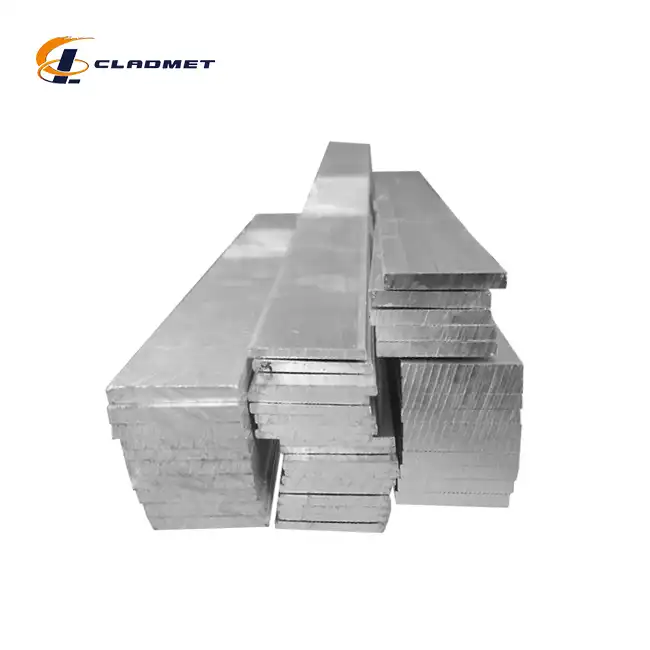

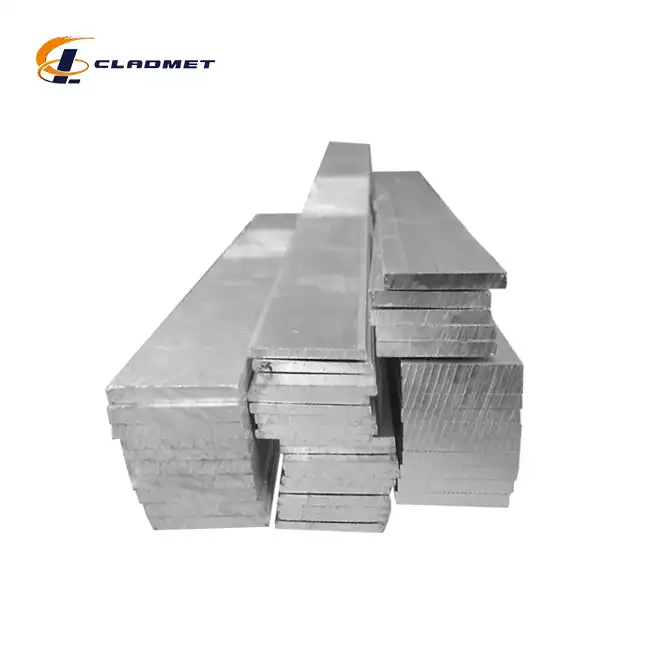

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Product Introduction

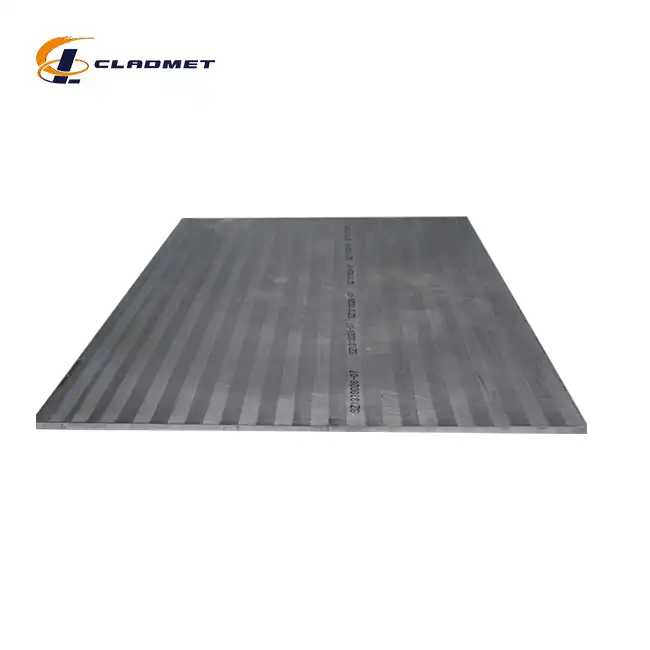

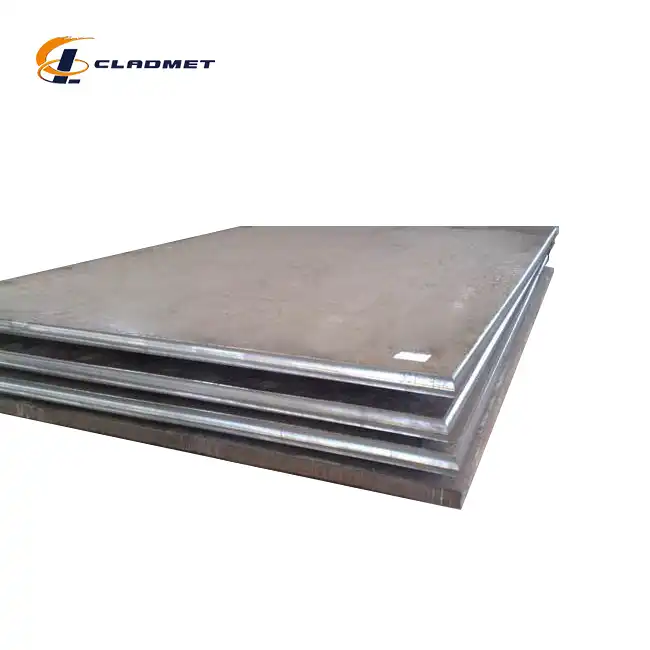

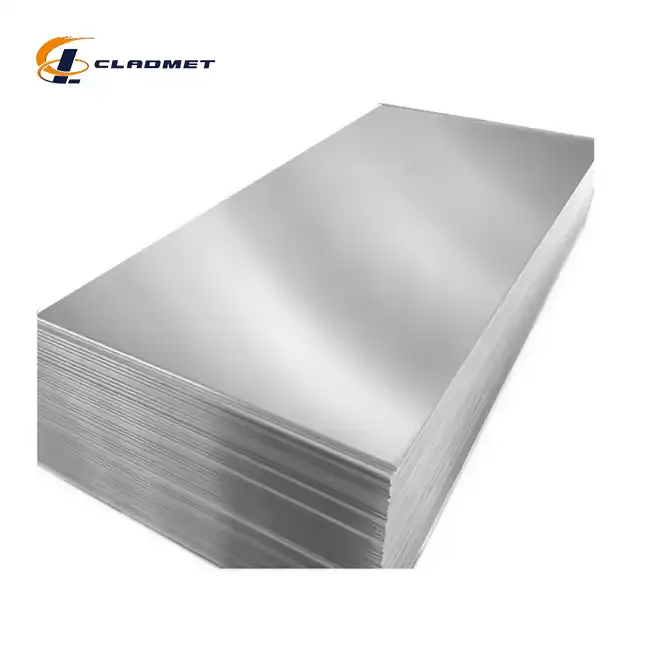

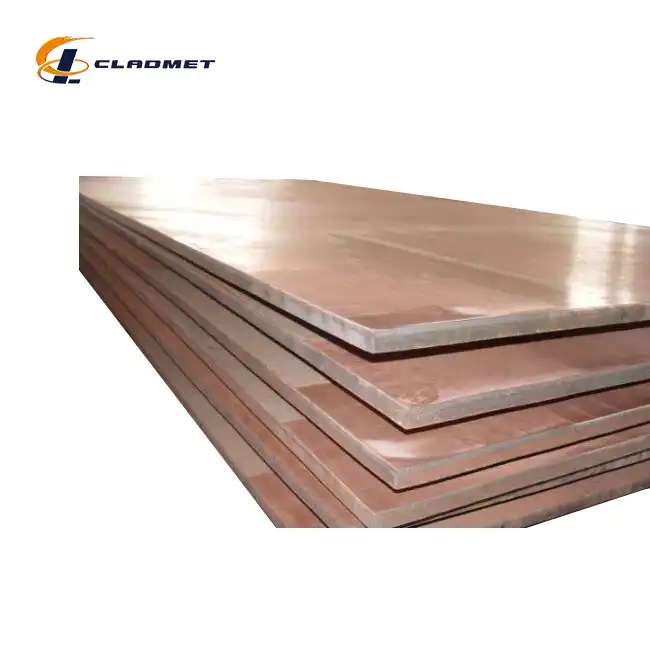

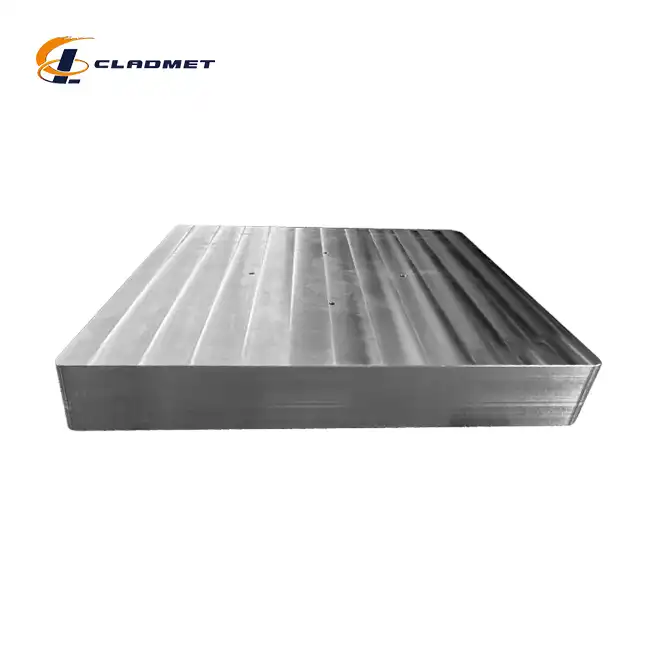

The Nickel Steel Clad Plate from Baoji JL Clad Metals Materials Co., Ltd combines the superior corrosion resistance of nickel with the strength and cost-efficiency of steel. This composite material is created through advanced bonding processes like explosion or roll bonding, ensuring high durability and performance in various demanding industrial environments. Widely used in sectors such as petrochemical, nuclear, and aerospace, they offer an ideal solution for applications requiring excellent mechanical properties and corrosion resistance.

Product Specifications

| Item | Details |

|---|---|

| Cladding Material | Nickel, Nickel Alloys |

| Base Metal | Carbon Steel, Stainless Steel |

| Cladding Size | Customized based on project needs |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Standards | GB/GBT, ASME/ASTM, JIS |

| Thickness | 2mm to 10mm for cladding, 10mm to 200mm for base |

| Length | Up to 12 meters |

| Width | Up to 3 meters |

| Surface Treatment | Polished, Brushed, or as required |

| Application Industries | Petrochemical, Nuclear, Aerospace, Chemical |

| Packaging | Wooden cases or steel pallets for safe transport |

| Transportation | By sea, air, or as specified by customer |

| Delivery Cycle | 3-6 months (or negotiable based on order size) |

|

|

|

|

Methods of Manufacturing Nickel Steel Clad Plates

Nickel steel clad plates are fabricated using various advanced bonding techniques that combine the durability of nickel and the strength of steel. These materials are widely used across industries for applications requiring corrosion resistance, structural integrity, and performance under harsh conditions. Below are the main methods used to produce nickel steel clad plates:

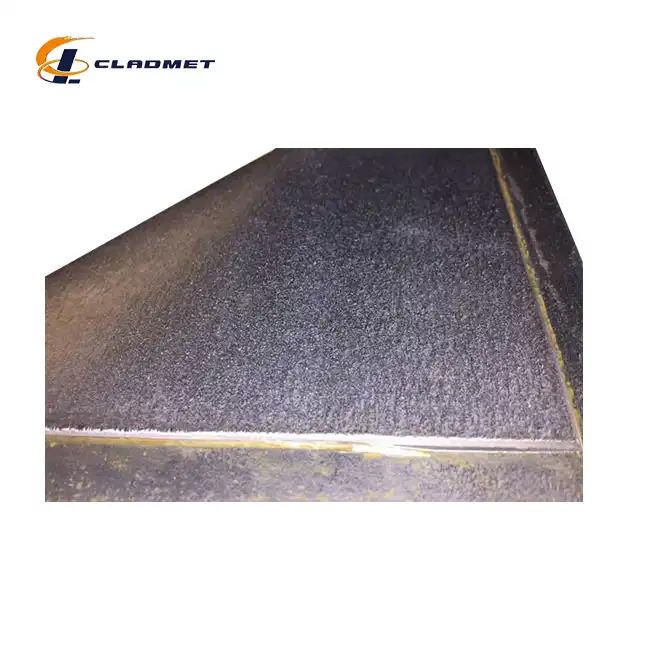

Explosive Bonding

Explosive bonding is a highly efficient method for creating a metallurgical bond between nickel and steel. By applying a controlled explosive force, the two materials are fused at high speed to form a strong, durable bond.

Material Preparation: Both the nickel and steel surfaces are meticulously cleaned and prepared to ensure they will bond effectively under the explosive force.

Detonation: A carefully placed explosive charge is detonated between the layers of nickel and steel, generating a high-velocity impact that causes the materials to collide and bond seamlessly.

Resulting Bond: The explosion generates a robust bond with excellent strength and durability, making this process ideal for applications that require both corrosion resistance and mechanical strength, such as heat exchangers and industrial machinery.

Explosive bonding is ideal for applications where high bond strength is essential, especially when the material needs to perform in extreme conditions, such as those encountered in the oil and gas or chemical processing industries.

Roll Bonding

Roll bonding is a cold-welding technique that involves the application of high pressure between the nickel and steel sheets to create a solid bond. This process is effective for producing large quantities of clad plates.

Surface Preparation: Both materials are cleaned and treated to improve surface adhesion and ensure a strong bond during the rolling process.

Pressing and Rolling: The nickel and steel sheets are passed through a set of rollers under high pressure, which forces the materials to bond together. Multiple passes through the rollers may be required to achieve a uniform bond.

End Result: The outcome is a seamless, durable bond that provides strength and resistance to corrosion, making roll bonding suitable for producing clad plates used in chemical processing, shipbuilding, and other industries.

Roll bonding is often employed for the production of large, flat clad plates that need to withstand harsh environmental conditions, such as those used in offshore drilling platforms and chemical reactors.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a high-temperature, high-pressure method used to create a diffusion bond between nickel and steel. The process involves enclosing the materials in a sealed container and applying heat and pressure to bond them at the atomic level.

Assembly and Encapsulation: The nickel and steel sheets are carefully placed in a sealed container to ensure they are well-aligned during the bonding process.

Heating and Pressurization: The container is subjected to high temperatures and pressures inside a HIP machine, which causes the atoms in both materials to diffuse into each other, forming a strong bond.

Resulting Bond: This process results in a uniform, high-quality bond with excellent resistance to corrosion and mechanical stress, making HIP ideal for applications requiring the highest level of bonding integrity, such as aerospace and critical industrial components.

HIP is used in industries that demand exceptional quality and strength, such as in the manufacture of pressure vessels, aerospace components, and parts for the oil and gas industry.

Key Features and Advantages of Nickel Steel Clad Plates

Corrosion Resistance

Nickel is known for its resistance to corrosion, particularly in aggressive environments like those encountered in chemical processing and marine applications. The combination of nickel’s corrosion resistance with the structural strength of steel ensures a material that can withstand harsh environmental conditions.

High Strength and Durability

Steel provides exceptional tensile strength and durability, while the nickel cladding enhances the material’s resistance to wear and corrosion. This combination creates a clad plate that is both tough and long-lasting, suitable for high-stress applications in industries such as oil and gas, marine engineering, and petrochemical processing.

Improved Thermal Conductivity

Steel has excellent thermal conductivity, making it ideal for use in heat exchangers, reactors, and other applications where efficient heat transfer is necessary. Nickel’s thermal properties complement steel’s conductivity, making these clad plates suitable for applications in power generation and industrial heating systems.

Cost-Effective

The use of nickel as a cladding material combined with steel allows for a more cost-effective solution compared to using pure nickel or other high-cost alloys. This combination offers substantial cost savings without compromising performance, making it an attractive option for industries looking to optimize both material costs and operational efficiency.

Customization Options

Nickel steel clad plates can be tailored to meet the specific requirements of various applications. Whether it’s adjusting the thickness of the cladding layer or customizing the plate size and surface finish, these materials can be engineered to suit the precise needs of different industries.

Resistance to Stress and Fatigue

The steel core provides excellent strength, while the nickel cladding helps protect the material from stress corrosion cracking and fatigue. This makes the plates highly reliable in applications where the material is subject to frequent mechanical stresses or exposure to extreme environmental conditions.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

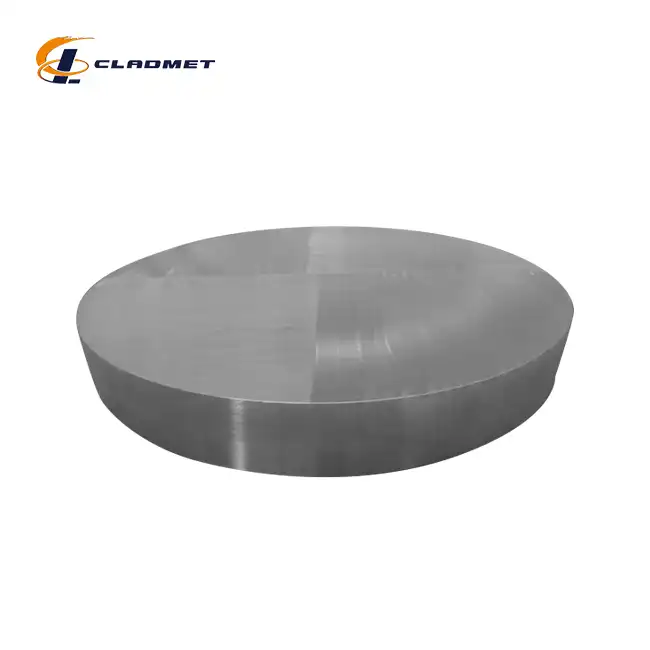

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals, we offer comprehensive OEM services, allowing customers to customize their Nickel Steel Clad Plates to fit specific project requirements. From material selection to surface treatment and dimensions, our technical team is available to provide expert guidance throughout the process.

FAQs

Q1: What is the minimum order quantity for Nickel Steel Clad Plates?

A1: The minimum order quantity depends on the project requirements, but we accept both small and large orders.

Q2: Can you provide custom sizes?

A2: Yes, we offer fully customizable sizes to meet the specific needs of your application.

Q3: How long is the delivery time?

A3: The standard delivery cycle is between 3 to 6 months, but this can be negotiated based on the order size.

Q4: Do you offer technical support for product installation?

A4: Yes, our technical team provides full support, including installation guidelines and after-sales services.

Contact Us

For more information about our Nickel Steel Clad Plate or to place an order, please contact us:

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)

_1737612944271.webp)