Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

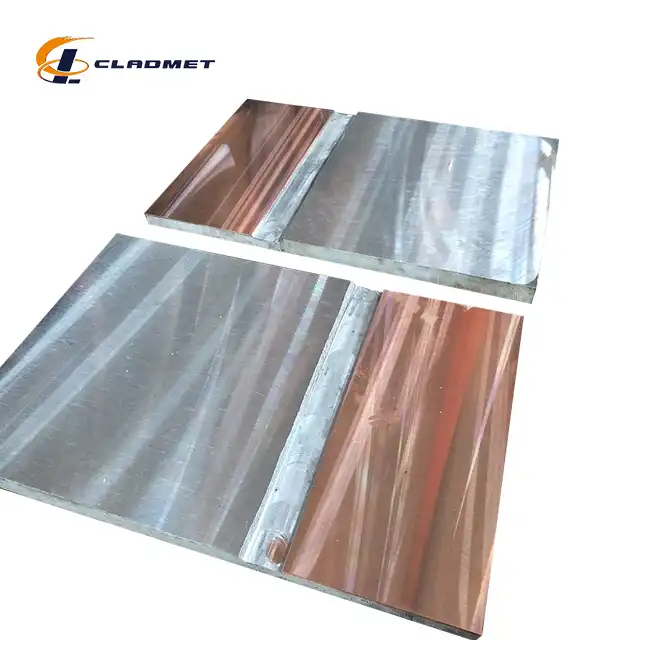

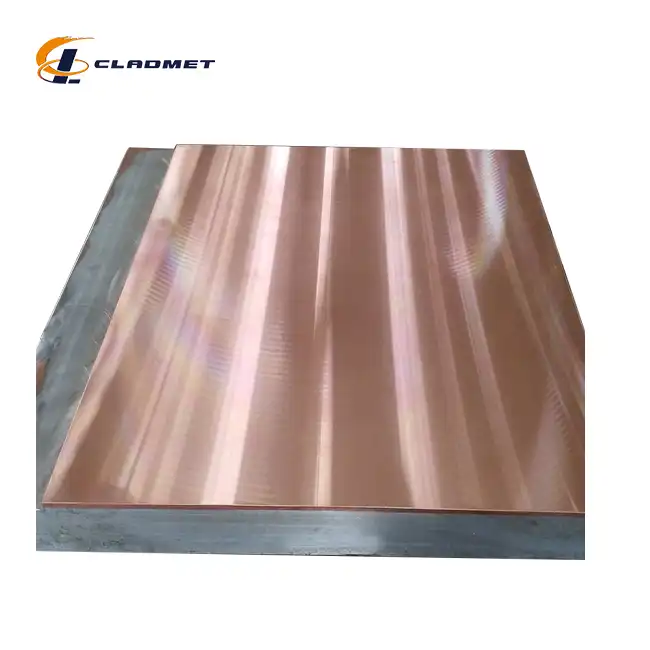

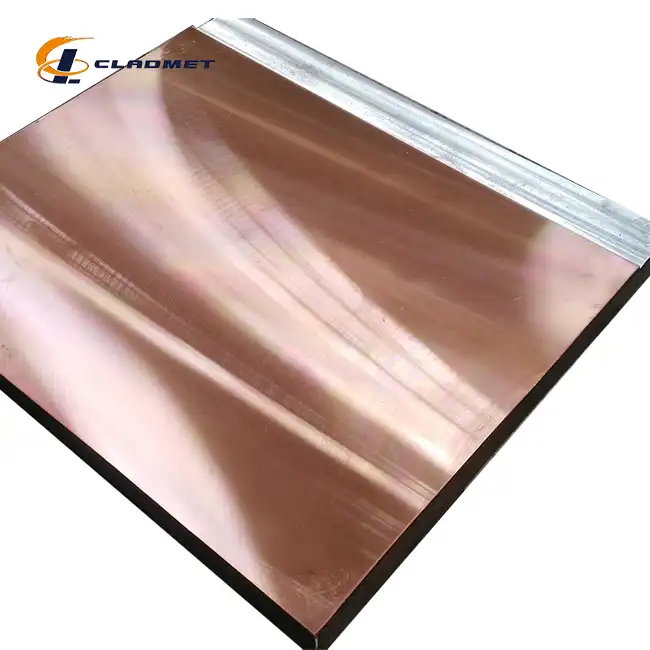

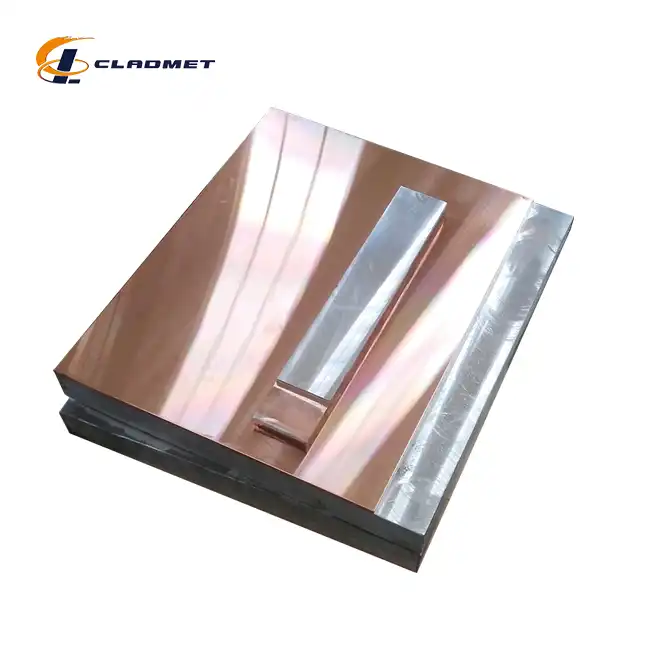

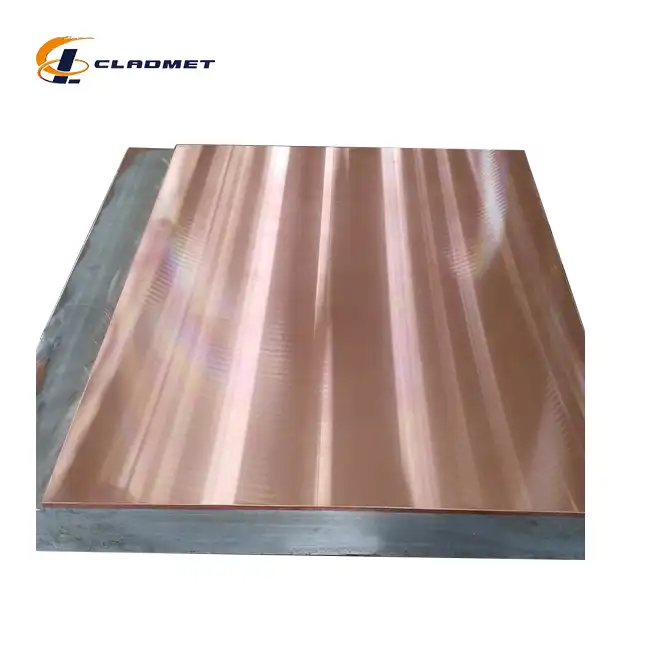

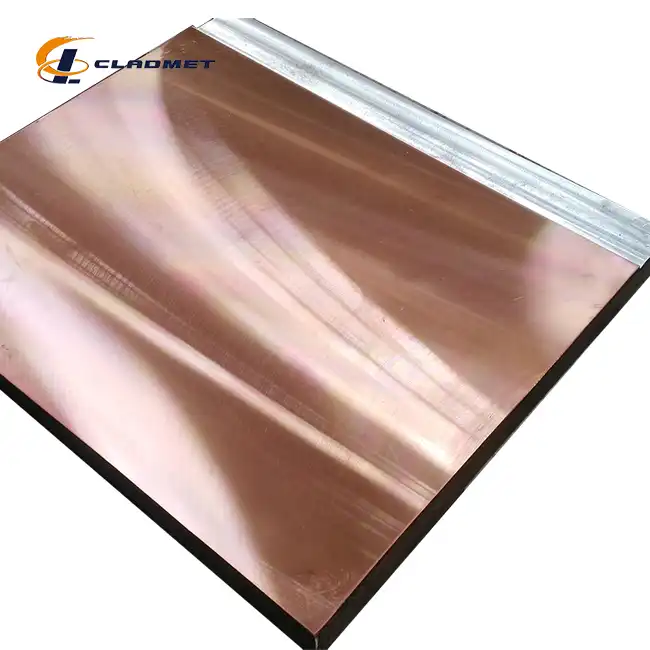

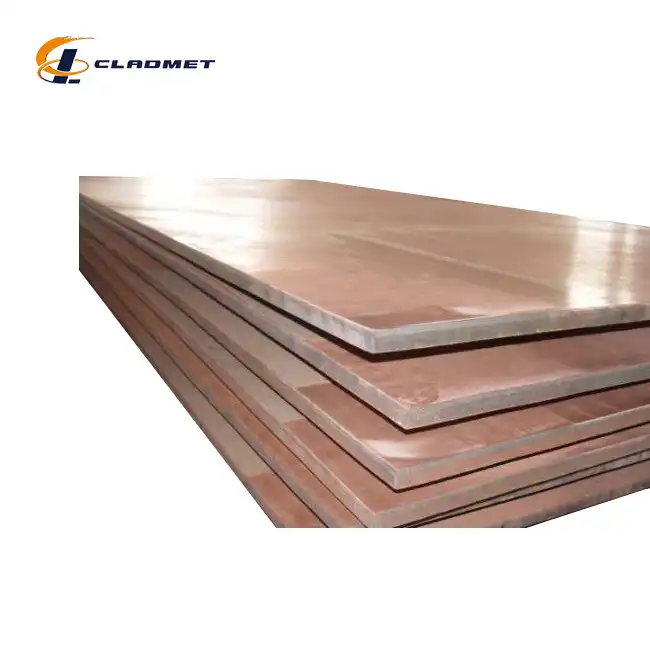

Titanium clad copper plates are a highly versatile and durable material created by bonding a layer of titanium onto a copper base. This process enhances the properties of both metals, providing exceptional corrosion resistance and electrical conductivity. These plates are widely used in industries that require superior performance in extreme environments, such as electroplating, chemical processing, and marine engineering.

Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in the clad metals industry, specializes in producing high-quality titanium clad copper plates using advanced technologies such as explosion bonding. With decades of expertise, we ensure that our products meet international standards, including GB/GBT, ASME/ASTM, and JIS, providing superior quality and reliability.

Product Specifications:

| Parameter | Details |

|---|---|

| Cladding Material | Titanium (Grade 1, Grade 2, Grade 5, etc.) |

| Base Material | Copper (C11000, C10200) |

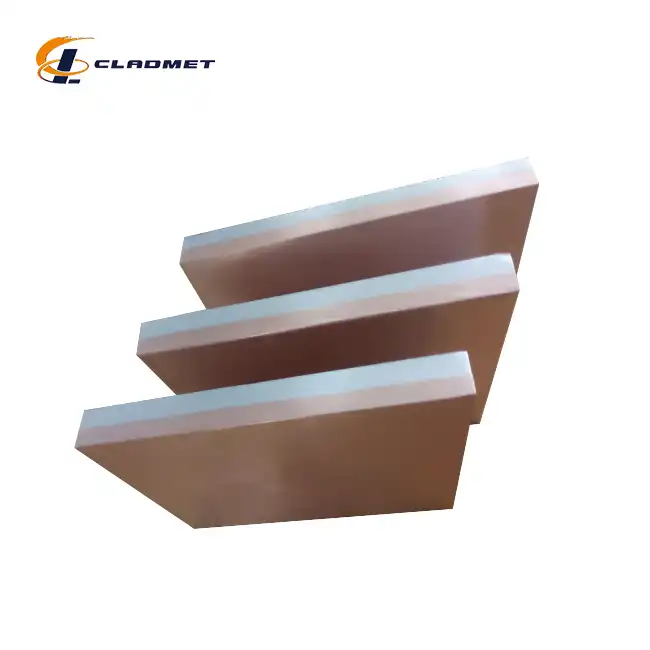

| Cladding Thickness | 0.5mm to 10mm |

| Base Metal Thickness | 2mm to 20mm |

| Cladding Technology | Explosion Bonding, Roll Bonding |

| Standard | GB/GBT, ASME/ASTM, JIS |

| Width | Up to 2000mm |

| Length | Up to 6000mm |

| Surface Treatment | Polished, Sandblasted, Anti-oxidation coating |

| Packaging | Wooden crates or as per customer requirements |

| Transportation | Road, Air, Sea |

| Delivery Cycle | 3-6 months or negotiable |

|

|

|

|

Manufacturing Processes for Titanium Clad Copper Plates

Titanium clad copper plates are engineered through a variety of bonding techniques that fuse titanium with copper, creating a composite material that leverages the strengths of both metals. These materials are highly valued for their durability, electrical conductivity, and resistance to corrosion. Below are the common methods used to create titanium clad copper plates.

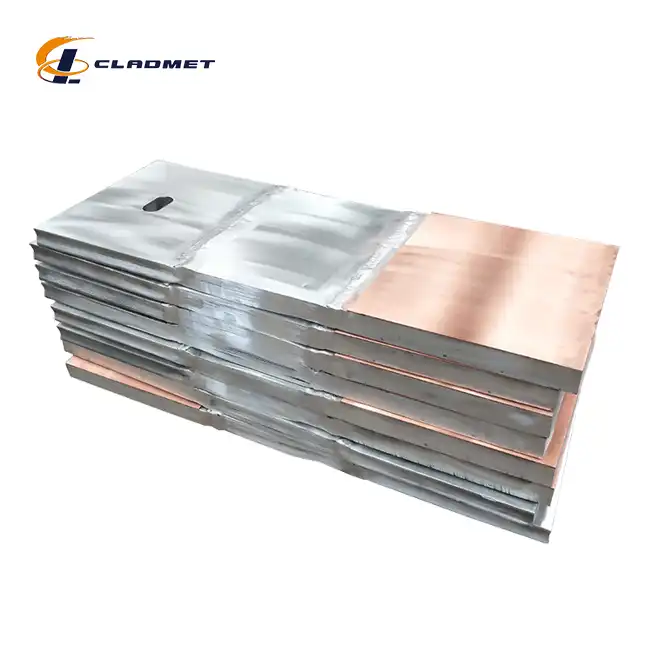

Explosive Welding

Explosive welding is a high-energy process used to bond titanium and copper through a controlled explosion, creating a robust, metallurgical bond between the two layers.

Preparation: The titanium and copper materials are carefully cleaned and arranged to ensure proper alignment and contact.

Explosion: An explosive charge is strategically placed between the two layers, and detonated to produce a high-speed collision that fuses the materials together.

Resulting Bond: This process generates a strong, permanent bond that is highly resistant to wear, corrosion, and mechanical stress, making it ideal for use in demanding applications such as heat exchangers, pressure vessels, and other heavy-duty equipment.

Explosive welding is commonly used when high bond strength is crucial, as it ensures a durable and long-lasting union between titanium and copper.

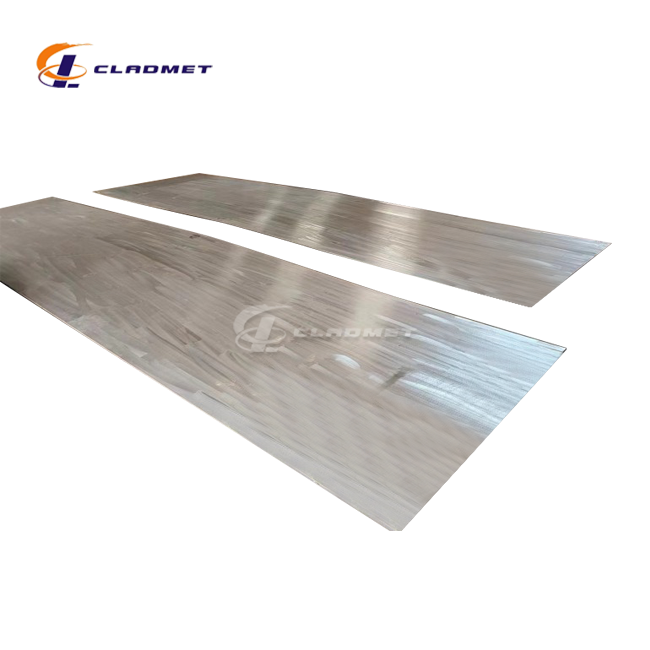

Roll Bonding

Roll bonding is a cold-welding method that utilizes high-pressure rollers to join titanium and copper. This approach provides a reliable bond between the two materials through mechanical deformation.

Surface Treatment: Both the copper and titanium layers are prepared through cleaning and surface roughening to ensure strong adhesion during the bonding process.

Pressure Application: The materials are passed through rollers under high pressure, which forces them to bond together without the use of heat or external energy.

End Result: The bonded layers are seamless and offer a consistent bond strength across the entire surface.

Roll bonding is ideal for producing titanium clad copper plates used in various industries, including chemical processing, electronics, and structural applications.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a process that involves applying high temperature and pressure in a sealed container to achieve a diffusion bond between the titanium and copper layers.

Assembly and Encapsulation: The titanium and copper sheets are arranged and sealed within a container that can withstand high temperatures and pressures.

Heat and Pressure: The sealed container is placed in a pressurization chamber, where heat and pressure are applied to cause atomic diffusion between the two layers, ensuring a solid bond.

Outcome: The result is a metallurgically bonded titanium-copper composite with excellent mechanical and corrosion-resistant properties.

HIP is particularly well-suited for applications that require high integrity and reliability, such as aerospace components, medical devices, and other precision-engineered parts.

Features and Advantages of Titanium Clad Copper Plates

Corrosion Resistance

The titanium layer provides outstanding resistance to corrosion, especially in harsh environments such as marine and chemical processing sectors. Copper itself also has a high degree of resistance to corrosion, ensuring that these plates are durable in corrosive environments.

Enhanced Electrical Conductivity

Copper’s natural ability to conduct electricity makes these plates highly effective for electrical applications. The titanium cladding does not interfere with copper’s conductivity, making the composite material ideal for use in electrical systems that require high performance and low resistance.

Strength-to-Weight Ratio

Titanium is known for its high strength-to-weight ratio, and when combined with copper, it maintains these properties without significantly adding weight. This makes titanium clad copper plates perfect for applications where strength is needed without a substantial increase in weight, such as in aerospace and transportation industries.

Thermal Conductivity

Copper is one of the best metals for heat transfer, and with the addition of titanium, these plates can be used in applications requiring efficient thermal management, such as heat exchangers and cooling systems.

Durability and Longevity

The combination of titanium and copper enhances the overall durability of the material, ensuring a long service life even in the most demanding environments. The plates are resistant to wear, stress, and environmental degradation, reducing the need for frequent replacements.

Cost-Effective Solution

Using titanium in combination with copper reduces the cost of manufacturing compared to using titanium alone while still providing the benefits of both metals. This balance of cost and performance makes titanium clad copper plates an economical choice for many industries.

Versatility

These composite plates can be tailored to meet the specific needs of different industries, with customizable thicknesses, sizes, and surface finishes. This versatility makes them suitable for a wide range of applications across various sectors.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service:

Baoji JL Clad Metals offers OEM services for custom orders. Whether you need specific dimensions, surface treatments, or additional features, our team will work with you to design and manufacture titanium clad copper plates that meet your exact specifications.

FAQ:

-

Q: What are the advantages of using titanium clad copper plates over solid titanium plates?

- A: Titanium clad copper plates provide the same corrosion resistance and durability as solid titanium at a lower cost, with added benefits of copper’s conductivity.

-

Q: What is the typical delivery time for orders?

- A: Our standard delivery cycle is 3-6 months, depending on order size and customization requirements.

-

Q: Can you provide certifications for your products?

- A: Yes, we can provide certifications such as GB/GBT, ASME/ASTM, and JIS upon request.

Contact Us:

For inquiries or to place an order, please contact us:

- Tel: +86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

By focusing on quality, compliance, and customization, Baoji JL Clad Metals ensures that our titanium clad copper plates meet the needs of industries requiring superior performance and durability.

_1737007724117.webp)

_1737612944271.webp)