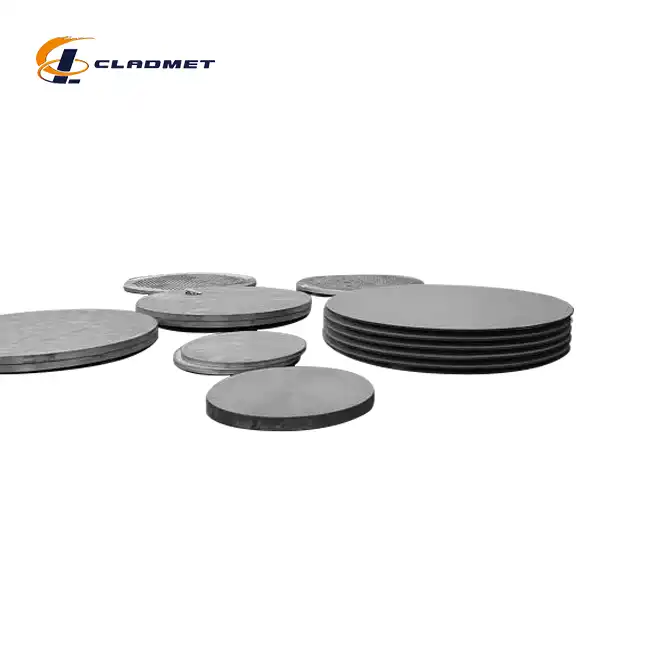

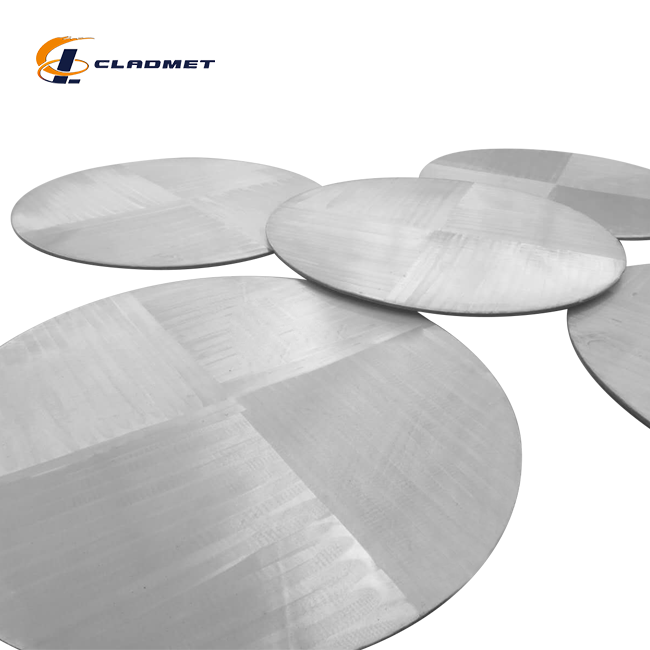

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

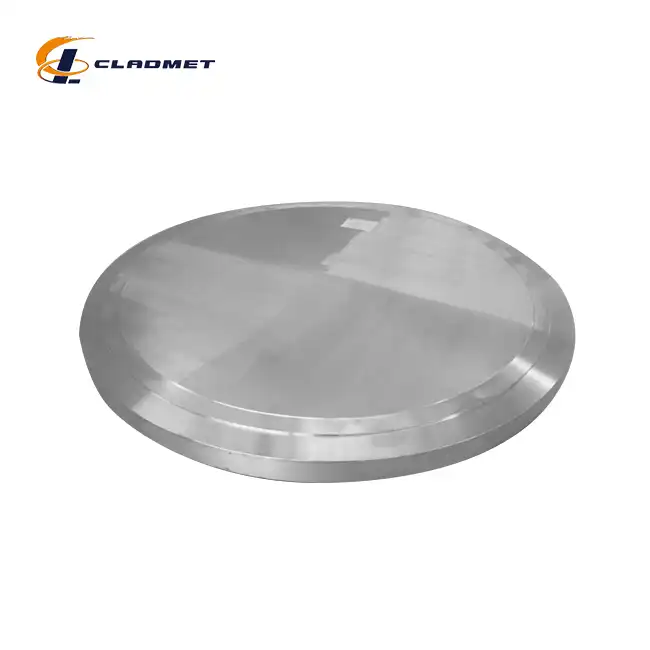

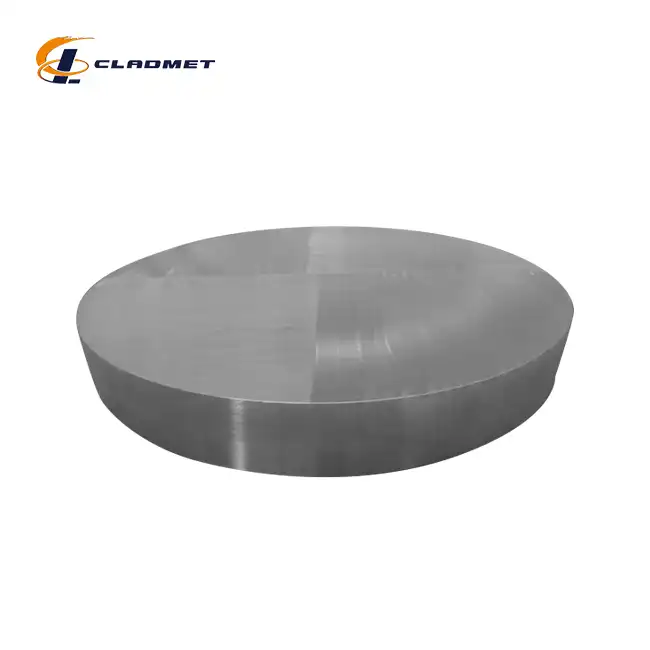

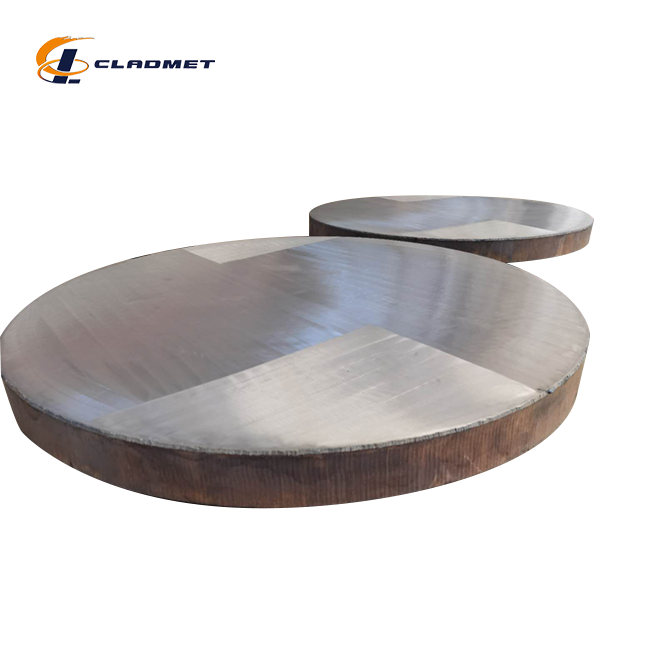

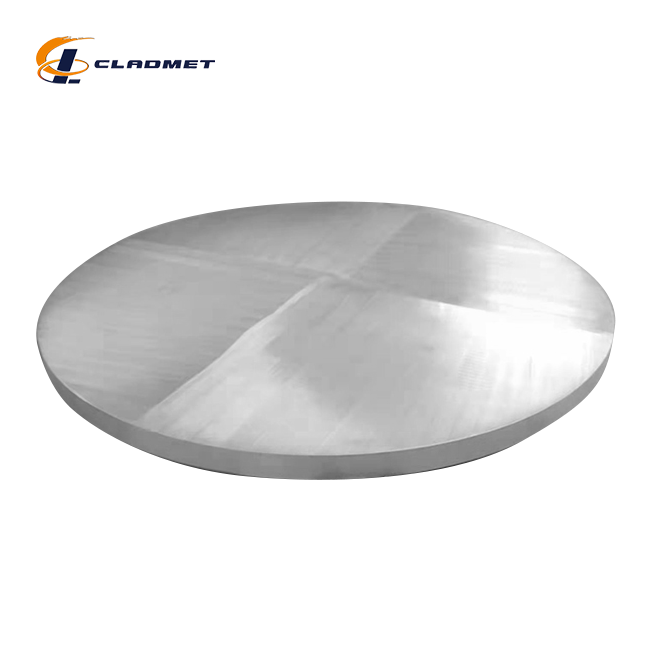

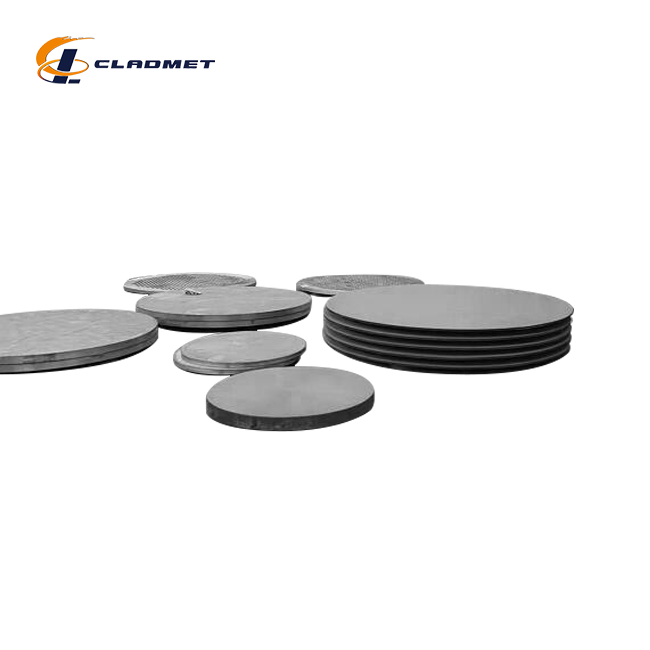

Product Introduction

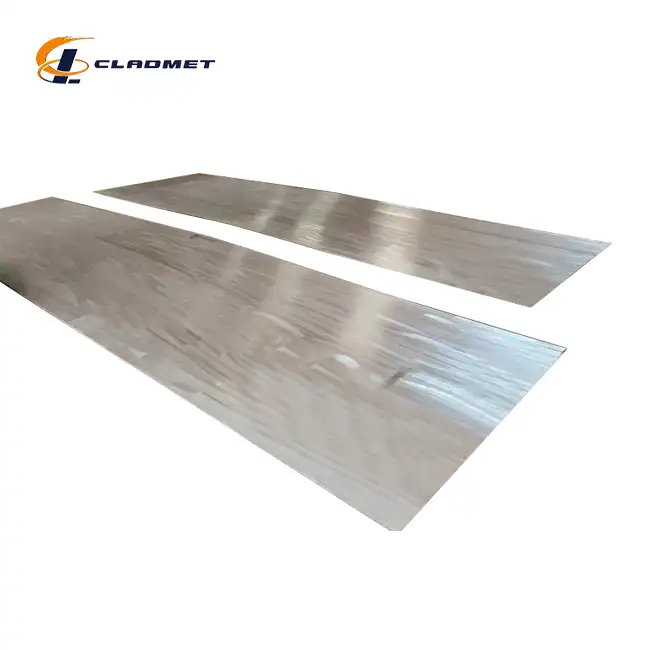

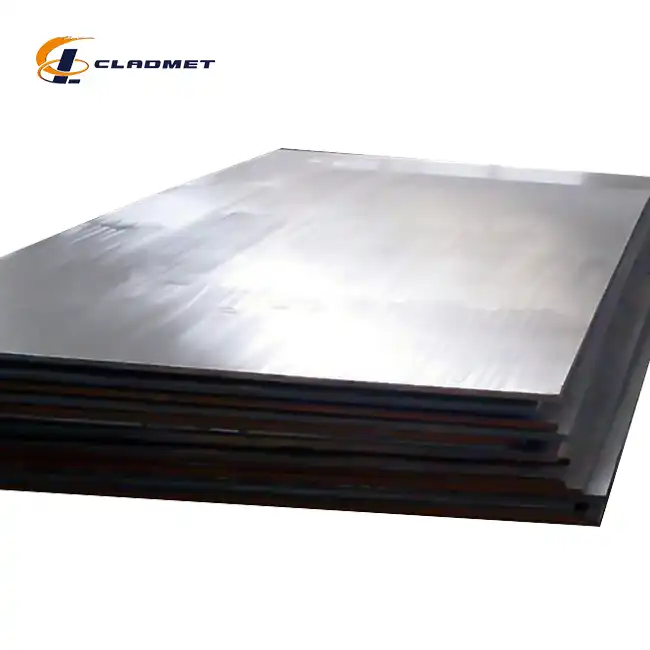

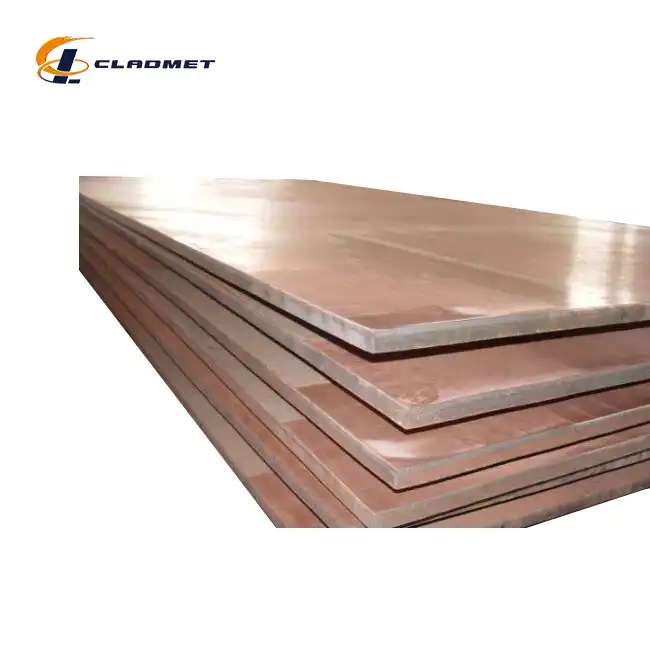

Clad steel plates are high-performance composite materials made by bonding two or more layers of different metals. These layers are combined through advanced techniques like roll bonding or explosion bonding, resulting in a product that offers the best of both worlds—strength, durability, and corrosion resistance. Baoji JL Clad Metals Materials Co., Ltd, established in 1988, is a leading manufacturer specializing in the production of the high-quality plates for a wide range of industrial applications. Our plates are designed to meet the stringent standards of industries such as oil and gas, chemical, aerospace, and power generation.

Product Specifications

| Parameter | Details |

|---|---|

| Cladding Material Range | Titanium, Nickel, Stainless Steel, Copper, Aluminum, etc. |

| Base Metal Range | Carbon Steel, Stainless Steel, Alloy Steel |

| Cladding Size | Custom sizes available based on client requirements |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

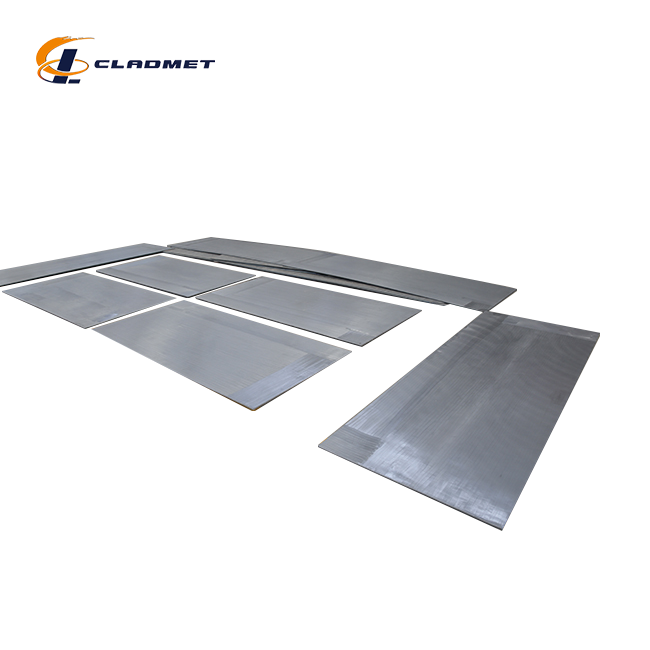

| Thickness | 3mm-300mm |

| Length | Up to 12 meters |

| Width | Up to 4 meters |

| Surface Treatment | Pickling, Polishing, Sandblasting |

| Application Industries | Oil & Gas, Chemical, Nuclear, Aerospace, Marine, Power |

| Packaging Method | Wooden Crates, Steel Straps, Custom Packaging |

| Transportation | Sea, Air, or Land |

| Delivery Cycle | 3-6 months (Negotiable based on order size) |

|

|

|

|

|

|

|

|

Manufacturing Processes

Steel clad plates are designed by combining the excellent properties of different metals through innovative bonding techniques. These processes create a durable, high-performance material that suits various demanding industries. The primary methods of producing steel clad plates are:

Explosive Bonding

This technique utilizes controlled explosions to generate an intense impact that causes the base material and steel to fuse together.

Preparation: Both the steel plate and the cladding material are carefully cleaned and arranged.

Explosive Setup: An explosive charge is placed between the materials to initiate the bond.

Impact Formation: The explosion creates a high-velocity impact, which forms a solid and resilient bond.

This approach is especially advantageous for producing materials used in high-stress applications like heat exchangers and industrial pressure vessels.

Roll Bonding

Roll bonding is a cold-working process where steel and its cladding layer are passed through heavy rollers to create a strong bond through high-pressure deformation.

Surface Treatment: The base material and cladding layer undergo thorough cleaning to ensure perfect bonding.

Pressing: The materials are subjected to significant pressure while passing through rollers, making the bond robust.

Multiple Passes: Depending on the requirements, several cycles through the rollers may be necessary to achieve a uniform bond.

Roll bonding is ideal for applications in industries like chemical processing, where high resistance to corrosion is critical.

Hot Isostatic Pressing (HIP)

This method involves placing the steel and cladding material in a sealed chamber, applying heat and pressure to create a molecular bond.

Sealing: The materials are enclosed in a high-pressure vessel to maintain a controlled environment.

Temperature and Pressure Application: The materials are heated to a high temperature while being subjected to uniform pressure.

Diffusion Bonding: The process encourages atomic diffusion between the layers, resulting in a high-integrity bond.

HIP is commonly used in aerospace and high-end industrial applications, where the bonding integrity needs to be exceptional.

Features and Advantages

Corrosion Resistance: Steel clad plates are known for their excellent resistance to corrosion, particularly in harsh chemical environments or offshore conditions.

Enhanced Durability: The cladding layer enhances the steel's resistance to wear and tear, extending the lifespan of equipment and structures.

Strength and Flexibility: While the core material provides strength, the cladding material ensures flexibility and resistance to environmental degradation.

Temperature Resistance: Steel clad plates offer remarkable resistance to high and low temperature extremes, making them suitable for a variety of industrial applications.

Customization Options: Available in different grades, thicknesses, and coatings, steel clad plates can be tailored to meet specific industrial needs.

Cost-Effectiveness: By combining the properties of multiple materials, steel clad plates offer enhanced performance at a lower cost compared to fully homogeneous materials.

Sustainability: Steel clad plates help extend the lifespan of industrial systems, contributing to sustainability efforts by reducing the need for frequent replacements.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

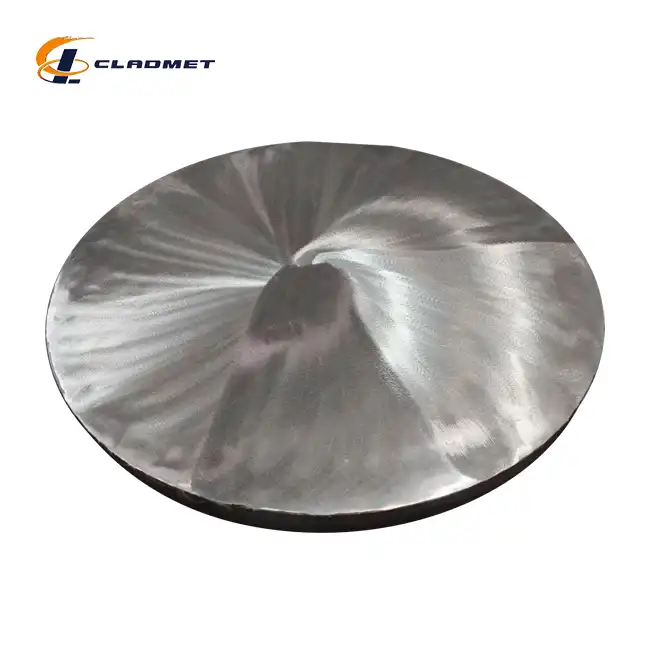

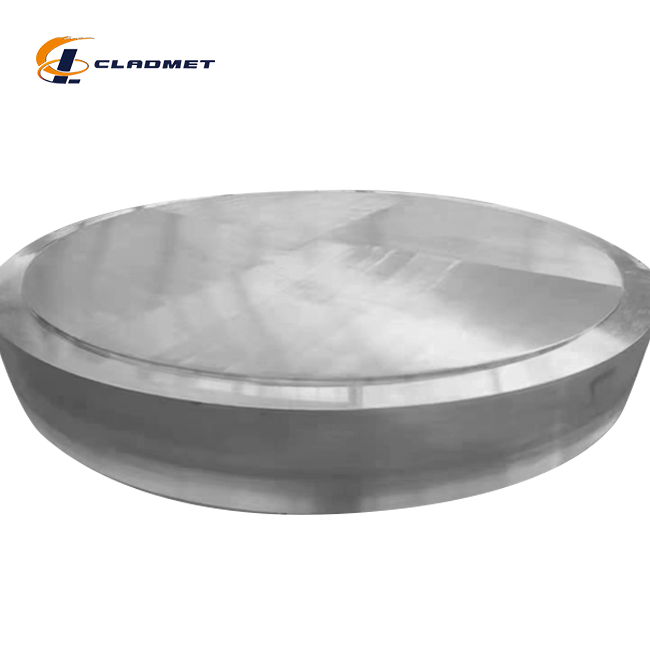

Main Products

Main Application Industries

OEM Service

We offer custom manufacturing services to meet the specific needs of our clients. Whether it's adjusting the cladding material or base metal combination, modifying thickness, or creating a custom size, we are committed to providing tailor-made solutions. Contact us to discuss your requirements, and our team of experts will guide you through the process.

FAQ

-

What is the lead time for delivery?

The typical delivery time is 3-6 months, but this can be negotiated based on order size and project urgency. -

What standards do your clad steel plates comply with?

Our products meet international standards such as GB/GBT, ASME/ASTM, and JIS. -

Can you provide custom sizes and materials?

Yes, we offer a wide range of custom options for cladding material, base metal, thickness, and dimensions. -

How are the products packaged?

We provide safe and secure packaging in wooden crates, steel straps, or custom packaging based on customer preferences.

Contact Us

For inquiries or to place an order, contact us at:

- Tel: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

We look forward to partnering with you on your next project!

_1737007724117.webp)