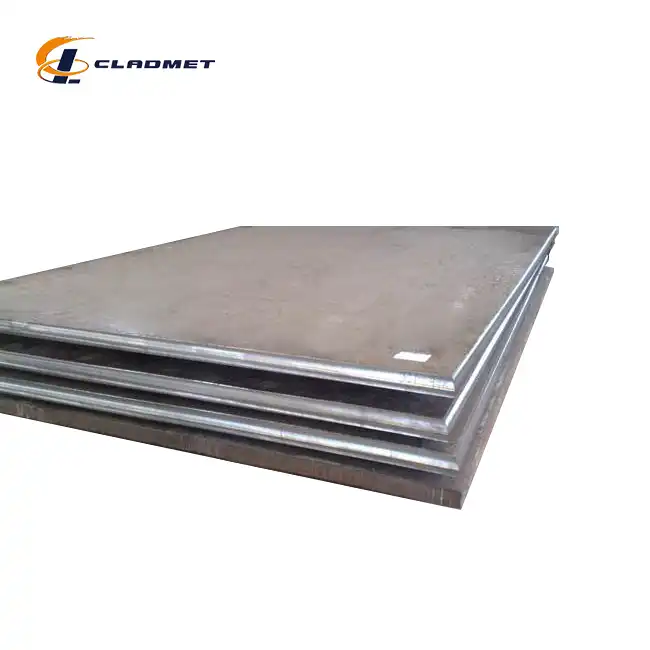

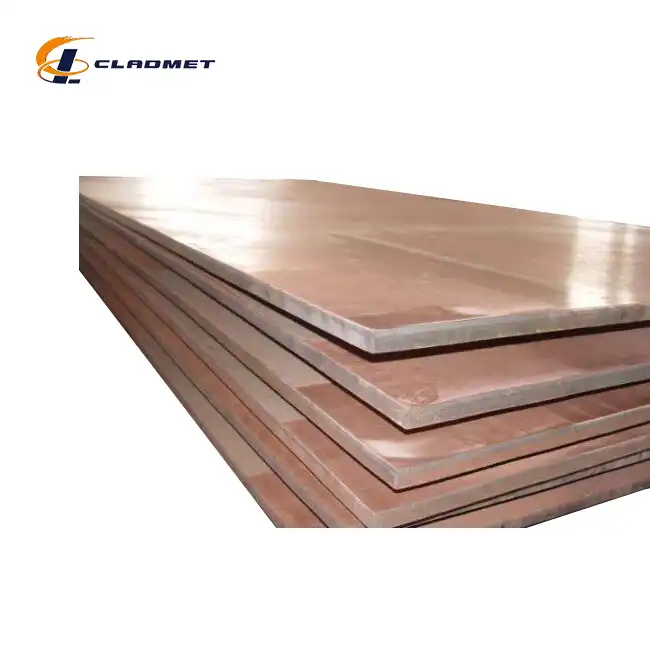

The Nickel-Stainless Steel Clad Plate is an inventive composite material that unites the consumption opposition of nickel with the strength and cost-effectiveness of hardened steel. Utilizing progressed holding advancements like blast holding or roll holding, this plate offers prevalent execution in requesting conditions like substance handling, oil and gas, and power age. It is the best option for industries looking to increase equipment durability and reduce costs associated with maintenance because it is built to withstand high temperatures, pressures, and corrosive conditions.

Product Specifications

| Cladding Material | Nickel 200, Nickel 201, Nickel-based alloys (Inconel 600, C276) |

|---|---|

| Base Material | Stainless Steel (304, 316, 316L, 321) |

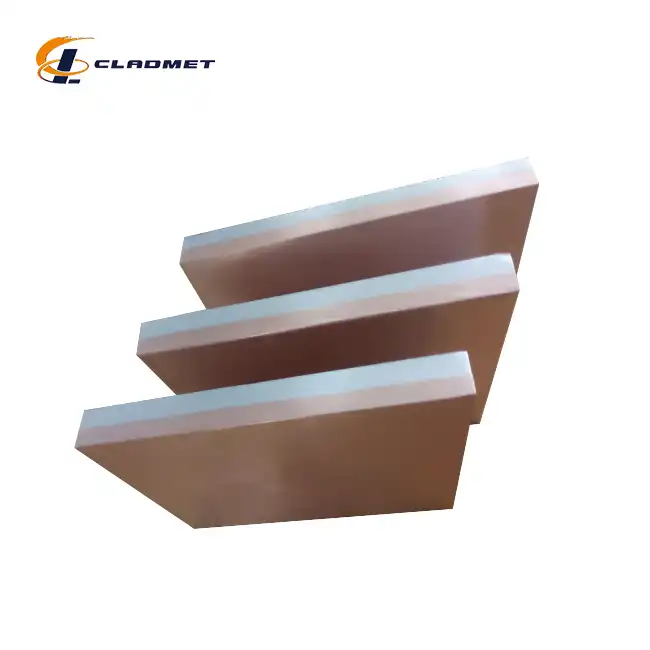

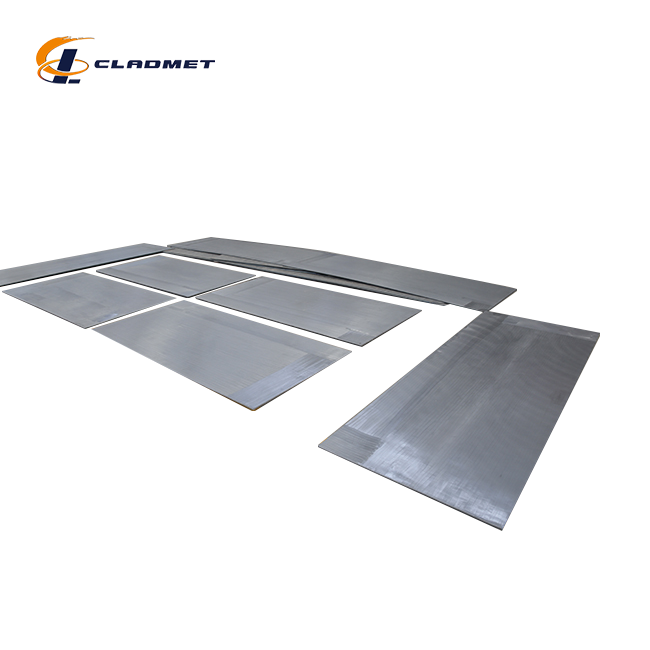

| Cladding Size Range | Thickness: 1-10mm, Length: 1000-12000mm, Width: 500-3000mm |

| Cladding Technology | Explosion bonding, Roll bonding |

| Standards | ASME, ASTM, JIS, GB/GBT |

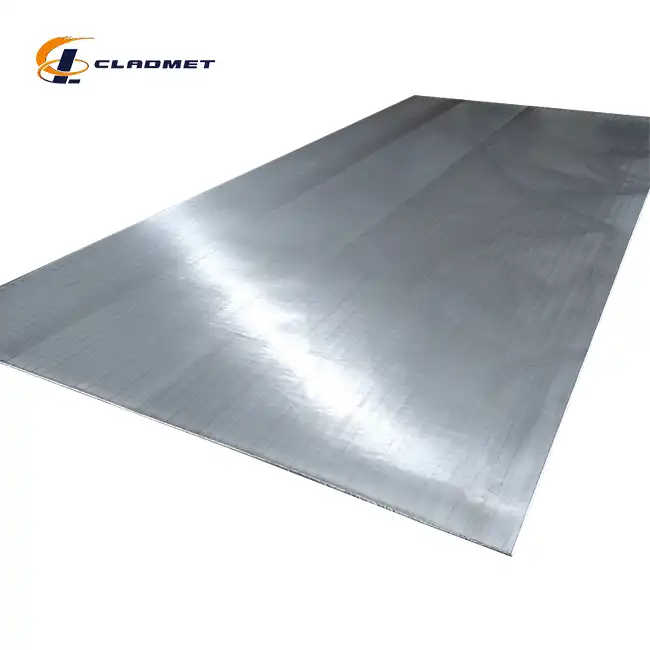

| Surface Treatment | Polished, Sandblasted, Pickled |

| Applications | Chemical industry, Oil & Gas, Power generation, Desalination |

| Packaging Method | Wooden crates, Steel straps, Moisture protection |

| Delivery Cycle | 3-6 months (negotiable based on quantity) |

|

|

|

|

|

|

|

|

Production Methods

The process of fabricating nickel-stainless steel clad plates involves innovative bonding technologies to merge the corrosion resistance and high-temperature stability of nickel with the structural integrity of stainless steel. The primary methods include:

Controlled Impact Bonding via Explosive Welding

This method harnesses the energy from a controlled explosion to join nickel and stainless steel. Key steps include:

Material Cleaning and Alignment: Ensuring the surfaces of nickel and stainless steel are clean and properly aligned.

Explosive Setup: Carefully placing a charge between the two layers to create a controlled impact.

High-Velocity Collision: The explosion forces the materials together at high speed, creating a durable metallurgical bond.

Explosive welding is particularly useful in applications requiring robust bonding, such as chemical reactors and storage vessels.

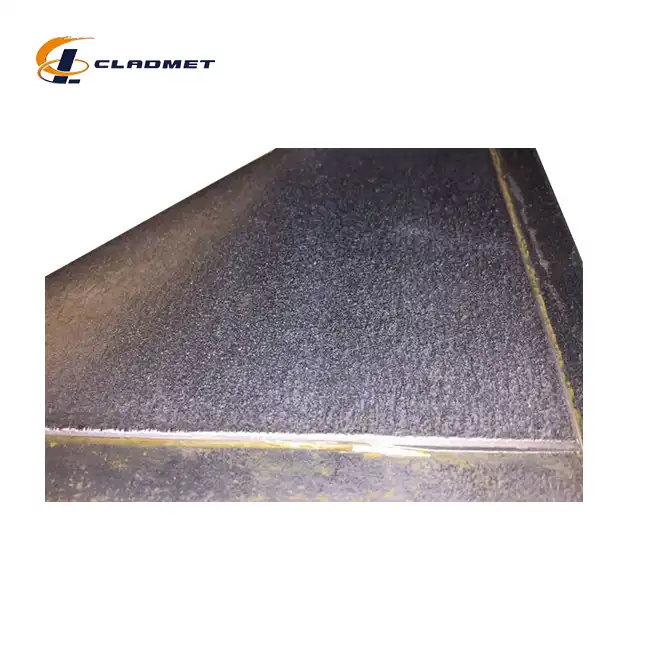

Cold Bonding through Roll Welding

This method involves applying extreme pressure to bond the nickel and stainless steel layers through a rolling process. The steps include:

Surface Preparation: Removing any impurities from the materials to enhance bonding.

Sequential Rolling: Repeatedly passing the layers through rollers under significant pressure to achieve a strong union.

Roll welding is widely employed in producing clad plates for construction, industrial, and energy applications.

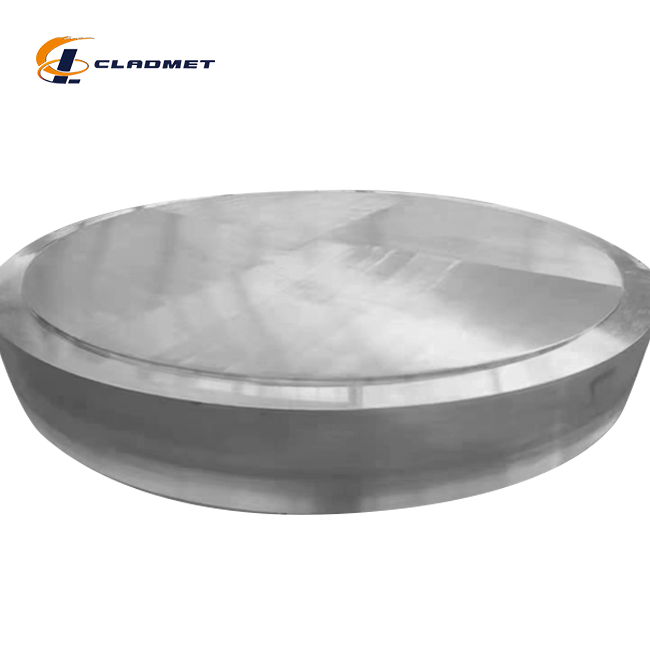

Diffusion Bonding via Hot Isostatic Pressing (HIP)

This technique utilizes a high-temperature and high-pressure environment to bond nickel and stainless steel at the molecular level. The process involves:

Material Encapsulation: Placing the materials in a sealed chamber to prevent contamination.

Heating and Compression: Applying heat and pressure simultaneously to encourage atomic diffusion between the layers.

This method is ideal for components requiring superior structural integrity, such as aerospace and marine applications.

Features and Advantages

Corrosion Resistance: Nickel’s ability to resist chemical and environmental degradation complements the stainless steel's durability, making these plates suitable for harsh environments.

Thermal Stability: These plates maintain excellent performance under high temperatures, ensuring reliable operation in heat-intensive applications.

Mechanical Strength: The stainless steel core provides robust structural support, while the nickel layer enhances performance under stress.

Customizable Dimensions: Available in various sizes and thicknesses to meet diverse industrial needs.

Low Maintenance: The inherent durability of both materials reduces wear and tear, lowering maintenance costs.

Enhanced Longevity: The combination of nickel and stainless steel ensures a longer service life compared to single-material alternatives.

Versatility: The plates are compatible with numerous fabrication processes, including machining, welding, and forming.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer OEM administrations to redo products as indicated by your particular prerequisites. Our skilled team is available to assist you with custom dimensions, surface treatments, or specialized bonding procedures. Contact us to talk about your project, and we'll come up with individual solutions.

FAQ

Q: What is the minimum order quantity?

A: The minimum order quantity depends on the product specifications. Please contact our sales team for detailed information.

Q: Can the clad plates be customized?

A: Yes, we offer customization options for size, thickness, and surface treatments to meet your specific needs.

Q: What is the typical lead time for delivery?

A: The standard delivery cycle is 3-6 months, but this can be negotiated depending on your order volume and urgency.

Q: How are the clad plates packaged?

A: We use secure wooden crates and steel straps, with moisture protection, to ensure safe transportation.

Contact Us

For more information about our Nickel-Stainless Steel Clad Plate or to place an order, please reach out to us:

Phone: +86-917-3372918

WhatsApp: 8613530170059

Email: sales@cladmet.com

Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China 721013

_1737007724117.webp)