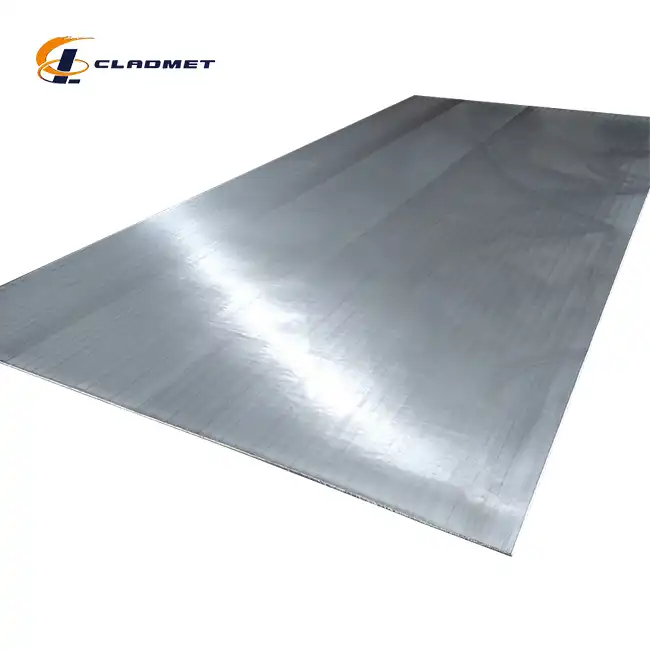

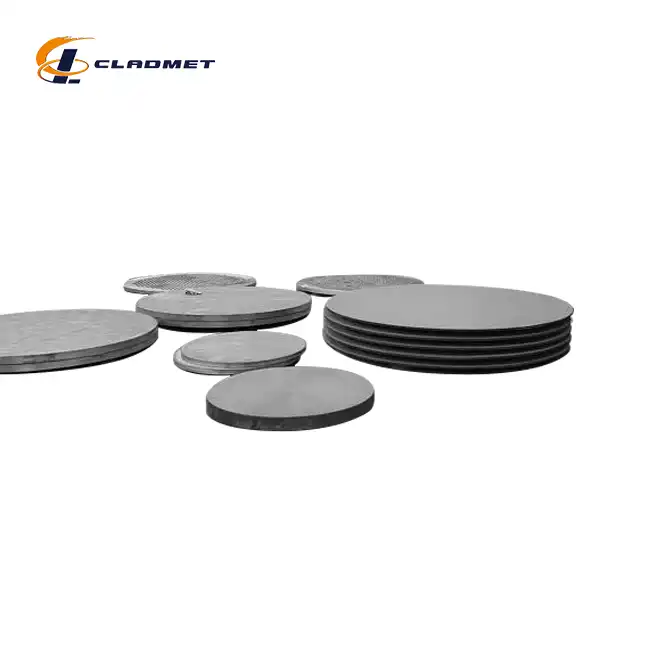

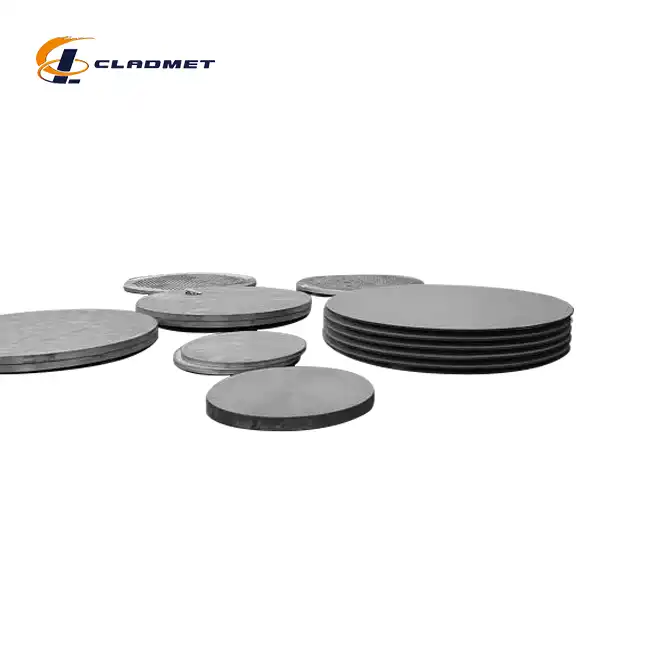

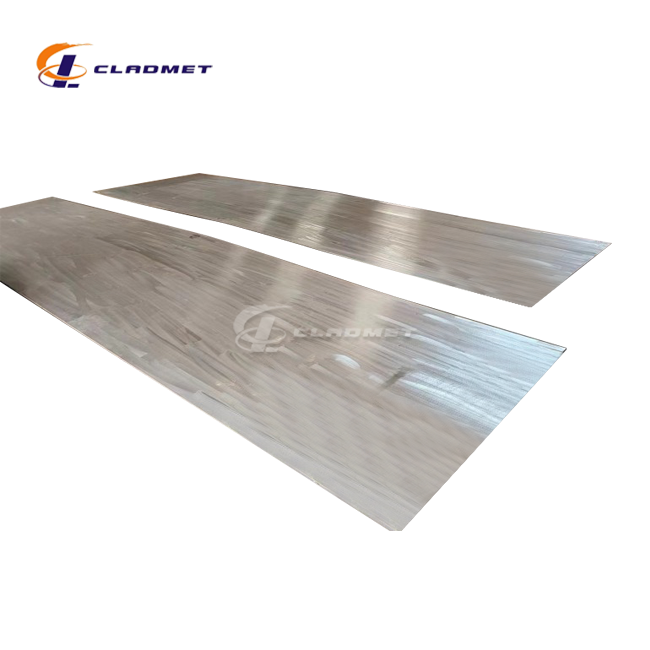

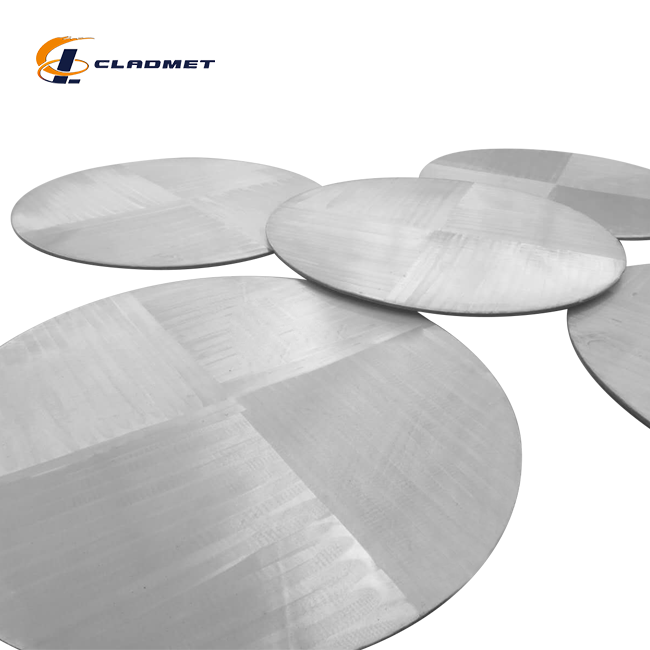

**2. Available Sizes and Support Customization** Standard sizes range from 1000mm to 3000mm. Custom sizes available.

**3. Product Applications** Used in chemical, aerospace, and marine industries for corrosion resistance.

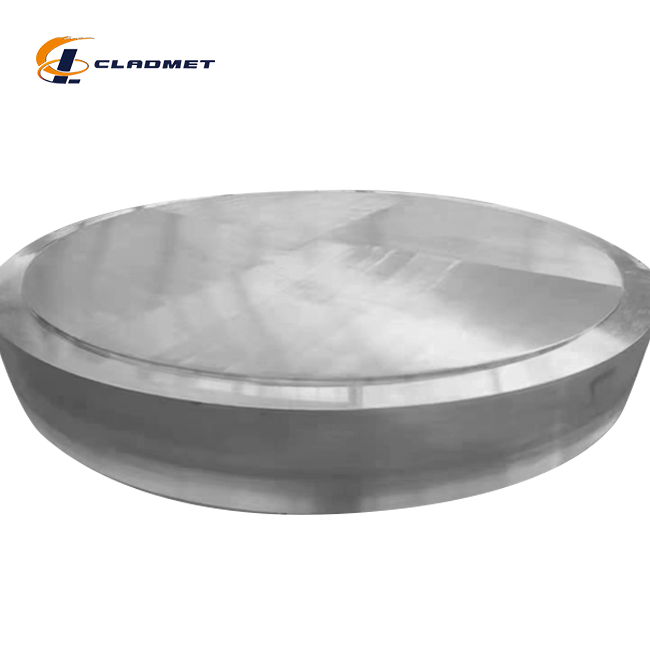

**4. Processing Technology** Explosive bonding process ensures high-strength and durable bonding.

**5. Quality Control and Testing** Strict QC standards, including ultrasonic, X-ray, and tensile strength tests.

**6. Product Implementation Standards** Complies with ASME, ASTM, and JIS standards. ISO9001-2000 certified, PED, ABS audited.

**7. Delivery** Available via air, sea, or express delivery. Fast shipping options.

**8. Packaging** Packaged in wooden crates with protective film for safe transport.

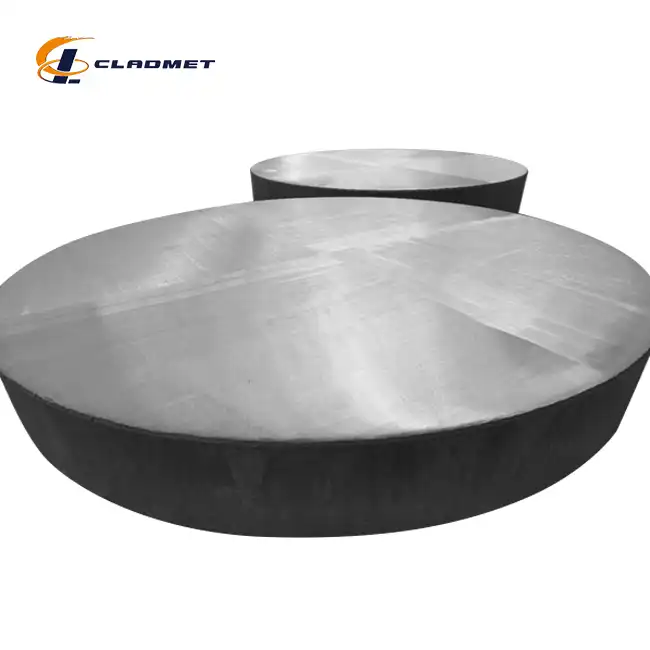

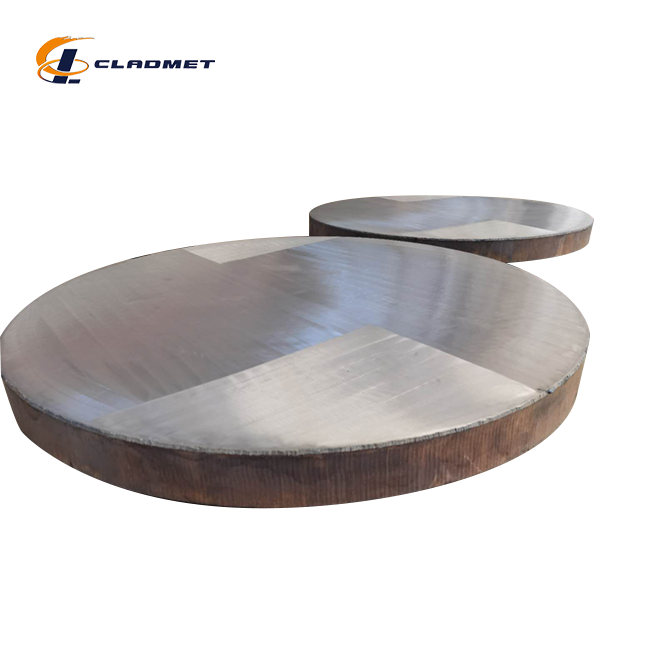

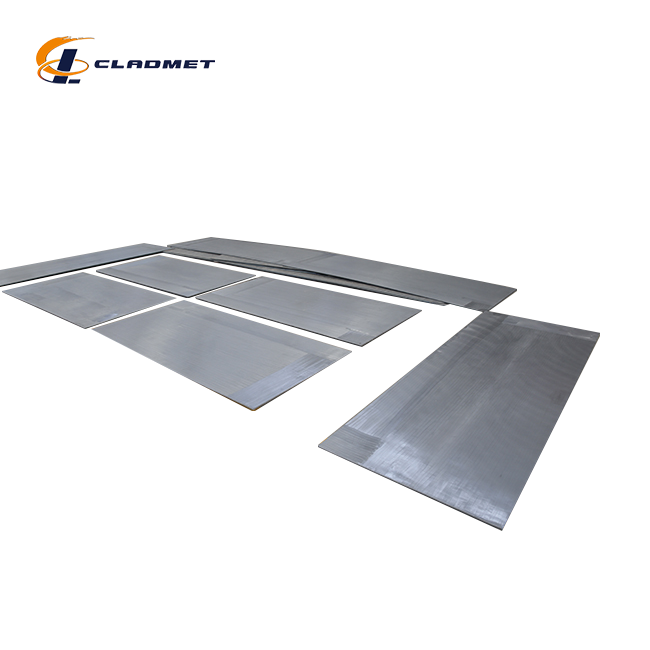

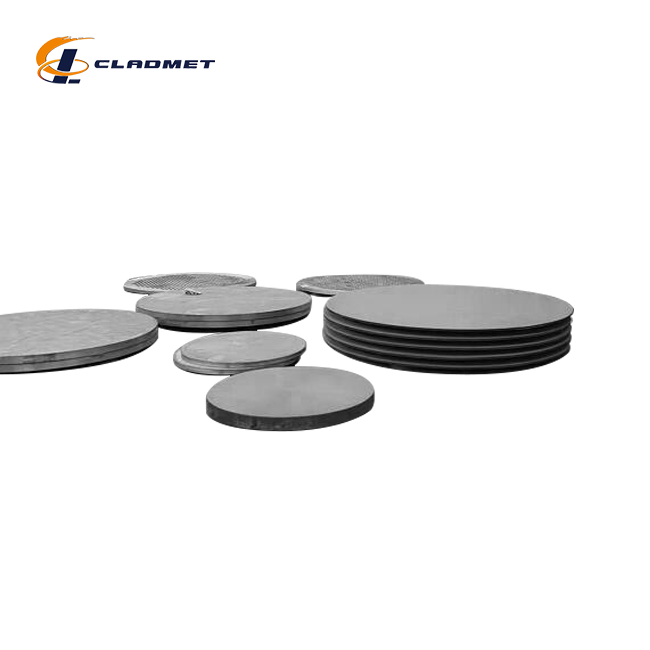

Product Introduction

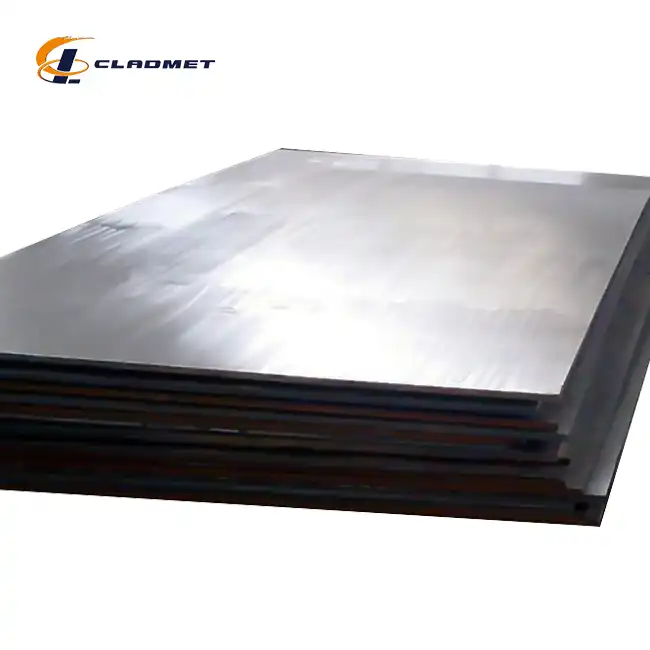

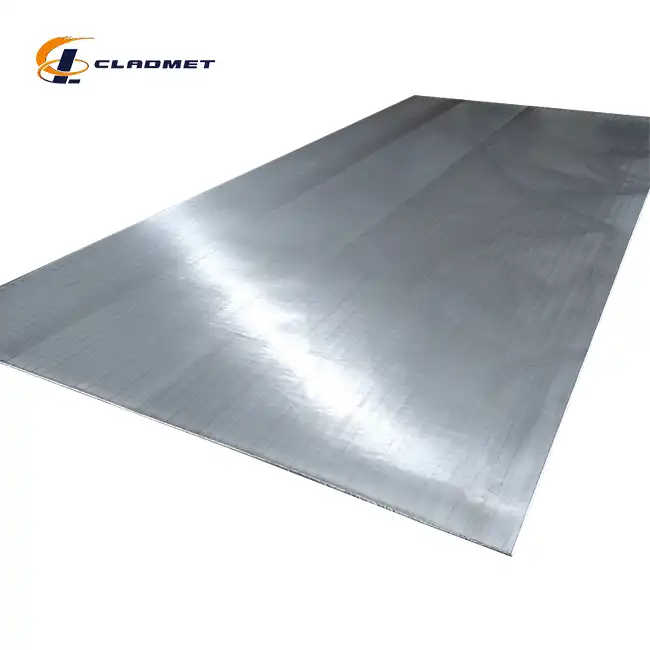

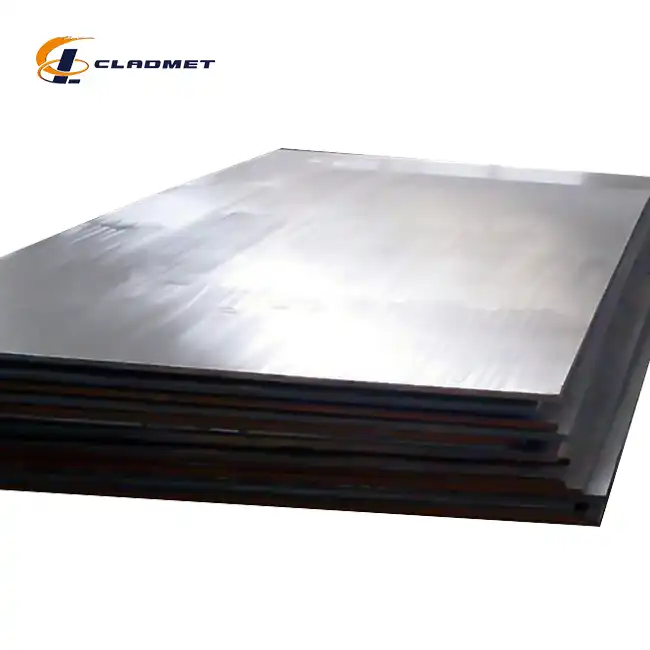

Hot rolled steel plate cladding is a composite material that bonds multiple layers of metals through advanced techniques, including roll-bonding. This material combines the strength and versatility of steel with the unique properties of other metals, such as corrosion resistance or enhanced wear performance. It’s widely used in industries where durability and customizability are paramount, including oil and gas, chemical processing, nuclear energy, aerospace, and more. By choosing the plate, industries can significantly improve equipment longevity and operational efficiency while reducing maintenance costs.

Product Specifications

| Parameter | Details |

|---|---|

| Cladding Material | Titanium, Nickel, Stainless Steel, Copper, Aluminium, Zirconium |

| Base Metal | Carbon Steel, Alloy Steel, Stainless Steel |

| Cladding Thickness | 2mm - 10mm |

| Base Metal Thickness | 8mm - 150mm |

| Plate Width | Up to 4000mm |

| Plate Length | Customizable (up to 12000mm) |

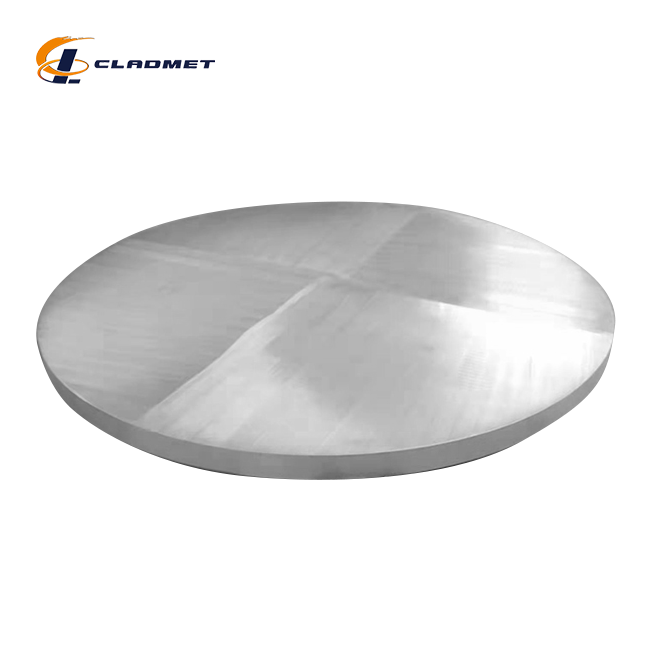

| Surface Treatment | Polished, Pickled, or Sandblasted |

| Standards | ASME/ASTM, GB/GBT, JIS |

| Applications | Oil & Gas, Chemical Processing, Power Generation, Marine, Aerospace |

| Packaging Method | Wooden crates or as per customer’s requirements |

| Delivery Cycle | 3-6 months or negotiable based on order size |

|

|

|

|

|

|

|

|

Manufacturing Techniques

Hot rolled steel plate cladding involves bonding a protective layer of metal to a steel base, utilizing the advantages of both materials to enhance performance. The process of creating hot rolled steel plate cladding requires specialized methods to ensure the materials are securely joined, providing superior durability and resistance to environmental factors. Several techniques can be employed to produce hot rolled steel plate cladding, each with its own unique benefits for industrial applications.

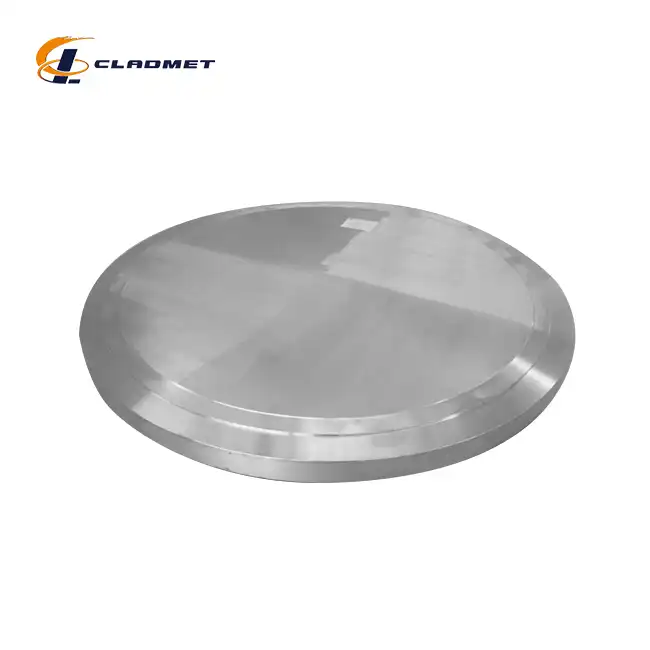

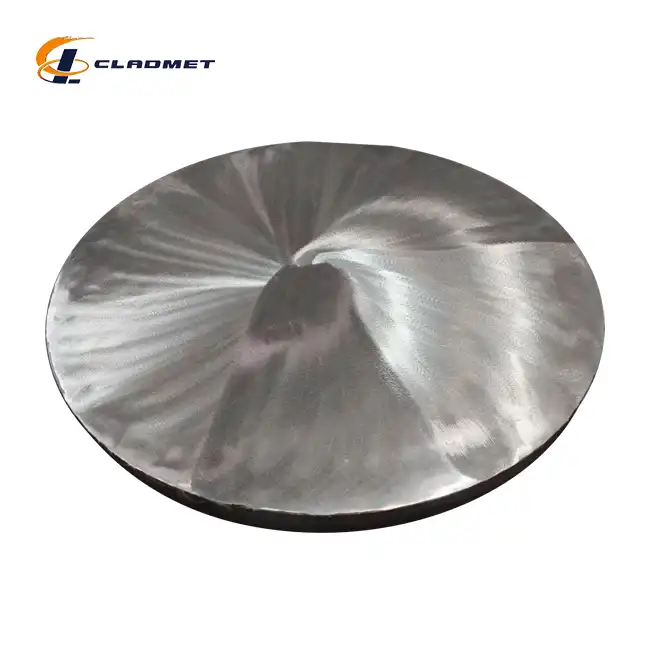

Explosive Bonding

Explosive bonding is a technique that uses controlled explosions to create a high-energy impact between the steel and the cladding material. The explosion results in the collision of the two layers at high speeds, forming a solid, metallurgical bond.

Preparation: The steel and cladding materials are carefully aligned and cleaned before being loaded into the bonding setup.

Explosion Detonation: Explosive charges are strategically placed between the layers, and the explosion generates sufficient force to bond them together at a molecular level.

Resulting Bond: This high-speed impact creates a bond that is durable and resistant to various mechanical stresses, ideal for demanding applications.

Explosive bonding is often used when a high-strength bond is required, such as in the production of heat exchangers, pressure vessels, and components used in the aerospace or marine industries.

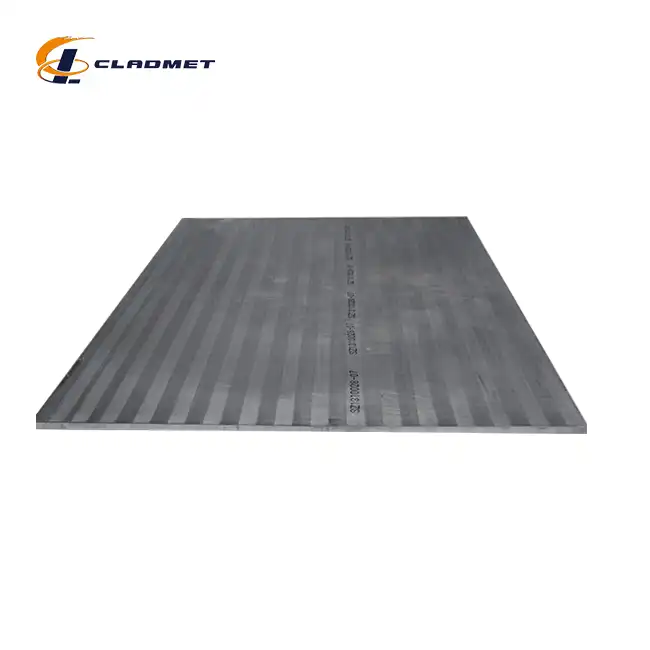

Roll Bonding

Roll bonding is a cold-welding method in which steel and the cladding material are fed through a series of rollers under high pressure. This technique causes the layers to fuse together through mechanical deformation, creating a strong bond without the need for heat.

Surface Treatment: Both the steel and cladding surfaces are thoroughly cleaned and prepared to ensure a strong connection.

Compression Process: The materials are passed through rollers under substantial pressure, bonding the layers together. Multiple passes may be required to achieve a uniform bond.

End Result: The cladding adheres tightly to the steel, ensuring long-lasting durability and resistance to environmental challenges.

Roll bonding is commonly used for creating clad plates for industries that need large sheets with high mechanical properties, such as chemical processing, oil and gas, and offshore engineering.

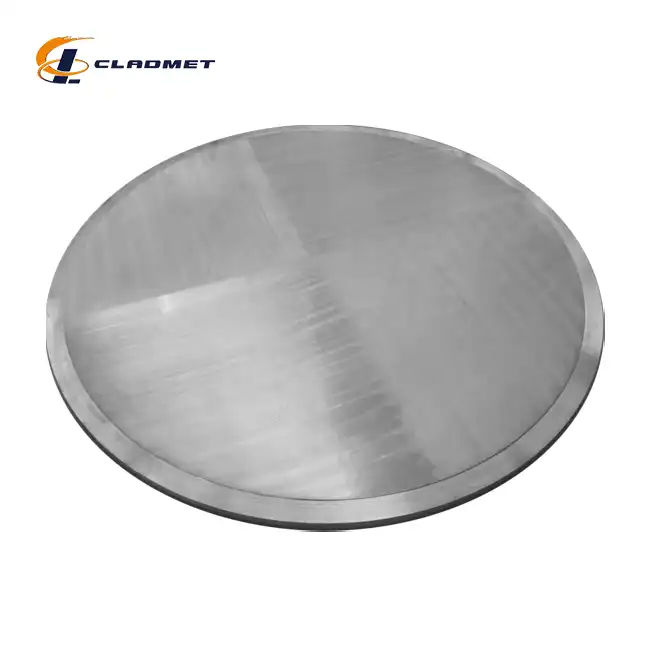

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing involves placing the steel and cladding material in a high-pressure chamber and subjecting them to elevated temperatures. The pressure and heat cause atomic diffusion between the materials, resulting in a diffusion bond.

Preparation and Sealing: The steel and cladding materials are assembled in a container, which is then sealed to create a pressurized environment.

Heat and Pressure: The sealed container is subjected to both heat and pressure, causing the materials to bond at the atomic level.

Final Bond: This process forms a homogeneous and robust connection, with the steel and cladding effectively becoming one unified material.

HIP is typically used for applications where high bonding integrity is required, such as in aerospace, energy, and other critical industries that demand a high level of performance from their materials.

Key Features and Advantages

Corrosion Resistance

The cladding layer, often composed of stainless steel, nickel alloys, or other corrosion-resistant materials, provides excellent protection against rust, oxidation, and chemical corrosion. This makes hot rolled steel plate cladding ideal for industries exposed to harsh environments, such as marine or chemical processing.

Strength and Durability

Hot rolled steel plate cladding enhances the mechanical strength of the steel, while the cladding material offers additional durability against wear and tear. The combined materials ensure that the final product is robust and resistant to the stresses encountered in various industrial applications.

Cost-Effectiveness

By using a more affordable base material like carbon steel and bonding it with a protective cladding material, manufacturers can reduce costs without compromising on performance. The longevity of the cladded steel also helps to lower maintenance and replacement costs over time.

Lightweight Performance

Despite the added cladding layer, hot rolled steel plate cladding offers an optimal strength-to-weight ratio. This makes it suitable for applications where weight is a concern, such as in transportation or aerospace industries.

Customization Options

Hot rolled steel plate cladding can be customized in terms of thickness, cladding material, and surface finish to meet the specific needs of various applications. This flexibility allows for tailored solutions for a wide range of industries.

Improved Resistance to Environmental Factors

The cladding material provides added resistance to extreme temperatures, corrosion, and chemical exposure. This makes it particularly useful in harsh environments, such as offshore oil rigs or chemical plants, where material performance is critical.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer customized OEM services, ensuring our hot rolled steel plate cladding solutions fit your exact requirements. Whether you need tailored sizes, materials, or specialized surface treatments, our team is ready to collaborate with you to create the ideal product.

FAQs

- What are the delivery times for custom orders? Delivery times typically range from 3-6 months depending on the complexity and size of the order. Specific timelines can be negotiated.

- Can you provide technical support for material selection? Yes, our experts are available to help guide material selection and ensure optimal performance for your application.

- What is the minimum order quantity? We offer flexible minimum order quantities depending on the product specifications and application needs.

Contact Us

- Tel: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

By choosing Baoji JL Clad Metals Materials Co., Ltd., you are assured of high-quality materials, competitive prices, and reliable supply chain solutions. Contact us today for more information or to place an order.

_1737007724117.webp)