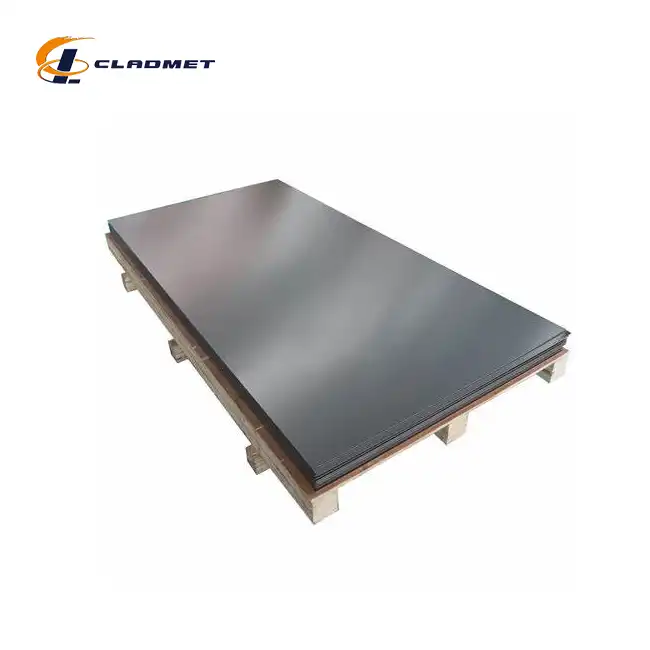

Standard sizes with customization options available.

Product Applications:

Used in aerospace, automotive, and industrial sectors.

Quality Control and Testing:

Rigorous testing procedures ensure reliability and performance.

Product Implementation Standards:

Compliant with ASME, ASTM, JIS standards.

ISO 9001:2000 certified, passed PED and ABS audits in 2024.

Delivery:

Multiple shipping options available, including air and sea freight.

Packaging:

Secure outer packaging to ensure product safety during transit.

Product Overview

Nconel 718, also known as UNS N07718 or GH4169, is a high performance nickel-based high temperature alloy. The alloy was developed by the U.S. International Nickel Corporation (Inco) in the 1950s, and has been widely used in many fields, such as aerospace, energy, and chemical industry, due to its excellent mechanical properties, corrosion resistance, and high-temperature stability.

Chemical composition and Microstructure

The primary chemical composition of Inconel 718 alloy consists of nickel (50%-55%), chromium (17%-21%), iron (residual, usually 15%-20%), niobium (4.75%-5.5%), molybdenum (2.8%-3.3%), titanium (0.65%-1.15%), and small amounts of aluminum, carbon, manganese, silicon, and other elements. The precise proportioning of these elements in the alloy allows it to perform well at high temperatures and in harsh environments.

Microstructurally, Inconel 718 alloy consists mainly of a γ (austenitic) matrix and precipitated phases such as γ' (Ni₃(Al,Ti)), γ'' (Ni₃Nb) and δ (Ni₃Nb) phases. These precipitated phases play a reinforcing role in the alloy, giving it higher strength and hardness.

|

|

|

|

Performance Advantages

Excellent High Temperature Strength: Nickel 718 maintains high strength at 700°C (1300°F), which is suitable for aero-engine, gas turbine and other high-temperature working conditions.

Physical and Mechanical Properties

Inconel 718 alloy has a density of about 8.24g/cm³ (or 8.19g/cm³ depending on the specific process and composition) and a melting point between 1260-1330°C. The alloy has an excellent mechanical properties at normal temperature. At normal temperaure, the alloy has excellent mechanical properties, with a tensile strength of up to 1200-1400 MPa, a yield strength of about 900-1150 MPa, an elongation of about 25%, and a hardness of about 40-44 HRC in the aged condition.

Especially at high temperatures, Inconel 718 alloy can maintain high mechanical properties and good stability. At 700°C, the alloy still maintains high strength and good toughness, which is mainly attributed to its internally stabilized γ' phase and γ'' phase structure.

Outstanding corrosion resistance: Extremely resistant to oxidation, chloride stress corrosion cracking, sulfides and acidic environments for use in the marine, oil and gas and chemical industries.

Good welding performance: can be welded before and after heat treatment, avoiding the problem of weld cracking that usually exists in alloy materials, suitable for the manufacture of complex structures.

Creep and fatigue resistance: Long-term stability at high temperatures and pressures for aerospace, turbine blades and energy applications.

Highly machinable: conventional cutting, machining and 3D printing are available for different manufacturing needs.

Composition & Mechanical Properties)

|

elemental |

(%)Ratio |

|

Ni |

50-55 |

|

Cr |

17-21 |

|

Fe |

Balance |

|

Mo |

2.8-3.3 |

|

Nb+Ta |

4.75-5.5 |

|

Performance |

value |

|

tensile strength |

≥1275 MPa |

|

yield strength |

≥1035 MPa |

|

elongation |

≥12% |

|

(HB)hardness |

331-363 |

Application Industry

Aerospace: engine turbine disks, turbine blades, fasteners, rotors, airframe structural parts

Oil and gas: downhole tools, valves, fasteners, drilling equipment

Offshore engineering: ship components, deep-sea pipelines, offshore drilling equipment

Energy industry: gas turbine components, reactor pressure vessels in nuclear power plants, control rod drive mechanisms and various elastic elements in nuclear fuel cycle systems.

Chemical industry: corrosion-resistant equipment, heat exchangers, pressure vessels

Cryogenic engineering: for the manufacture of cryogenic storage containers such as liquid nitrogen and liquid hydrogen.

Mold Making: Used to make high-temperature molds that withstand high temperatures and high pressure working environments.

OEM Service

We offer customized OEM services to meet your specific needs. Our team collaborates closely with clients to develop tailored solutions, ensuring that our Pure Nickel Alloy Plates fit seamlessly into your applications. Whether you require unique dimensions or specialized properties, we are here to help.

For inquiries or more information about our Pure Nickel Alloy Plates, please reach out to us:

At Baoji JL Clad Metals Materials Co., Ltd., we are dedicated to providing you with high-quality products and exceptional service. Let us help you find the perfect solution for your needs!

Company Advantages

As a core supplier in this field, Julong Titanium Steel Composite Plate mainly analyzes our core advantages from three dimensions: technical barriers, cost control, and application scenario expansion.

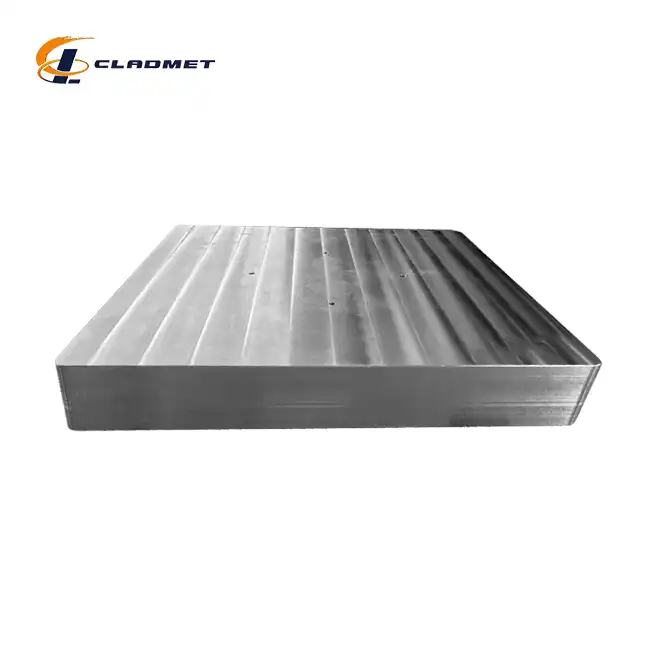

1. Composite Technology Barrier Structure

The explosive welding process breaks through the core technology of multi-layer metal explosion welding. The interface bonding strength of titanium-steel composite plates reaches more than 380MPa, and the shear strength exceeds 210MPa, far exceeding the international standard (ASTM B898). Through the independently developed gradient heat treatment process, the interface residual stress is effectively eliminated, so that the composite plate maintains stability under working conditions of -196℃ to 450℃, and is successfully applied to extreme environments such as LNG storage tanks.

2. Cost Control System

Faced with the current situation of raw material fluctuations (the price amplitude of titanium plates in 2024 reached 42%), Julong Metal established a dynamic procurement strategy and signed an annual framework agreement with Baoti Group to lock in 80% of the basic usage. When the titanium price is low in 2024, 60% of the annual raw material reserves will be completed, reducing the comprehensive procurement cost by 15%.

Julong has its own melting furnace and plasma welding equipment. We convert scraps into small composite tube sheets and strengthen the quality control and inspection system of the entire line, so that the defect detection rate has increased from 92% to 98%, and the quality loss cost has decreased by 35%.

III. Innovation and expansion of application scenarios

1: New energy field: For the conductive slot project, Julong uses titanium steel composite plate (coating 1mm+3mm) TA1+Q35B, and signs a set of orders of 100 tons in 2024, with a unit price 26% lower than the traditional stainless steel solution.

2: Marine engineering: In response to the needs of deep-sea oil and gas development, composite plate products innovatively adopt a three-layer structure of TA10/316L/Q345R. In this project, the material has a service life of 3 times that of traditional duplex steel in a water depth of 1,500 meters and an H2S corrosive environment, and the maintenance cycle is extended from 2 years to 6 years.

Why choose us?

Professional manufacturers can supply directly, no middleman markup, to ensure competitive price.

Various specifications & customized services to meet different engineering needs.

Rigorous quality testing in accordance with ASTM B637 / AMS 5662 / AMS 5663 standards.

Fast shipment & global logistics support to minimize procurement lead time.

FAQ

1.What is the difference between Nickel 718 and Inconel 625?

Nickel 718 emphasizes high-temperature strength and creep resistance, while Inconel 625 mainly highlights corrosion resistance. If higher mechanical strength is required, Nickel 718 is more suitable.

2.What are the manufacturing processes for Inconel 718 alloy?

The manufacturing process involves a number of links such as smelting, forging, rolling and heat treatment. During smelting, the quality of raw materials and alloy composition need to be strictly controlled to ensure the purity and uniformity of the alloy. During forging and rolling, the microstructure and mechanical properties of the alloy can be optimized through reasonable temperature and deformation.

3. Is Nickel 718 heat treatable?

Yes, Nickel 718 can be Age Hardened (Age Hardening), which allows the elements in the alloy to fully dissolve and precipitate to form the desired precipitated phases, thereby increasing the strength and hardness of the alloy.

4. Can the Nickel 718 be used in a hydrogen atmosphere?

Its resistance to hydrogen corrosion is high, but it is recommended that it be evaluated under specific pressure and temperature conditions to ensure safety in use.

5.What specifications can you offer?

Plates, rods, tubes, forgings and powders (for 3D printing) are available and support custom sizes.

6. Does it support third-party testing?

We can provide test reports from international certification organizations such as SGS, TÜV, BV, etc. to ensure that the quality of the materials meets the purchasing standards.

7. Research and Development

Researchers have further improved the performance and reliability of Inconel 718 alloy by optimizing its composition, improving manufacturing processes and heat treatment systems. At the same time, in-depth research has been carried out on the microstructure, fatigue performance, high-temperature creep performance and other aspects of Inconel 718 alloy, providing a theoretical basis for its application in more severe environments.

The research and application of Inconel 718 alloy has a high manufacturing cost and is prone to defects such as cracks and segregation during processing. Therefore, how to further reduce manufacturing costs and improve processing performance and reliability has become the focus of current research.

Contact us

Phone&Tel:+86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

Our Factory

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

_1737007724117.webp)