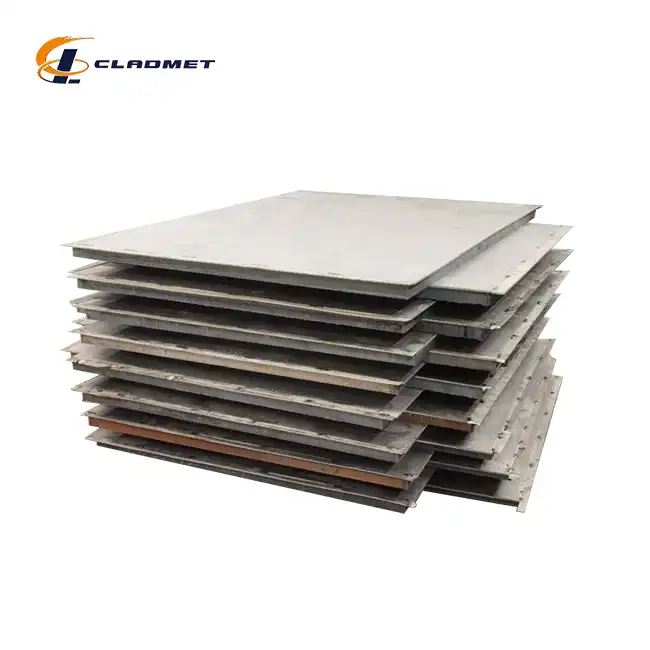

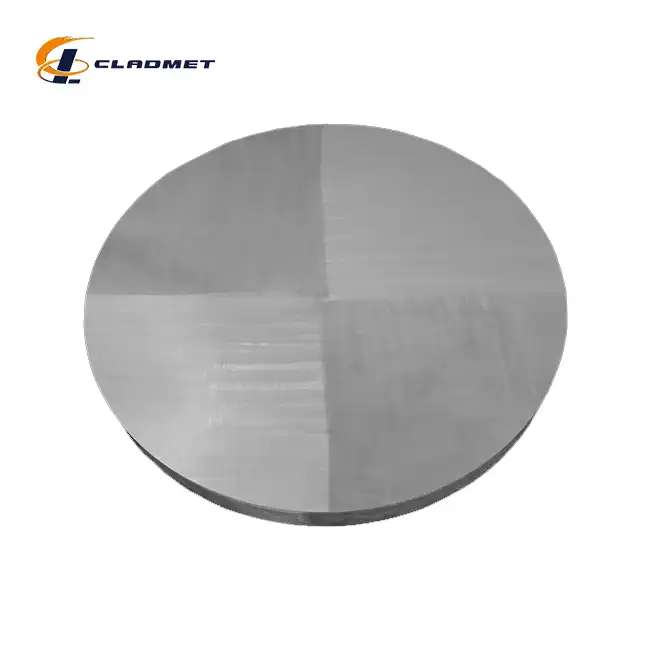

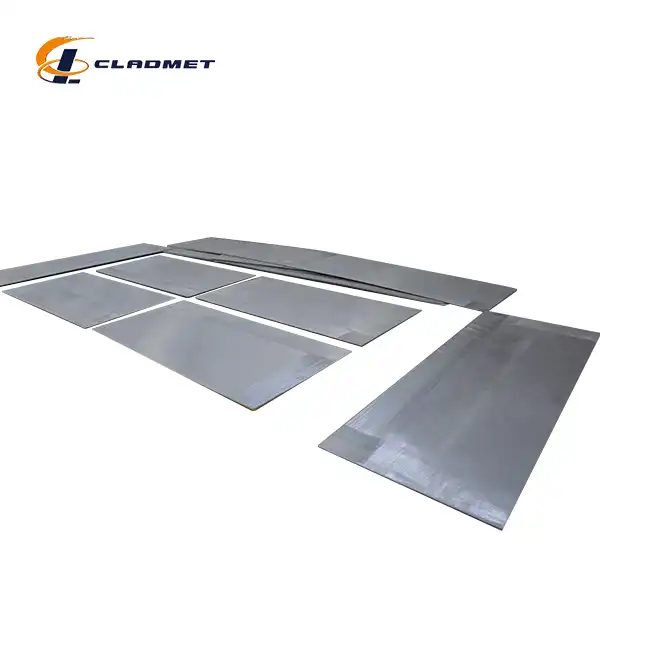

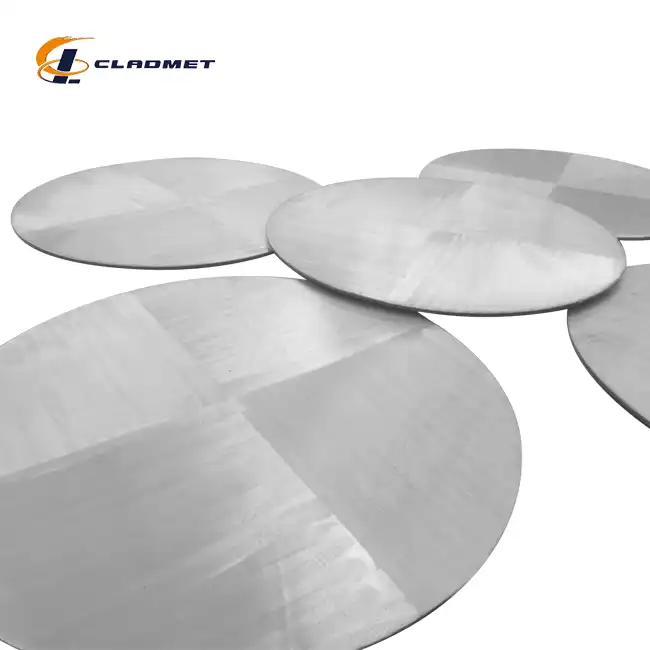

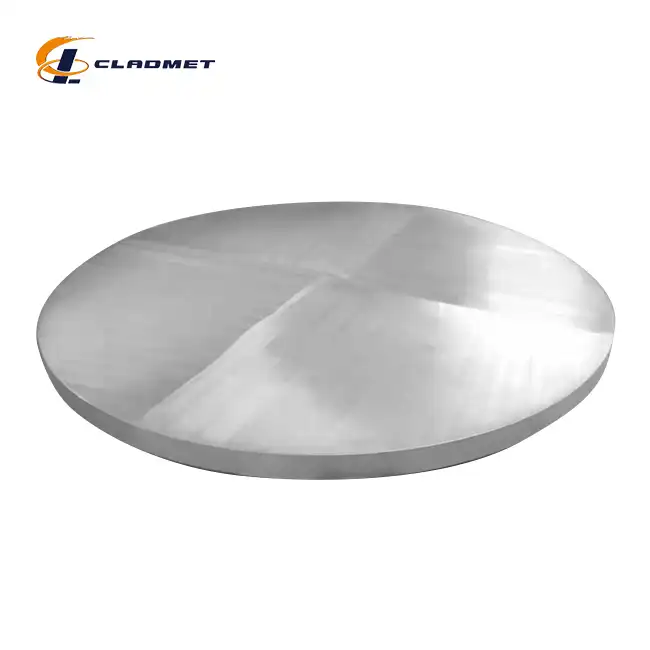

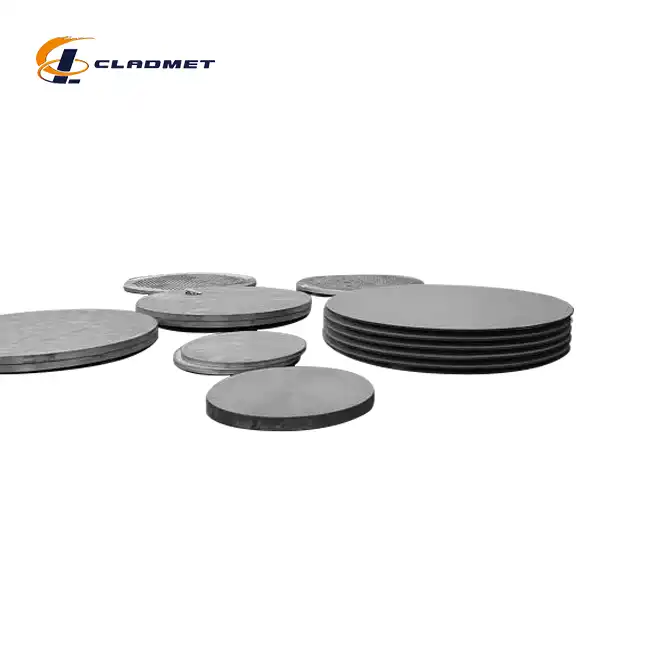

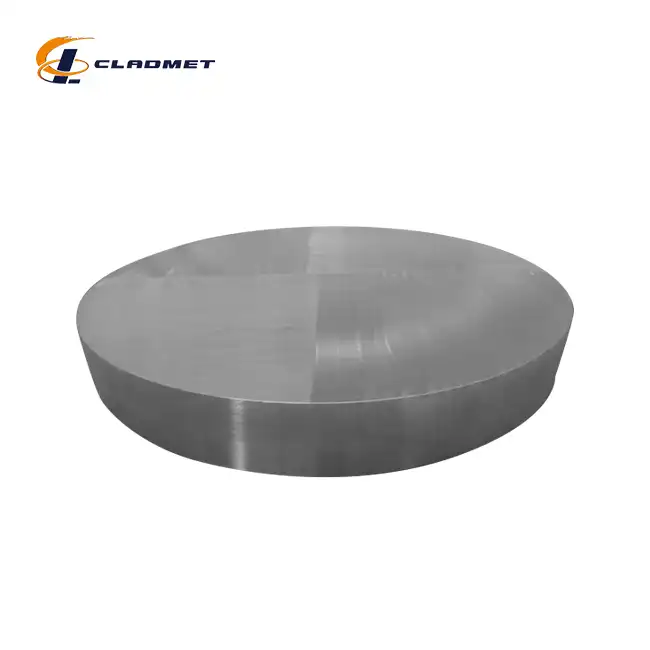

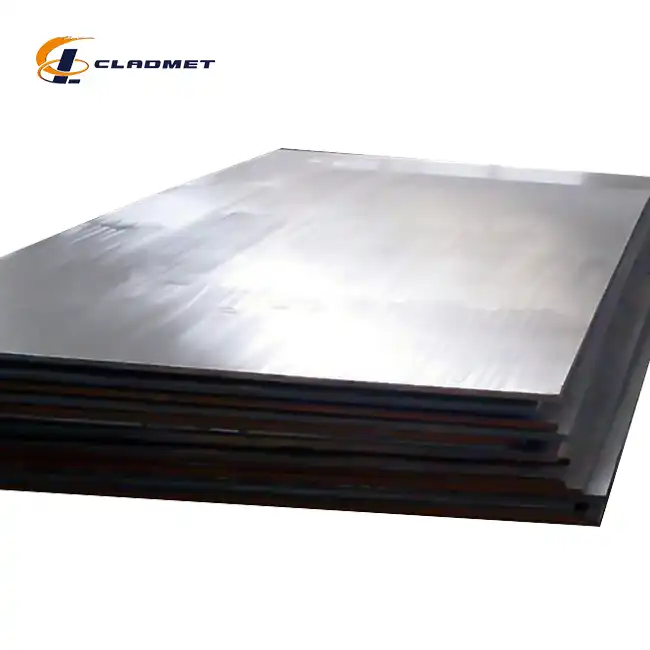

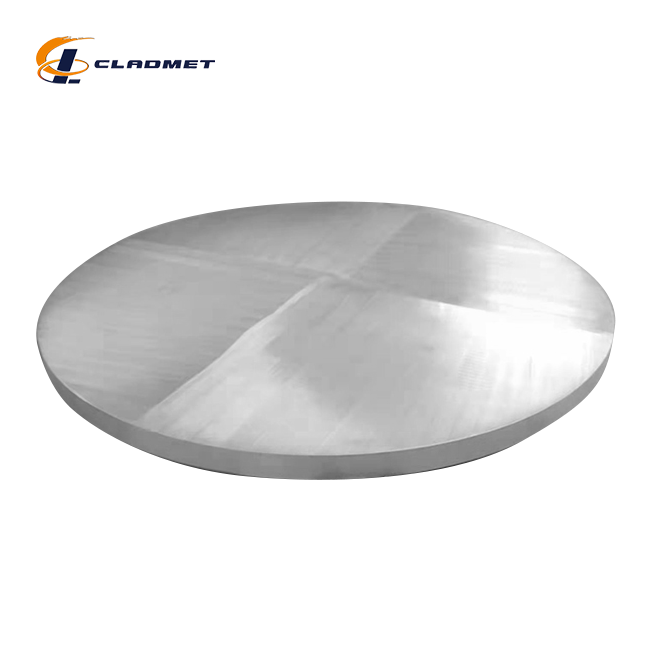

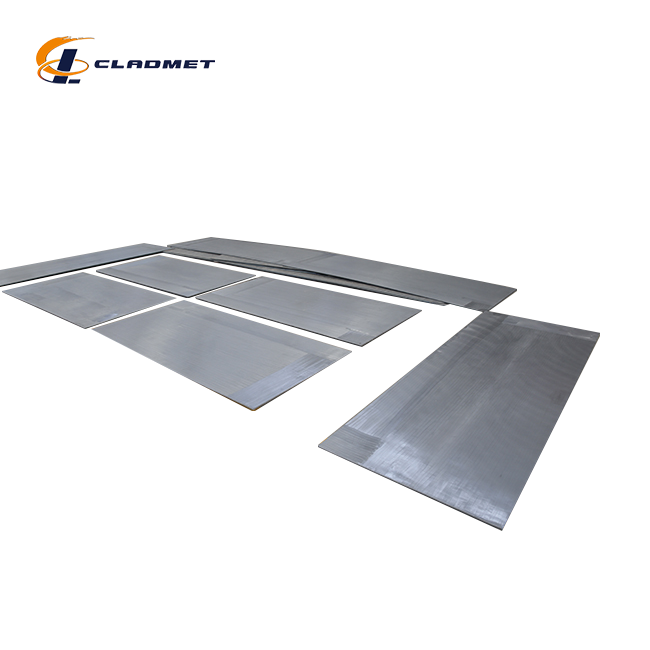

Titanium alloy steel clad plate

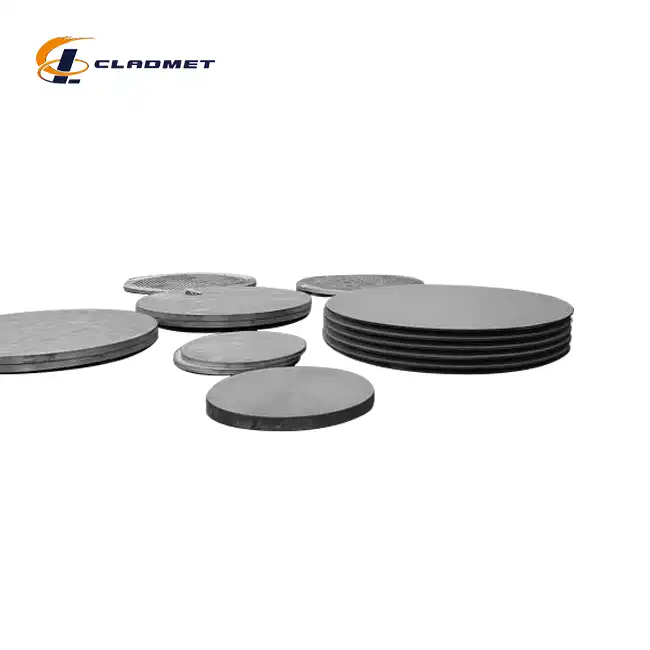

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Product Introduction

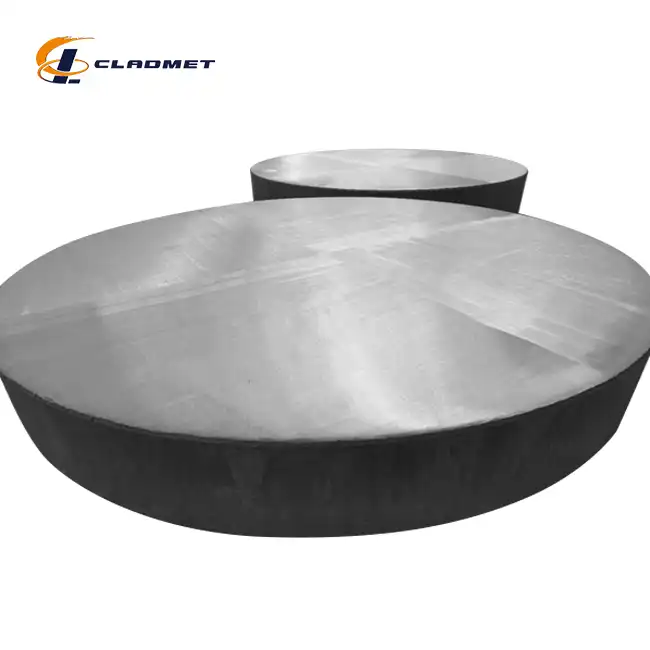

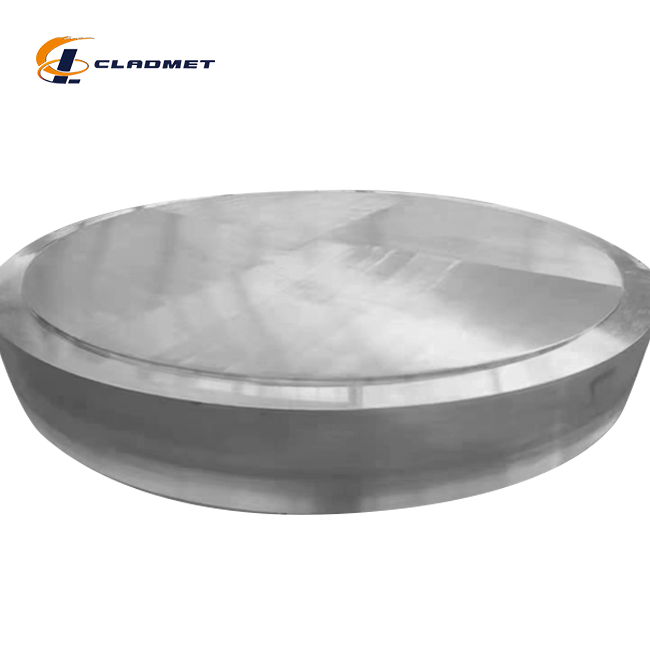

The Titanium alloy steel clad plate is a high-performance composite material designed to meet the demands of modern industrial applications. These clad plates are made by bonding titanium alloy to steel, offering superior corrosion resistance, strength, and durability. They are widely used across industries such as petrochemical, aerospace, pharmaceutical, and more, where both the structural strength of steel and the corrosion resistance of titanium are crucial.

With over 20 years of expertise, Baoji JL Clad Metals Materials Co., Ltd specializes in manufacturing top-quality clad plates, adhering to international standards and providing tailor-made solutions for various industries.

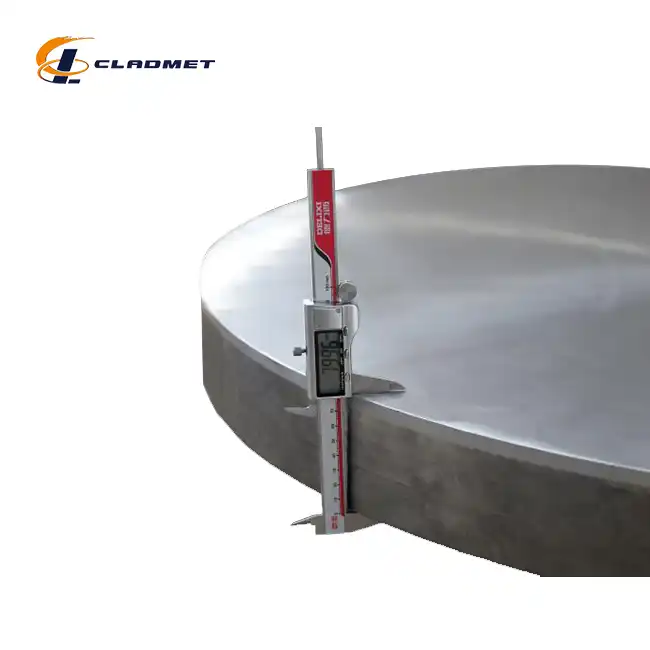

Product Specifications

| Specification | Details |

|---|---|

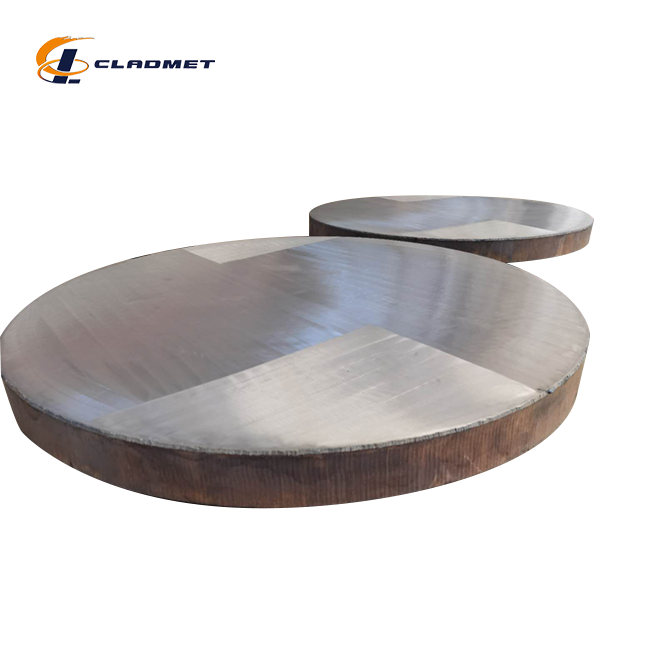

| Cladding Material | Titanium and its alloy |

| Base Metal | Steel (carbon steel or stainless steel) |

| Cladding Technology | Explosion bonding, roll bonding |

| Standards | GB/GBT, ASME/ASTM, JIS |

| Thickness Range | Cladding: 1-10 mm, Base: 5-50 mm |

| Length & Width | Customizable, up to 3 meters width and 12 meters length |

| Surface Treatment | Polished, sandblasted, pickling |

| Application Industries | Petrochemical, Aerospace, Marine, Pharmaceutical, Power Generation, Environmental Protection |

| Packaging Method | Wooden crates, steel frames |

| Transportation | By sea or air, based on customer requirements |

| Delivery Cycle | 3-6 months or negotiable |

|

|

|

|

|

|

|

|

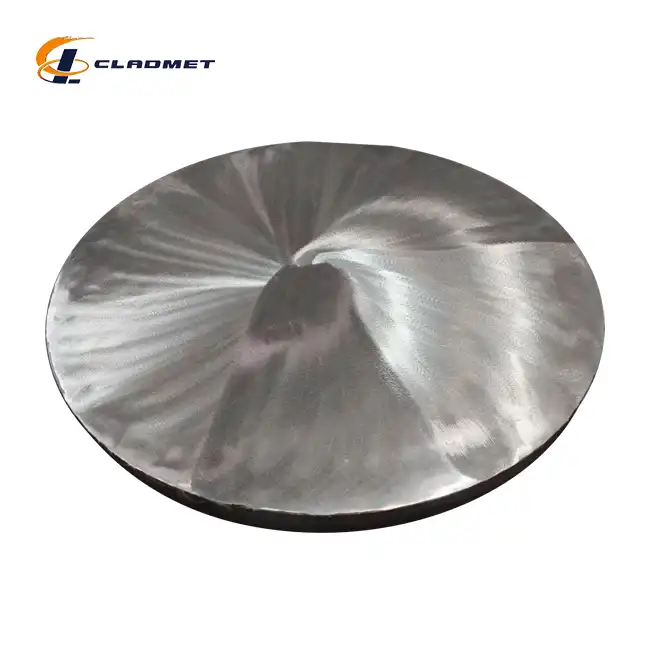

Manufacturing Processes

The creation of titanium alloy steel clad plates integrates cutting-edge technologies to combine titanium alloy's superior performance with steel's robust structural integrity. The main techniques include:

Explosive Bonding

This process employs high-energy shock waves to achieve a permanent connection between the titanium alloy layer and the steel base.

Pre-Bonding Preparation: The surfaces of both materials are cleaned and aligned to ensure seamless bonding.

Charge Placement: Explosives are strategically placed to create a controlled impact force.

Impact Welding: The shock wave generated by the explosion forces the titanium alloy and steel to collide at high velocity, forming a robust metallurgical bond.

Explosive bonding is particularly effective in producing clad plates that can withstand extreme environments, such as those encountered in pressure vessels and heat exchangers.

Compression Rolling

This method uses mechanical pressure to join the layers of titanium alloy and steel during a rolling process.

Surface Conditioning: Both layers are prepared to remove impurities and enhance bonding.

High-Pressure Rolling: The materials pass through powerful rollers that compress them together, creating a strong, cohesive bond.

Multiple Passes: Repeated rolling ensures uniformity and a tight bond across the entire surface.

Compression rolling is commonly utilized for producing large, flat clad plates used in chemical processing and structural applications.

Thermal Diffusion Bonding

This process applies heat and pressure in a vacuum or controlled atmosphere, enabling atomic-level bonding between the titanium alloy and steel.

Encapsulation: The materials are sealed within a protective environment to avoid contamination.

Heat and Pressure Application: High temperatures and pressure are applied to facilitate the diffusion of atoms at the interface, resulting in a strong and stable bond.

This method is ideal for applications that demand exceptional bonding integrity, such as aerospace and energy systems.

Features and Benefits

Outstanding Corrosion Resistance: The titanium alloy layer provides excellent protection against oxidation, chemicals, and saltwater exposure.

Enhanced Mechanical Strength: The steel base adds structural durability, making the plates suitable for demanding applications.

Lightweight Advantage: Titanium alloy reduces the overall weight of the material while maintaining high strength.

Thermal Performance: Superior heat resistance allows these plates to perform well in high-temperature environments.

Longevity: The combination of materials minimizes wear and tear, reducing maintenance and replacement costs over time.

Customizable Design: Available in various sizes, thicknesses, and configurations to suit specific industry requirements.

Cost Efficiency: By combining materials, the cost is significantly lower than using pure titanium alloys while achieving comparable performance.

Explosive Composite Plate Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals Materials Co., Ltd, we offer full OEM services to meet your specific project requirements. Our expert team will work closely with you to ensure the dimensions, materials, and standards align with your industrial needs.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom Titanium alloy steel clad plates?

A1: The MOQ can be discussed based on the specific project requirements.

Q2: Can I get a sample of the clad plate?

A2: Yes, we can provide samples upon request for testing and evaluation.

Q3: How long is the typical delivery time?

A3: The standard delivery cycle is 3-6 months, depending on the size and complexity of the order.

Q4: Are your products certified?

A4: Yes, we adhere to international standards such as GB/GBT, ASME/ASTM, JIS, and have passed ISO9001-2000, PED, and ABS certifications.

Contact Us

For more information or to place an order, please contact us at:

- WhatsApp: +8615353335118

- Email: stephanie@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)