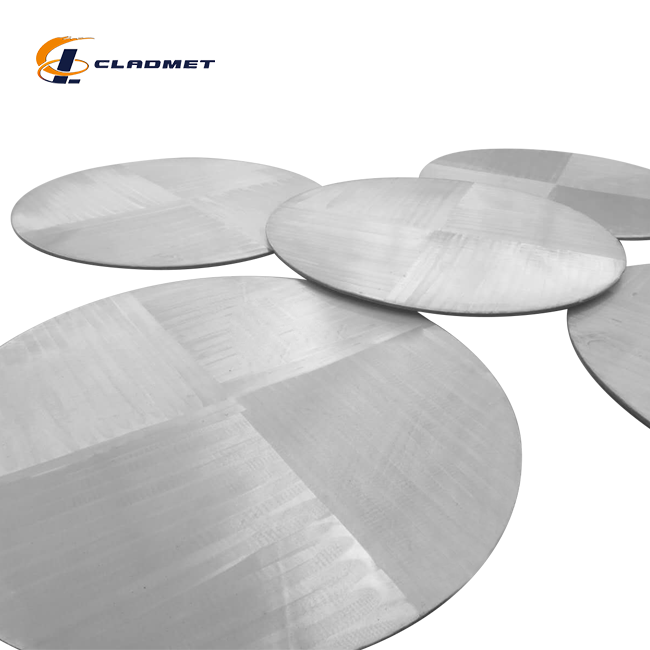

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Introduction

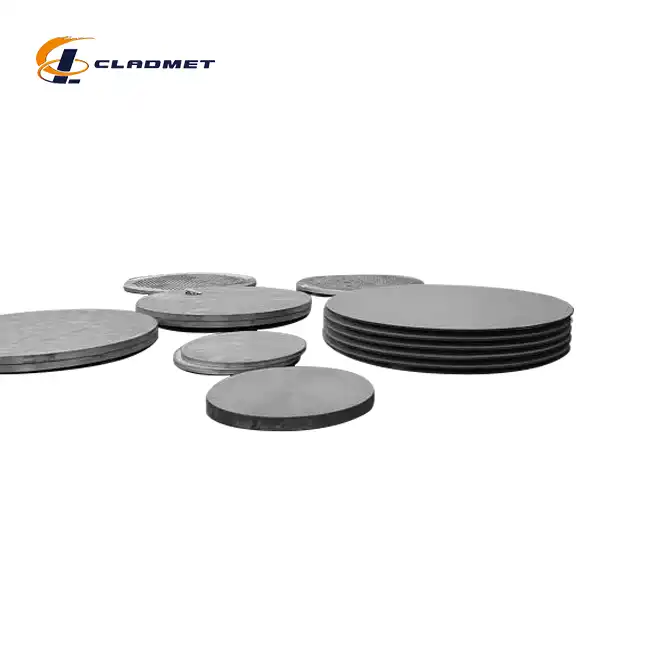

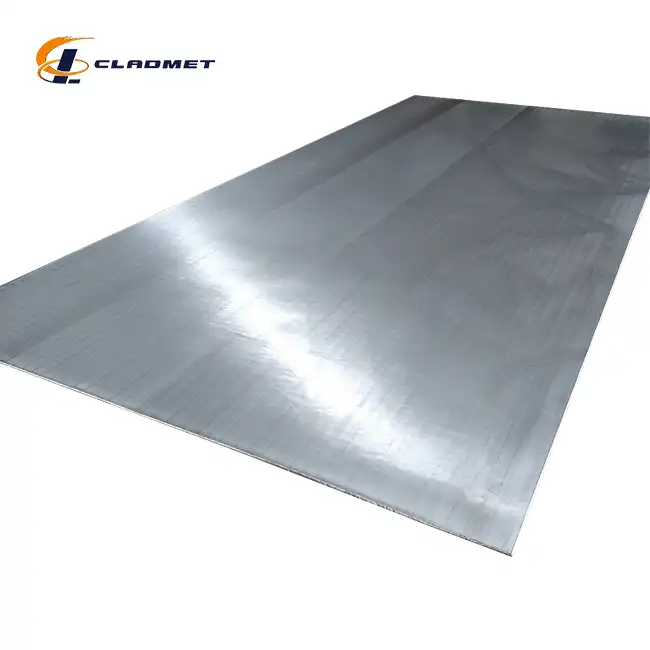

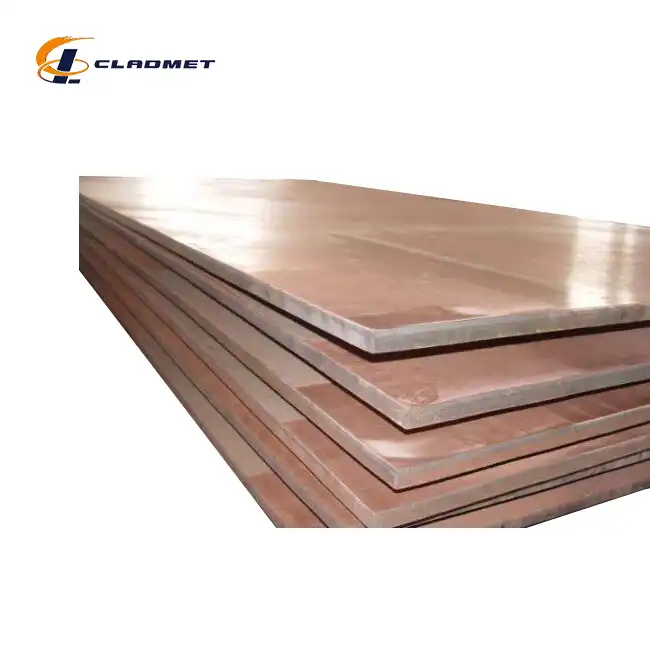

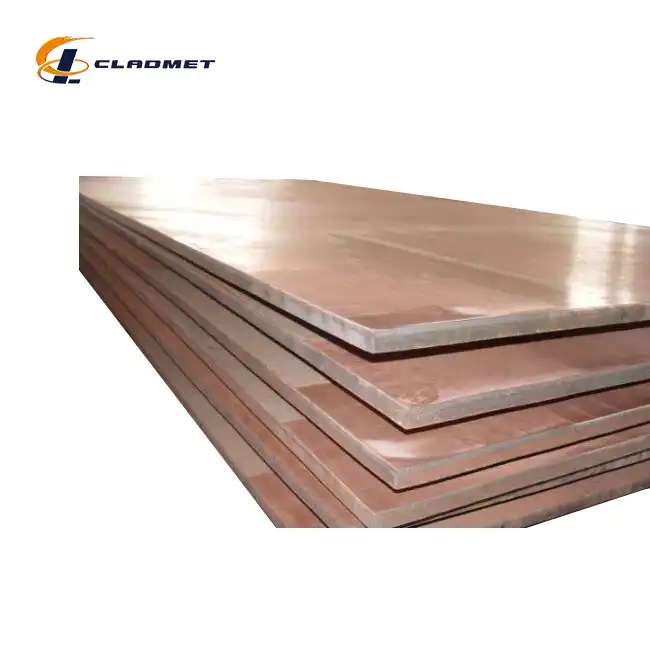

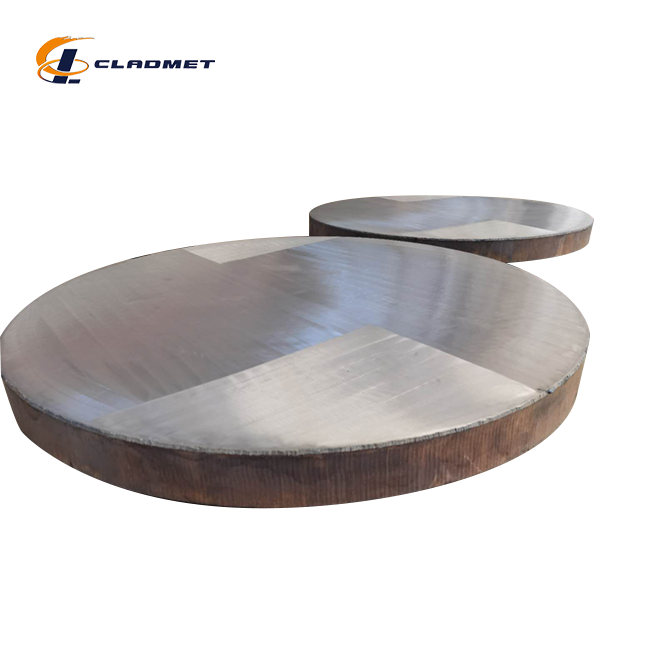

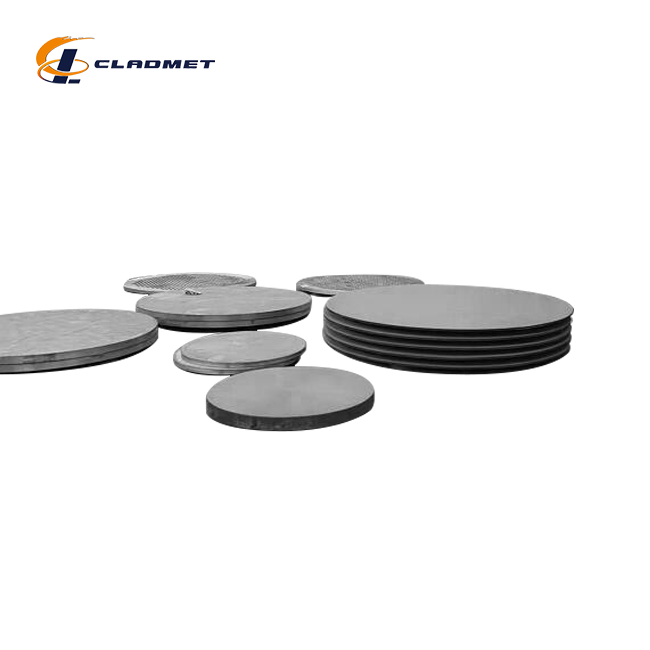

The wear resistant clad steel plate from Baoji JL Clad Metals Materials Co., Ltd. offers an innovative solution to industries requiring materials that provide superior wear resistance, durability, and strength. Designed to withstand harsh environments and abrasive conditions, this clad plate is ideal for industries like oil and gas, mining, power generation, and more. By combining two or more layers of metals, the wear-resistant clad steel plate enhances performance, offering unparalleled longevity and reliability.

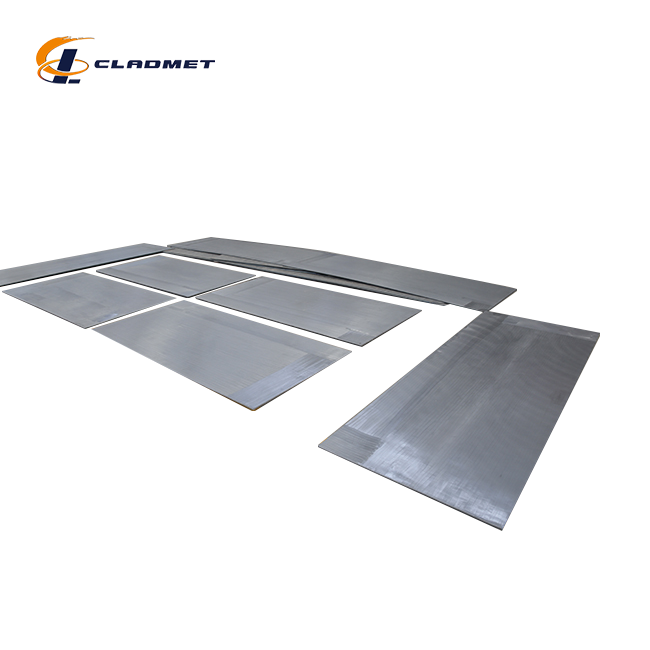

Product Specifications

The following table provides detailed specifications for our wear resistant clad steel plate:

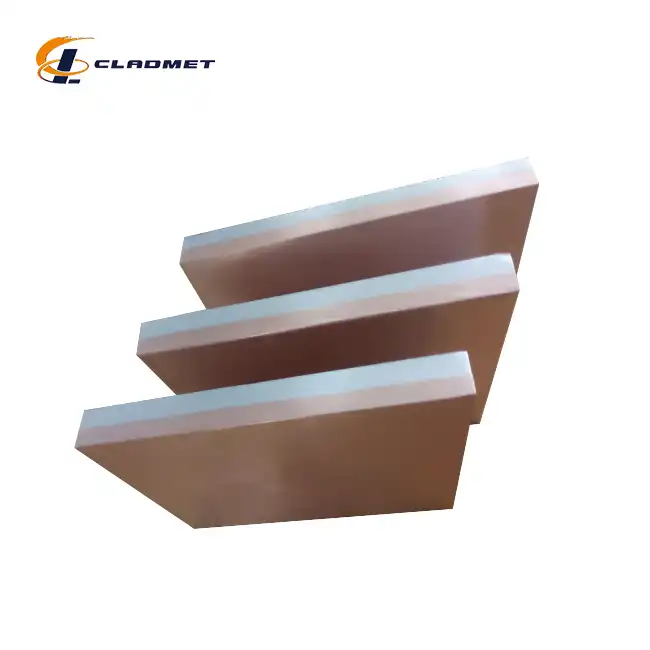

| Cladding Material Range | Titanium, Nickel, Stainless Steel, Copper, Aluminum, Zirconium |

|---|---|

| Base Metal Range | Carbon Steel, Alloy Steel, Stainless Steel |

| Cladding Technology | Explosion Bonding, Roll Bonding |

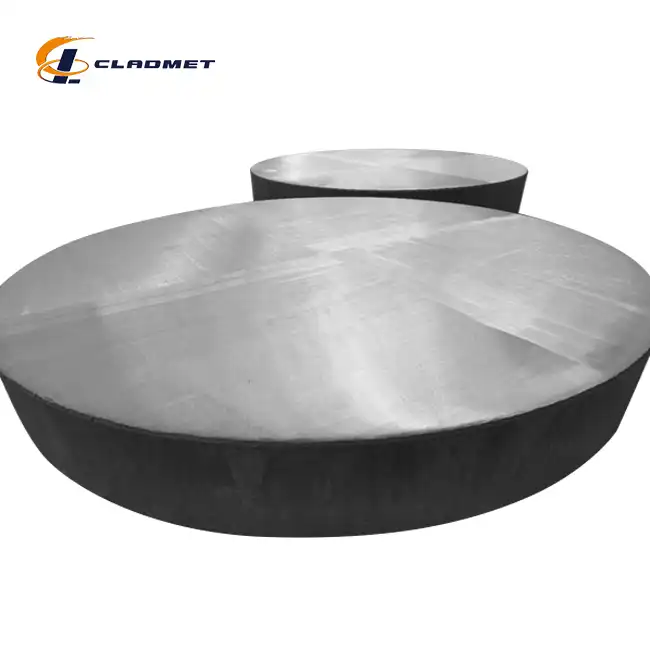

| Thickness | 5mm - 200mm |

| Width | Up to 4000mm |

| Length | Customizable, up to 12 meters |

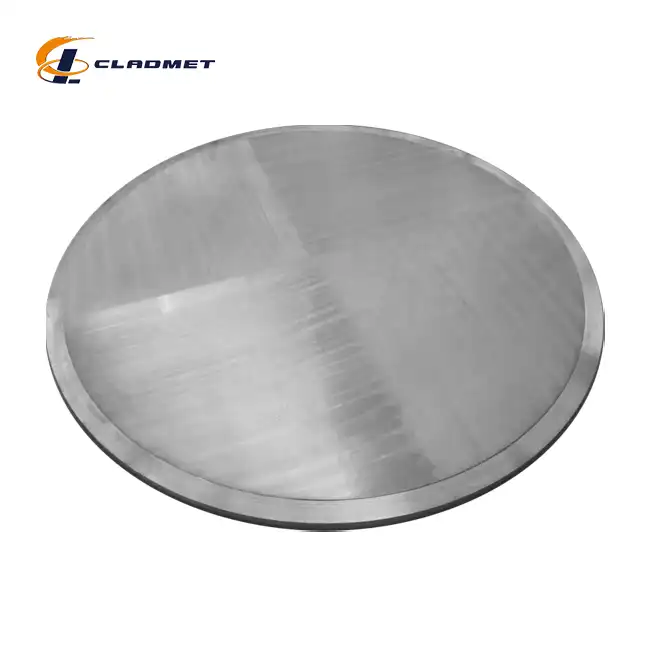

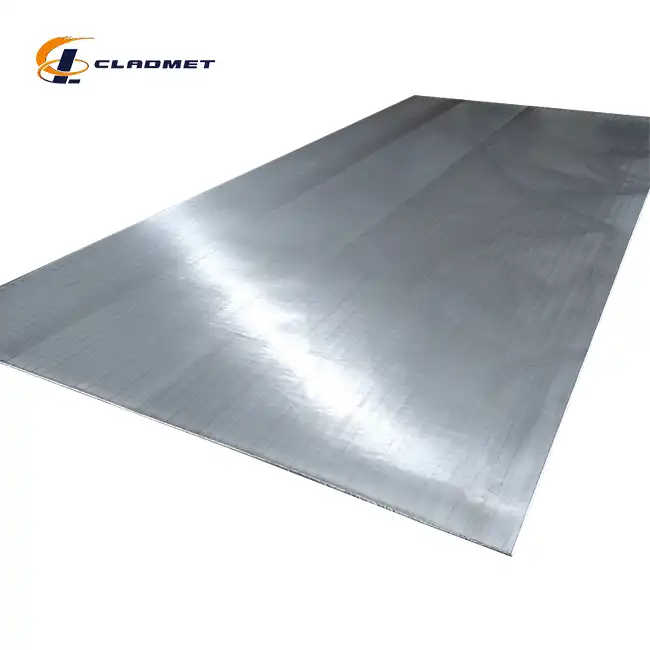

| Surface Treatment | Sandblasting, Polishing, Anti-corrosion coating |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Delivery Cycle | 3-6 months or negotiable |

| Packaging Method | Seaworthy wooden cases, steel frames |

| Transportation | By sea, air, or land |

|

|

|

|

|

|

|

|

Wear-Resistant Cladding Process

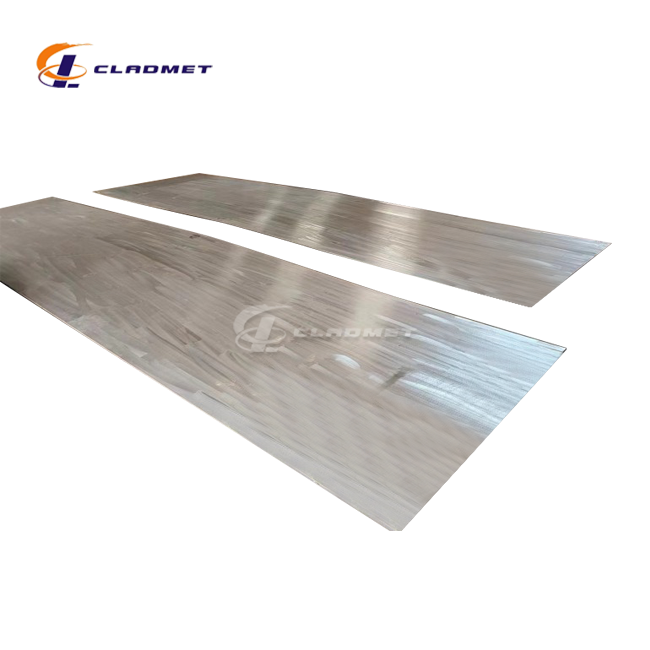

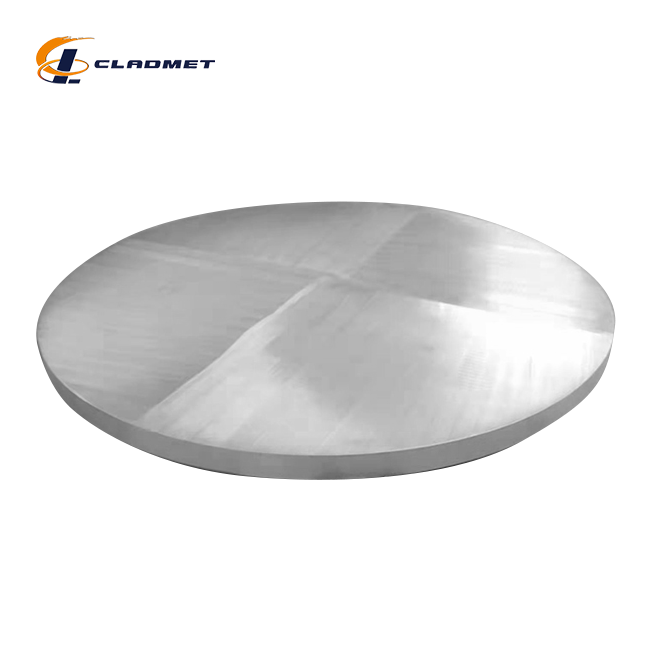

Wear-resistant clad steel plates are created by bonding a tough, abrasion-resistant steel layer onto a more ductile base material. This combination provides superior protection against wear, abrasion, and impact while retaining the flexibility and toughness of the underlying steel. Several advanced manufacturing techniques are used to achieve a strong, durable bond between the cladding and base material.

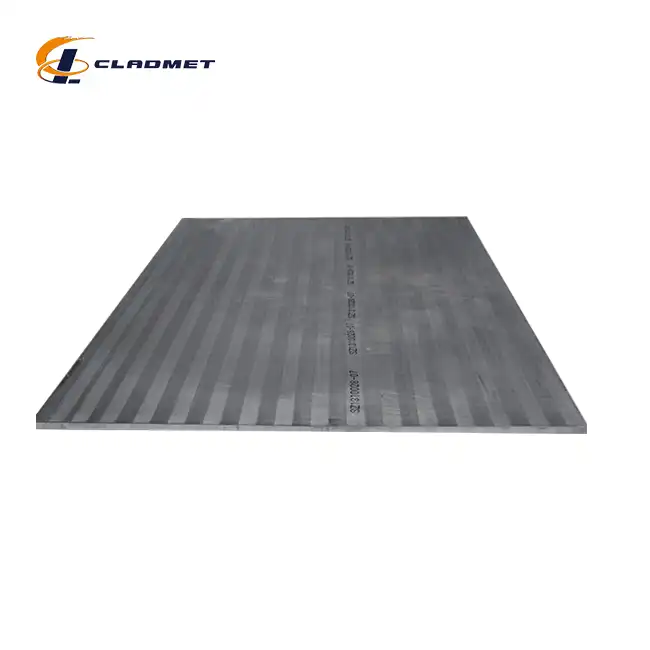

Explosive Bonding

Explosive bonding is a dynamic process where a controlled explosion generates a high-velocity impact, causing the wear-resistant steel layer to bond with the base material. The explosion ensures a robust, permanent connection without altering the properties of the materials involved.

Preparation: Both materials are thoroughly cleaned and aligned to ensure a perfect bond.

Explosion Initiation: An explosive charge is placed between the two layers, and detonated, creating a high-speed impact.

Bond Formation: The resulting shock wave causes the materials to fuse, creating a strong, metallurgical bond.

Explosive bonding is ideal for applications where maximum strength is essential, such as in mining equipment, heavy-duty machinery, and other industrial applications subject to high wear.

Roll Bonding

Roll bonding involves passing the base material and wear-resistant steel sheet through rollers under high pressure, forcing the materials to bond together.

Surface Preparation: Both the wear-resistant steel and the base metal are thoroughly cleaned to ensure a clean bonding surface.

Rolling Process: The two layers are fed through rollers, where the applied pressure causes them to adhere to each other, forming a solid bond.

Multiple Passes: The materials may go through multiple passes to ensure that the bond is uniform and durable.

Roll bonding is widely used to produce wear-resistant clad plates for industries that require high durability, such as steel mills, cement factories, and construction.

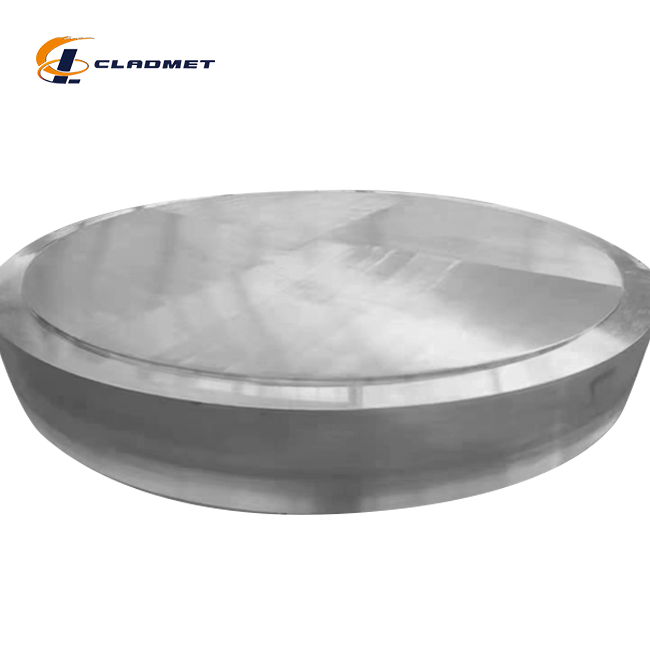

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing involves enclosing the base material and wear-resistant steel in a sealed container, then subjecting them to high temperature and pressure. This process enables atomic diffusion between the materials, forming a solid and durable bond.

Encapsulation: The wear-resistant steel and base material are placed in a sealed chamber, ensuring they are in close contact.

Heating and Pressurization: The sealed container is exposed to high temperatures and pressures, allowing the materials to bond on a molecular level.

Uniform Bonding: The heat and pressure result in a uniform, high-integrity bond that enhances the overall strength of the clad plate.

HIP is suitable for applications where high integrity and precision are required, including the aerospace and energy sectors.

Features and Advantages

Exceptional Wear Resistance

The wear-resistant layer provides outstanding resistance to abrasion and erosion, making these plates perfect for applications that involve frequent contact with harsh environments or abrasive materials. This feature greatly extends the lifespan of equipment and reduces maintenance costs.

Impact Resistance

Wear-resistant clad steel plates are designed to withstand high levels of mechanical stress and impact, ensuring that machinery and equipment can function efficiently even under harsh operational conditions.

Corrosion Protection

In addition to wear resistance, the clad steel plates offer excellent protection against corrosion, ensuring durability in industries like mining, construction, and chemical processing, where exposure to aggressive substances is common.

Strength-to-Weight Efficiency

The bonding process allows wear-resistant steel to provide superior strength without significantly increasing the overall weight of the material. This makes it suitable for applications where both high durability and lightweight properties are needed.

Cost-Effective Solution

Wear-resistant clad plates are a cost-effective alternative to solid wear-resistant steel components. The cladding allows manufacturers to use less expensive base materials while still achieving the same durability and strength as fully solid wear-resistant components.

Customization Options

Wear-resistant clad steel plates can be customized to meet the specific needs of industries, with varying thicknesses, surface treatments, and sizes available. This flexibility allows the plates to be adapted to a wide range of industrial requirements.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer flexible OEM services to meet your specific needs, including custom sizes, cladding materials, and surface treatments. Our team provides full support throughout the design, manufacturing, and delivery processes.

FAQ

- What is the delivery time for wear-resistant clad steel plates?

- The typical delivery cycle is 3-6 months, depending on the order size and customization requirements.

- Can wear resistant clad steel plate be customized?

- Yes, we offer customization in terms of cladding materials, base metals, thickness, width, length, and surface treatments.

- What industries use wear-resistant clad steel plates?

- These plates are widely used in oil and gas, mining, power generation, marine engineering, and chemical processing industries.

Contact Us

For more information on our wear-resistant clad steel plates, contact us at:

- Tel: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China 721013

_1737007724117.webp)