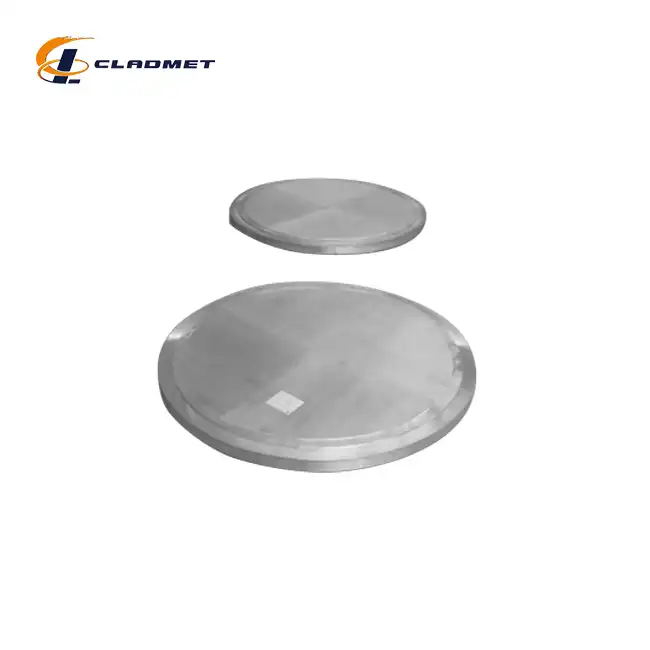

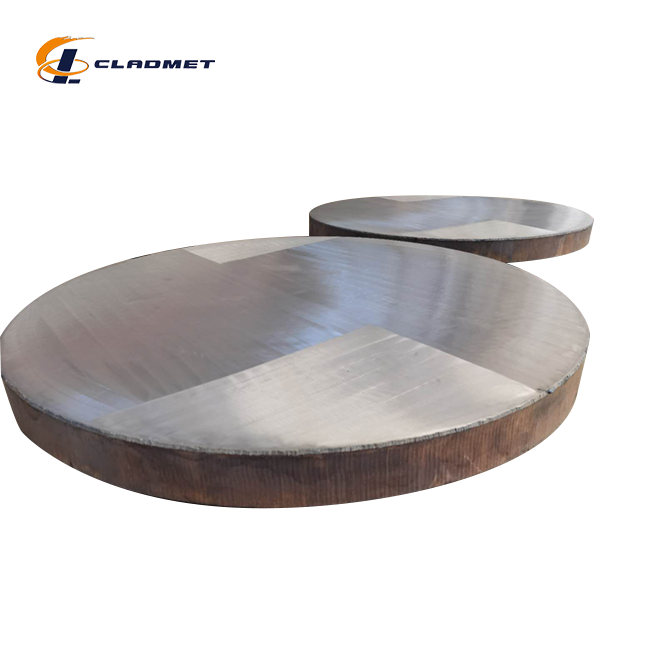

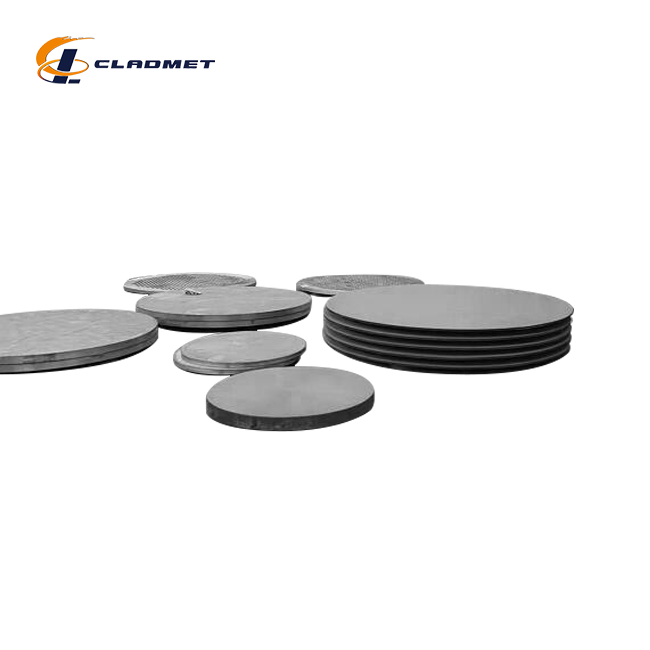

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Product Introduction

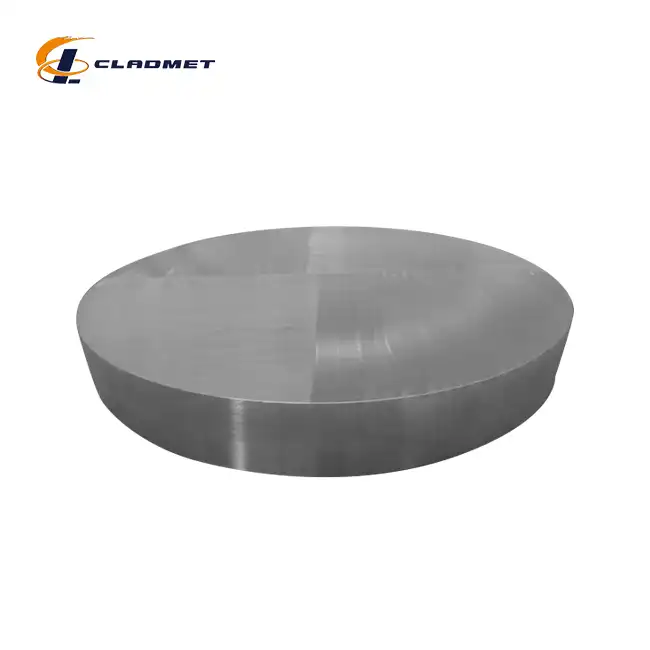

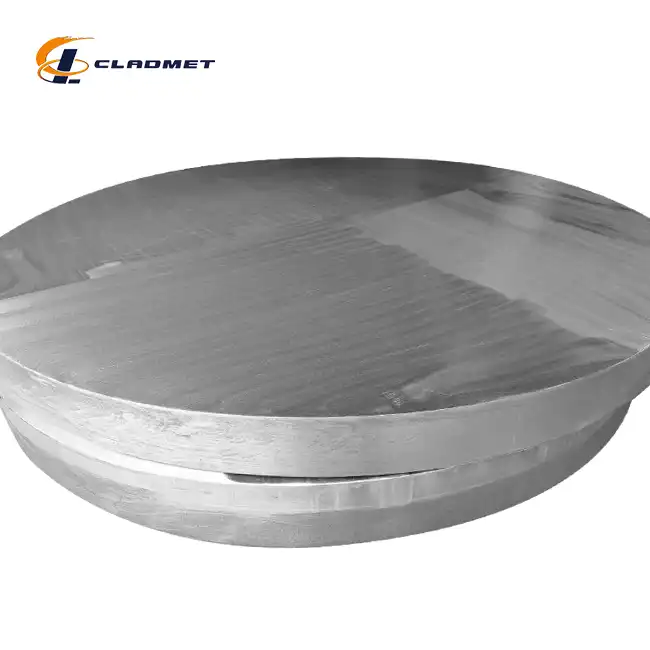

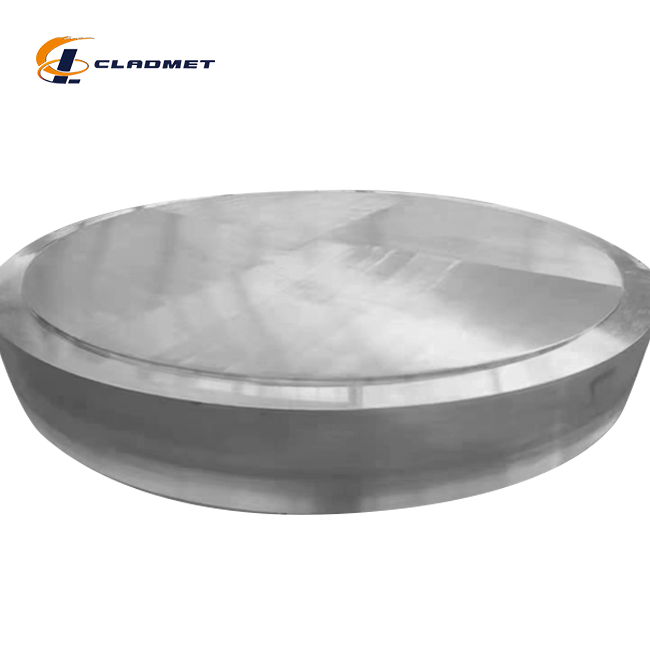

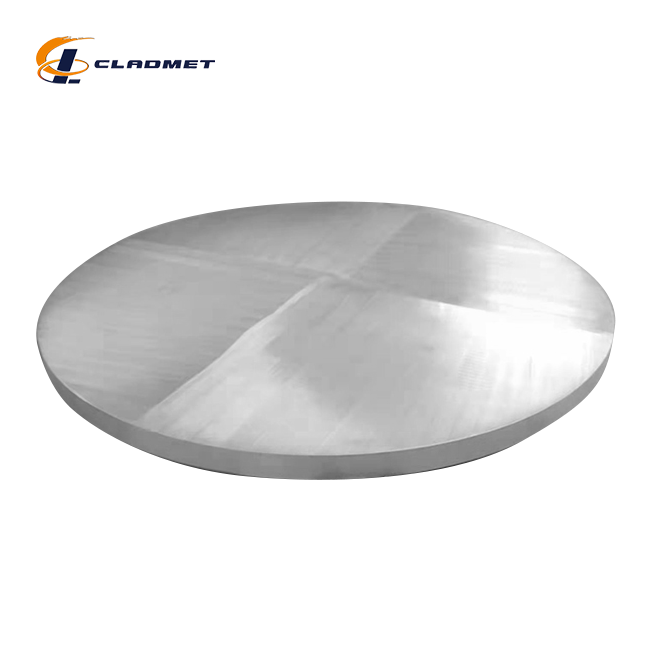

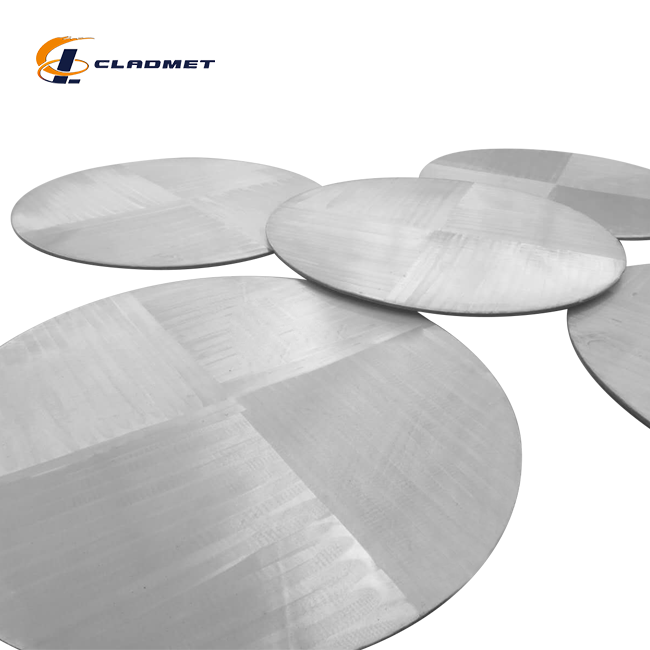

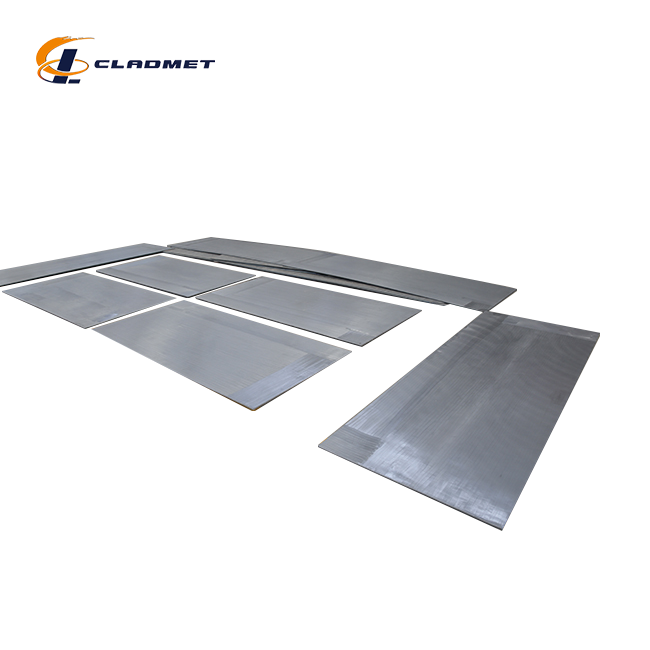

Cladding steel plates are composite materials made by bonding different metals, enhancing their strength, corrosion resistance, and wear resistance. At Baoji JL Clad Metals, we specialize in manufacturing the high-quality plates through advanced bonding techniques like roll-bonding and explosion-bonding. Our plates are designed to meet the rigorous demands of industries such as oil & gas, aerospace, chemical processing, and marine engineering, providing exceptional durability and performance in harsh environments.

Product Specifications

| Parameter | Description |

|---|---|

| Base Material | Carbon Steel, Low Alloy Steel, or Stainless Steel (e.g., Q235B, Q345B, A516 Gr.70, etc.) |

| Cladding Material | Stainless Steel, Titanium, Copper, Nickel Alloy, Aluminum, or Custom Materials |

| Total Thickness Range | 6 mm - 200 mm (e.g., 2 mm Cladding + 8 mm Base) |

| Clad Layer Thickness | 1 mm - 20 mm (customizable) |

| Base Layer Thickness | 5 mm - 180 mm (customizable) |

| Width Range | Up to 4000 mm |

| Length Range | Up to 12000 mm |

| Bonding Technology | Explosion Bonding, Hot Rolling, or Explosion + Rolling |

| Bonding Strength | ≥ 140 MPa |

| Shear Strength | ≥ 105 MPa |

| Corrosion Resistance | Excellent resistance to acids, alkalis, seawater, and other environments depending on cladding material |

| Thermal Conductivity | High thermal performance based on cladding material properties |

| Heat Resistance | High-temperature performance based on cladding material |

| Application Industries | Chemical Processing, Oil & Gas, Power Generation, Marine Engineering, Desalination, Aerospace, and more |

| Standards Compliance | ASTM B898, ASME SB-898, GB/T 8165, and other international standards |

| Surface Finish | Polished, Sandblasted, or Customized |

| Customizations Available | Thickness Ratio, Size, Material Combinations, Surface Finish, etc. |

|

|

|

|

|

|

|

|

Manufacturing Methods

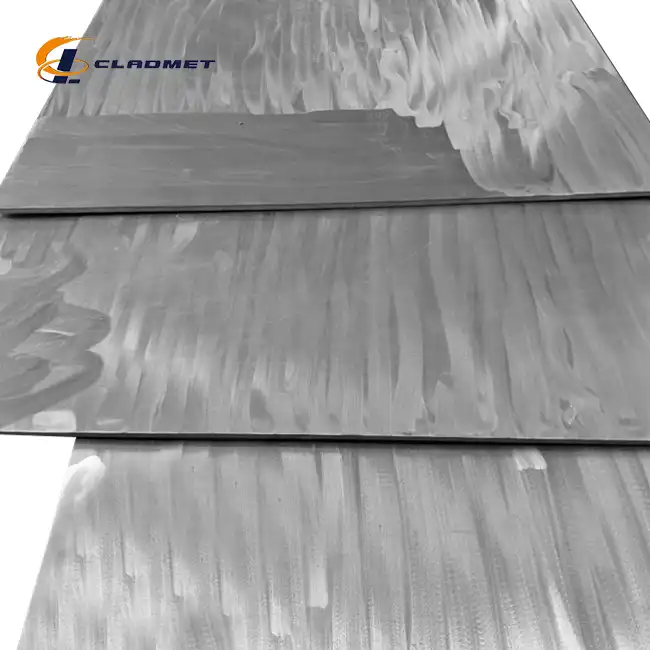

Cladding steel plates are produced by bonding a layer of protective metal to a steel base, combining the strength of steel with the corrosion resistance and other specialized properties of the cladding material. This fusion enhances the durability of the steel while reducing the overall weight and cost. Several advanced techniques are used to bond the two materials, each offering unique benefits for different industrial needs.

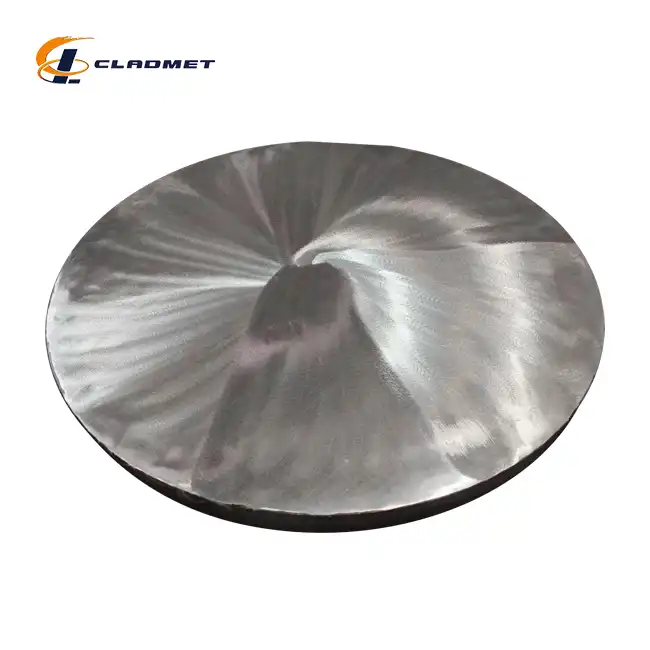

Explosive Bonding

Explosive bonding involves using controlled explosions to bond two materials with a high-speed impact. The explosion forces the base steel and the cladding material to collide, creating a high-strength bond at the molecular level. This process is often used for applications where superior bond strength is necessary, such as in extreme environments.

Material Preparation: Both the steel and cladding are prepared and aligned before the explosive charge is set.

Explosion Process: The explosive material is detonated, causing a high-speed collision between the layers, which forms a solid bond.

Resulting Bond: The impact forms a metallurgical bond that is highly durable and resistant to various stresses.

This method is ideal for producing cladding steel plates that require exceptional strength, often used in industries like energy production, shipbuilding, and heavy machinery.

Roll Bonding

Roll bonding is a cold welding process where steel and the cladding material are passed through rollers under high pressure. This process bonds the layers together without the need for heat, producing a seamless connection between the steel and cladding.

Surface Cleaning: Both the base steel and cladding are cleaned to ensure the bond is secure and free of contaminants.

Rolling Process: The materials are compressed together as they pass through the rollers, which apply pressure to fuse them into a single sheet.

Multiple Passes: Sometimes, multiple passes through the rollers are necessary to ensure a complete and uniform bond.

Roll bonding is commonly used for producing large sheets of cladded steel for a variety of industrial uses, including chemical processing and construction applications, where cost-effectiveness and efficiency are key considerations.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a method that involves placing the steel and cladding into a sealed container and subjecting them to both high heat and pressure. This process creates a diffusion bond between the materials, resulting in a high-quality and robust cladding.

Containerization: The steel and cladding are sealed in a pressure chamber.

High Heat and Pressure: The chamber is subjected to elevated temperatures and high pressure, causing the materials to fuse together at the atomic level.

Strengthened Bond: The fusion creates a durable bond that resists fatigue, corrosion, and wear.

This technique is ideal for high-performance applications in industries such as aerospace, energy, and the chemical sector, where the integrity of the bond is paramount.

Key Features and Advantages

Exceptional Corrosion Resistance: The cladding material, such as stainless steel or nickel alloys, provides outstanding protection against corrosion, making cladding steel plates ideal for environments exposed to chemicals, seawater, or extreme temperatures.

Durability: The combined strength of the steel base and the corrosion-resistant cladding ensures that the material can withstand mechanical wear, pressure, and harsh environmental conditions, extending the lifespan of the equipment.

Cost Efficiency: By using a less expensive steel base material and bonding it with a thin layer of more expensive, corrosion-resistant metal, cladding steel plates provide a cost-effective solution that reduces the need for frequent replacement and maintenance.

Versatility: Cladding steel plates can be customized to meet specific industrial needs, offering a variety of thicknesses, materials, and surface finishes to suit different applications.

Improved Performance: The cladding layer enhances the overall mechanical properties of the steel, offering better resistance to heat, chemicals, and corrosion, while maintaining the steel’s strength and structural integrity.

Lightweight: The cladding layer adds minimal weight to the steel, ensuring that the material remains easy to handle and suitable for lightweight yet strong applications.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer comprehensive OEM services, allowing you to customize the plates according to your specific requirements. From material selection to surface treatments and dimensions, we provide flexible options to meet the diverse needs of your industry.

FAQs

1. What are the delivery times?

Standard delivery cycles range from 3 to 6 months, but this can be negotiated based on the project scale and requirements.

2. Can I customize the cladding material?

Yes, we offer a wide range of cladding and base metals. Please contact us for more information on custom orders.

3. What certifications do your products comply with?

Our cladding steel plates are manufactured according to GB/GBT, ASME, ASTM, and JIS standards. We are also ISO9001-2000 certified.

Contact Us

For inquiries and orders, feel free to contact us:

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)