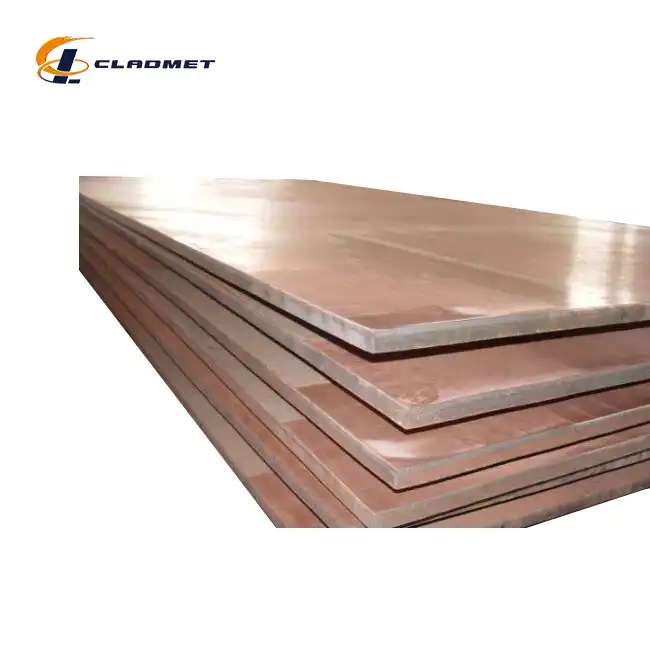

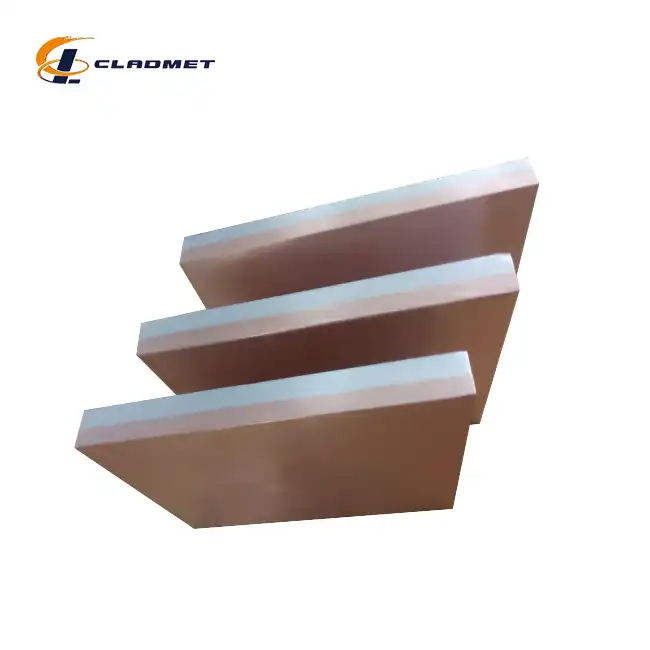

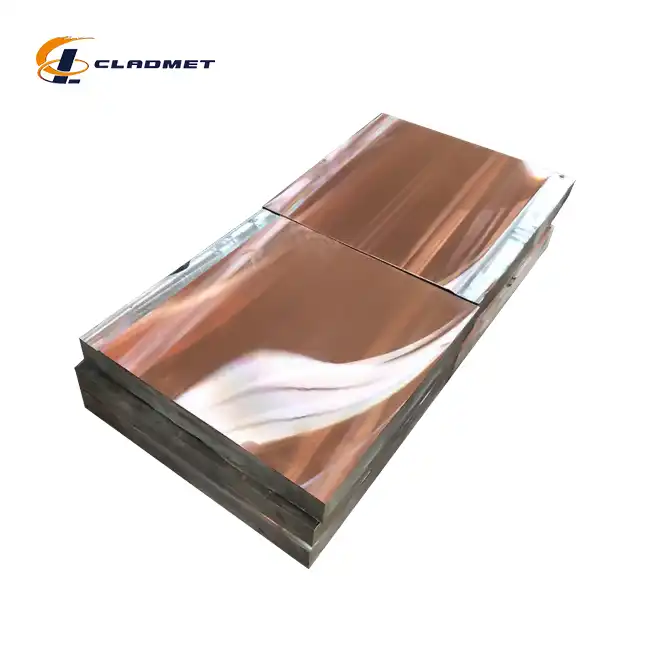

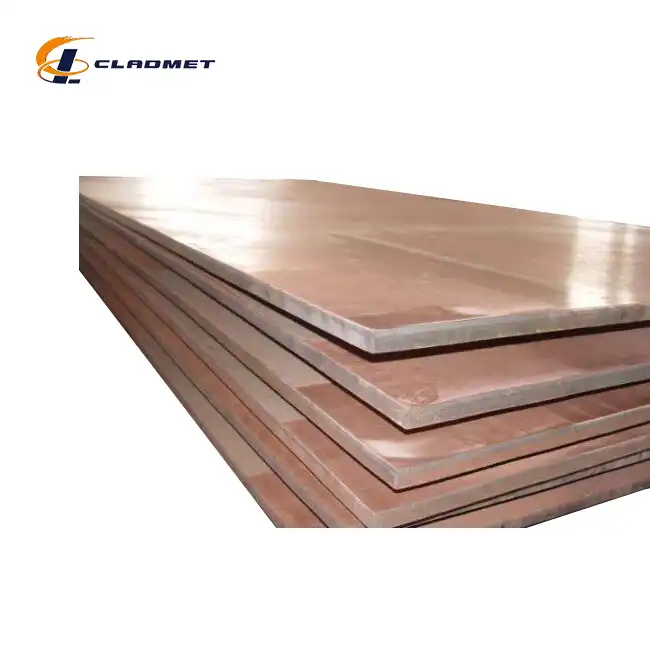

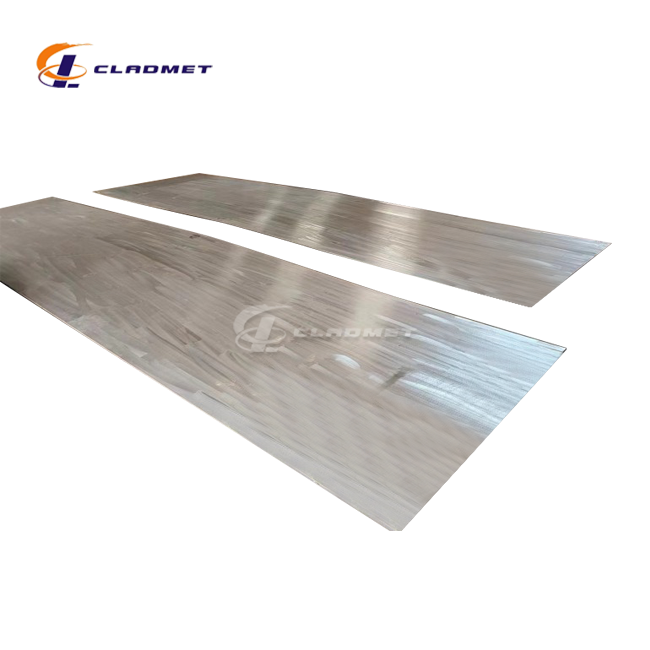

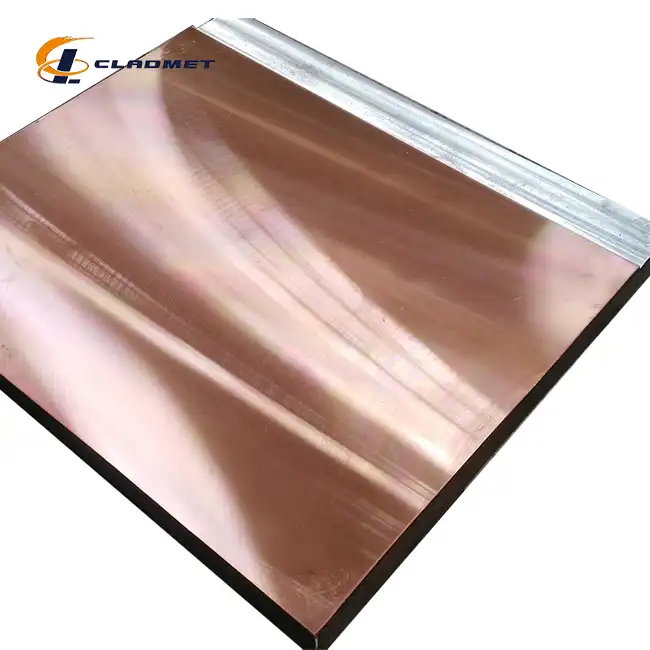

Copper stainless steel clad plate

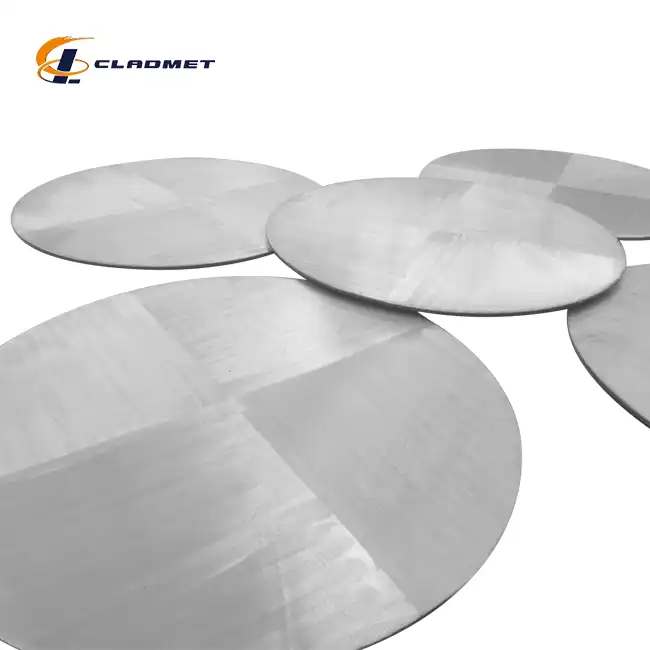

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

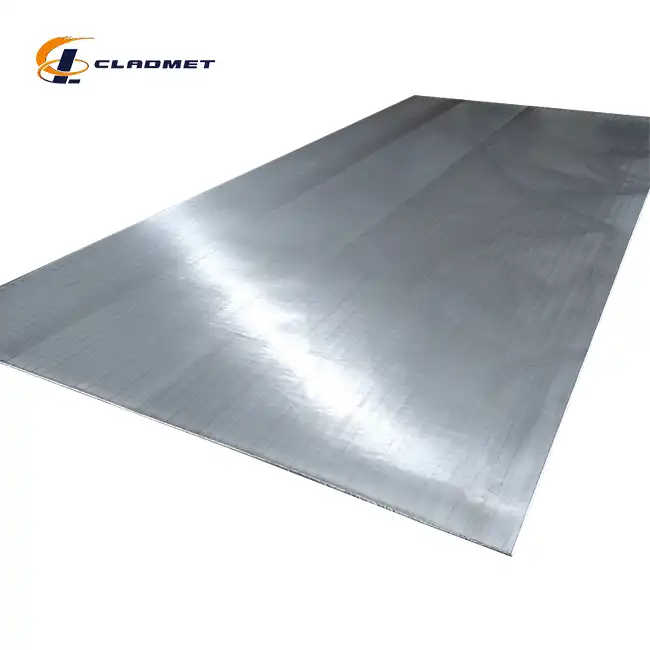

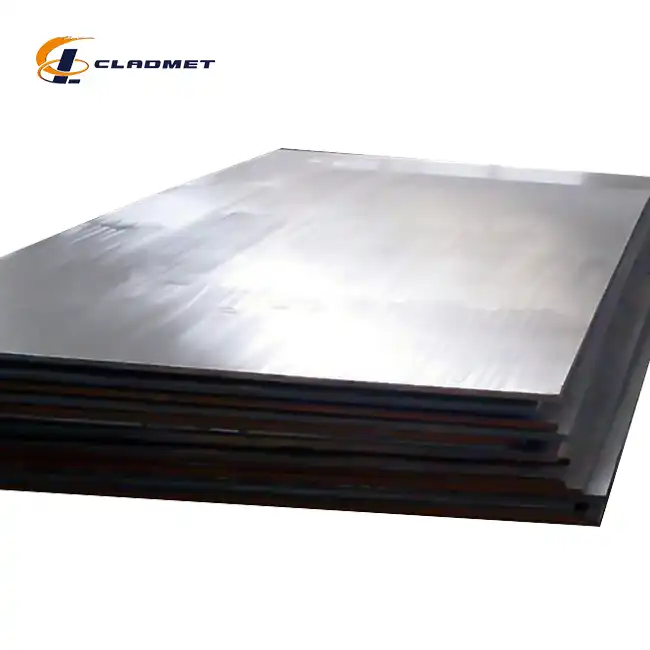

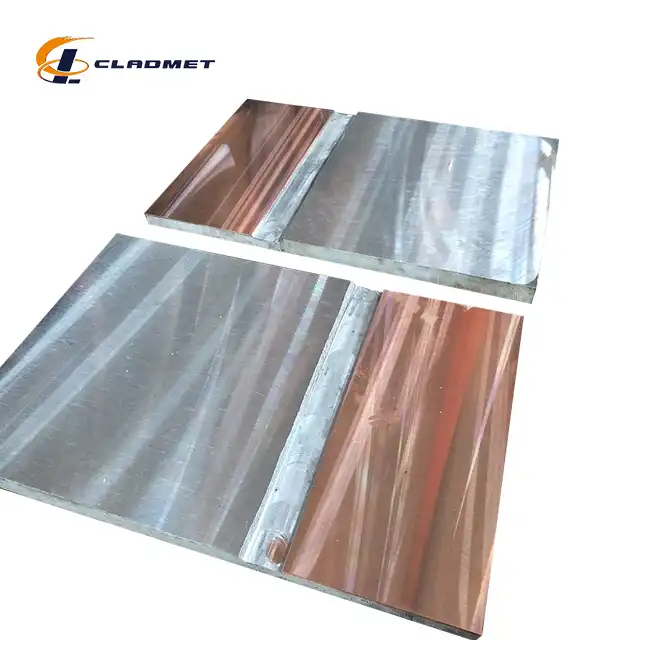

Introduction To Copper Stainless Steel Clad Plate

The Copper Stainless Steel Clad Plate is an elite exhibition, complex composite material that joins the incredible warm conductivity and erosion obstruction of copper with the toughness and strength of treated steel. This one-of-a-kind combination of metals is made for heavy-duty industrial applications where strength and resistance to harsh conditions are crucial. It has superior mechanical properties. Industries like energy, electronics, and chemical processing all depend on the product for reliable material performance.

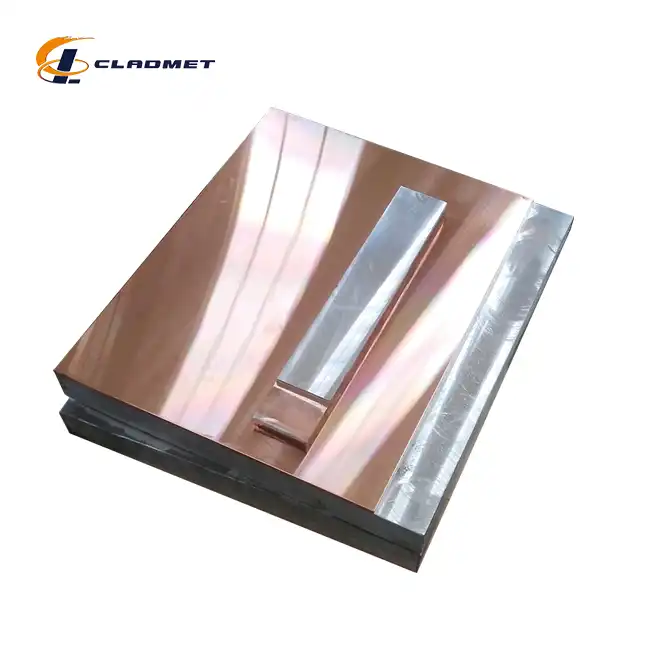

Product Specifications

| Specification | Details |

|---|---|

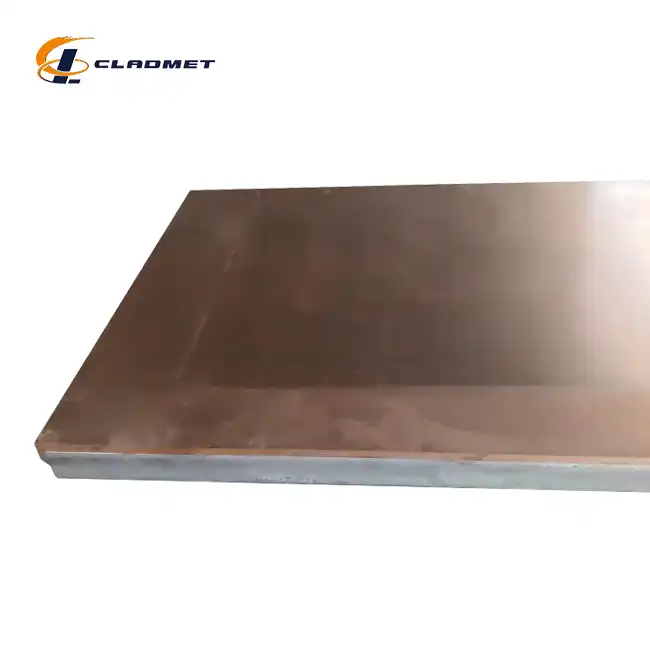

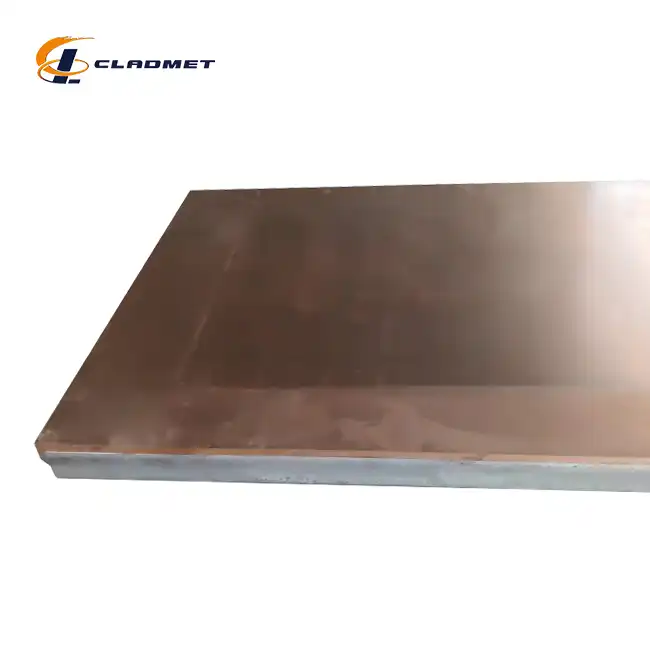

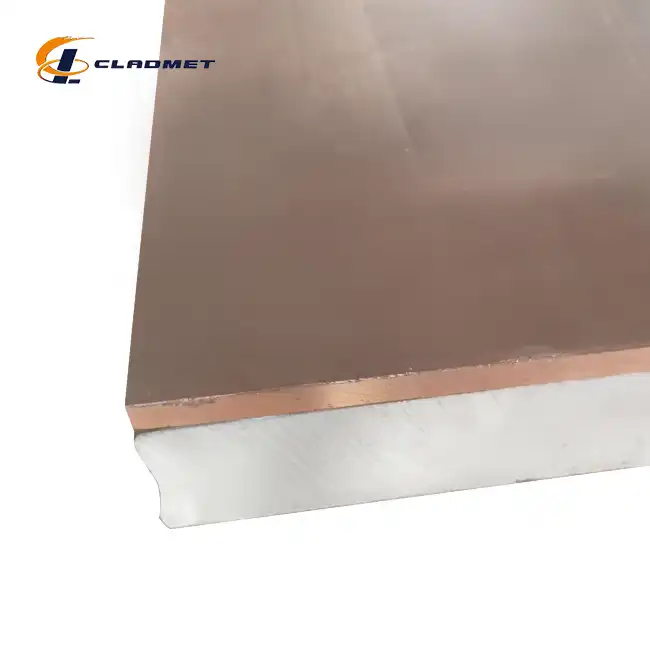

| Cladding Material | Copper (99.9% purity) |

| Base Metal | Stainless Steel (AISI 304, AISI 316, etc.) |

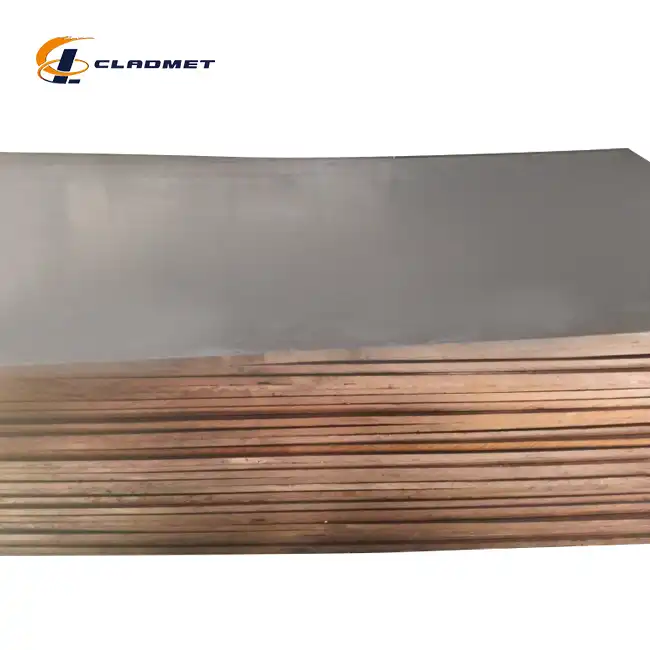

| Cladding Thickness | 2-20 mm |

| Base Metal Thickness | 5-50 mm |

| Overall Length | 1000-3000 mm |

| Overall Width | 1000-2000 mm |

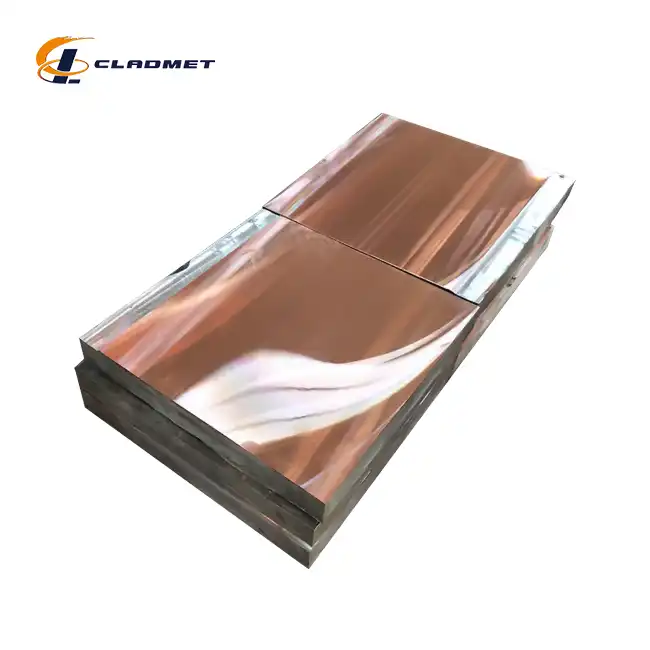

| Cladding Technology | Explosive Bonding, Roll Bonding |

| Standards | GB/GBT, ASME/ASTM, JIS |

| Surface Treatment | Polished, Brushed, Mill Finish |

| Packaging | Wooden pallets, protective film for surface protection |

| Delivery Cycle | 3-6 months (or negotiable depending on order size) |

|

|

|

|

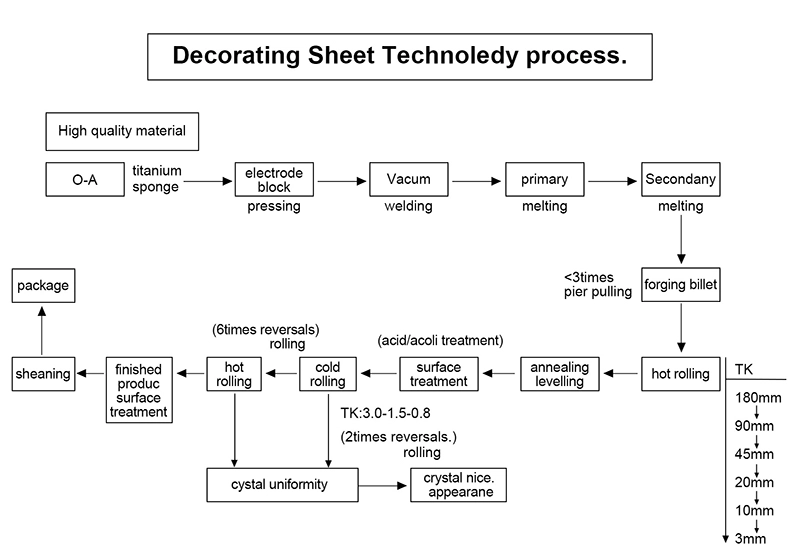

Advanced Manufacturing Techniques

The production of copper-stainless steel clad plates involves state-of-the-art technologies to combine the excellent conductivity of copper with the corrosion resistance and mechanical strength of stainless steel. The principal methods are:

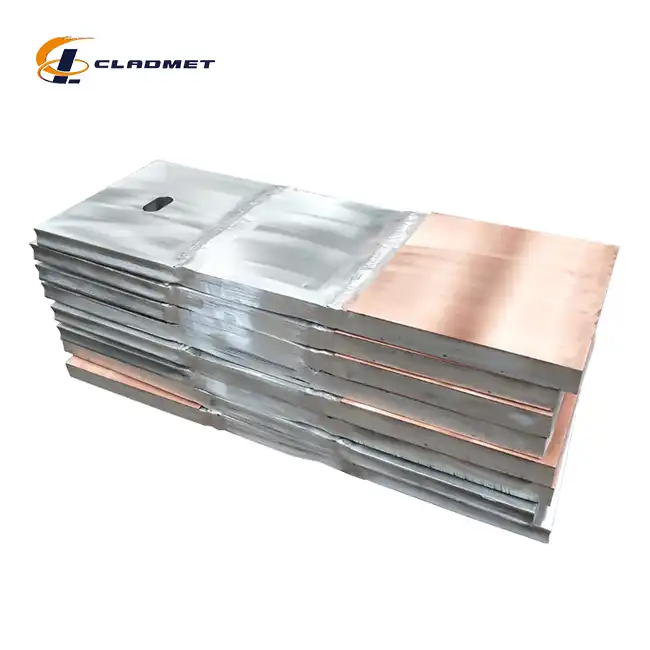

Dynamic Impact Welding

This process utilizes explosive energy to join copper and stainless steel layers through a strong metallurgical bond. The key steps are:

Surface Treatment and Alignment: Ensuring both materials are clean and properly arranged to facilitate effective bonding.

Explosive Activation: Strategically placing and detonating a controlled explosive charge between the layers.

High-Energy Collision: The explosive force drives the materials together, creating a durable bond at the interface.

Dynamic impact welding is widely employed in applications demanding high bond strength and reliability, such as electrical equipment and heat exchangers.

Cold Rolling and Pressure Welding

In this method, copper and stainless steel layers are joined by applying significant pressure during a rolling process. The procedure includes:

Preparation of Surfaces: Both layers are cleaned to remove impurities, ensuring better adhesion.

Sequential Rolling: Passing the materials through high-pressure rollers repeatedly to achieve a uniform and seamless bond.

Cold rolling is commonly used for producing clad plates with precise thickness and smooth finishes, ideal for industrial and architectural uses.

Hot Diffusion Welding via Isostatic Pressing

This technique applies heat and pressure in a controlled environment to achieve a molecular-level bond. The steps include:

Encapsulation: The copper and stainless steel layers are sealed to prevent contamination during processing.

Heat and Pressure Application: The materials are subjected to high temperatures and uniform pressure, leading to atomic diffusion at the interface.

Hot isostatic pressing is especially effective for critical applications where the bond's integrity must withstand extreme conditions, such as in power plants or marine equipment.

Features and Advantages

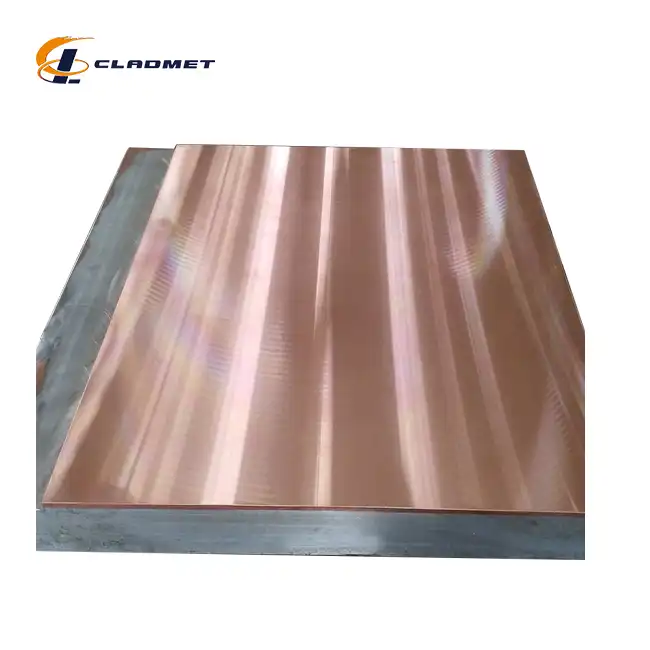

Exceptional Corrosion Resistance: Stainless steel protects the copper core from chemical and environmental degradation, extending the lifespan of the clad plate.

Superior Electrical Conductivity: The copper layer ensures excellent conductivity, critical for electrical systems and thermal applications.

Enhanced Structural Strength: Stainless steel provides rigidity and durability, enabling the clad plate to perform well under stress.

Thermal Stability: The materials maintain their properties in high-temperature environments, ensuring reliability.

Customizability: The dimensions, thickness, and finish of the clad plates can be tailored to meet specific project requirements.

Economic Efficiency: Combining copper and stainless steel reduces material costs compared to using pure copper while maintaining high performance.

Eco-Friendly: These clad plates contribute to sustainability by reducing the need for single-use materials and enabling recycling at the end of their lifecycle.

Explosive composite plate production site

Explosion welding process

|

|

Our Factory

Production Site

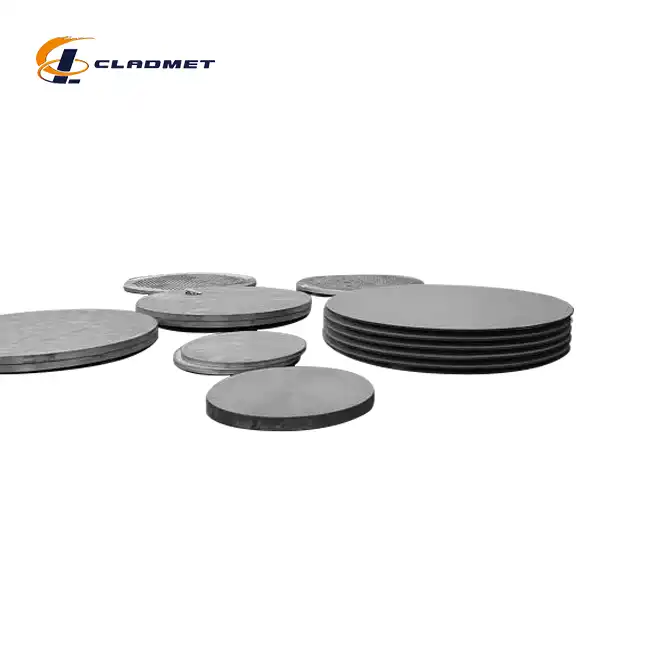

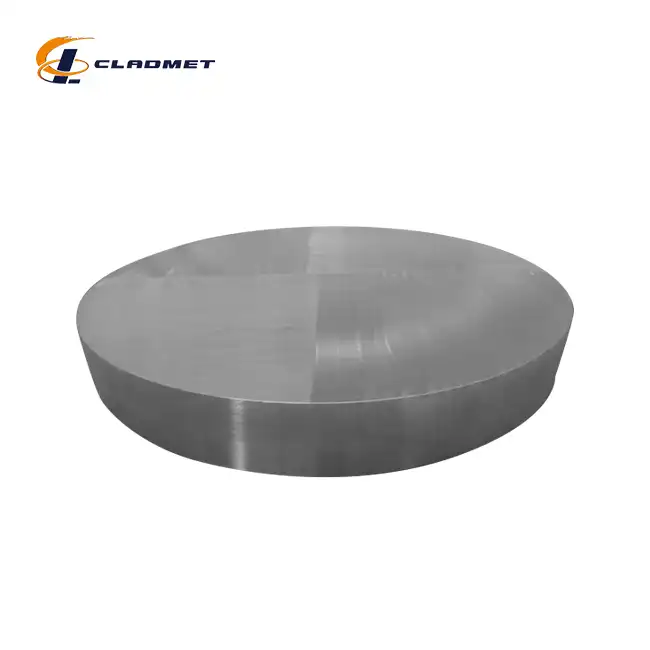

Main Products

Application Industries

Due to their distinctive properties and advantages, titanium clad plates are utilized extensively in a variety of industries. The following are some key application regions:

Oil and Gas: The products are highly valued in the oil and gas industry due to their exceptional resistance to corrosion, particularly in harsh offshore environments and refineries. These plates are able to withstand aggressive media and high pressure, thereby extending the equipment's lifespan and lowering the cost of maintenance.

Synthetic Handling: The products are advantageous to the chemical processing industry because they are ideal for use in processing plants where corrosive chemicals are frequently encountered. Because of their chemical inertness, they do not react with the substances being processed, preserving the production process's integrity.

Aerospace: The products are an excellent choice for high-performance aerospace components because the aerospace industry requires materials that are both lightweight and strong. In addition to offering resistance to environmental factors like extreme temperatures and corrosion, their favorable strength-to-weight ratio contributes to fuel efficiency and overall aircraft design performance.

Drug Industry: The products are utilized in equipment that must meet stringent standards in the pharmaceutical industry, where cleanliness and hygiene are of the utmost importance. Their protection from consumption guarantees that they don't sully delicate cycles, making them reasonable for different applications, including capacity tanks, channeling frameworks, and handling hardware.

Marine Technology: The marine designing field benefits from the products because of their capacity to oppose erosion in seawater and other marine conditions. Ships, offshore platforms, and other marine structures are built with these plates, which ensure long-term durability even in the harshest environments.

OEM Service

To meet specific customer requirements, we provide complete OEM services. Our team will collaborate with you to deliver products that meet your exact specifications, whether you require custom dimensions, surface treatments, or packaging options.

FAQs

-

What is the minimum order quantity (MOQ)?

- The MOQ varies depending on the product specification, but it is typically 1 ton per order.

-

How long is the delivery time?

- Standard delivery time is 3-6 months, but it may be adjusted based on the order volume.

-

Can you provide custom sizes?

- Yes, we offer fully customizable sizes to suit your project’s needs.

-

Do you provide technical support?

- Absolutely. Our technical team is available to assist you with any product-related queries or application challenges.

Contact Us

For more information or to request a quote, please contact us:

- WhatsApp: +8615353335118

- Email: stephanie@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)