Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

Titanium-Carbon Steel Clad Flange Introduction

Structure of Clad Flange

A pipe flange refers to the flange used in pipe equipment. The flanges have holes and bolts to close the two flanges. The flanges are sealed with gaskets. Flanges are classified as thread connection (wire buckle connection) flanges, welded flanges, and clamp flanges. Flange thickness varies according to different pressures, and the bolts are also different.

A flange connection first involves placing two pipes, pipe fittings, or equipment fixed onto two flanges, second is to add a gasket between two flanges, then fastening them together with bolts to complete the connection. Some pipe fittings and equipment have their own flange plates. Flange connection is an important connection mode for pipeline construction. Flange connection is easy to use and affordable. In industrial pipes, within homes, the pipes are small in diameter and of low pressure, there are no flange connections. But in a boiler room or at its production site, there are flange-connected pipes and equipment.

In summary, flanges are extensively utilized in industrial applications. Are you seeking cost-effective and high-performance flanges? Nickel and nickel-base alloy clad steel flanges, stainless steel clad flanges, titanium steel clad flanges, etc., are your choices. Gallianz is able to provide you with professional clad flanges for your special use.

Key Features of Clad Flanges

Corrosion Resistance: The cladding material, often made from stainless steel, nickel alloys, or other corrosion-resistant metals, protects the flange from corrosive environments, which is crucial in industries such as chemical processing, oil and gas, and marine applications.

Cost-Effectiveness: Although the cladding material itself might be expensive, clad flanges are more cost-effective overall compared to solid flanges made entirely from corrosion-resistant materials. This is because only a thin layer of the costly material is used.

Durability and Longevity: The combination of a robust base material (typically carbon or low-alloy steel) with a corrosion-resistant surface layer extends service life and minimizes maintenance requirements.

Mechanical Strength: Clad flanges maintain the high mechanical strength of the base material, enabling them to endure high pressure and mechanical stress while leveraging the corrosion resistance of the cladding.

Versatility: These flanges are suitable for a broad spectrum of applications, such as pipelines, pressure vessels, and heat exchangers, owing to their adaptability across various environments and conditions.

Quality and Safety: The bonding process between the base material and the cladding is meticulously controlled, ensuring consistent quality and integrity of the clad layer, essential for safe operation in high-stress environments.

Compliance with Standards: Clad flanges are manufactured to meet stringent industry standards (such as ASME, ASTM, and API), ensuring they meet the necessary specifications for safety, reliability, and performance.

Resistance to Wear and Tear: The cladding layer offers superior resistance to wear and tear, enhancing the flange's performance in applications where it is exposed to abrasive substances or high-velocity fluids.

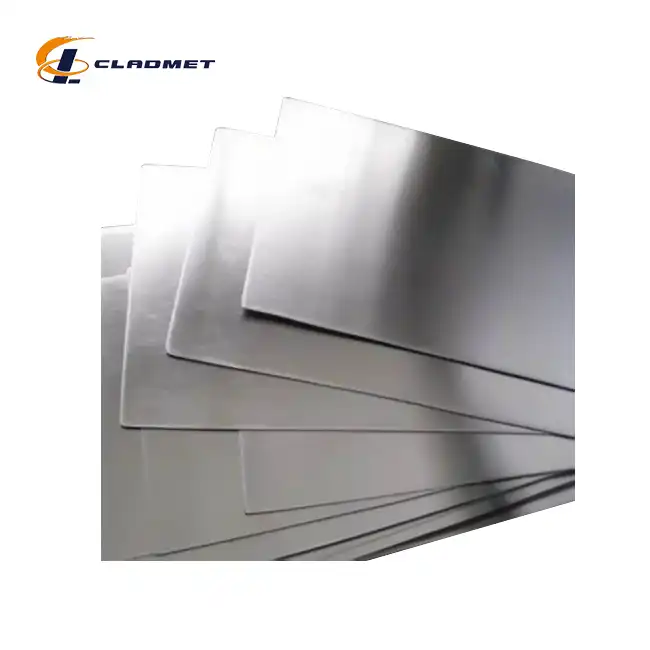

Product Specifications

Below is a detailed table of the specifications for our products:

| Clad Flanges Specifications | |

| Feature | Specification |

| Flange Type | All standard flange types (Weld Neck, Slip-On, Blind, etc.) as per ASME B16.5 or B16.47 |

| Base Material | * Carbon Steel (SA 105, SA 216, etc.) * Low Alloy Steel |

| Cladding Material | * Stainless Steel (304, 316L, etc.) * Nickel Alloys (Inconel, Hastelloy) * Other Corrosion Resistant Alloys (depending on application) |

| Cladding Thickness | Typically 3 mm to 12 mm |

| Cladding Method | * Weld Overlay * Explosion Bonding |

| Pressure Rating | Same as equivalent un-clad flange rating (ASME B16.5 or B16.47) |

| Temperature Rating | Determined by base material and cladding material properties |

| Applications | * High pressure and high temperature service * Corrosive environments * Applications requiring special properties (e.g., wear resistance) |

| Standards | * Manufacturing typically follows ASME B16.5 or B16.47 for dimensions * Material specifications based on relevant ASTM standards (e.g., ASTM B898 for Titanium cladding) |

|

|

|

|

Manufacturing Methods

Explosive Welding

Explosive welding is a process where a high-energy detonation causes two materials, titanium and carbon steel, to bond under intense impact. The materials are precisely positioned and then detonated to create a metallurgical bond between the layers. This method is commonly used for titanium-carbon steel clad flanges in applications that require strong, reliable bonds capable of withstanding harsh conditions, such as offshore platforms and chemical processing units.

Roll Bonding

Roll bonding is a technique that applies mechanical pressure to bond the titanium layer onto the carbon steel base. Both materials are passed through rollers under high pressure, which results in a strong, cold-welded bond. This process is ideal for creating titanium-carbon steel clad flanges used in heat exchangers and pressure vessels, where uniform bonding and high strength are essential for safe and efficient performance.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a high-temperature, high-pressure process that involves sealing the titanium and carbon steel together in a container and applying pressure and heat. This results in a diffusion bond between the materials. HIP is often used when the titanium-carbon steel clad flange needs to maintain high integrity in critical applications, such as in aerospace, power generation, and chemical industries.

Key Benefits and Features

Enhanced Corrosion Resistance

Titanium is well-known for its resistance to corrosion, especially in aggressive environments like seawater and acidic solutions. By cladding carbon steel with titanium, the resulting flange gains superior protection against corrosion, making it ideal for use in harsh environments such as marine, offshore, and chemical processing industries. This corrosion resistance ensures a longer lifespan for equipment and reduced maintenance costs.

Strong Mechanical Properties

Carbon steel provides the necessary mechanical strength for the flange, while the titanium layer offers additional durability without significantly increasing weight. This combination of materials ensures that the titanium-carbon steel clad flange is robust enough to handle high-pressure and high-temperature applications while maintaining its integrity over time.

Cost Efficiency

While titanium is a high-cost material, using it as a cladding layer over carbon steel allows manufacturers to create a cost-effective product that benefits from the best of both materials. This approach reduces the overall cost of the flange while maintaining high performance, making it suitable for large-scale industrial applications where cost-efficiency is important.

Improved Performance in Extreme Conditions

The titanium layer on the flange improves its resistance to extreme temperatures and harsh chemical environments. This makes titanium-carbon steel clad flanges ideal for use in applications such as reactors, pressure vessels, and heat exchangers, where the materials are subjected to high heat and corrosive chemicals.

Customization for Various Applications

Titanium-carbon steel clad flanges can be customized to meet the specific requirements of different industries, including size, thickness, and surface treatments. This flexibility ensures that the flange will perform optimally in various applications, from oil and gas refineries to marine structures.

Increased Durability and Longevity

The titanium cladding significantly extends the life of the flange by providing a protective barrier against corrosion and wear. This increased durability translates to fewer replacements and lower maintenance costs, which is particularly advantageous for industries like offshore oil and gas where downtime can be costly.

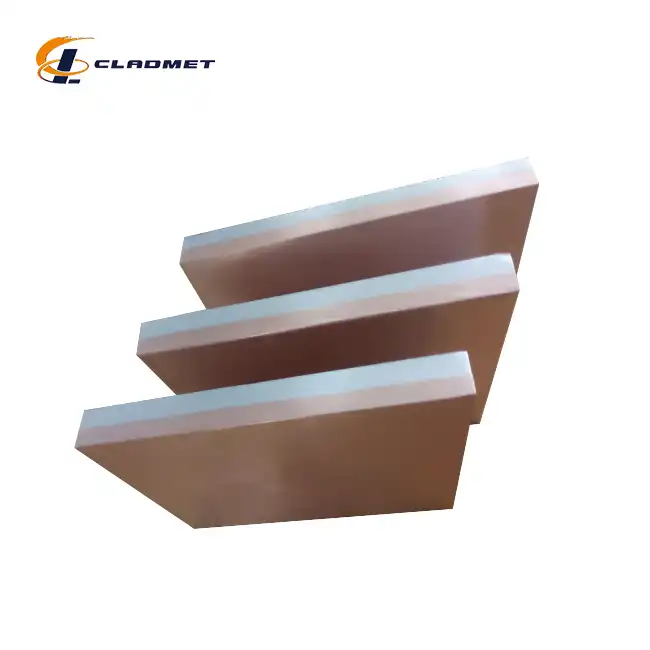

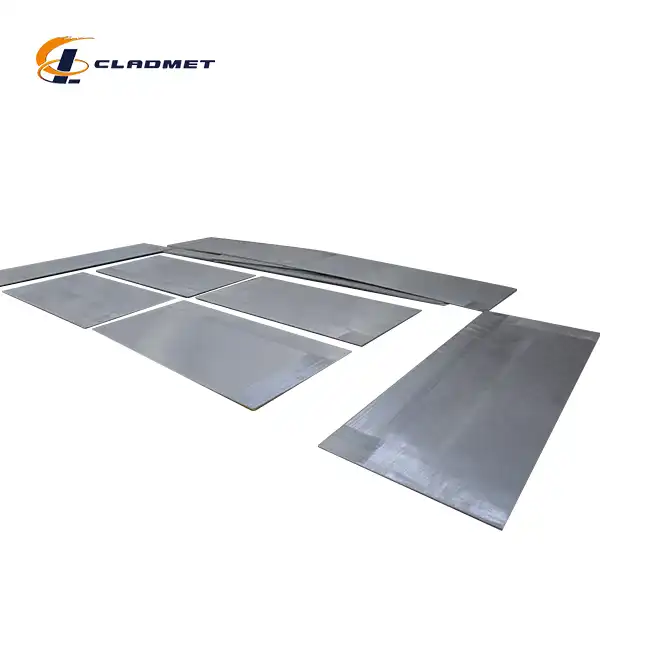

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

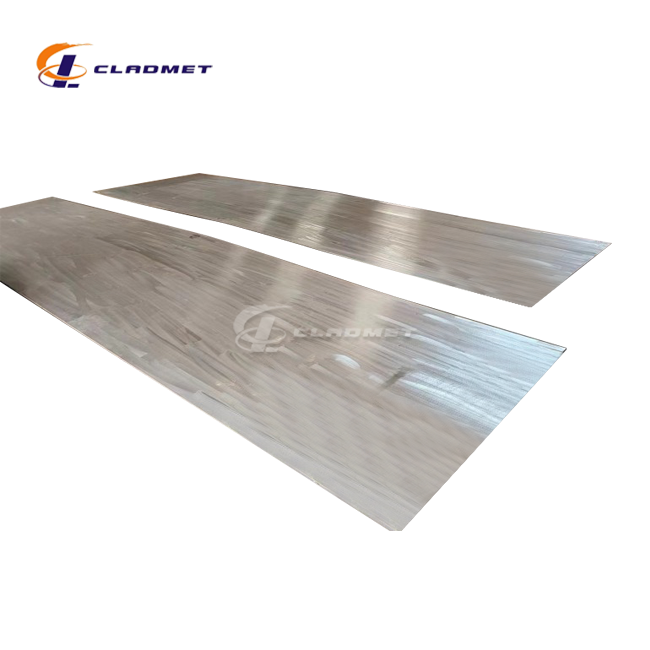

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer OEM services for our products, allowing you to customize specifications, dimensions, and surface treatments according to your project requirements. Whether you need a specific flange type or a tailored size, our team is equipped to deliver.

FAQ

Q1: What are the main advantages of using products?

A1: These flanges combine the strength of carbon steel with the corrosion resistance of titanium, making them highly durable and cost-effective for industrial applications.

Q2: Can you customize the size and thickness of the flanges?

A2: Yes, we offer full customization based on your specifications, including thickness, diameter, and pressure ratings.

Q3: How long does delivery typically take?

A3: The delivery cycle is usually 3-6 months, but this can be adjusted based on the order size and customer requirements.

Q4: What industries are these flanges best suited for?

A4: They are ideal for industries such as oil and gas, chemical processing, power generation, and marine engineering.

Contact Us

For inquiries or to place an order, please contact us via the following:

Let Baoji JL Clad Metals Materials Co., Ltd. provide you with the best Titanium-Carbon Steel Clad Flanges for your industrial needs!

- Phone: +86-917-3372918

- WhatsApp: +8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)