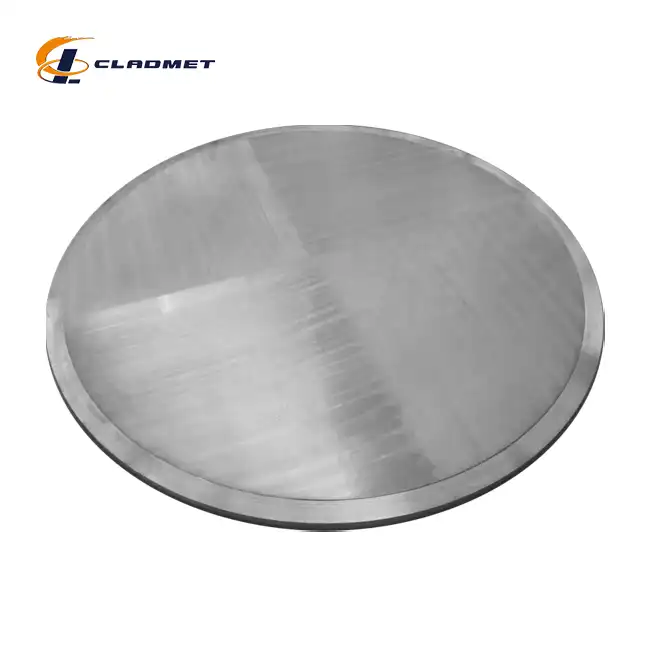

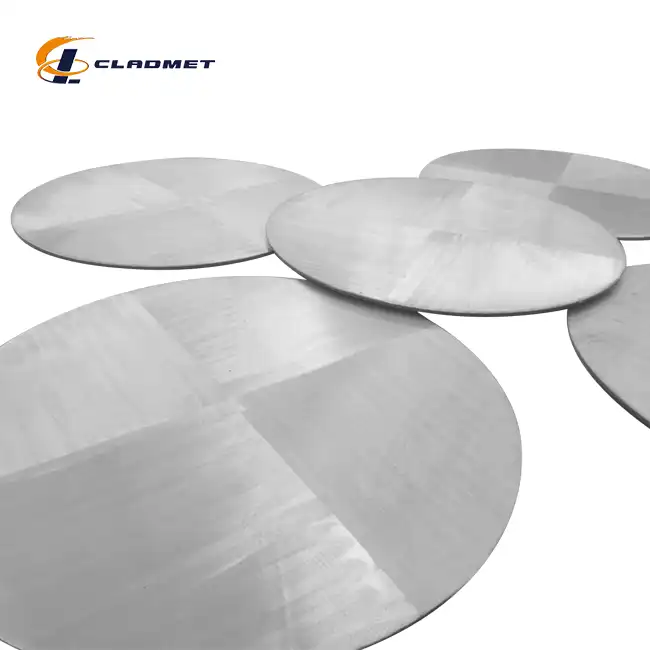

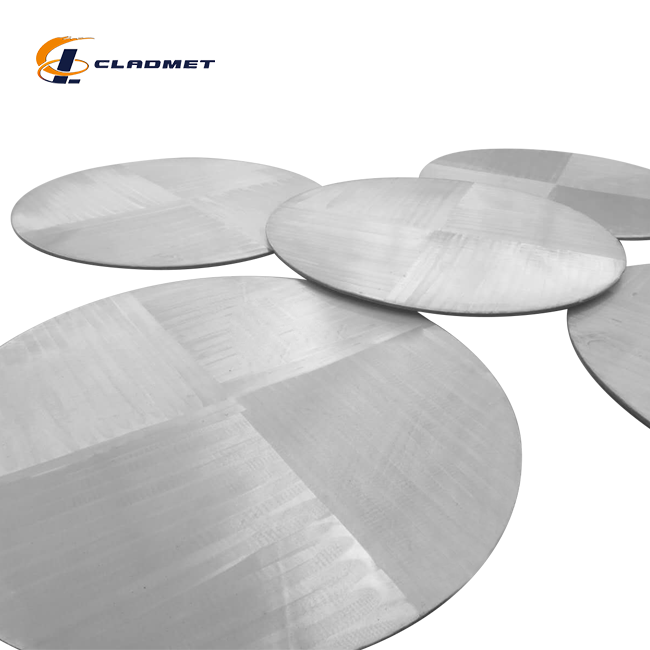

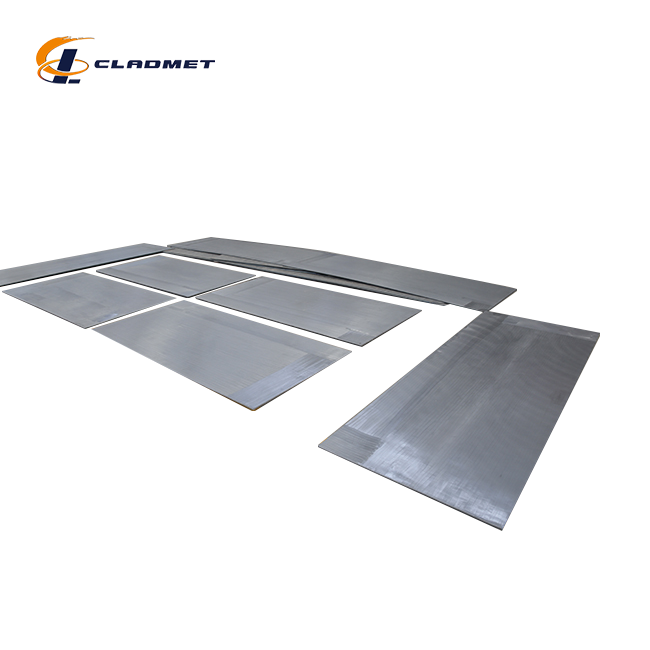

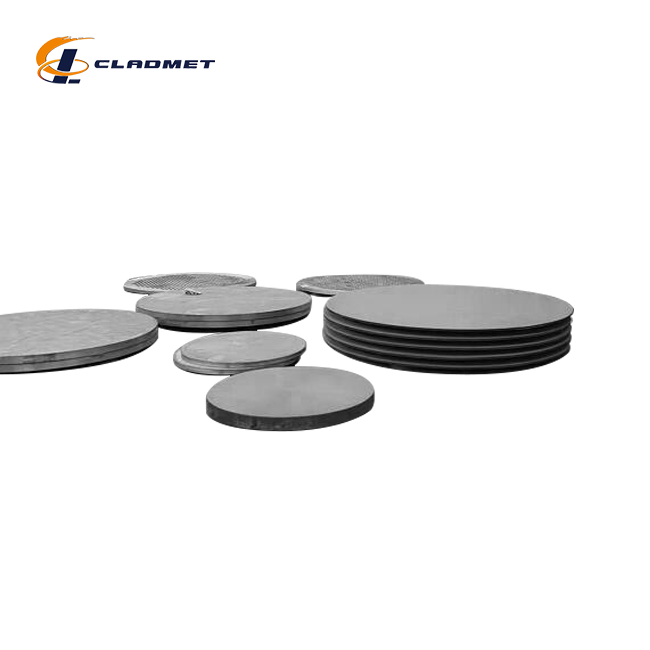

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

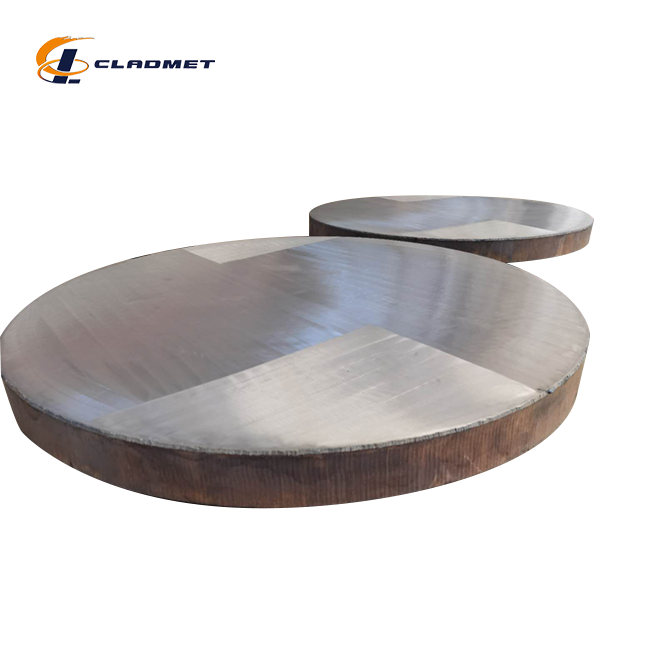

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Product Introduction

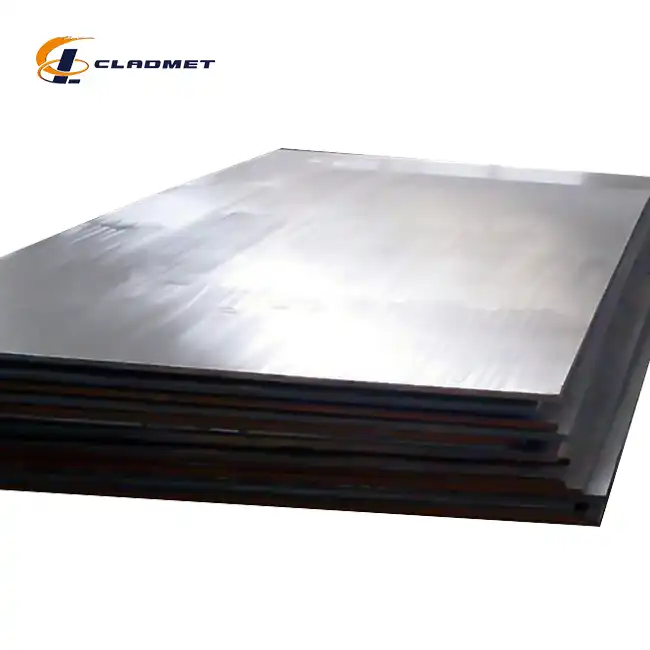

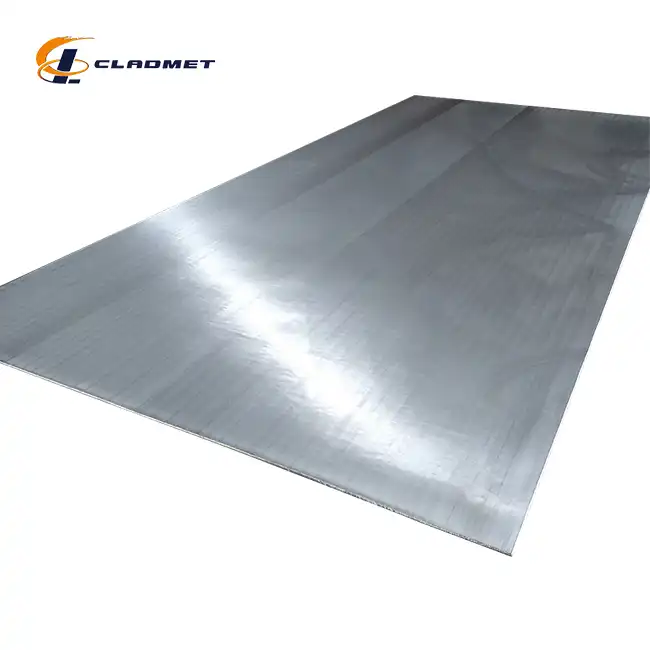

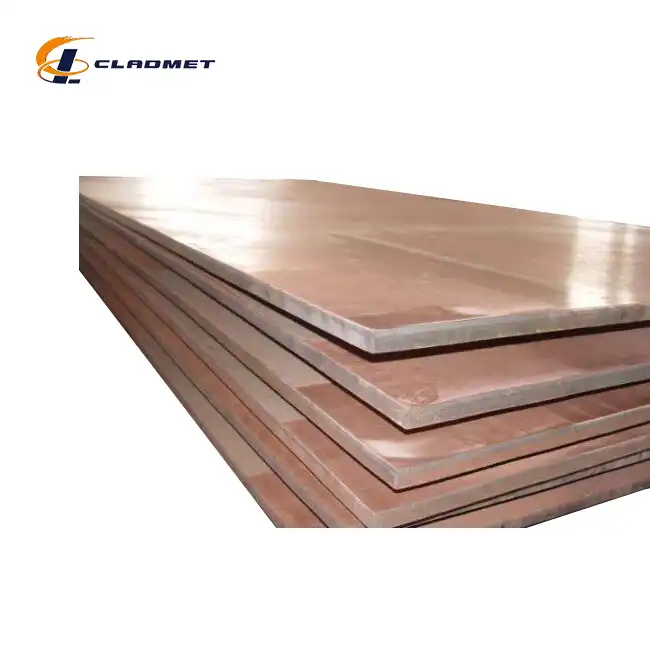

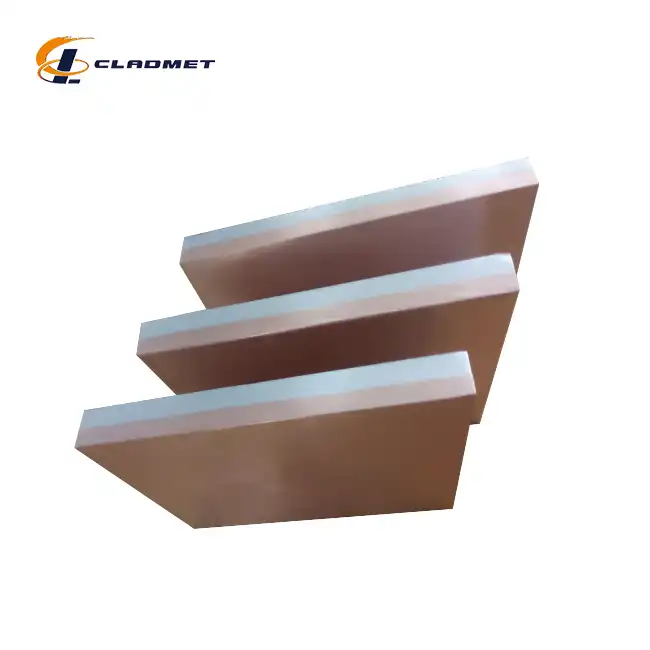

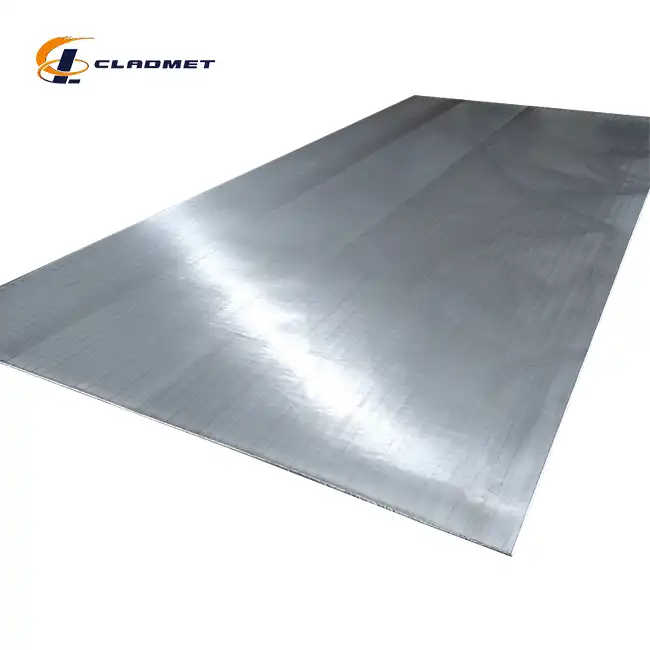

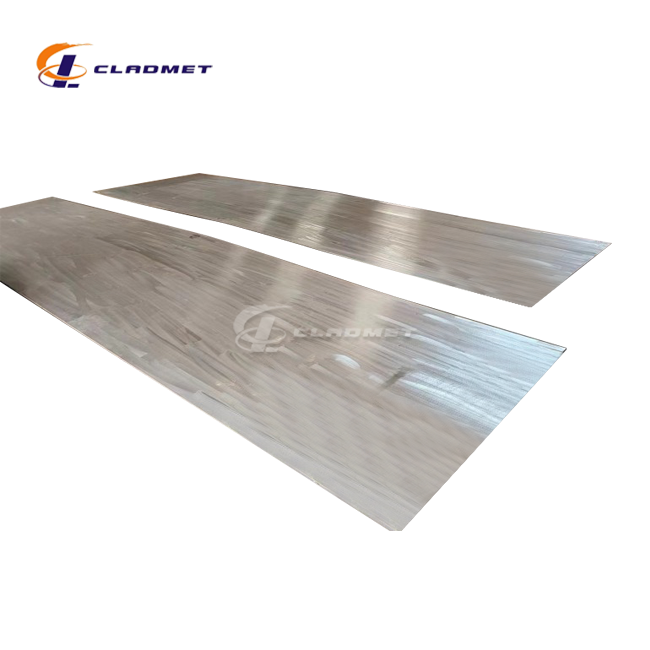

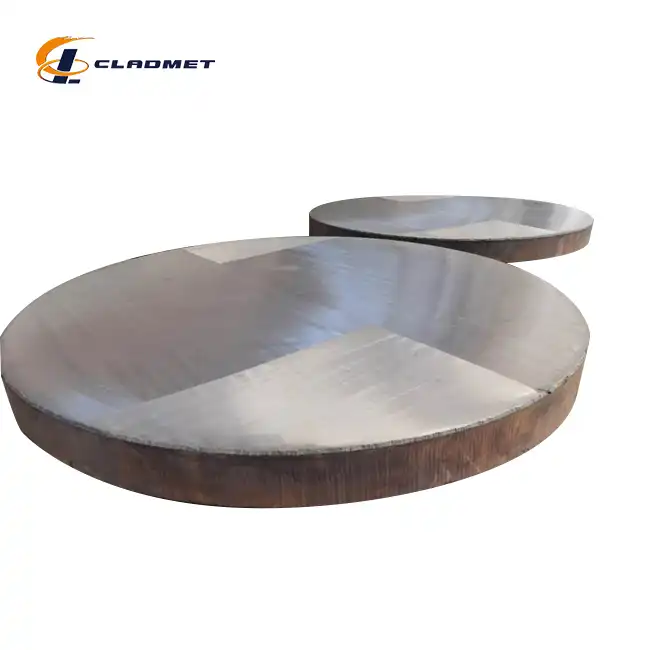

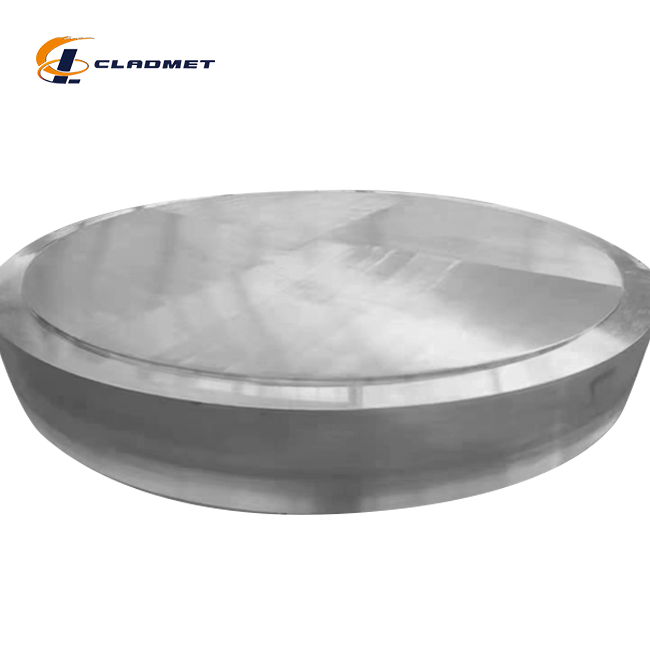

Clad stainless steel plates are a type of composite material made by bonding different metals together to create a material that combines the best properties of each metal. These plates offer exceptional corrosion resistance, strength, and durability, making them a reliable choice in industries where performance under harsh conditions is crucial. The plates are manufactured using advanced bonding processes like explosion bonding and roll bonding, ensuring a seamless integration of metals. Baoji JL Clad Metals Materials Co., Ltd specializes in producing the high-quality plates for various applications, ensuring compliance with international standards such as ASME, ASTM, and JIS.

Product Specifications

| Category | Details |

|---|---|

| Cladding Material | Stainless Steel (304, 316, etc.) |

| Base Metal | Carbon Steel, Alloy Steel |

| Cladding Size | Customized according to customer specifications |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Product Standards | ASME, ASTM, JIS |

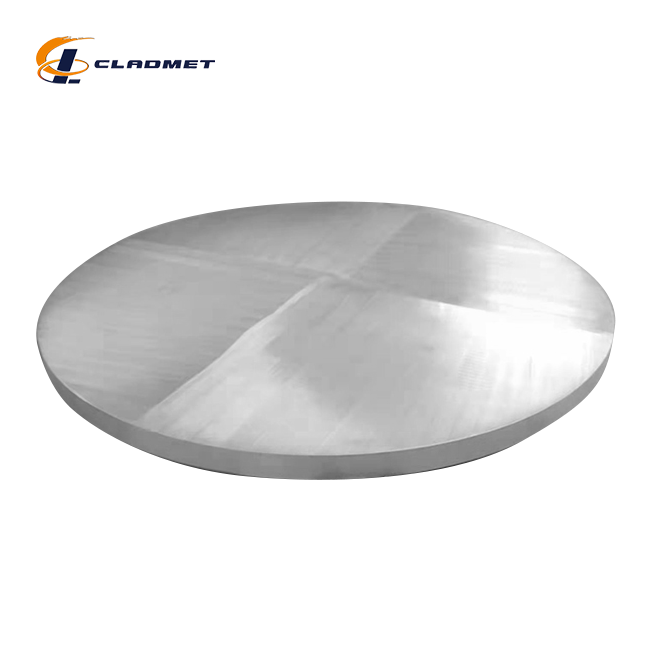

| Thickness | 3mm – 200mm |

| Length | Up to 12m |

| Width | Up to 4m |

| Surface Treatment | Pickling, Polishing, Coating |

| Packaging | Wooden crates or pallets, wrapped for protection |

| Delivery Cycle | 3-6 months or negotiable |

|

|

|

|

|

|

|

|

Manufacturing Techniques

Stainless steel clad plates combine the strength of carbon or alloy steel with the exceptional corrosion resistance of stainless steel. These plates are widely used across many industries due to their superior performance. Several methods are used to bond the stainless steel layer to the base material, ensuring a reliable and durable bond. These methods include:

Explosive Bonding

Explosive bonding is a high-energy process that creates a metallurgical bond between the stainless steel and the base metal by using a controlled explosion. The explosion generates intense pressure, causing the metals to fuse together without melting.

Preparation: Both the stainless steel and the base material are cleaned and positioned in preparation for the bonding process.

Detonation: Explosive charges are strategically placed between the two materials and detonated.

Bond Formation: The explosion forces the materials to collide at high velocity, creating a strong bond between the stainless steel and the base material.

This method is ideal for applications that require a bond with high strength, such as pressure vessels, heat exchangers, and other critical equipment exposed to extreme conditions.

Roll Bonding

Roll bonding is a cold-welding process where the stainless steel and the base metal are passed through rollers under high pressure. This method mechanically bonds the materials together.

Surface Cleaning: Both materials undergo a thorough cleaning to ensure optimal bonding.

Rolling Process: The materials are passed through a set of rollers, which apply pressure to create a solid bond. Multiple passes may be needed to ensure a uniform bond.

Continuous Bonding: The materials are tightly pressed together as they pass through the rollers, creating a smooth and seamless composite plate.

Roll bonding is commonly used for large-scale production of plates and sheets that require a balance of strength and corrosion resistance. This process is frequently used in industries such as chemical processing, offshore applications, and construction.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a bonding method that involves subjecting the stainless steel and the base material to both high temperature and pressure in a sealed chamber, resulting in a diffusion bond between the two layers.

Assembly: The stainless steel and base material are sealed in a high-pressure container.

Pressurization and Heating: The sealed container is heated to high temperatures and subjected to high pressure, allowing the materials to bond through atomic diffusion.

Uniform Bonding: This method results in a uniform, high-integrity bond that offers exceptional durability and resistance to mechanical stress.

HIP is often used for critical components in aerospace, energy, and defense industries, where high-strength, high-performance materials are required.

Advantages of Stainless Steel Clad Plates

Corrosion Resistance: The stainless steel layer offers exceptional resistance to rust, corrosion, and chemical degradation, making these plates ideal for use in harsh environments like chemical plants, marine applications, and offshore structures.

Strength and Durability: The base material, typically carbon or alloy steel, provides high tensile strength, while the stainless steel cladding enhances the material's durability.

Cost-Effectiveness: By using stainless steel cladding, the need for entirely stainless steel components is reduced, offering a cost-effective alternative while still benefiting from corrosion resistance.

Thermal Resistance: Stainless steel’s ability to withstand high temperatures makes these plates suitable for applications involving heat exchangers, boilers, and other equipment exposed to thermal stress.

Versatility: These plates can be tailored to meet specific industrial needs by adjusting the thickness of the stainless steel cladding and the base material, making them suitable for various applications.

Improved Longevity: The corrosion resistance of stainless steel extends the life of the composite plates, reducing the frequency of replacements and maintenance costs.

Mechanical Strength: The stainless steel layer improves the composite’s resistance to abrasion, impact, and mechanical wear, making them ideal for demanding applications.

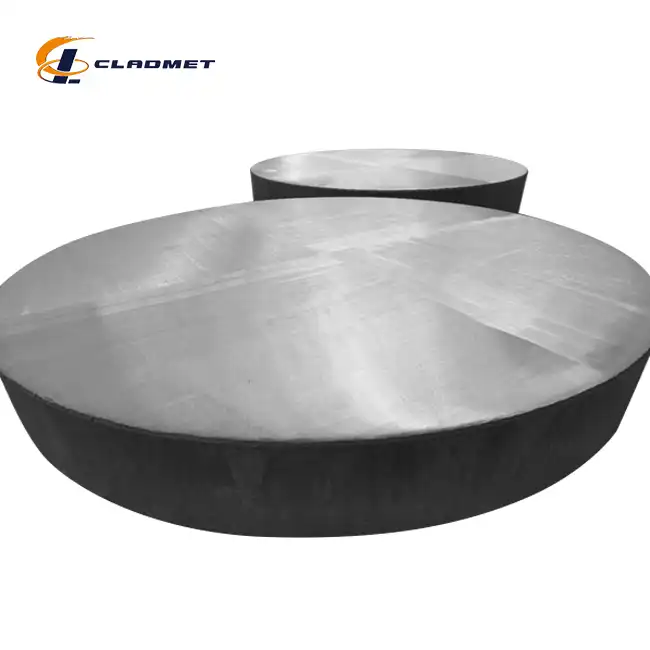

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

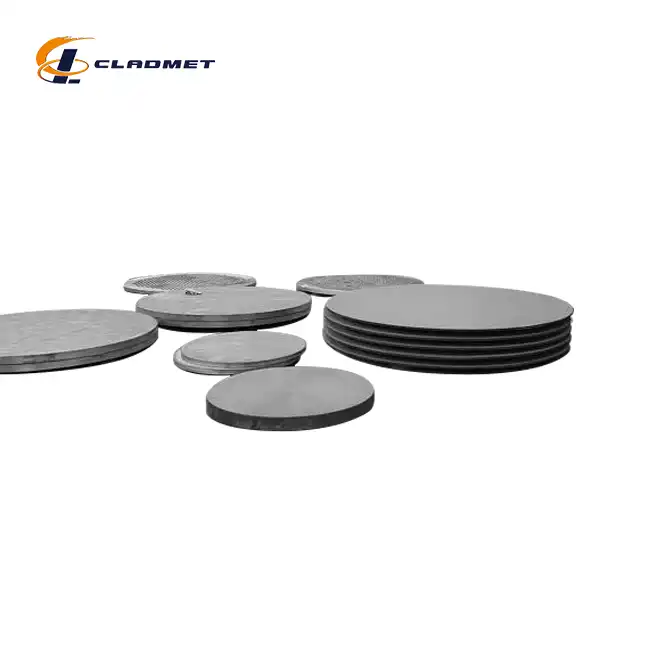

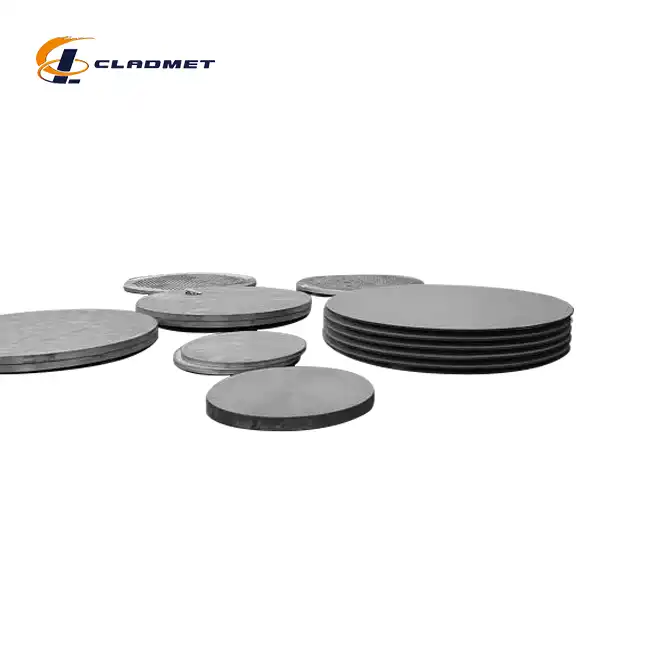

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals Materials Co., Ltd, we offer OEM services to provide tailored solutions for our clients. Our team works closely with you to customize the size, material, and specifications of clad stainless steel plates to suit your specific industry needs.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for orders?

A1: The standard delivery cycle is 3-6 months, depending on the order size and customization. However, we can negotiate delivery times to meet urgent needs.

Q2: What industries benefit the most from the steel plates?

A2: Industries such as oil & gas, chemical, nuclear, aerospace, marine, and pharmaceuticals benefit from these plates due to their corrosion resistance, strength, and longevity.

Q3: Can the plates be customized to specific project requirements?

A3: Yes, we offer a wide range of customization options to meet the unique demands of your project, including material composition, thickness, and surface treatment.

Q4: What quality certifications does JL Clad Metals hold?

A4: We are ISO 9001:2000 certified and have also passed PED and ABS international qualifications in 2024, ensuring the highest standards of quality.

Contact Us

For more information or to request a quote, please reach out to us:

- Phone: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

By choosing JL Clad Metals, you ensure that your industrial needs are met with top-quality, reliable materials backed by over 30 years of expertise.

_1737007724117.webp)