Standard sizes with customization options available.

Product Applications:

Used in aerospace, automotive, and industrial sectors.

Quality Control and Testing:

Rigorous testing procedures ensure reliability and performance.

Product Implementation Standards:

Compliant with ASME, ASTM, JIS standards.

ISO 9001:2000 certified, passed PED and ABS audits in 2024.

Delivery:

Multiple shipping options available, including air and sea freight.

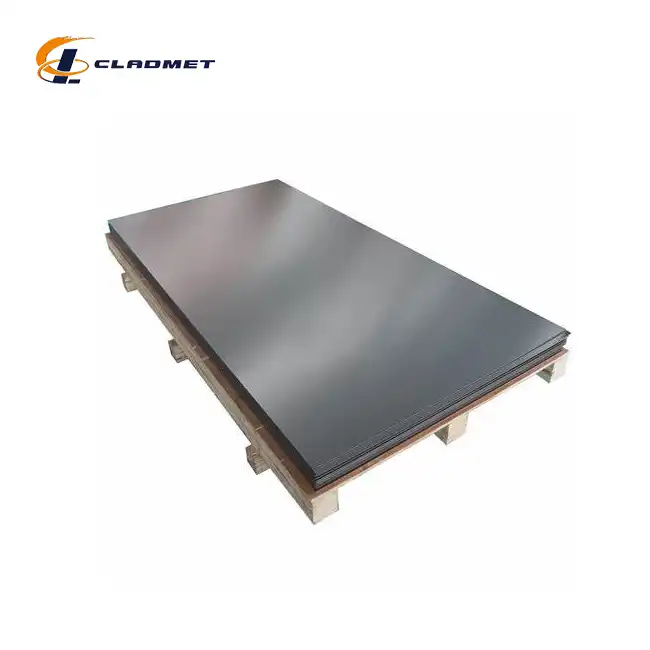

Packaging:

Secure outer packaging to ensure product safety during transit.

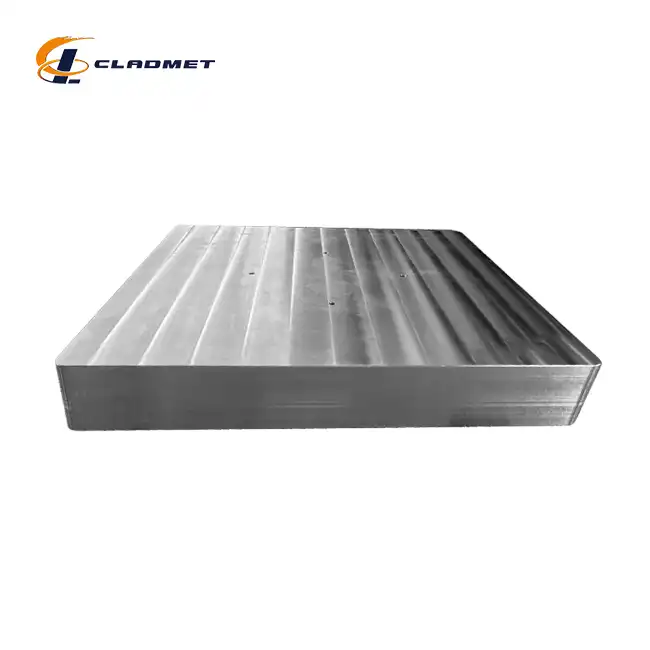

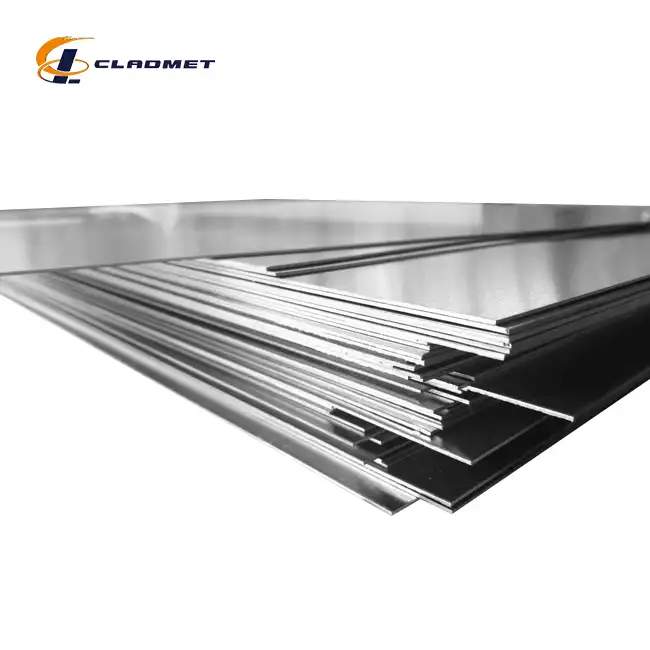

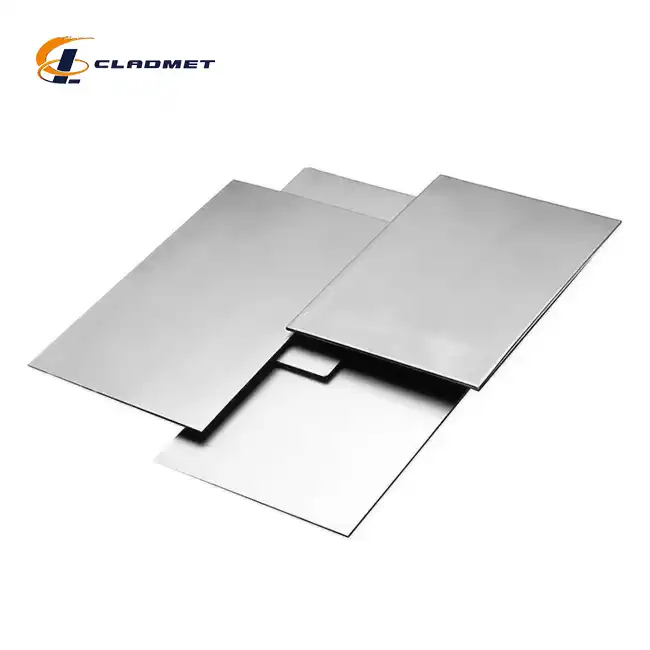

AMS 4911 Titanium Plate Product Details

Quality AMS 4911 Titanium Plate - A Reliable Supplier for Your Business

If you are looking for high-strength, lightweight, and corrosion-resistant titanium plates, our AMS 4911 Titanium Plates are the perfect solution. We specialize in wholesale supply, meeting the needs of industries that require top performance in aerospace, medical, chemical, and industrial applications.

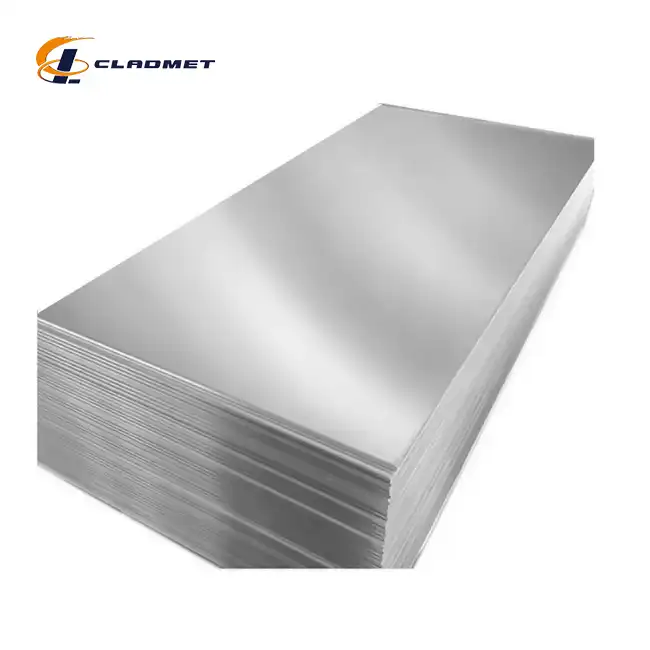

Product Specifications

Below is a detailed specification table for our AMS 4911 titanium plates:

| Parameter | Details |

|---|---|

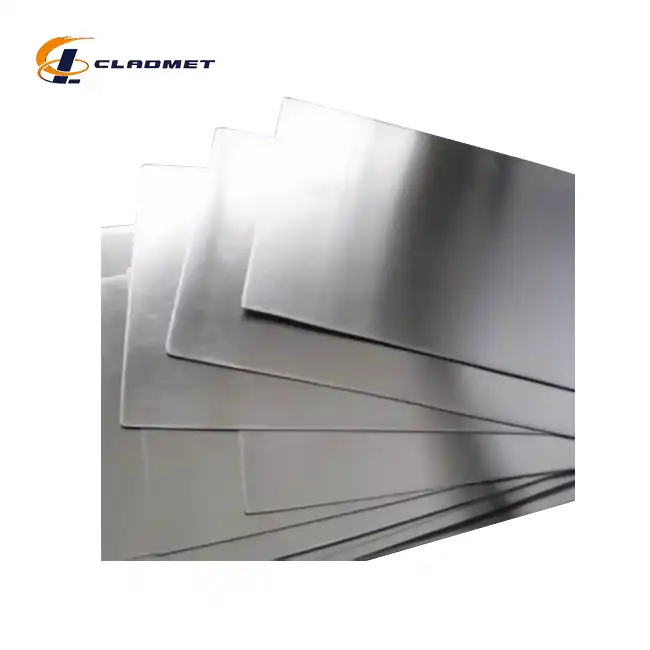

| Material Grade | AMS 4911 (Titanium Alloy Gr5) |

| Thickness Range | 0.5 mm – 100 mm |

| Width Range | Up to 3000 mm |

| Length Range | Up to 6000 mm |

| Density | 4.43 g/cm³ |

| Tensile Strength | ≥990 MPa |

| Yield Strength | ≥860 MPa |

| Elongation | ≥10% |

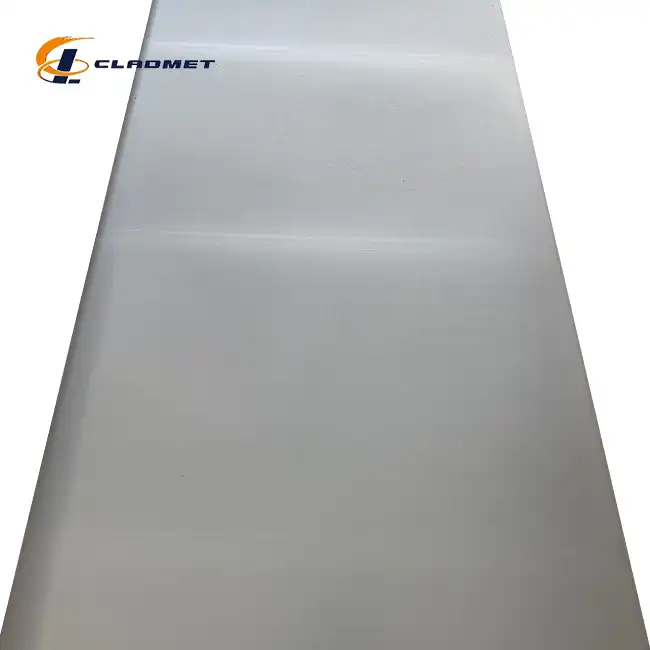

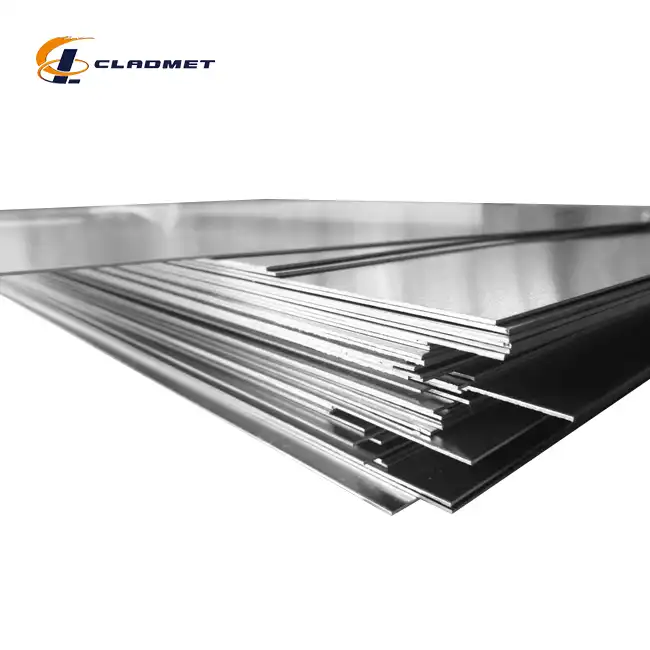

| Surface Finish | Mill Finish, Polished, Pickled |

| Standards Compliance | ASTM B265, ASME SB-265, AMS 4911 |

| Packaging | Wooden cases or customized packing for export |

| Delivery Cycle | 2 to 6 weeks |

Why Choose Our AMS 4911 Titanium Plates?

✅ Engineered for Performance - Our AMS 4911 Titanium Plates meet stringent aerospace and industrial standards, ensuring superior strength, corrosion resistance and durability.

✅ Wholesale only, buy direct from the manufacturer - no middlemen, no unnecessary markups - competitive pricing and reliable bulk supply.

✅ Certified Quality - We strictly adhere to ASTM, ASME, JIS and GB standards and hold ISO 9001:2015, PED and ABS certifications, guaranteeing consistent quality and compliance.

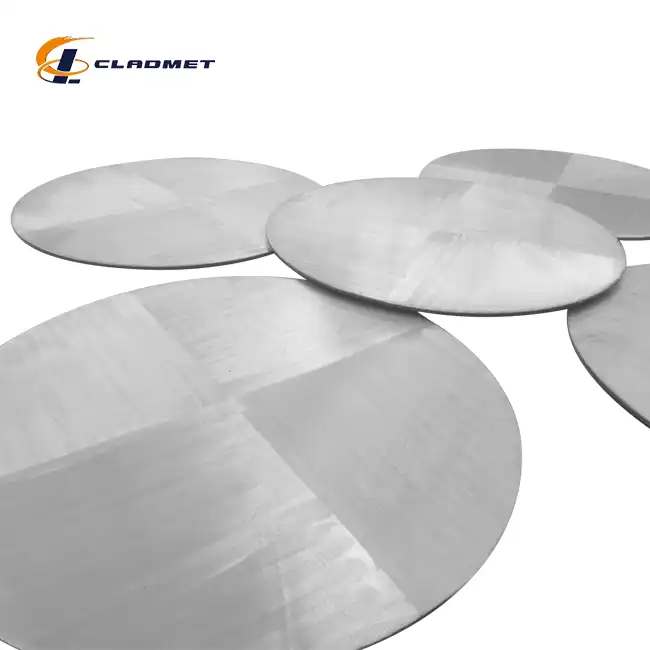

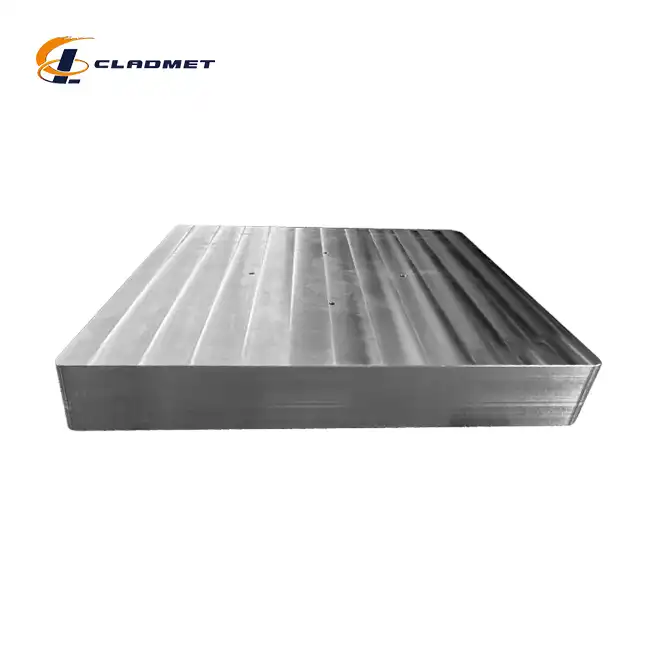

✅ Custom Sizes Available - Need a specific thickness or size? We offer custom cutting and machining services.

✅ Backed by Expertise - With nearly 40 years of experience, our engineering expert R&D team ensures best-in-class product development and support.

|

|

|

Precision Manufacturing Processes - Ensure Unparalleled Quality

We understand that titanium plates, especially AMS 4911 grade, must meet stringent performance and safety standards. That’s why we implement a rigorous manufacturing process to ensure that every plate meets our customers’ expectations.

Step 1: Raw Material Selection and Metallurgy

🔹 We use high-purity titanium sponge, ensuring the final product has superior strength and corrosion resistance.

🔹 Titanium undergoes multiple vacuum melting (VAR – Vacuum Arc Remelting) to achieve a uniform composition and remove impurities.

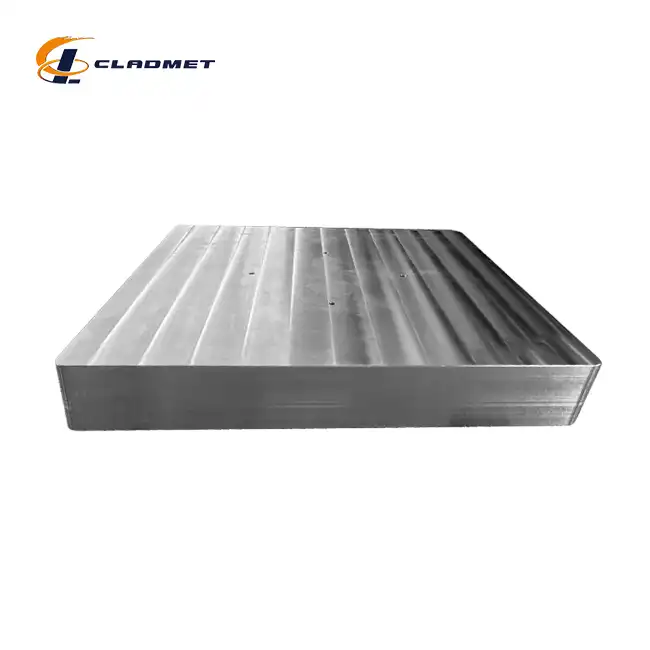

Step 2: Hot Rolling and Forging

🔹 Titanium ingots are hot rolled and forged to refine their grain structure and improve mechanical properties.

🔹 Strict temperature control during rolling ensures consistent thickness and smooth surface.

Step 3: Annealing and Heat Treatment

🔹 To optimize mechanical properties and stress relief, our plates undergo a carefully controlled annealing process in a vacuum or inert gas furnace.

🔹 This step ensures that the material maintains its strength while improving ductility.

Step 4: Precision Cold Rolling and Thickness Control

🔹 We utilize advanced cold rolling technology for high-precision thickness control (1mm, 3mm, 5mm and custom sizes available).

🔹 Before further processing, non-destructive testing (NDT) is performed to detect any micro defects.

Step 5: Surface Treatment and Pickling

🔹 Titanium plates are pickled to remove the oxide layer and enhance corrosion resistance.

🔹 We provide customized surface treatments based on customer requirements.

Step 6: Rigorous Quality Inspection and Testing

Each AMS 4911 titanium plate undergoes a comprehensive quality control process, including:

✅ Ultrasonic Testing (UT) – to detect internal defects.

✅ Tensile and Hardness Testing – to ensure strength and durability.

✅ Dimensional Inspection – to ensure accurate thickness and flatness.

✅ Chemical Composition Analysis – to confirm compliance with AMS 4911 standards.

This rigorous manufacturing process ensures that every titanium plate we deliver meets the standards of the aerospace, industrial, and medical industries.

Who We Are - Your Trusted Titanium Supplier

Baoji JL Composite Metal Materials Co., Ltd. has been a leading composite metal manufacturer since 1988. With nearly 40 years of expertise, we focus on high-performance metal materials to serve global industries.

🔹 Strong R&D Support - Collaboration with top universities and research institutions ensures continuous innovation.

🔹 Strict Quality Control - Meets ASTM, ASME, JIS and GB standards to ensure excellent product reliability.

🔹 Global Presence - Trusted by customers in the aerospace, marine, medical and industrial fields.

🔹 Advanced Manufacturing - Cutting-edge production technology ensures precision and consistency.

If you are looking for a reliable AMS 4911 titanium plate supplier, we are committed to meeting your business needs.

Our Factory

Main Application Industries

OEM Service

We offer OEM services to meet your specific needs. Whether it’s custom dimensions, surface finishes, or tailored solutions, our team is ready to assist.

FAQ

❓ What is AMS 4911 Titanium Plate Used For?

🔹 AMS 4911 is widely used in aerospace, marine, medical implants, and high-performance industrial parts due to its excellent strength, lightweight properties, and corrosion resistance.

❓ Do you offer custom sizes?

🔹 Yes! We offer customized thicknesses and sizes based on your project requirements.

❓ What is your Minimum Order Quantity (MOQ)?

🔹 As a wholesale supplier, we only accept bulk orders. Please contact us for MOQ details.

❓ What certifications do you have?

🔹 We are ISO 9001:2015, PED, and ABS certified, ensuring all materials meet international quality standards.

❓ How to place an order?

🔹 Simply send us an inquiry - our team will respond promptly with pricing, delivery time, and order details.

Who We Are - Your Trusted Titanium Supplier

Baoji JL Clad Metals Materials Co., Ltd. has been a leading clad metal manufacturer since 1988. With nearly 40 years of expertise, we focus on high-performance metal materials to serve global industries.

🔹 Strong R&D Support - Collaboration with top universities and research institutes ensures continuous innovation.

🔹 Strict Quality Control - Comply with ASTM, ASME, JIS and GB standards to ensure excellent product reliability.

🔹 Global Presence - Trusted by customers in the aerospace, marine, medical and industrial fields.

🔹 Advanced Manufacturing - Cutting-edge production technology ensures precision and consistency.

If you are looking for a reliable AMS 4911 titanium plate supplier, we are committed to meeting your business needs.

Contact Us

For more information or to place an order, please contact us:

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China 721013

Let Baoji JL Clad Metals Materials Co., Ltd be your trusted partner for high-quality AMS 4911 titanium plates.

_1737007724117.webp)