Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

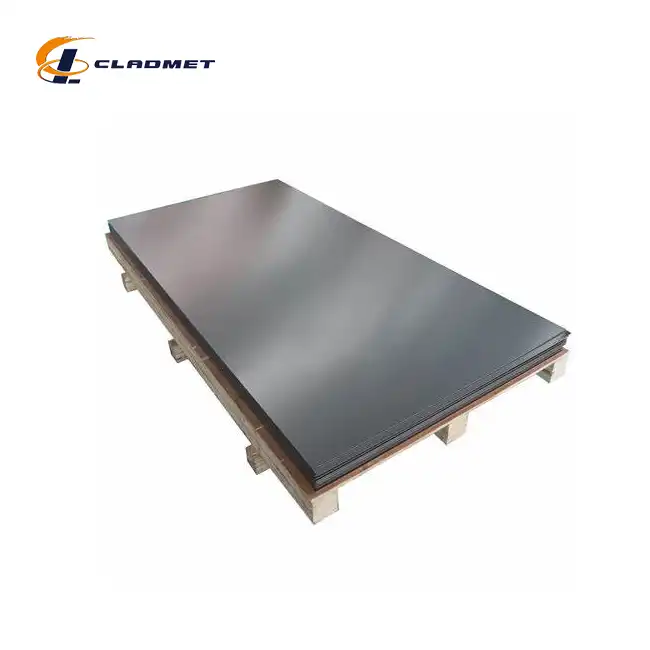

Packaging

Secure wooden crate packaging for international shipping.

The titanium clad copper rod is an advanced composite material that combines the superior conductivity of copper with the excellent corrosion resistance of titanium. This product is widely used in various industrial applications where both high electrical conductivity and resistance to corrosive environments are crucial. The combination of these two metals creates a versatile product that delivers high performance and durability, especially in environments exposed to chemicals, seawater, or other harsh conditions.

At Baoji JL Clad Metals Materials Co., Ltd, we specialize in manufacturing high-quality products, adhering to strict international standards such as GB/GBT, ASME/ASTM, and JIS. With over 20 years of experience, we provide reliable and high-performance solutions to meet the evolving needs of our global customers.

Product Specifications

| Cladding Material | Titanium (Grade 1 or Grade 2) |

|---|---|

| Base Metal | Copper (T2 or T3) |

| Diameter Range | 10mm to 100mm |

| Length | Customizable up to 6 meters |

| Cladding Technology | Explosive Welding/ Hot Rolling |

| Product Standards | GB/GBT, ASME/ASTM, JIS |

| Surface Treatment | Polished, Pickled, or Machined |

| Packaging Method | Wooden crates, protected from moisture and damage |

| Delivery Cycle | 3-6 months, or negotiable based on order size |

|

|

|

|

Manufacturing Processes for Titanium Clad Copper Rods

Explosive Welding

Explosive welding involves creating a powerful, controlled explosion between the titanium and copper layers, causing them to bond at a molecular level. The impact from the explosion forces the materials to fuse together without the need for external adhesives or welding materials, creating a durable and robust bond. This method is particularly suitable for applications that require a high-strength connection between the two materials, such as in heat exchangers, pressure vessels, and high-stress environments.

Roll Bonding

Roll bonding is a cold-welding process in which titanium and copper are passed through a series of rollers under immense pressure. This technique ensures that the two metals are firmly bonded together, creating a uniform clad material. Roll bonding is particularly effective for producing rods with a smooth surface and consistent properties. The method is often used in manufacturing titanium clad copper rods for various industrial applications such as chemical processing systems and offshore structures.

Hot Isostatic Pressing (HIP)

HIP involves placing the titanium and copper components in a sealed container and subjecting them to both high temperature and pressure. This process promotes atomic diffusion, resulting in a seamless, molecularly bonded structure. HIP is ideal for applications that demand excellent bonding integrity, such as aerospace components, marine equipment, and high-performance tools.

Key Advantages of Titanium Clad Copper Rods

Corrosion Resistance

Titanium's natural resistance to corrosion is one of the primary benefits of titanium clad copper rods. The titanium outer layer protects the copper core from environmental factors such as seawater, chemicals, and industrial fluids, ensuring a longer service life and reliability in harsh conditions. This makes these rods ideal for marine applications, offshore structures, and chemical processing.

Superior Electrical Conductivity

The copper core provides outstanding electrical conductivity, which is crucial for many electrical and electronic applications. These rods are used in power transmission, wiring, and connectors where efficient and consistent electrical performance is necessary.

High Strength-to-Weight Ratio

Titanium's lightweight yet high-strength properties make these rods a valuable choice for industries where both strength and weight are critical. The combination of titanium's strength and copper’s conductivity in a lightweight rod offers superior mechanical performance without unnecessary bulk.

Customizable to Industry Needs

Titanium clad copper rods can be customized to meet the specific requirements of various industries. This includes adjustments to size, diameter, surface finish, and other parameters, making the rods adaptable to a wide range of applications, from high-pressure systems to power grids.

Extended Durability

The robust combination of titanium and copper in these rods results in exceptional durability. The resistance of titanium to wear, corrosion, and oxidation ensures that these rods last longer in demanding environments. This durability reduces maintenance and replacement costs over time.

Cost-Effective Solution

By combining two materials with distinct advantages, titanium clad copper rods offer a cost-effective solution compared to using pure copper or titanium alone. They provide a long-lasting, reliable product that minimizes the need for replacements, lowering the overall cost of ownership.

Enhanced Performance

The high electrical conductivity of the copper core and the strength of the titanium cladding combine to improve performance in critical applications. These rods are designed for environments where both durability and high efficiency are necessary, such as in power distribution systems or marine technology.

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer comprehensive OEM services, customizing the product’s size, thickness, and surface treatment to meet the specific needs of our customers. Whether you need rods for small-scale applications or large industrial projects, Baoji JL Clad Metals is equipped to handle orders of any size, ensuring timely delivery and consistent quality.

FAQ

Q: What is the minimum order quantity (MOQ) for our products?

A: Our MOQ depends on the specific dimensions and requirements of your order. Please contact us for detailed information.

Q: How long is the lead time?

A: Our standard delivery cycle is between 3 to 6 months. However, this can be negotiated based on the size and complexity of your order.

Q: Can you provide custom sizes?

A: Yes, we specialize in custom solutions. Please provide your specifications, and we will tailor the product to your needs.

Q: What standards do your products adhere to?

A: All our products conform to international standards such as GB/GBT, ASME/ASTM, and JIS. We are also ISO9001-2000 certified and have passed PED and ABS certifications.

Contact Us

For more information or to place an order, please contact us:

- Phone: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

We look forward to assisting you with all your titanium clad copper rod needs!

_1737007724117.webp)

_1737611948854.webp)

_1737611949120.webp)

_1737611951046.webp)

_1737611949973.webp)

_1737611764680.webp)