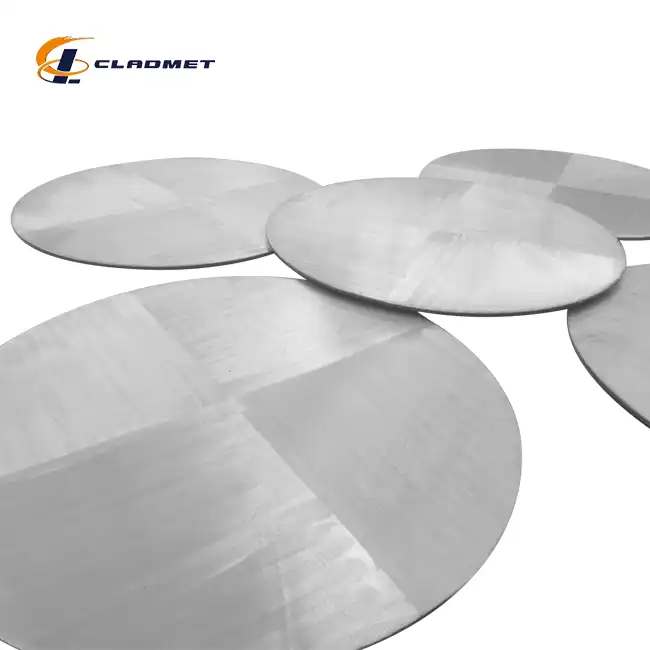

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

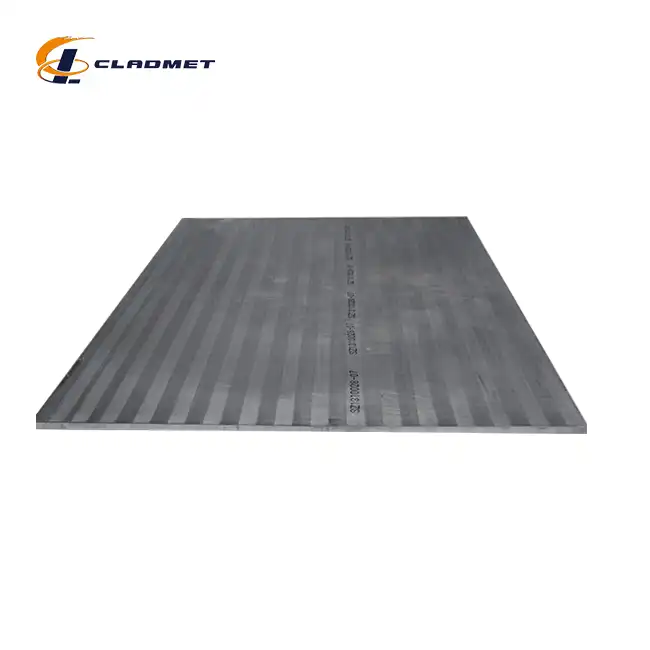

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Product Introduction

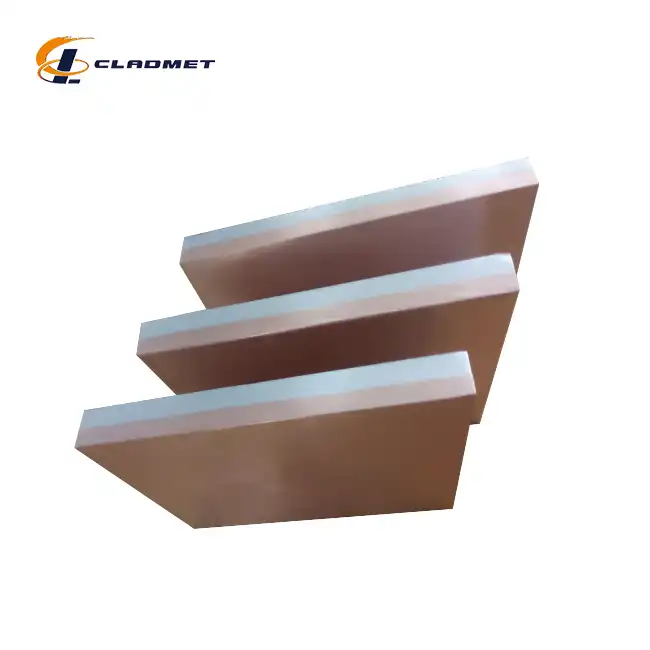

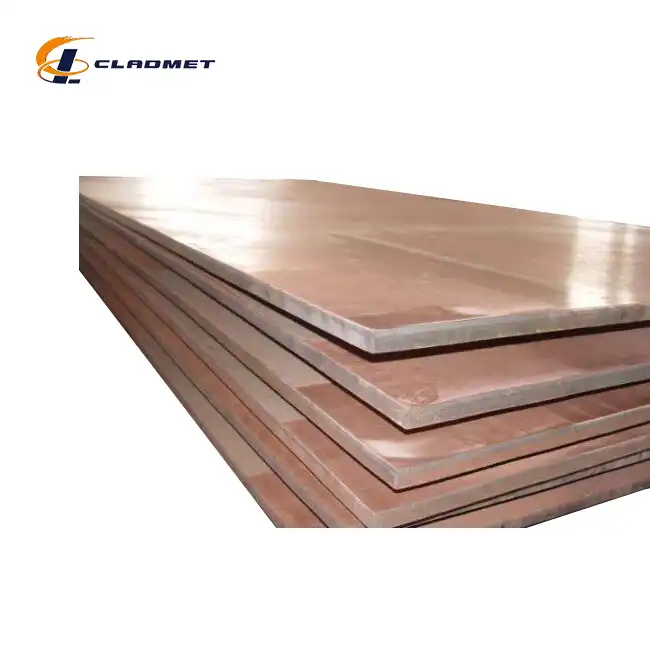

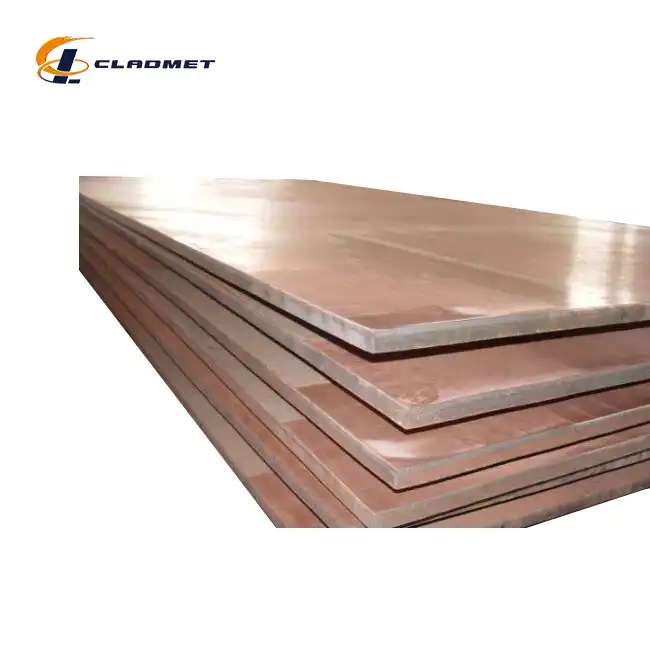

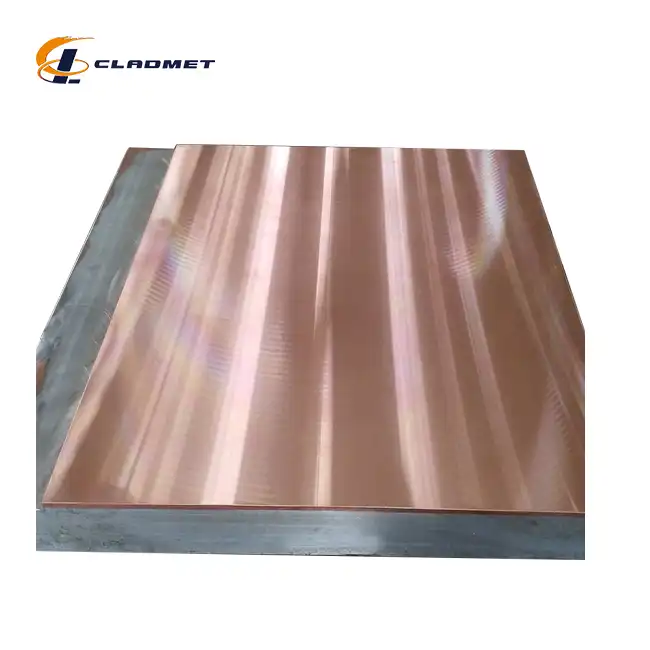

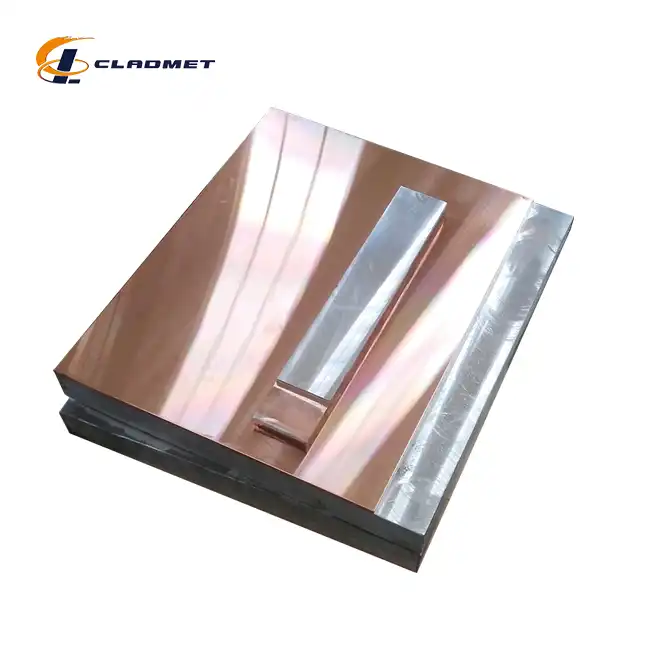

The Copper Clad Steel Plate is a composite material that combines the high conductivity of copper with the strength and durability of steel. This advanced bonding process creates a superior material that offers exceptional strength, corrosion resistance, and cost-effectiveness. Whether used in industrial settings, electrical applications, or construction, the steel plates are versatile and reliable solutions. Baoji JL Clad Metals Materials Co., Ltd. has over 20 years of experience in manufacturing high-quality clad metals, ensuring top-tier products that meet international standards like GB/GBT, ASME/ASTM, and JIS.

Product Specifications

| Parameter | Details |

|---|---|

| Cladding Material | Pure Copper, Copper Alloys |

| Base Metal | Carbon Steel, Stainless Steel |

| Cladding Size | Customizable as per project requirements |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Thickness (mm) | 2-200 |

| Length (mm) | Up to 12,000 |

| Width (mm) | Up to 3,000 |

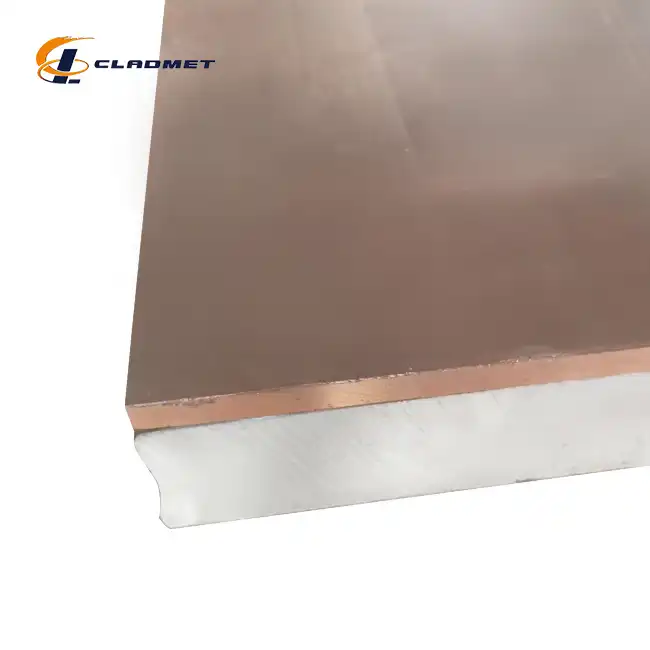

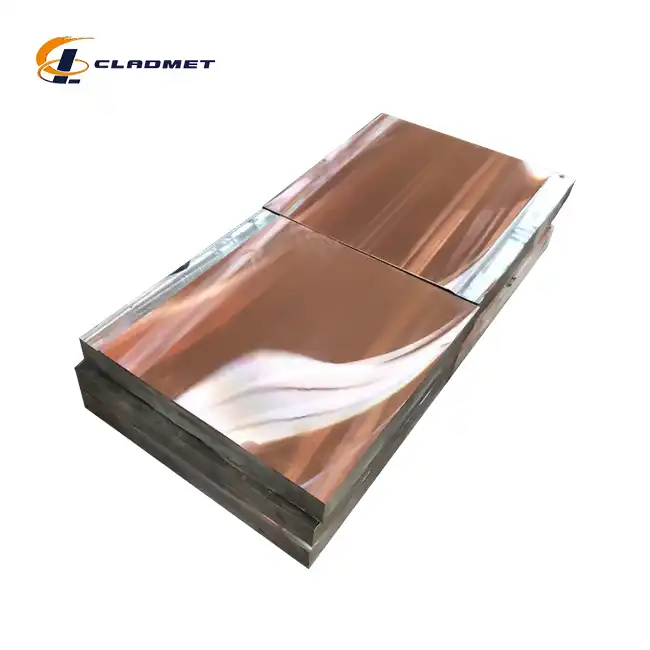

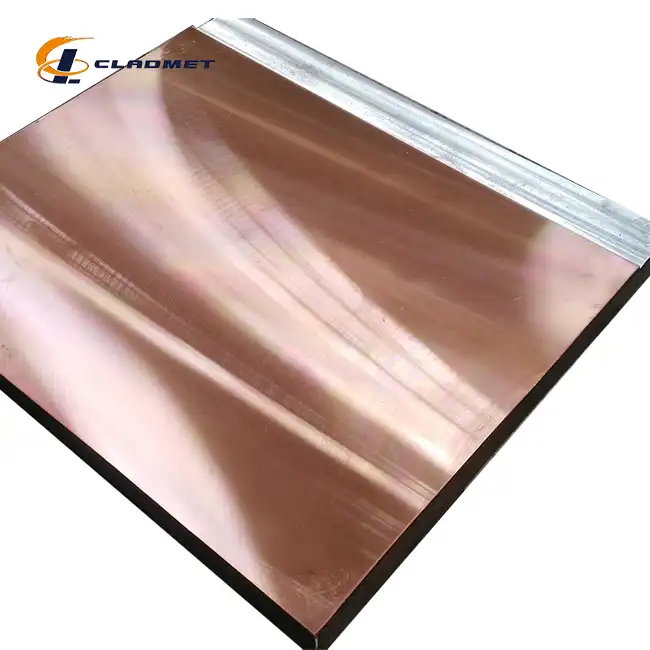

| Surface Treatment | Polished, Anti-Corrosion Coating, etc. |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Delivery Cycle | 3-6 months or negotiable |

| Packaging | Custom packaging to ensure safe transport |

| Application Industries | Oil & Gas, Electrical, Construction, etc. |

|

|

|

|

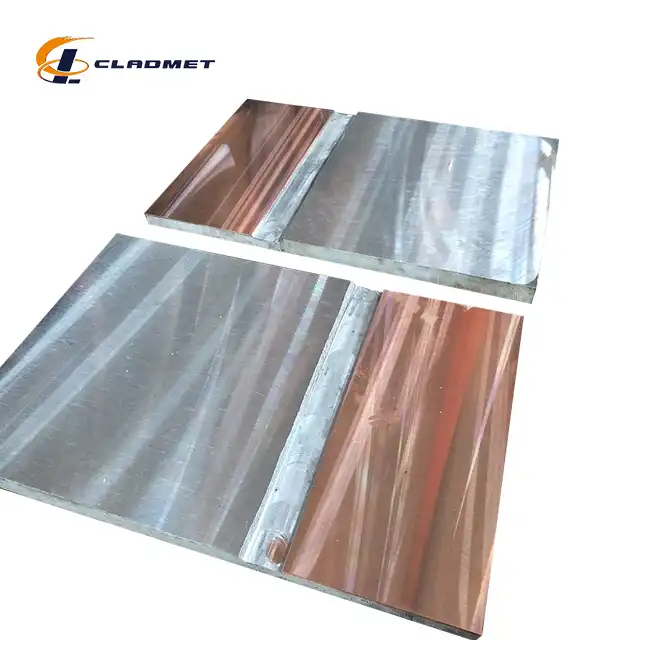

Copper Cladding Process

Copper-clad steel plates are manufactured by bonding a layer of copper to a steel base material, combining the beneficial properties of both metals. This cladding process enhances the mechanical performance and durability of steel, providing excellent corrosion resistance, electrical conductivity, and thermal properties. Several techniques are commonly used to create these high-performance composite materials.

Explosion Welding

Explosion welding is a technique that uses a controlled explosive charge to generate a high-energy impact, forcing the copper layer to bond with the steel. The result is a strong, permanent metallurgical bond between the materials.

Preparation: Both the steel and copper surfaces are carefully cleaned and positioned before the explosive charge is applied.

Explosion Initiation: The explosive material between the two layers is detonated, creating a high-speed collision that fuses the materials together.

Bond Formation: The force of the explosion causes the copper and steel to bond metallurgically, forming a robust and durable connection.

This method is particularly effective when high bond strength is necessary, such as in the construction of heat exchangers, pressure vessels, and electrical components that demand a high degree of durability and electrical conductivity.

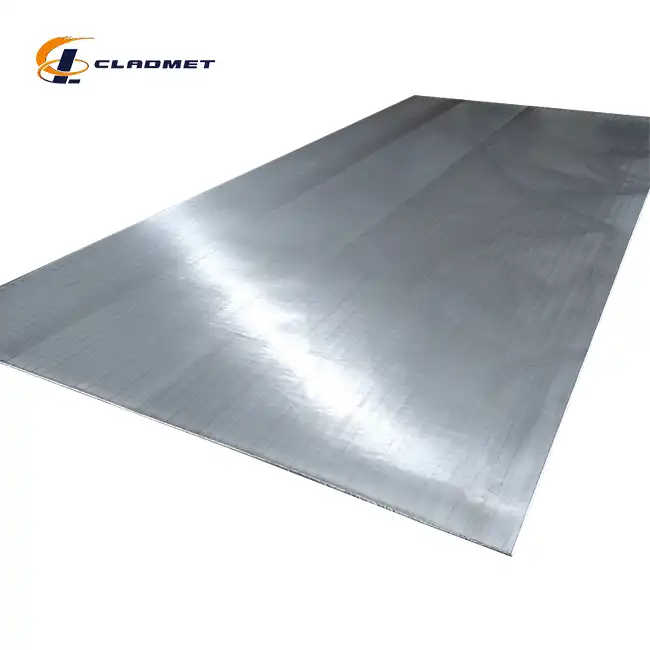

Roll Bonding

Roll bonding is a cold-welding technique where the steel and copper layers are passed through rollers under intense pressure. The high pressure causes the materials to fuse together without any need for heat or chemicals.

Surface Preparation: Both layers are thoroughly cleaned and pre-treated to ensure a clean, smooth bonding surface.

Rolling Process: The materials are passed through rollers under high pressure, causing the layers to bond together through deformation.

Multiple Passes: The process may require multiple passes to achieve a fully bonded composite material, ensuring uniformity and consistency in the bond.

Roll bonding is ideal for producing copper-clad steel plates for use in applications requiring high strength and resistance to wear and corrosion, such as electrical and electronic industries.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing involves encapsulating the copper and steel layers within a sealed container and then subjecting them to both high pressure and temperature in a controlled environment. This technique facilitates the diffusion bonding between the copper and steel on an atomic level.

Encapsulation: The two layers are arranged within a sealed chamber, ensuring intimate contact.

Heating and Pressurization: The sealed chamber is subjected to both high heat and pressure, encouraging atomic diffusion and resulting in a robust bond.

Diffusion Bonding: The process creates a uniform, high-quality bond between the copper and steel layers, which is highly durable and resistant to environmental stresses.

HIP is frequently used in industries that require high-performance materials, such as aerospace and high-tech manufacturing, where both strength and material integrity are crucial.

Features and Advantages

Enhanced Corrosion Resistance

The copper layer provides excellent resistance to corrosion, especially in environments that are prone to rust or exposure to harsh chemicals. Copper-clad steel plates are ideal for use in environments such as marine settings or chemical processing facilities.

Improved Electrical and Thermal Conductivity

Copper is an excellent conductor of both electricity and heat, which makes copper-clad steel plates highly effective in applications that require the transfer of heat or electricity. This makes them particularly beneficial for electrical components, heat exchangers, and cooling systems.

High Strength-to-Weight Ratio

Copper-clad steel plates combine the strength and durability of steel with the conductivity and corrosion resistance of copper, while maintaining a relatively low weight compared to other materials. This balance of properties makes them ideal for applications in the electronics, power generation, and transport industries.

Durability and Longevity

The bonding process enhances the longevity of copper-clad steel plates, making them resistant to wear and tear while providing a protective barrier against corrosion. This ensures that the equipment and structures made with these plates will have a longer lifespan, reducing replacement costs and downtime.

Cost-Effective Manufacturing

Copper-clad steel plates provide a cost-effective alternative to fully copper or fully steel materials. By combining the two metals, manufacturers can take advantage of copper’s properties at a fraction of the cost, while still retaining the necessary structural integrity of steel.

Customization and Versatility

Copper-clad steel plates can be customized to meet the specific needs of various industries. The thickness of the copper layer, the type of steel used as the base material, and the surface treatments can all be tailored to suit different applications, offering versatility in terms of size, strength, and other characteristics.

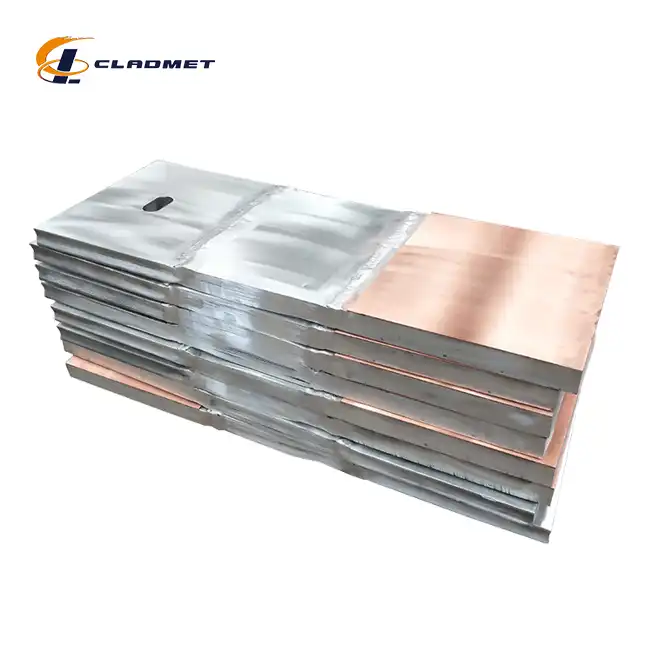

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

Baoji JL Clad Metals Materials Co., Ltd. offers customized manufacturing solutions to meet the specific needs of each client. We provide tailored dimensions, thicknesses, and finishes, ensuring that our steel plates are designed for your particular applications. Our technical team is available to offer guidance throughout the design and manufacturing process, ensuring optimal product performance.

FAQs

-

What is the delivery time for the steel plates?

Our typical delivery cycle is between 3 to 6 months, but it can be negotiated depending on the order volume and project requirements. -

How durable are the steel plates in harsh environments?

Thanks to the combination of copper and steel, our plates offer excellent durability and corrosion resistance, making them suitable for challenging environments such as chemical plants and marine applications. -

Can I order custom-sized plates?

Yes, we offer fully customizable options to meet the unique specifications of your project.

Contact Us

For more information or to place an order for Copper Clad Steel Plates, please reach out to us:

- Tel: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

By choosing Baoji JL Clad Metals Materials Co., Ltd., you're ensuring high-quality products, timely delivery, and expert technical support. Reach out today for more details or custom solutions tailored to your industrial needs!

_1737007724117.webp)