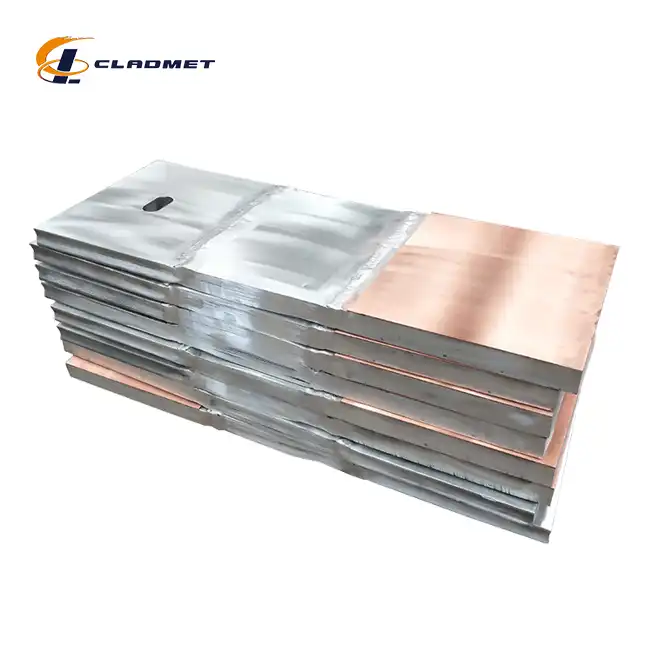

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

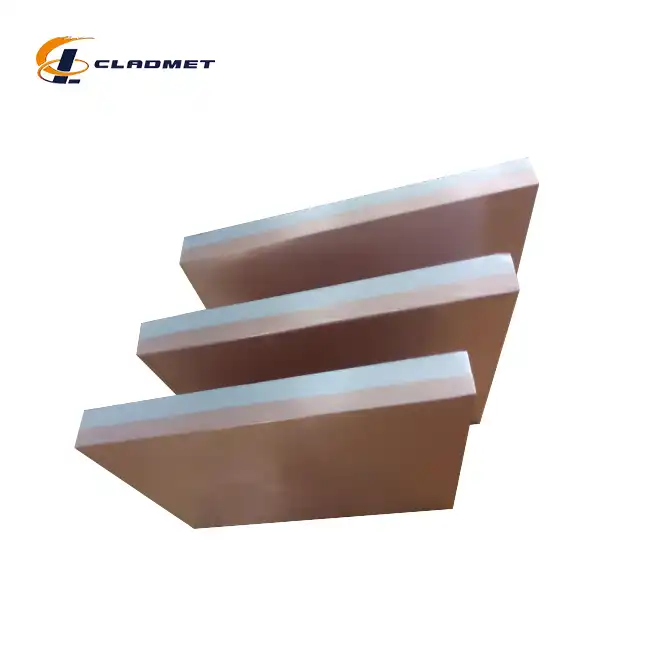

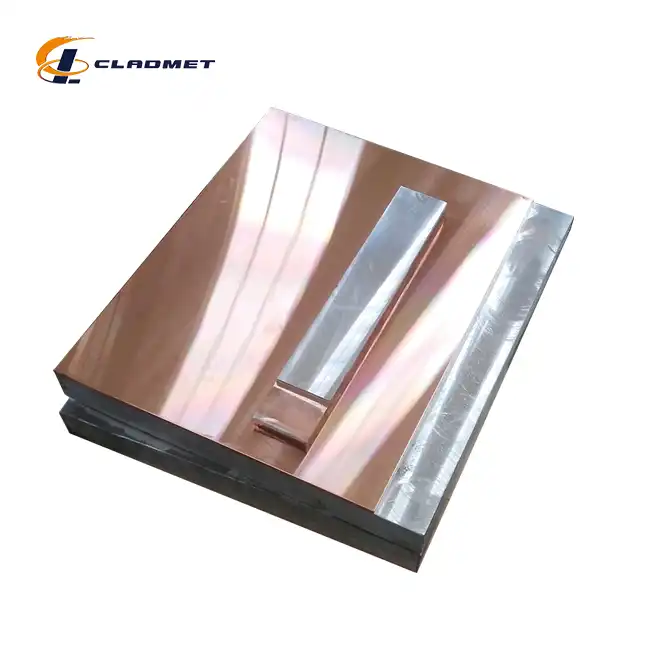

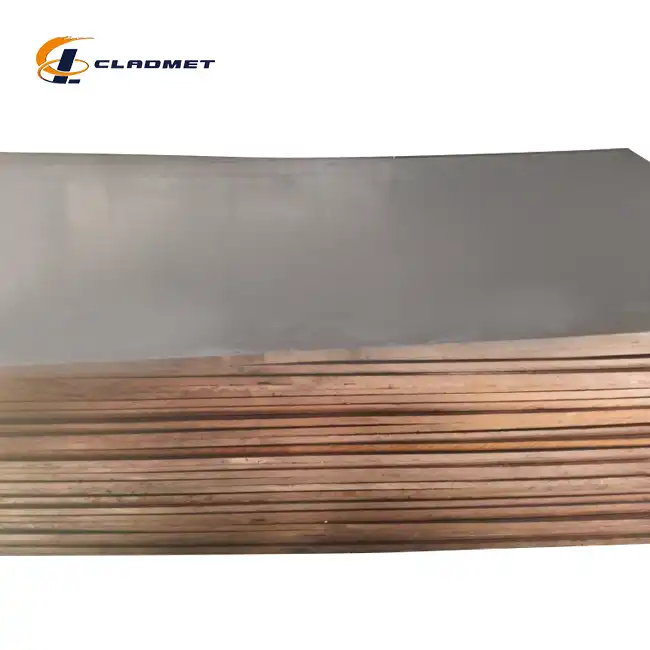

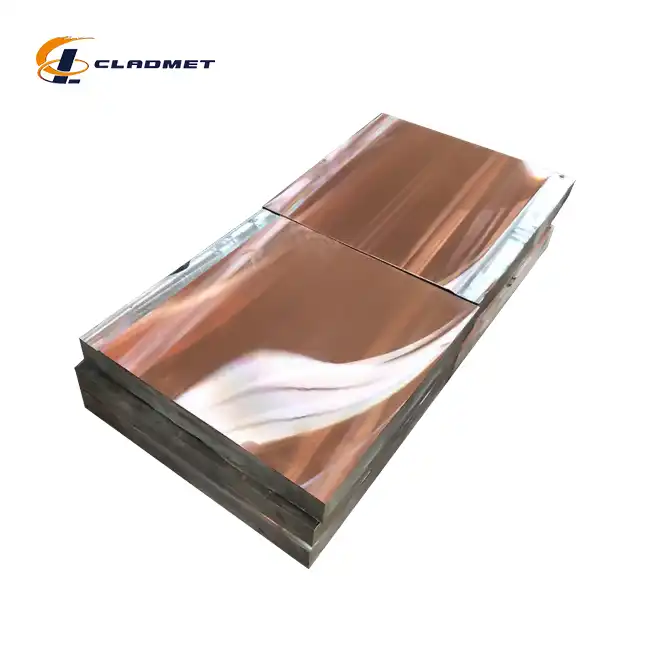

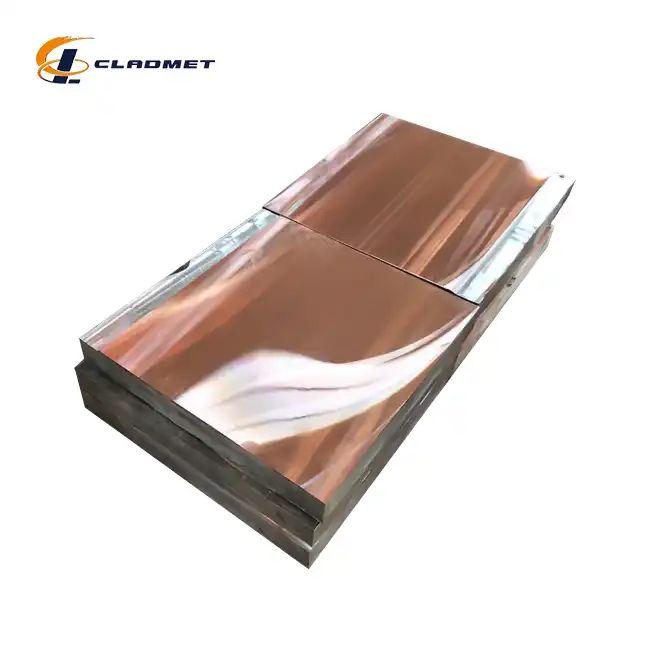

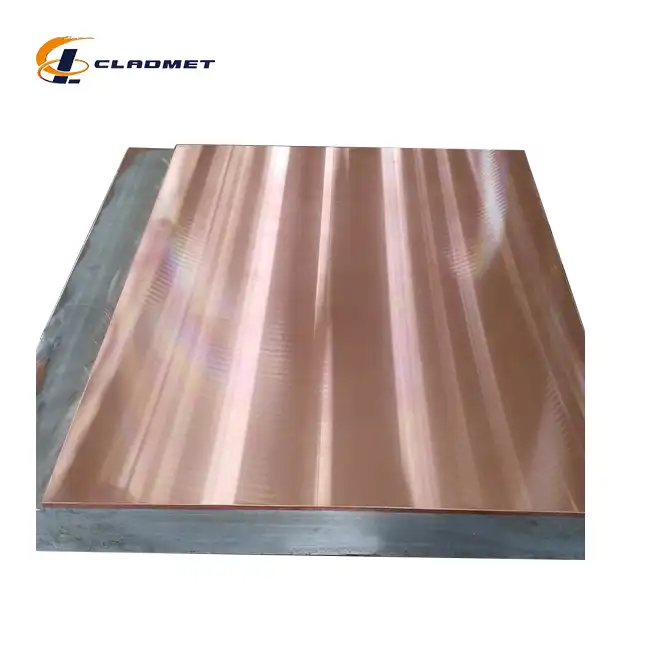

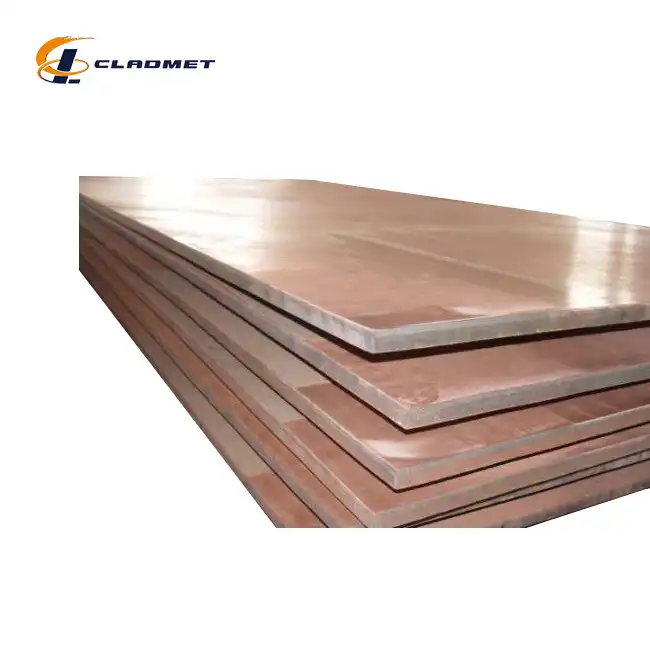

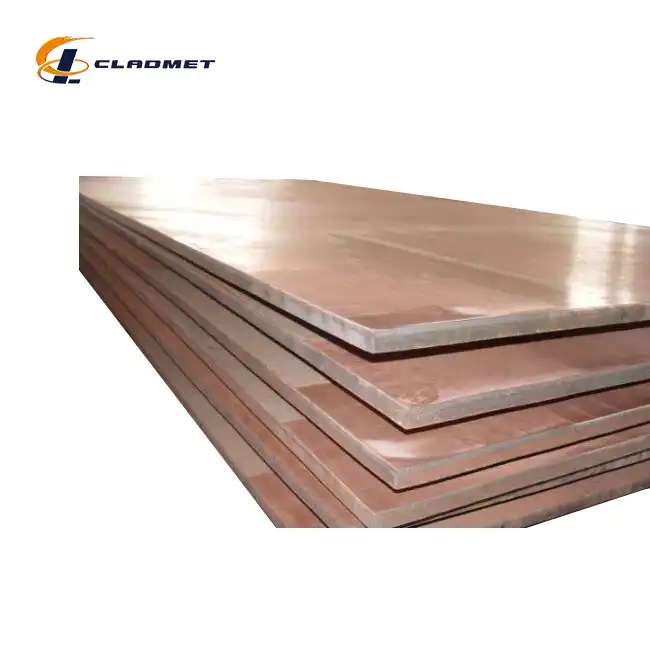

Aluminum Copper Clad Plate Product Introduction

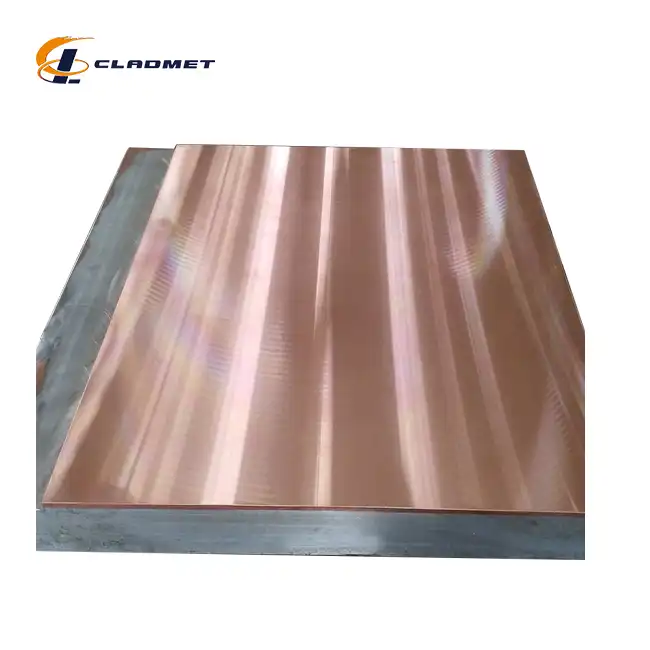

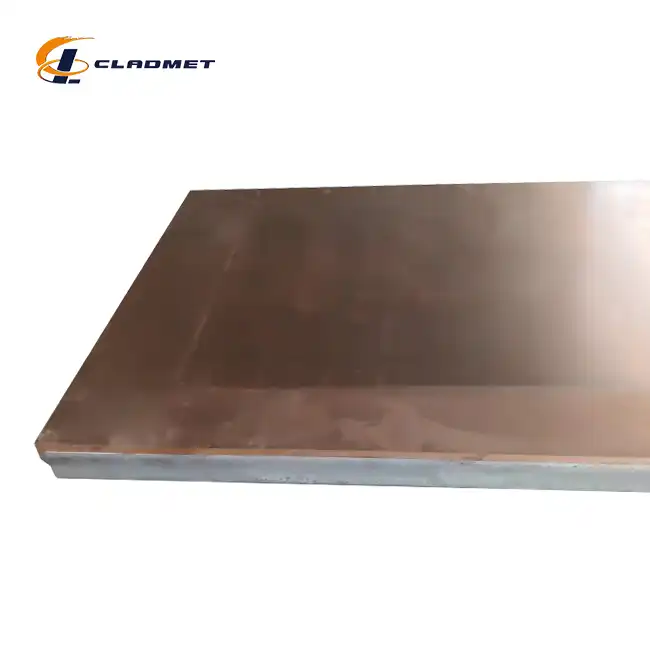

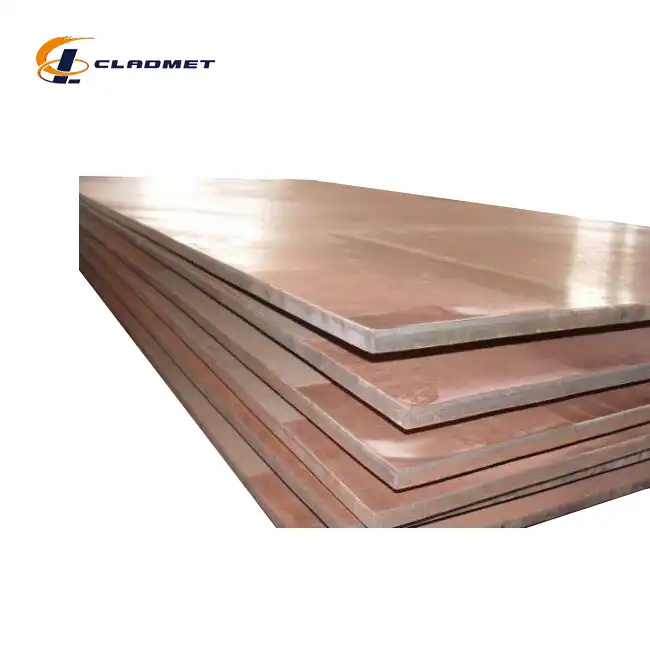

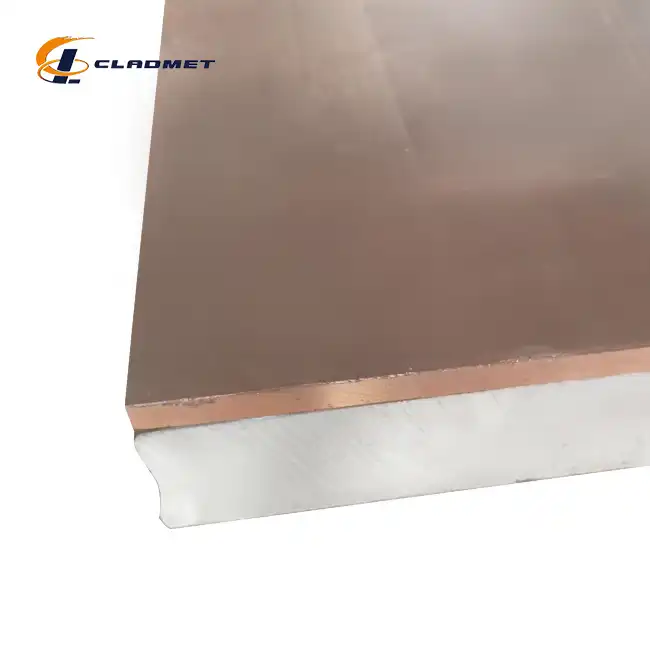

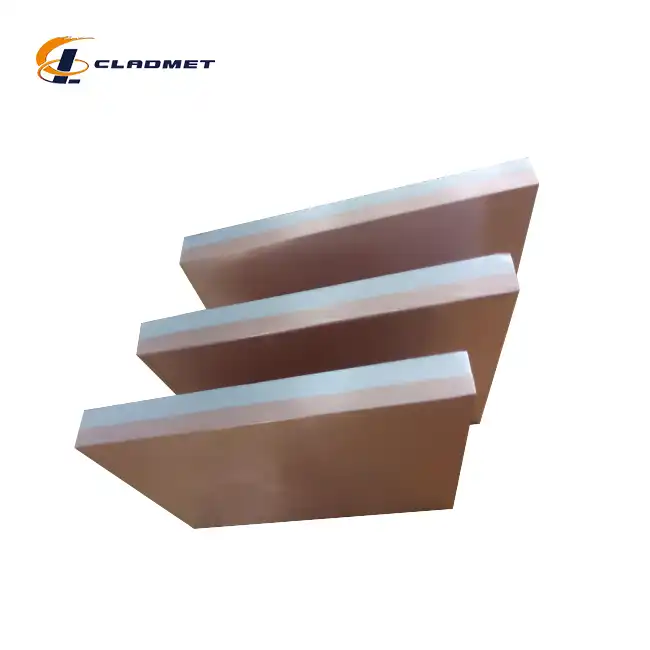

The Aluminum Copper Clad Plate is a high-performance, bimetallic material that combines the advantages of aluminum's lightweight properties with copper's excellent electrical and thermal conductivity. It is produced by bonding aluminum and copper together using advanced explosion welding (EXW) techniques, resulting in a highly durable and versatile product. These clad plates offer superior strength, corrosion resistance, and conductivity, making them ideal for a wide range of industrial applications.

With over 20 years of experience, Baoji JL Clad Metals Materials Co., Ltd. is a trusted manufacturer of clad metals, specializing in the production of Aluminum Copper Clad Plates that meet international quality standards. Our products are widely used in sectors such as electrical engineering, automotive manufacturing, and power distribution.

Product Specifications

| Item | Details |

|---|---|

| Cladding Material Range | Copper (C11000, C12000), Aluminum (1060, 3003, 6061) |

| Base Metal Range | Aluminum (6061, 1060), Copper (C11000, C12000) |

| Cladding Size | Thickness: 0.5mm - 20mm, Width: Up to 2500mm, Length: Custom |

| Cladding Technology | Explosion welding, Roll bonding |

| Product Standards | GB/T, ASTM, JIS, ASME |

| Surface Treatment | Smooth finish, Brushed, Polished |

| Delivery Cycle | 3-6 months or negotiable |

| Packaging | Wooden crates or pallets for secure transport |

|

|

|

|

Manufacturing Methods for Aluminum-Copper Cladding

Aluminum-copper clad plates combine the properties of both metals, offering a unique combination of light weight, high electrical conductivity, and thermal efficiency. The process of bonding aluminum and copper involves several advanced methods to ensure a high-performance composite material that meets the demands of various industries.

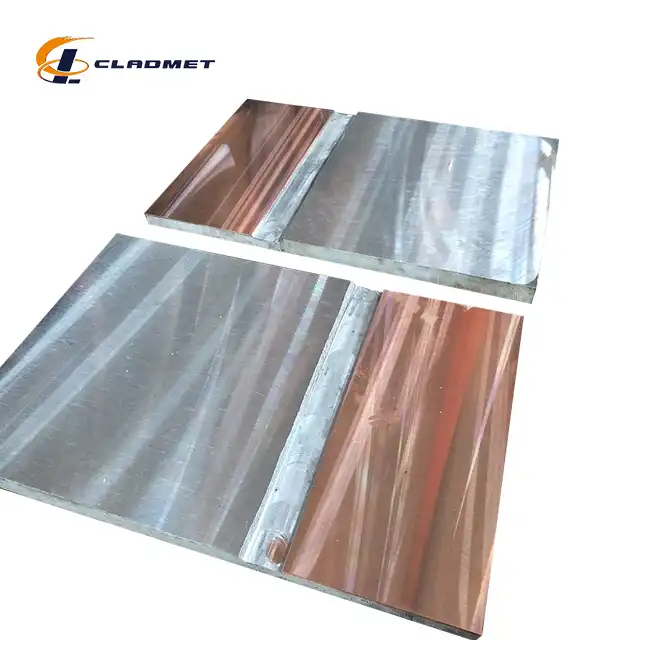

Explosive Bonding

Explosive bonding is a technique that uses a controlled explosive charge to rapidly bond aluminum and copper together. This results in a strong metallurgical bond that is both durable and highly resistant to stress.

Preparation: The aluminum and copper sheets are carefully cleaned and positioned to ensure proper alignment before the explosion.

Explosion Impact: The explosive charge generates a shockwave that causes the materials to collide at high speeds, forming a solid bond.

Outcome: The explosive bonding process results in a metallurgically bonded plate that is highly resistant to physical stresses and corrosion.

This method is commonly used when high bond strength and durability are critical, making it ideal for applications in the manufacturing of electrical components, power generation systems, and heat exchangers.

Roll Bonding

Roll bonding is a cold-welding process in which aluminum and copper are passed through rollers under high pressure. The pressure from the rollers causes the two metals to bond together without the use of heat.

Surface Preparation: Both aluminum and copper surfaces are thoroughly cleaned to ensure optimal bonding conditions.

Rolling Process: The aluminum and copper sheets are fed through a set of rollers, applying pressure to create a strong bond.

End Result: The bond formed through roll bonding ensures the two materials are tightly fused, resulting in a durable, high-performance clad plate.

Roll bonding is used extensively in the production of aluminum-copper clad plates for applications in the automotive, electrical, and aerospace industries.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) involves placing the aluminum and copper together in a sealed chamber and applying heat and pressure. The result is a diffusion bond at the atomic level, ensuring a uniform and strong connection.

Assembly and Sealing: The aluminum and copper layers are carefully arranged in a sealed chamber.

High Temperature and Pressure: The chamber is then heated and pressurized, causing the metals to bond through atomic diffusion.

Resulting Bond: HIP provides a strong, uniform bond that is ideal for applications where both strength and high bonding integrity are required.

This method is often chosen for manufacturing critical components in aerospace, automotive, and industrial applications that require superior strength and reliability.

Key Features and Advantages

Excellent Electrical Conductivity

Copper’s natural high conductivity is preserved in aluminum-copper clad plates, making them ideal for electrical applications that require efficient energy transfer. The aluminum provides structural support while the copper ensures optimal conductivity.

Lightweight Construction

The aluminum layer reduces the overall weight of the clad plate, making it a favorable choice for industries such as aerospace, automotive, and electronics where reducing weight without sacrificing performance is crucial.

Thermal Efficiency

Copper is an excellent conductor of heat, and when combined with aluminum, it enhances the thermal efficiency of the material. This makes aluminum-copper clad plates perfect for use in heat exchangers, radiators, and other thermal management systems.

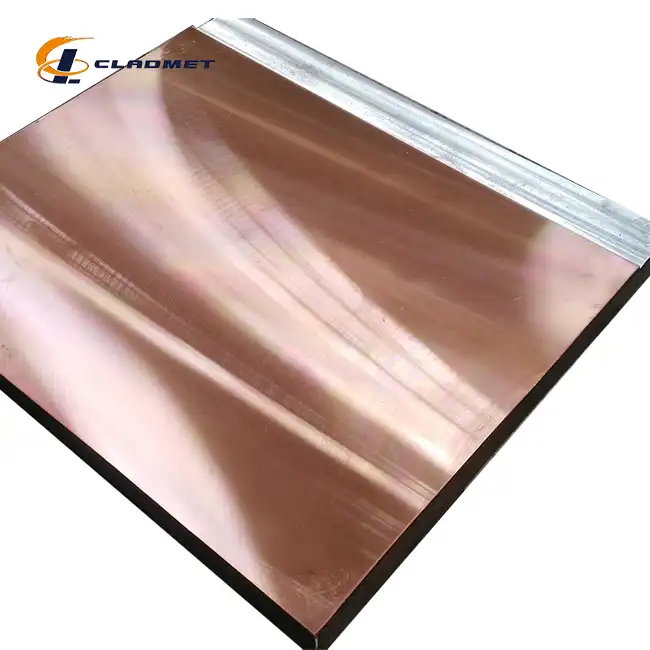

Corrosion Resistance

Both copper and aluminum are naturally resistant to corrosion, and their combination further enhances the durability of the clad plate. This makes aluminum-copper clad plates highly suitable for use in harsh environments such as marine or chemical processing industries.

Cost-Effectiveness

By using aluminum, which is more affordable than pure copper, aluminum-copper clad plates offer a cost-effective solution without compromising on the high-performance properties of copper.

Customization Options

Aluminum-copper clad plates can be customized in terms of thickness, size, and surface treatment, allowing for tailored solutions to meet the specific needs of different industries.

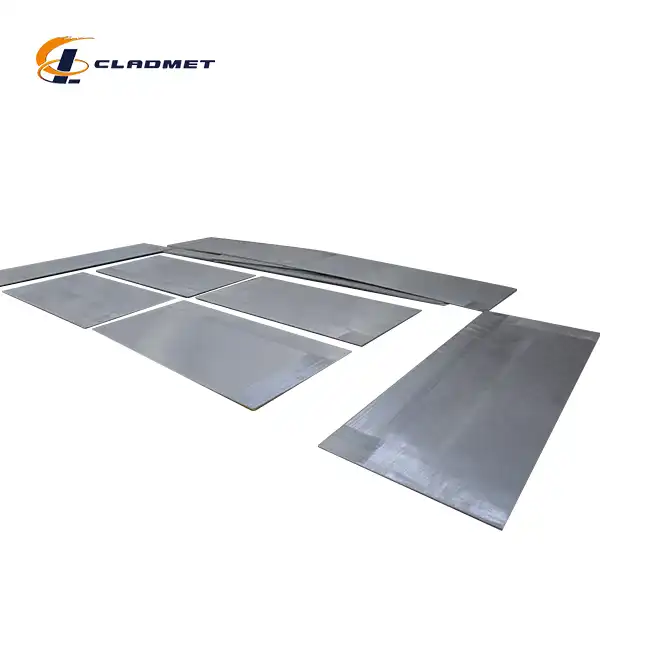

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

At Baoji JL Clad Metals, we offer comprehensive OEM services tailored to your specific requirements. Our expert team can assist you in customizing Aluminum Copper Clad Plates to match the dimensions, surface treatments, and performance specifications you need for your project.

FAQ

Q: What is the delivery time for products?

A: The standard delivery time is 3-6 months, but it can be negotiated based on order size and urgency.

Q: Are custom sizes available?

A: Yes, we can customize the dimensions of the clad plates to meet your specific requirements.

Q: What industries can benefit from using products?

A: They are commonly used in electrical engineering, automotive manufacturing, power distribution, telecommunications, and industrial machinery.

Q: Do you provide surface treatments?

A: Yes, we offer a range of surface treatments including smooth, brushed, and polished finishes.

Contact Us

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)

_1737611948854.webp)