Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

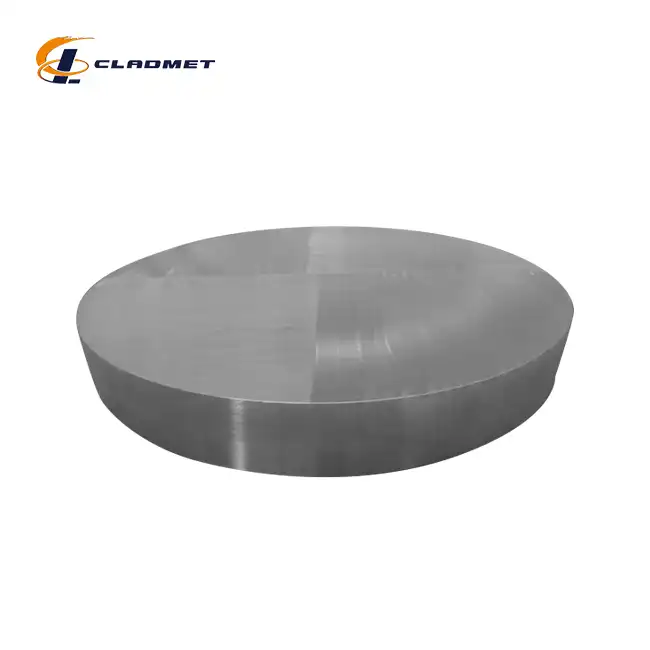

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

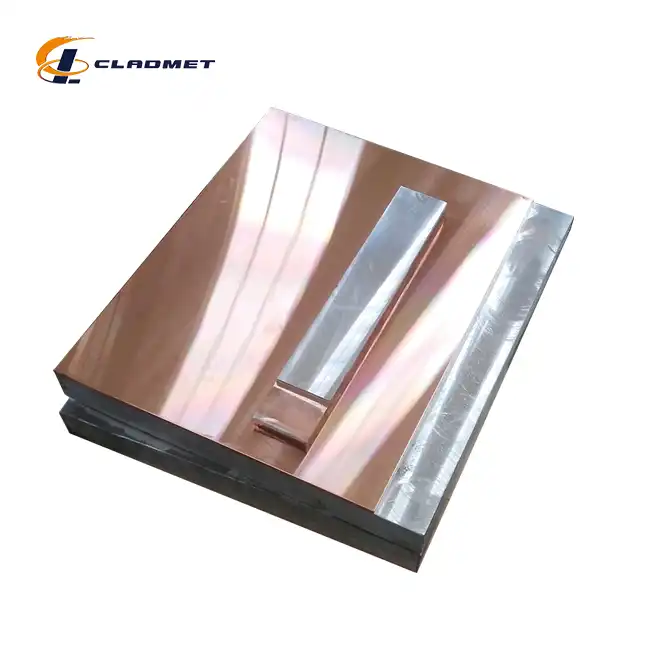

All Clad Copper Plated Introduction

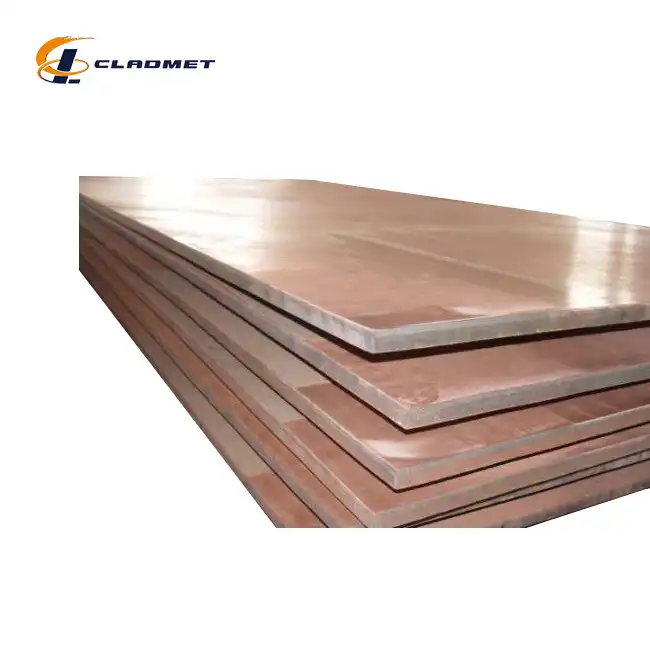

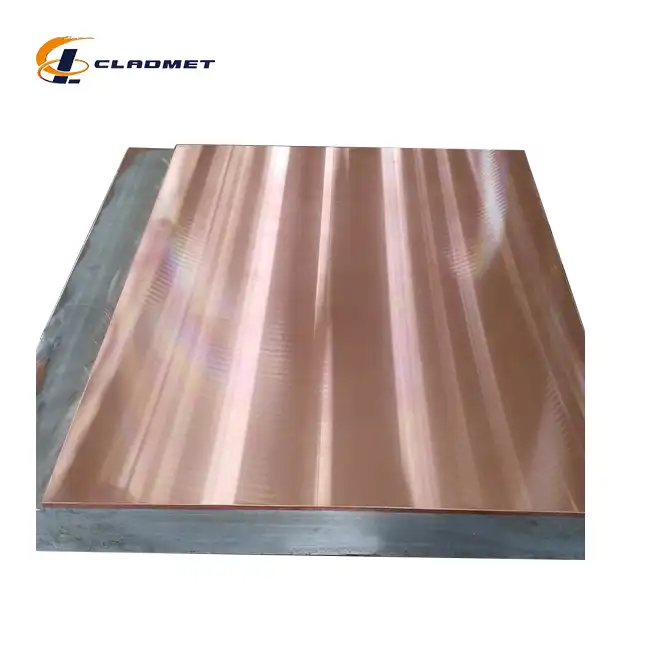

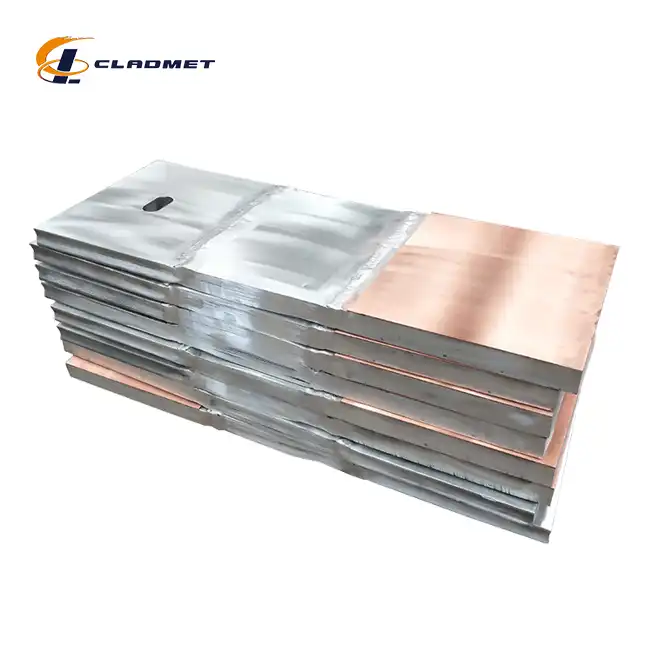

Baoji JL Clad Metals Materials Co., Ltd., a leading EXW clad metals manufacturer, proudly presents its premium all clad copper plated products. These advanced composite materials combine the strength and durability of various metals with the exceptional conductivity and corrosion resistance of copper, making them the ideal solution for industries requiring high-performance materials. Our copper-plated cladding products are trusted by clients worldwide, thanks to their superior quality, customization options, and adherence to international standards.

Product Specifications

| Parameter | Details |

|---|---|

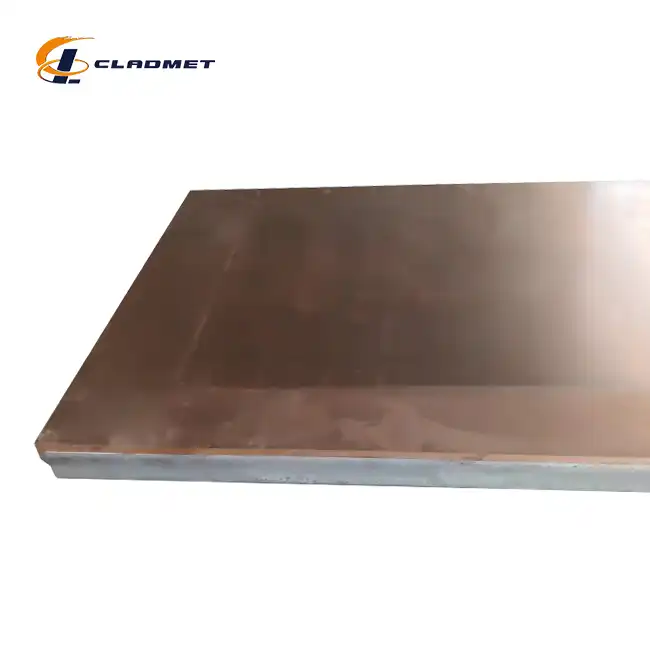

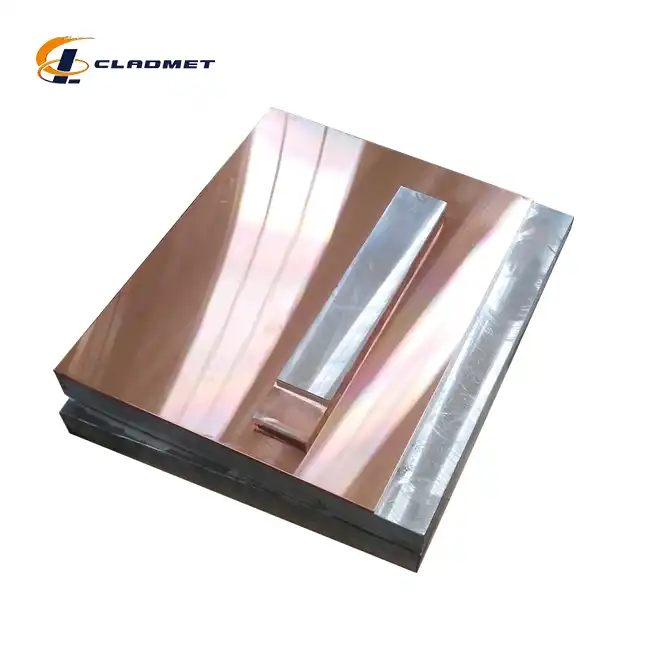

| Cladding Material | Copper |

| Base Metal | Carbon steel, stainless steel |

| Cladding Size | Customizable based on client specifications |

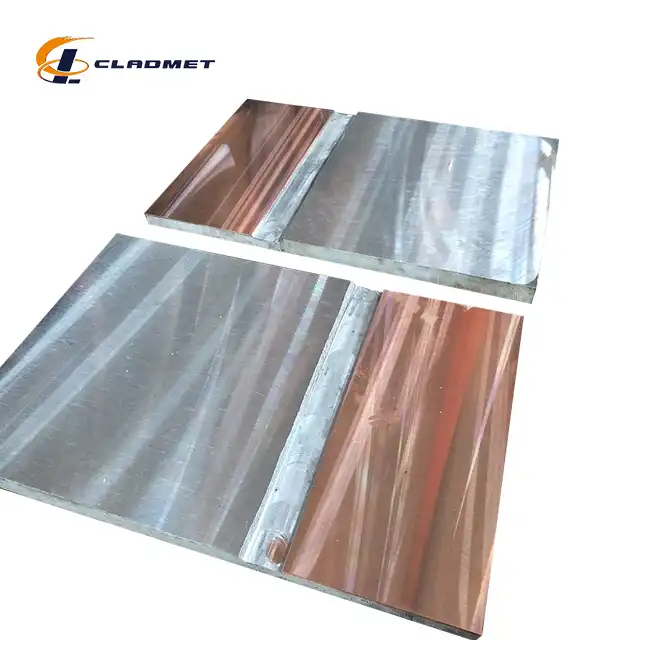

| Cladding Technology | Explosion-bonding, roll-bonding |

| Thickness | 2 mm to 200 mm |

| Length | Up to 12 meters |

| Width | Up to 4 meters |

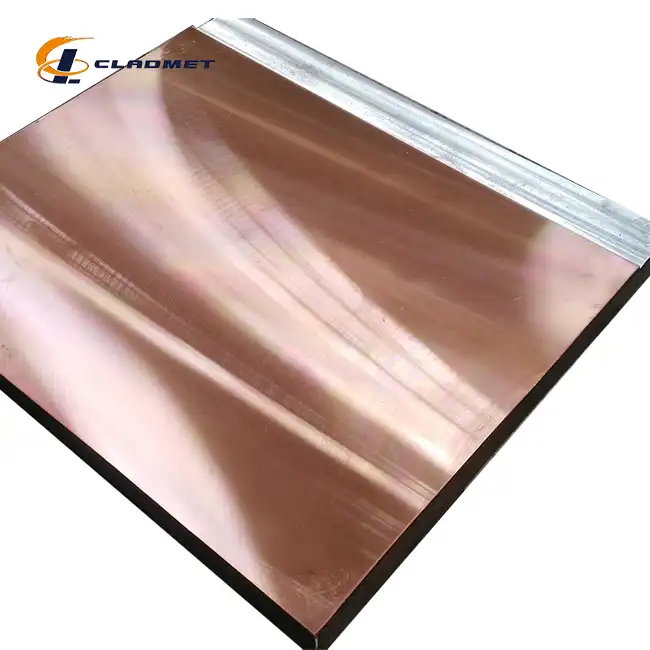

| Surface Treatment | Polished, brushed, or coated |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Delivery Cycle | 3-6 months or negotiable |

| Packaging Method | Wooden crates, palletized for safe transport |

| Transportation | Available via sea, air, or land |

|

|

|

|

Manufacturing Methods for All-Clad Copper Plating

All-clad copper plated products combine the high electrical conductivity and thermal efficiency of copper with the strength and durability of a base material. This fusion of copper with other metals results in a composite material that is used in various industries requiring both performance and cost-effectiveness. Several advanced processes are employed to create all-clad copper plates, ensuring a reliable bond between the copper and the substrate.

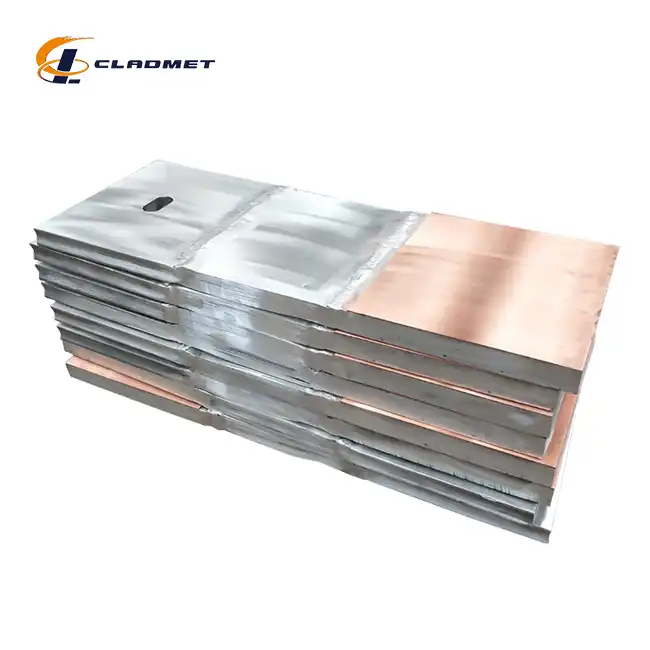

Explosive Bonding

Explosive bonding is a method that creates a solid, metallurgical bond between the base metal and copper through the application of a controlled explosive charge. This technique is especially suited for high-performance applications requiring a robust and permanent bond.

Preparation: The base metal and copper sheets are aligned and cleaned meticulously to remove contaminants.

Explosion Impact: A controlled explosive charge is detonated between the two materials, generating a high-speed collision that bonds them together.

Outcome: The explosion results in a metallurgical bond, ensuring a strong union between the two layers that is resistant to stresses, corrosion, and environmental wear.

This process is used in industries such as energy, electronics, and manufacturing of large-scale components like heat exchangers, where bond strength is critical.

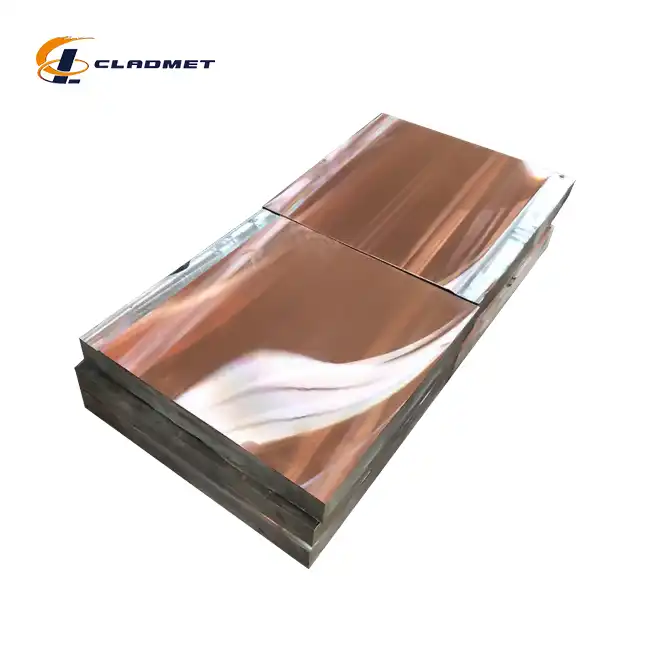

Roll Bonding

Roll bonding is a cold-welding technique where the base material and copper are passed through rollers under high pressure to form a bond. This method creates an intimate, consistent bond between the layers without the need for additional heat or energy-intensive processes.

Surface Preparation: Both copper and the base material are thoroughly cleaned and prepared to ensure a strong bond.

Rolling Process: The materials are then fed through a set of rollers, applying immense pressure that fuses the materials together.

End Result: This results in a highly durable bond between the copper and the substrate, which is essential for products used in electrical, industrial, and chemical environments.

Roll bonding is commonly employed in the manufacturing of copper-clad plates and sheets for various sectors, including electronics, automotive, and construction.

Electroplating

Electroplating is a process in which copper is applied to the base material through the use of an electric current. This process involves the deposition of a thin layer of copper onto the substrate, creating a uniform and protective coating.

Surface Treatment: The base material is cleaned and prepped to ensure proper adhesion.

Copper Deposition: A copper-rich solution is used to facilitate the electroplating process, where copper ions are deposited onto the base material.

Resulting Coating: This method forms a durable, corrosion-resistant copper layer that enhances the performance of the substrate, particularly in applications where high conductivity is needed.

Electroplating is particularly effective for applications requiring fine coatings of copper, such as in the production of wiring, connectors, and other electronic components.

Key Features and Advantages

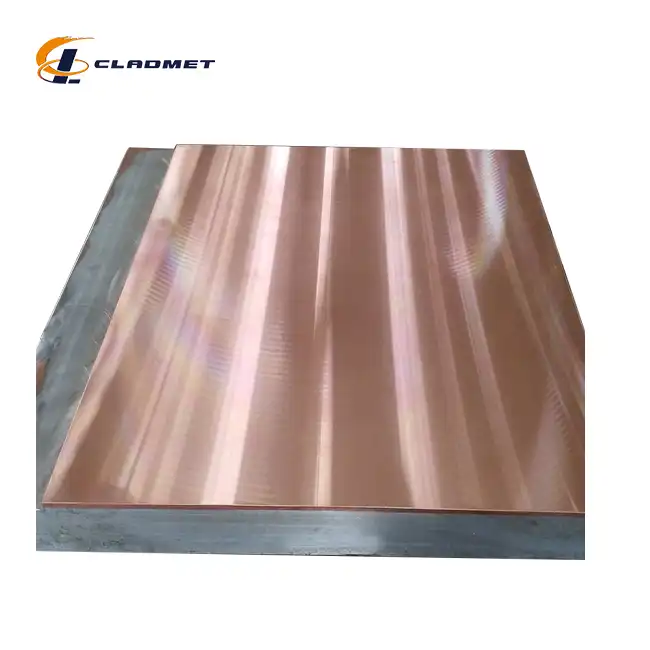

Superior Electrical Conductivity

Copper is renowned for its excellent electrical conductivity. When bonded to a base material, it ensures that the composite plate is suitable for applications requiring efficient energy transfer, such as electrical wiring, circuit boards, and power distribution systems.

Lightweight and Strong

The base material used in all-clad copper plates is typically lightweight, which, when combined with copper's conductivity, makes these products ideal for industries like aerospace and automotive, where strength and weight reduction are crucial.

Corrosion Resistance

Copper offers natural resistance to corrosion, and when used in combination with other metals, it increases the overall durability of the material. This makes all-clad copper plates perfect for use in marine, chemical, and offshore industries where exposure to corrosive environments is common.

Thermal Conductivity

Copper's superior thermal conductivity ensures that these plates can efficiently transfer heat, making them ideal for use in heat exchangers, cooling systems, and electronic components where heat management is critical.

Cost-Effective

By combining copper with a base material, all-clad copper plates provide an efficient solution that reduces the overall cost of manufacturing while maintaining high performance. The use of a base material also allows for savings in raw material costs compared to using pure copper.

Customization Flexibility

These plates can be tailored to specific industry requirements, offering customization in terms of size, thickness, and surface treatment. This adaptability makes them ideal for a wide range of applications across different sectors.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer full OEM (Original Equipment Manufacturer) services, providing customized solutions for all industries. Our team works closely with clients to design, manufacture, and deliver high-performance clad plates tailored to meet unique specifications. Whether you need a specific cladding material, size, or thickness, we are committed to delivering the best solutions for your needs.

FAQs

-

What is the delivery time?

Delivery typically takes between 3 to 6 months, depending on the size and complexity of the order. Special requests may be negotiable. -

What industries are most suitable for copper clad plates?

Our plates are widely used in the electrical, chemical, oil and gas, aerospace, marine, automotive, and power generation industries. -

Can the product be customized?

Yes, our all clad copper plated products can be customized to meet your specific requirements in terms of size, thickness, and application. -

What certifications do your products meet?

JL Clad Metals products adhere to GB/GBT, ASME/ASTM, and JIS standards. We are also ISO9001-2000 certified and have obtained PED and ABS international qualifications.

Contact Us

For more information or to place an order, feel free to contact us:

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

Boost your industrial applications with our high-performance, reliable all clad copper plated solutions!

_1737007724117.webp)