Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

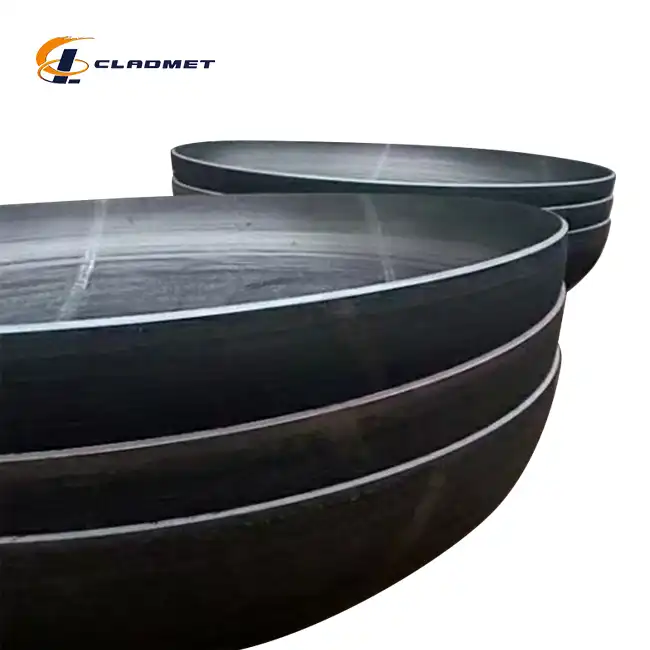

Titanium-carbon steel clad head Introduction

Compared to other metals, Titanium-carbon steel clad head is a lustrous and silver transition metal with low density and high corrosion resistance to sea water, aqua regia and chlorine, etc. Titanium is alloyed with aluminum, manganese, iron, molybdenum and other metals to increase strength, to withstand high temperatures, and to lighten the resultant alloy.

Advanced Refractory Metals is a leading supplier of Titanium-carbon steel clad head. We offer competitive pricing and great lead times on all our materials, and we're capable of supplying custom materials per any specs/drawings you provide us with.

Product Specifications

| Parameter | Description |

|---|---|

| Base Material | Carbon Steel (e.g., Q235B, Q345B, A516 Gr.70, etc.) |

| Cladding Material | Titanium (e.g., TA1, TA2, Gr1, Gr2, etc.) |

| Head Type | Elliptical, Torispherical, Hemispherical, Flat, or Custom Shape |

| Diameter Range | 300 mm - 5000 mm (customizable) |

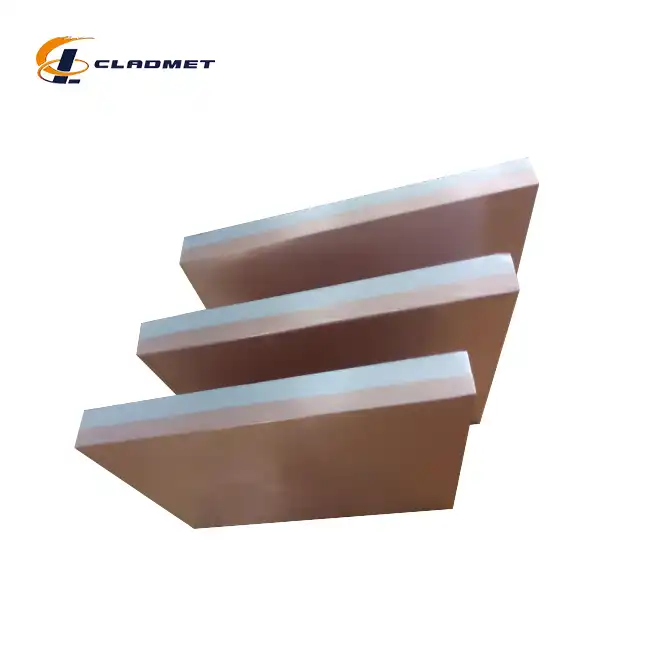

| Total Thickness Range | 5 mm - 200 mm (e.g., 2 mm Titanium + 8 mm Carbon Steel) |

| Clad Layer Thickness | 1 mm - 10 mm (customizable) |

| Base Layer Thickness | 4 mm - 190 mm (customizable) |

| Bonding Technology | Explosion Bonding or Hot Rolling |

| Bonding Strength | ≥ 140 MPa |

| Shear Strength | ≥ 105 MPa |

| Corrosion Resistance | Excellent resistance to acids, alkalis, and seawater environments |

| Heat Resistance | Superior performance under high temperatures depending on titanium grade |

| Application Industries | Pressure Vessels, Heat Exchangers, Chemical Reactors, Marine Equipment, Desalination, etc. |

| Standards Compliance | ASTM B898, ASME SB-898, GB/T 25198, and other relevant standards |

| Surface Finish | Polished, Sandblasted, or Customized |

| Customizations Available | Diameter, Thickness Ratio, Shape, Surface Finish, etc. |

|

|

|

|

Manufacturing Processes

Explosive Bonding

Explosive bonding is a highly effective method for joining titanium and carbon steel. In this process, a carefully prepared assembly of the two metals is placed in a specific configuration, and an explosive charge is detonated between them. The explosion generates an intense shockwave, which forces the metals to collide at high speeds, resulting in a strong metallurgical bond. Explosive bonding is especially useful for titanium-carbon steel clad heads used in environments that require high bond strength, such as offshore structures and chemical reactors.

Roll Bonding

Roll bonding is another technique used for producing titanium-carbon steel clad heads. The base material (carbon steel) and the cladding material (titanium) are passed through a set of rollers under high pressure. This cold-forming process ensures that the two metals fuse together, creating a solid bond between the layers. Roll bonding is ideal for applications that demand uniform bonding and is commonly employed in manufacturing pressure vessel components and heads for heat exchangers.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) involves subjecting the titanium-carbon steel assembly to high temperatures and pressure inside a sealed container. The materials are subjected to these conditions, which facilitates atomic diffusion, resulting in a diffusion bond that ensures high integrity and strength between the layers. HIP is typically used for critical applications where the bonding strength and reliability of the titanium-carbon steel clad head are paramount, such as in aerospace and power generation industries.

Key Benefits and Features

Corrosion Resistance

Titanium is known for its exceptional corrosion resistance, especially in environments exposed to seawater, acidic solutions, or chemicals. By applying a titanium cladding to the carbon steel, the clad head gains enhanced protection against corrosion, ensuring that the component remains durable and functional in harsh conditions, such as those encountered in the chemical, oil, and gas industries.

High Strength and Durability

The carbon steel base material provides significant mechanical strength, while the titanium cladding enhances the durability of the component without adding excessive weight. This combination makes titanium-carbon steel clad heads suitable for high-pressure applications, where structural integrity is critical, such as in pressure vessels and reactors.

Cost-Effective Performance

While titanium is a high-cost material, by using carbon steel as the base metal, manufacturers can create a more cost-effective solution without compromising performance. This combination of materials offers a favorable balance of cost and durability, making it an ideal choice for industries looking to reduce material costs while maintaining high performance.

Customizable and Versatile

Titanium-carbon steel clad heads can be tailored to meet specific industry requirements in terms of size, thickness, and surface treatments. This flexibility ensures that the component can be adapted to a wide variety of applications, including those in the oil and gas, chemical, and power generation sectors. Customization can also extend to the cladding thickness, allowing for further optimization of the product's performance.

Improved Heat Resistance

Titanium-carbon steel clad heads are well-suited for applications involving extreme temperatures. The titanium layer provides additional protection against oxidation and heat-induced damage, making them ideal for use in environments where heat and high-pressure conditions are present, such as in power plants and industrial reactors.

Longer Service Life

The combination of titanium's resistance to corrosion and the robust mechanical properties of carbon steel results in a longer service life for clad heads. This increased longevity reduces the need for frequent replacements and minimizes maintenance costs, which is especially beneficial in industries where downtime is costly.

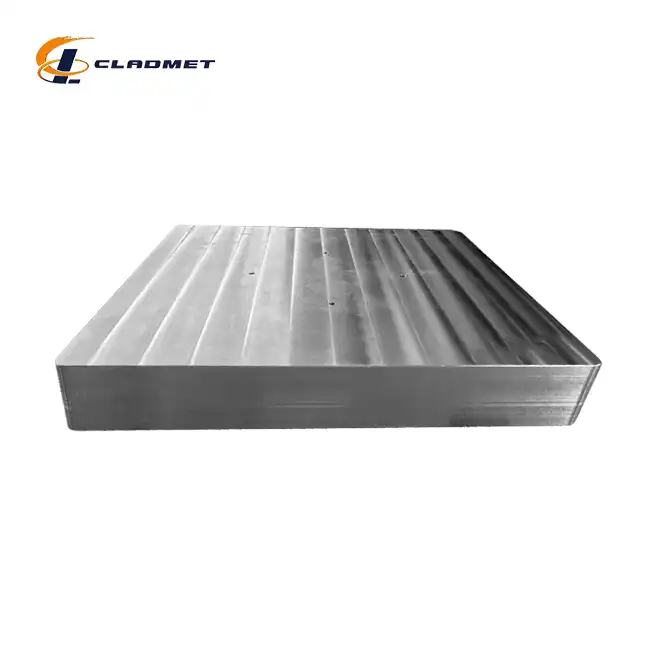

Explosive Composite Panel Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

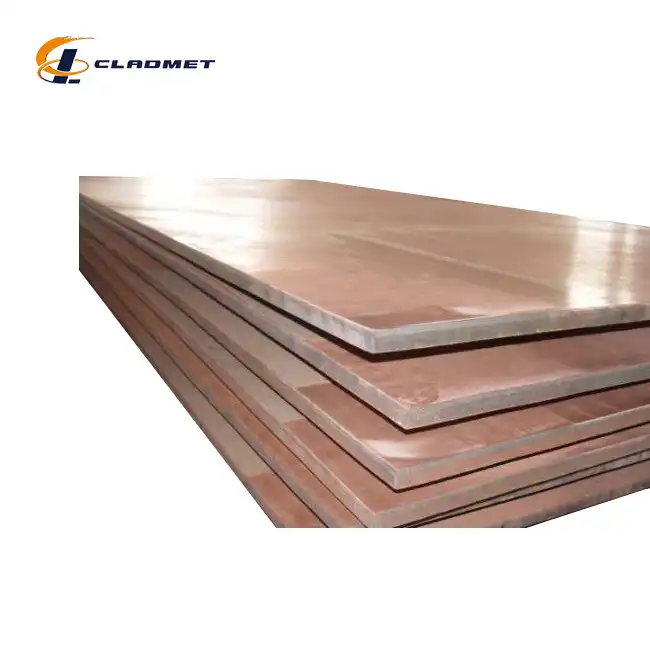

Main Products

Main Application Industries

OEM Service

We provide comprehensive OEM services to ensure that your products meet all of your specific requirements by tailoring them to your exact specifications. This includes the ability to make unique sizes and apply special surface treatments. This gives you a lot of freedom to personalize your products and makes them work better and look better.

FAQ

Q: What is the lead time for the titanium-carbon steel clad head?

A: The typical delivery cycle is 3-6 months, but this can be negotiated based on your requirements.

Q: Can I get a sample before placing a bulk order?

A: Yes, we provide samples for testing to ensure that our product meets your standards.

Q: What payment methods do you accept?

A: We accept bank transfers, credit cards, and other payment methods for your convenience.

Q: How do you ensure product quality?

A: We strictly adhere to GB/GBT, ASME/ASTM, and JIS standards, and we are ISO9001-2000 certified.

Contact Us

For inquiries or to place an order, please reach out to us:

- Phone: tel:+86-917-3372918

- WhatsApp: 8613530170059

- Email: sales@cladmet.com

- Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)

_1737611894905.webp)