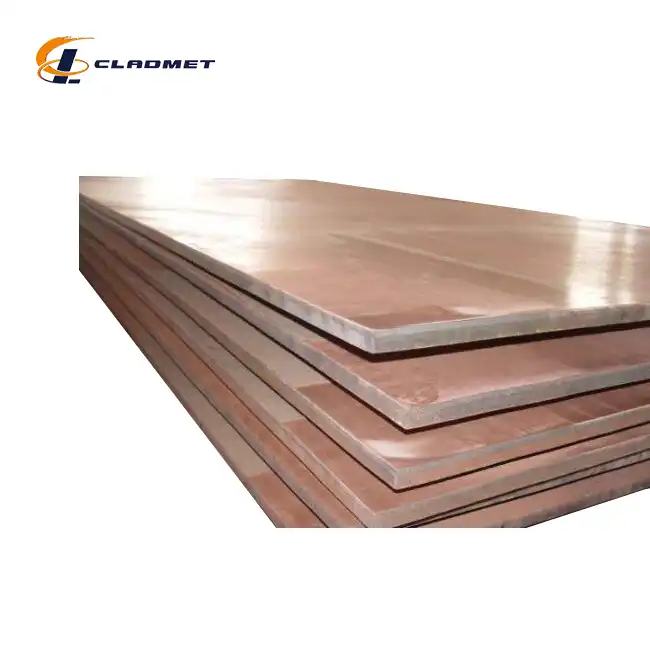

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

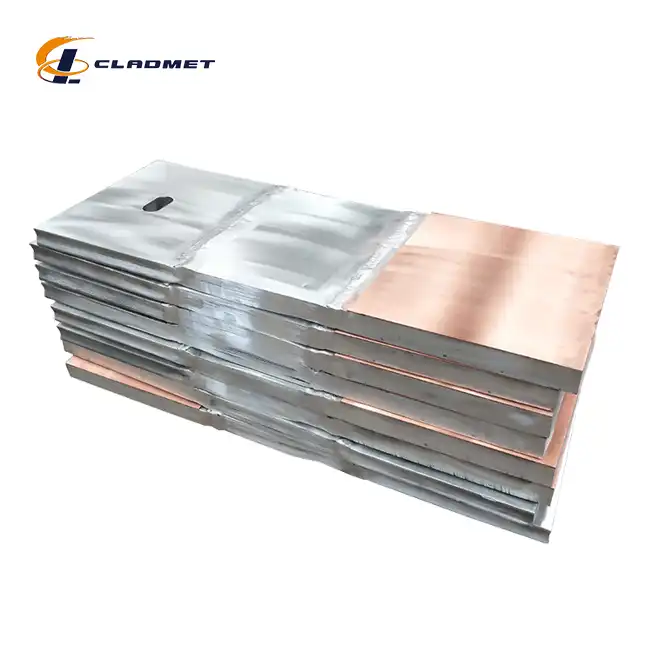

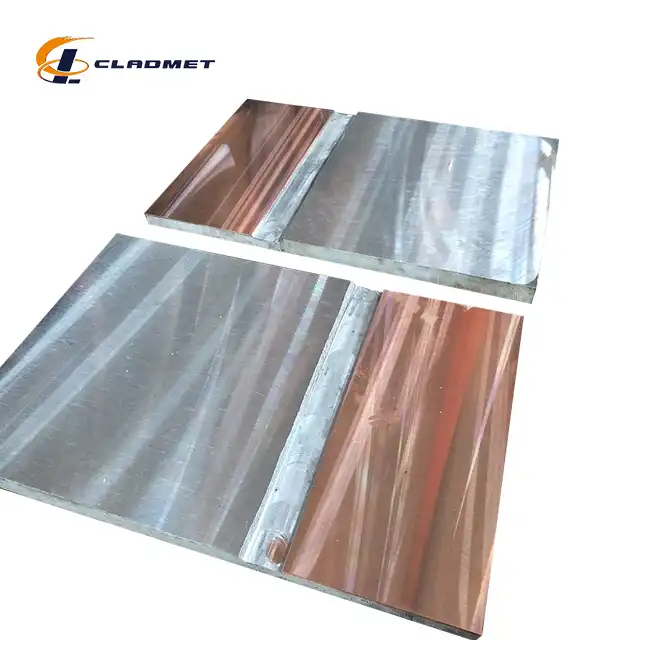

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

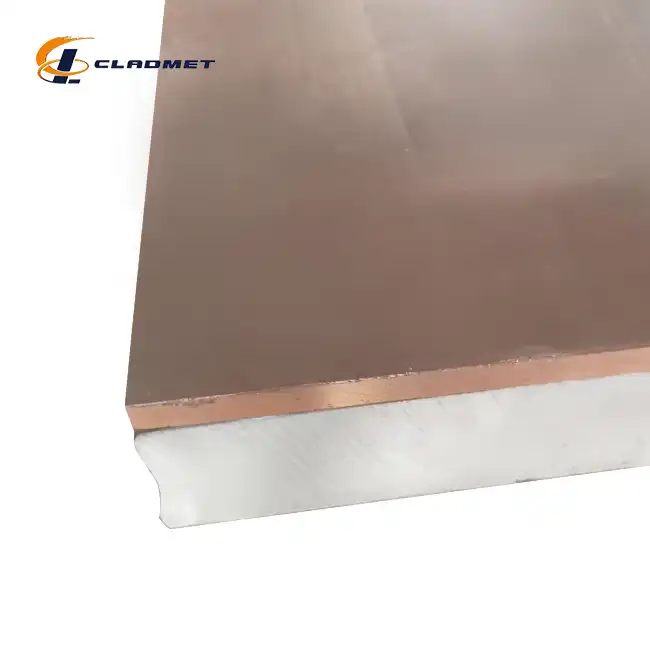

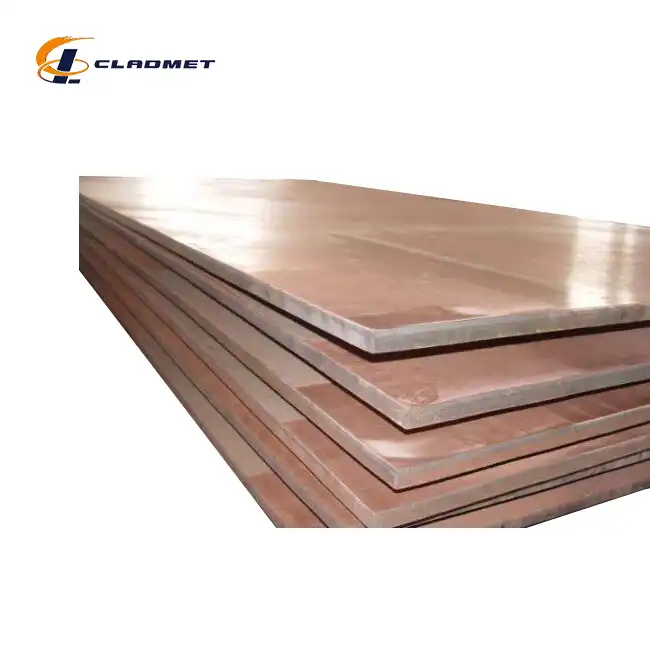

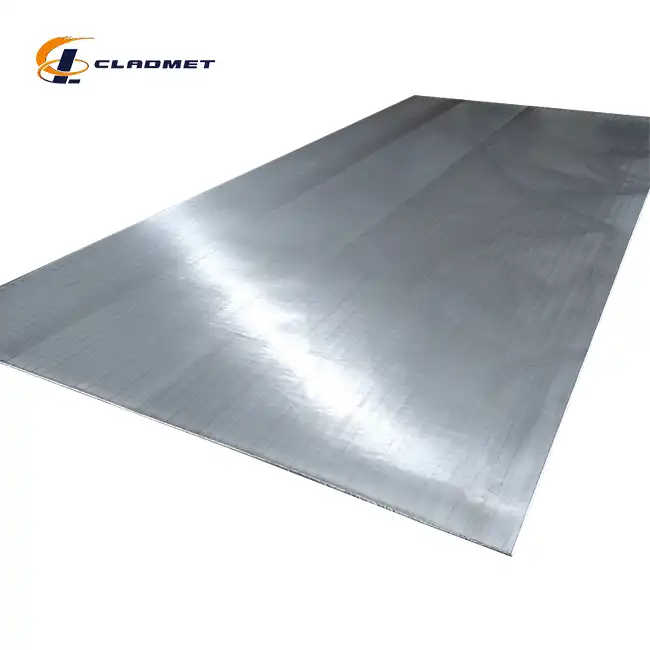

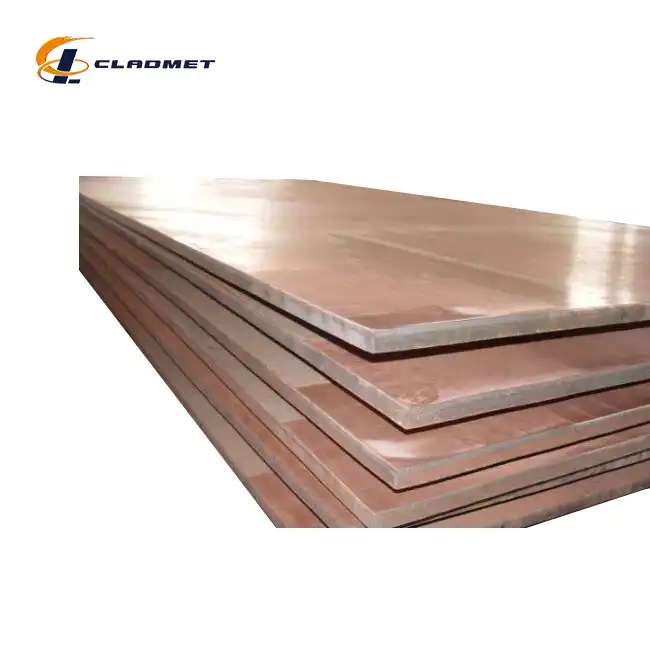

Copper Carbon Steel Clad Plate: High Performance for Industrial Applications

We at Baoji JL Clad Metals Materials Co., Ltd. are experts in the production of copper carbon steel clad plate of the highest quality. These plates are a versatile option for industries that require exceptional strength, resistance to corrosion, and durability. We have developed advanced bonding processes, such as explosion-bonding and roll-bonding, over the course of more than two decades to meet the various requirements of our global clients in industries like oil and gas, aerospace, and chemical processing.

Product Specifications

| Parameter | Description |

|---|---|

| Base Material | Carbon Steel (e.g., Q235B, Q345B, A516 Gr.70, etc.) |

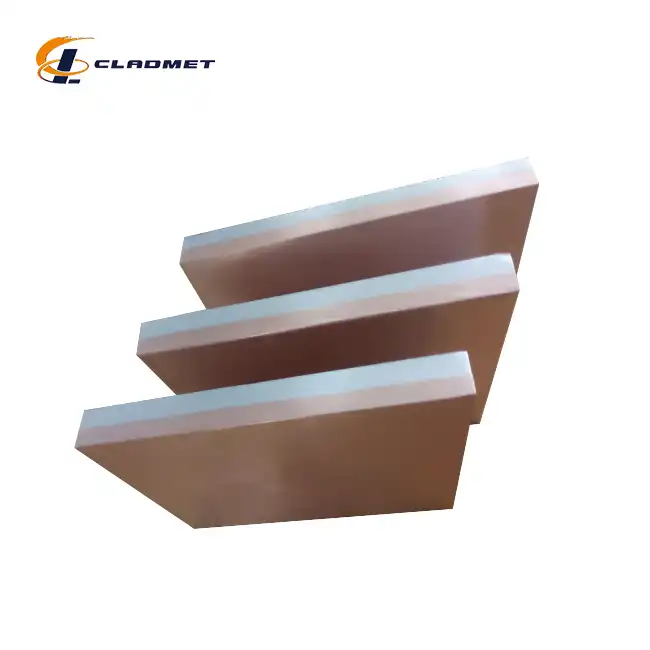

| Cladding Material | Copper (e.g., T1, T2, C11000, C12200, etc.) |

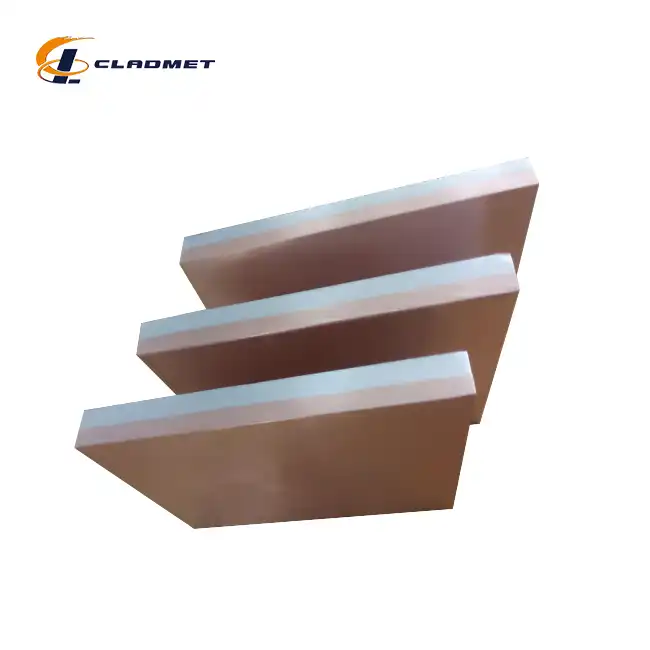

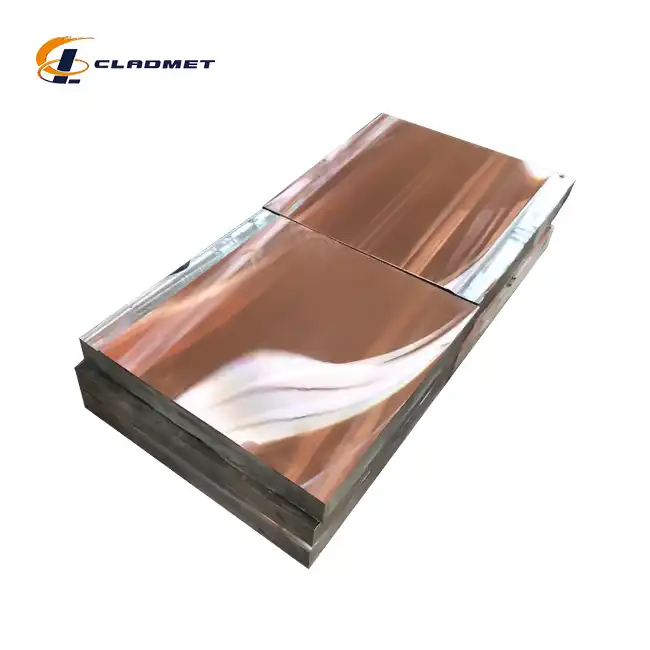

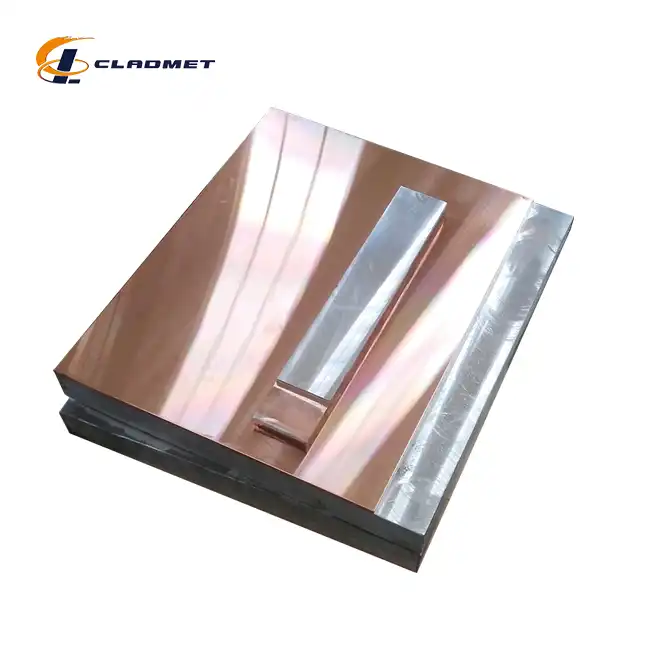

| Thickness Range | Total: 6 mm - 200 mm (e.g., 2 mm Copper + 8 mm Carbon Steel) |

| Clad Layer Thickness | 1 mm - 20 mm (customizable) |

| Base Layer Thickness | 5 mm - 180 mm (customizable) |

| Width Range | Up to 3000 mm |

| Length Range | Up to 12000 mm |

| Bonding Technology | Explosion Bonding or Hot Rolling |

| Bonding Strength | ≥ 130 MPa |

| Shear Strength | ≥ 100 MPa |

| Electrical Conductivity | Excellent (Clad Layer: ~99% IACS for pure copper grades) |

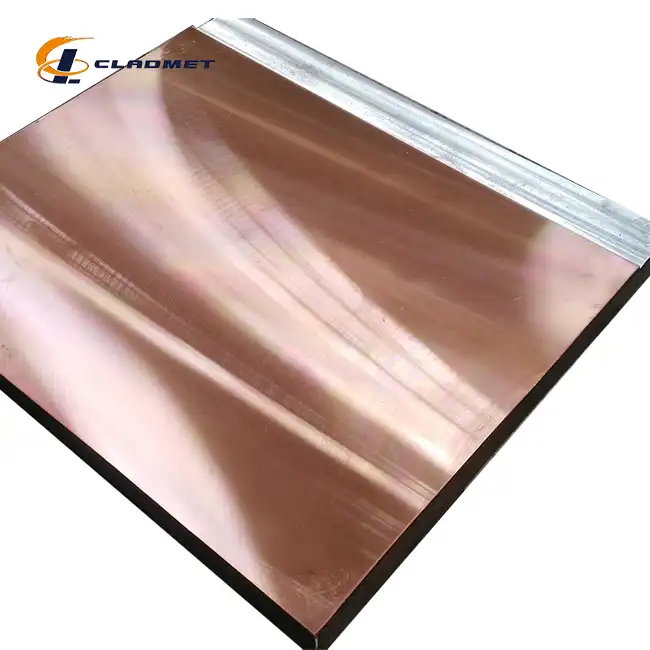

| Corrosion Resistance | Superior resistance to corrosion in chemical and marine environments |

| Application Industries | Power Generation, Chemical, Shipbuilding, Desalination, Architecture, Electronics, etc. |

| Standards Compliance | ASTM B432, ASME SB-432, GB/T 8165, etc. |

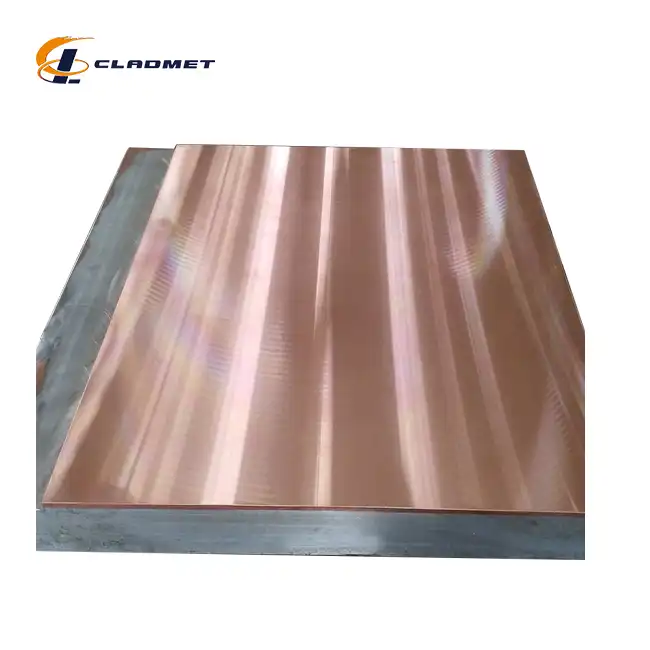

| Surface Finish | Polished, Sandblasted, or Customized |

| Customizations Available | Size, Material Grade, Thickness Ratio, and More |

|

|

|

|

Manufacturing Processes

The production of copper carbon steel clad plates involves advanced bonding techniques to combine copper's excellent conductivity and corrosion resistance with carbon steel's structural strength. Key methods include:

Dynamic Bonding through Explosive Welding

This process uses controlled energy to create a metallurgical bond between copper and carbon steel. Steps include:

Preparation Phase: Meticulous cleaning and arrangement of copper and carbon steel layers.

Explosive Setup: Strategically placing an explosive charge to facilitate a controlled impact.

Impact and Bond Formation: Detonation drives the layers together at high velocity, achieving a strong and durable bond.

This method is ideal for demanding environments, such as power generation and petrochemical processing.

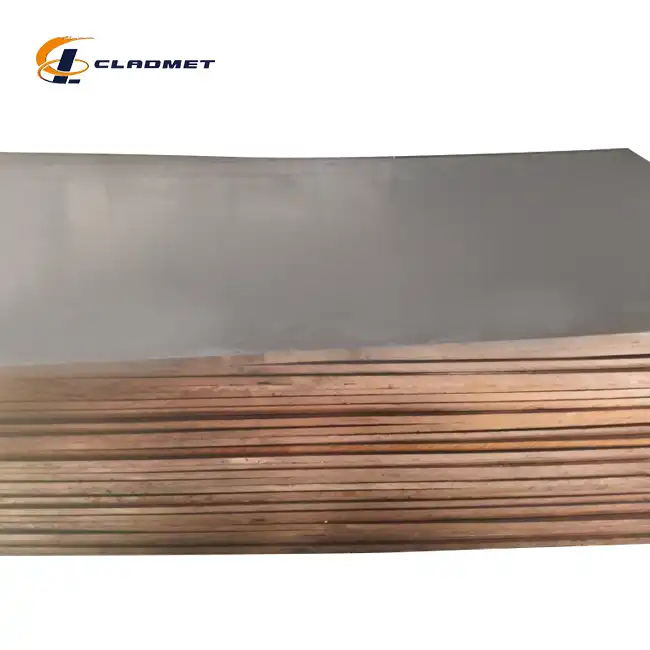

Pressure Bonding via Rolling Techniques

In this approach, copper and carbon steel sheets are passed through high-pressure rollers, resulting in a seamless bond. The process comprises:

Surface Conditioning: Ensuring both materials are free from contaminants.

Layer Compression: Applying intense rolling pressure to achieve a robust connection.

This technique is particularly suited for producing large, uniform plates for infrastructure and construction.

Thermal Diffusion Bonding

By exposing the materials to controlled heat and pressure, a diffusion bond is created at the atomic level. The process includes:

Layer Assembly: Secure placement of the materials in a sealed environment.

Controlled Thermal Application: Uniform heating and compression to achieve molecular integration.

This method is commonly used for applications requiring precision and high reliability, such as aerospace and electronics.

Product Features and Benefits

Outstanding Electrical and Thermal Conductivity: Copper provides superior energy transfer capabilities, making these plates essential for electrical and heat transfer systems.

High Mechanical Strength: Carbon steel's structural integrity supports heavy loads and enhances durability.

Exceptional Corrosion Resistance: The copper layer protects against chemical and environmental degradation, ensuring longevity.

Cost-Effectiveness: Combining copper's premium performance with carbon steel's affordability offers an excellent balance of quality and value.

Customizable Design Options: Available in various thicknesses, dimensions, and configurations to meet specific requirements.

Sustainability: The durability and recyclability of copper carbon steel clad plates contribute to reduced material waste and environmental impact.

Reduced Maintenance Costs: The robust design minimizes wear and tear, lowering the frequency of replacements.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

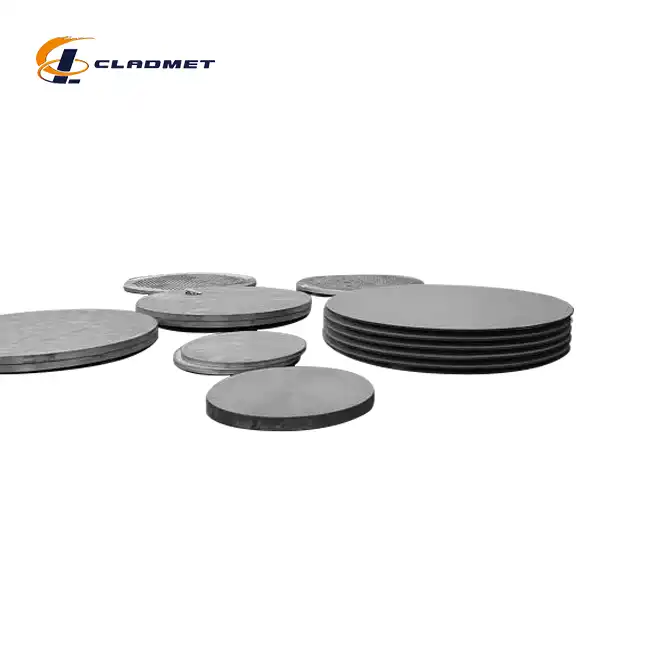

Main Products

Main Application Industries

OEM Service

We provide individualized solutions to meet the requirements of your project. Our team collaborates closely with customers to ensure that the finished product meets all technical specifications. Our OEM services offer a adaptable strategy for custom solutions, from material selection to size customization.

Frequently Asked Questions (FAQ)

1. What are the available thickness ranges?

We offer thicknesses ranging from 1.5mm to 10mm for the copper layer, with the carbon steel base customizable to your specifications.

2. What industries use copper carbon steel clad plates?

Our clad plates are widely used in industries such as oil and gas, chemical processing, aerospace, and environmental engineering.

3. Can you provide custom sizes and specifications?

Yes, we offer full customization of sizes, thicknesses, and surface treatments to suit your project’s unique requirements.

4. What is your typical delivery cycle?

Our standard delivery cycle is 3-6 months, but it can be negotiable based on order size and urgency.

Contact Us

For more information or to place an order, please reach out to us:

- Tel: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)