Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

Product Introduction

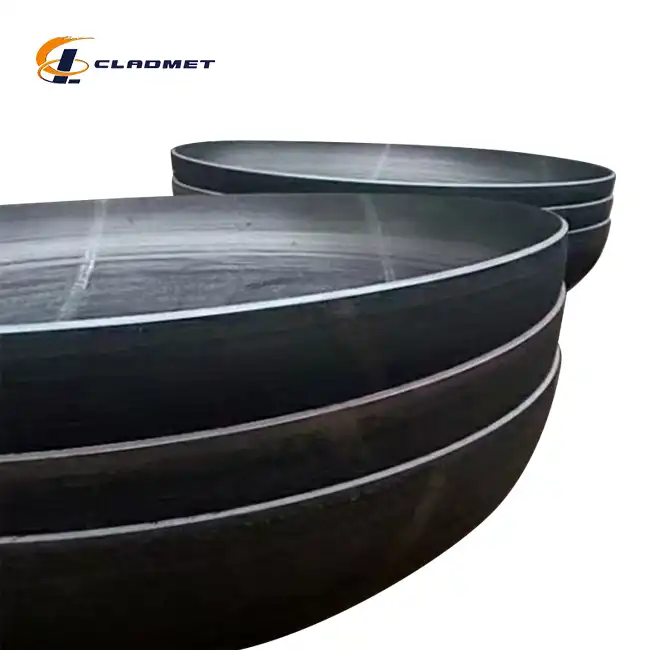

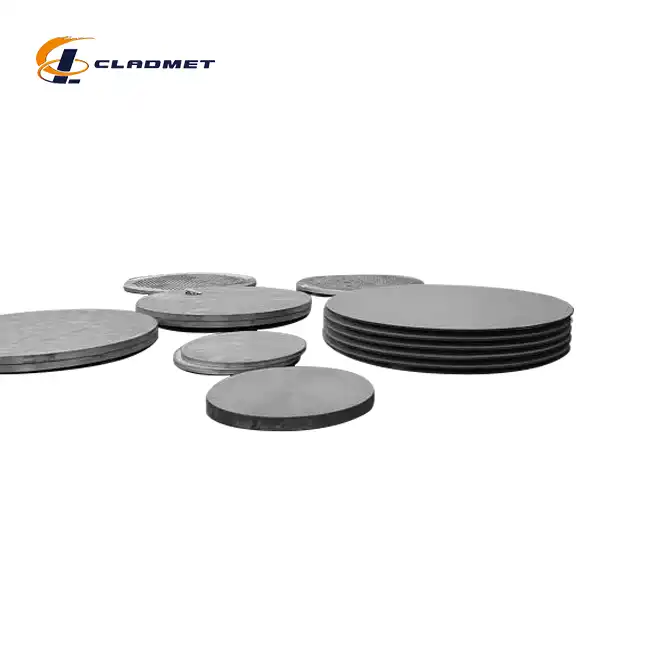

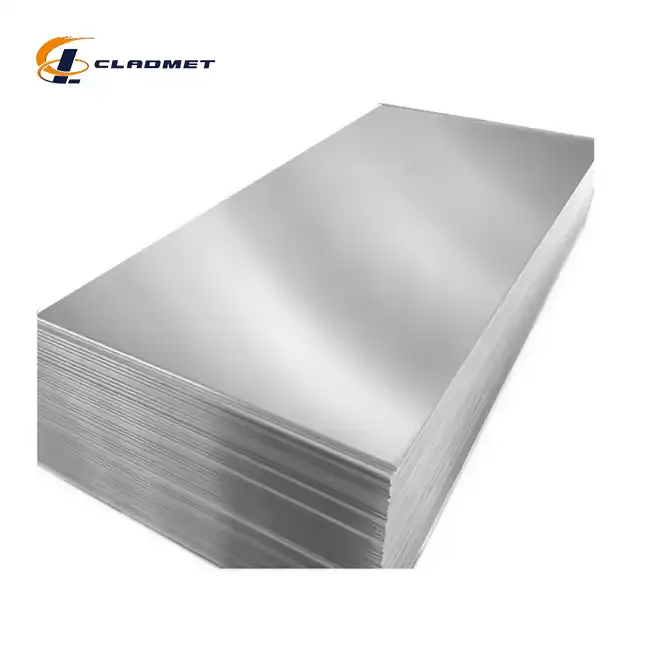

The 316L stainless steel-carbon steel clad head is a highly versatile and robust solution for industries requiring a strong, corrosion-resistant material. Combining the excellent corrosion resistance of 316L stainless steel with the strength and cost-effectiveness of carbon steel, this clad head is ideal for high-pressure applications, chemical environments, and industries where equipment durability and safety are paramount. Manufactured using advanced explosion welding (EXW) technology, our clad heads ensure seamless bonding between the layers, delivering exceptional performance under demanding conditions.

Product Specifications

| Product Name | 316L Stainless Steel-Carbon Steel Clad Head |

|---|---|

| Diameter | Customizable (up to 2000mm) |

| Thickness (Stainless Steel) | 2mm–10mm |

| Thickness (Carbon Steel) | 10mm–60mm |

| Technology | Explosion welding (EXW), roll bonding |

| Substrate | Carbon steel |

| Composite Material | 316L stainless steel |

| Standards | GB/GBT, ASME/ASTM, JIS |

| Product Inspection | 100% Ultrasonic Testing (UT), X-ray |

| Surface Treatment | Pickling, polishing |

| Covering Material Range | 316L stainless steel |

| Parent Material Range | Carbon steel |

| Length | Up to 12 meters |

| Width | Customizable |

| Delivery Cycle | 3-6 months (negotiable) |

| Packaging | Standard export packaging |

| Transportation | Sea, air, land |

|

|

|

|

Manufacturing Processes

Explosive Welding

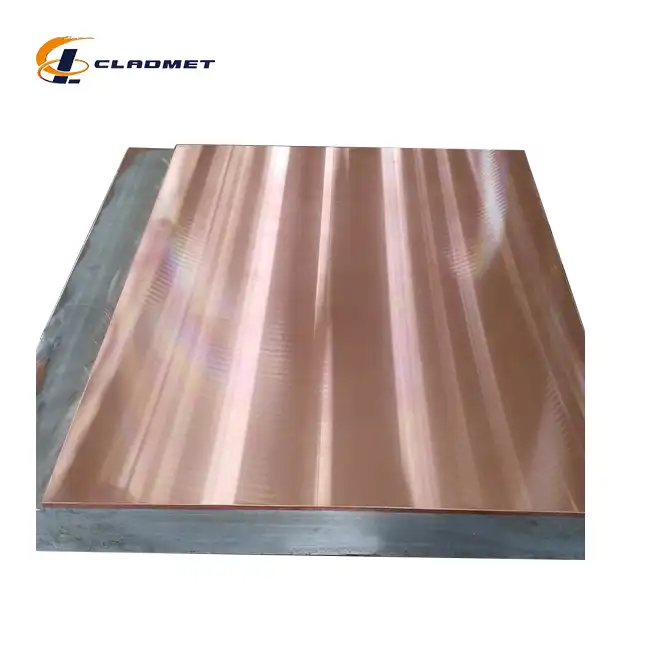

Explosive welding is a high-energy bonding process that generates a metallurgical connection between the 316L stainless steel and carbon steel layers. The explosive charge creates a shockwave that forces the two materials to bond under intense pressure, ensuring a strong and durable union. This method is often preferred for applications requiring high bond strength and is ideal for producing 316L stainless steel-carbon steel clad heads used in pressure vessels, heat exchangers, and similar equipment.

Roll Bonding

Roll bonding is a cold-welding technique where the materials are passed through a series of rollers under high pressure. The force exerted by the rollers ensures that the stainless steel and carbon steel layers bond securely. This method is suitable for producing clad heads where uniform thickness and strong bonding are essential. It is commonly used in the production of components for industries like chemical processing, where corrosion resistance is critical.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) involves encapsulating the stainless steel and carbon steel in a sealed container, which is then exposed to both high temperature and pressure. The HIP process facilitates atomic diffusion, forming a solid bond between the two layers. This method is ideal for creating 316L stainless steel-carbon steel clad heads in high-performance applications, such as aerospace and oil and gas industries, where material integrity and bonding strength are of utmost importance.

Key Features and Advantages

Exceptional Corrosion Resistance

316L stainless steel offers outstanding resistance to corrosion, particularly in harsh environments such as chemical processing and marine applications. The stainless steel layer of the clad head protects the underlying carbon steel from corrosion, increasing the longevity of the component and reducing maintenance costs. This makes the 316L stainless steel-carbon steel clad head highly suitable for equipment exposed to corrosive substances or extreme environmental conditions.

Strength and Durability

Carbon steel, known for its high tensile strength and mechanical properties, provides the 316L stainless steel-carbon steel clad head with a robust structural foundation. This combination ensures the component is capable of withstanding high pressures and mechanical stresses, making it ideal for applications that require both strength and durability.

Cost-Effectiveness

While 316L stainless steel offers superior corrosion resistance, it is more expensive than carbon steel. By using carbon steel as the base material, manufacturers can reduce costs while still maintaining excellent performance. This cost-effective solution makes the 316L stainless steel-carbon steel clad head an attractive choice for a wide range of industries.

Thermal Stability

316L stainless steel-carbon steel clad heads perform exceptionally well in high-temperature environments. The stainless steel layer helps maintain the structural integrity of the head in extreme conditions, ensuring reliable performance in applications like power generation and chemical processing where heat management is critical.

Customizable Design

316L stainless steel-carbon steel clad heads can be customized in terms of thickness, surface treatment, and material properties to meet specific industry requirements. Whether the application demands additional surface hardness or improved chemical resistance, these clad heads can be tailored to meet exact specifications, offering flexibility in design.

Enhanced Safety

The combination of stainless steel and carbon steel ensures that these clad heads provide reliable, long-lasting performance under high-stress conditions. This makes them an ideal choice for safety-critical applications in industries such as petrochemicals, pharmaceuticals, and power generation, where failure is not an option.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals Materials Co., Ltd, we provide comprehensive OEM services to meet specific customer requirements. Our team of experts works closely with clients to develop tailor-made solutions that align with your exact specifications. Whether you need customized dimensions, specific material combinations, or specialized surface treatments, we are here to assist in bringing your vision to life.

FAQs

Q1: What is the typical delivery cycle for a 316L stainless steel-carbon steel clad head?

A: Our standard delivery cycle is 3-6 months, depending on the complexity and size of the order. However, we can negotiate delivery times based on your project needs.

Q2: Can the clad head be customized for my specific application?

A: Yes, we offer fully customizable options for diameter, thickness, and surface treatments to ensure compatibility with your industrial requirements.

Q3: What industries commonly use clad heads?

A: Clad heads are frequently used in industries such as chemical processing, oil and gas, power generation, and pharmaceuticals due to their strength and corrosion resistance.

Contact Us

For more information or to request a quote, please contact us:

- Phone: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China 721013

_1737007724117.webp)