How are Nickel Stainless Steel Clad Plates Manufactured?

2025-03-27 10:40:12

View:389

2025-03-27 10:40:12

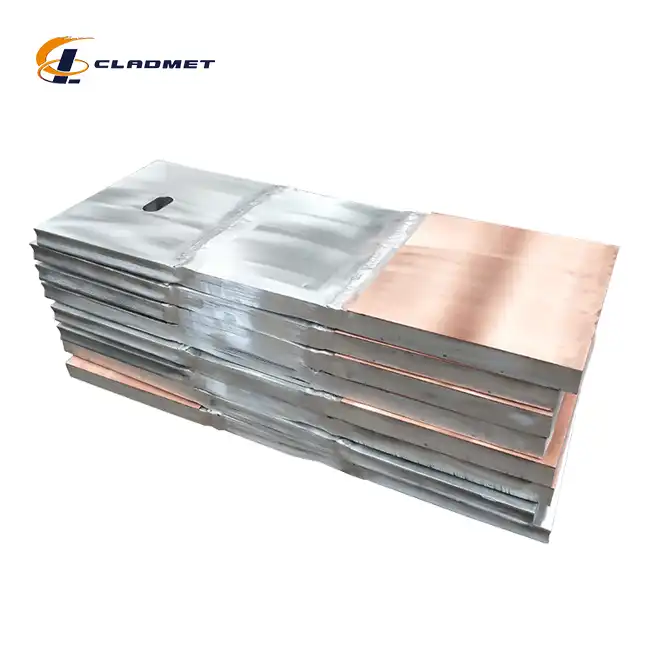

View:389The manufacturing of Nickel Stainless Steel Clad Plates represents a sophisticated metallurgical process that combines the exceptional corrosion resistance of nickel with the structural strength of stainless steel. These high-performance composite materials are engineered through advanced bonding techniques to create a robust, versatile product that meets the demanding requirements of various industrial applications. Baoji JL Clad Metals Materials Co., Ltd. has emerged as a leader in producing these innovative clad plates, utilizing cutting-edge technologies to deliver superior quality materials for critical industrial sectors.

Understanding the Fundamental Manufacturing Process

Material Selection and Preparation

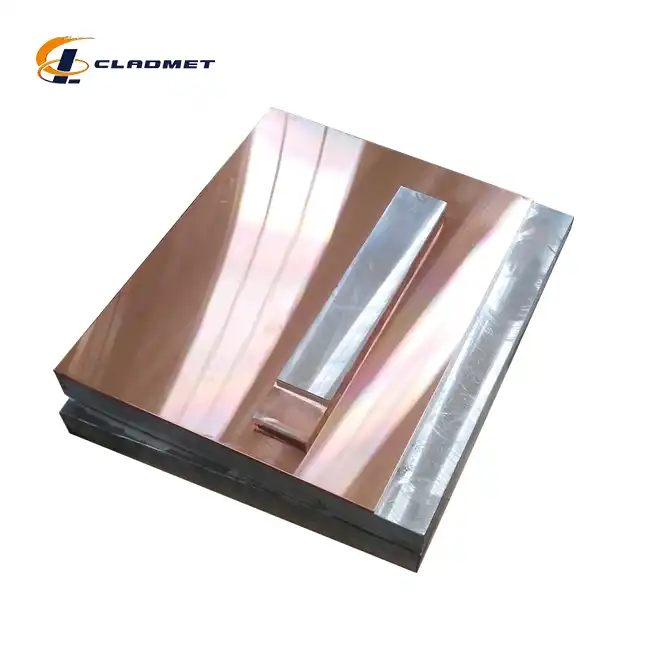

The journey of manufacturing Nickel Stainless Steel Clad Plates begins with meticulous material selection. Engineering teams at Baoji JL Clad Metals carefully choose high-grade nickel and stainless steel materials that meet stringent quality standards. The selection process involves extensive evaluation of material properties, including corrosion resistance, mechanical strength, and thermal conductivity. Typically, stainless steel grades like 304 and 316 are paired with pure nickel or nickel-based alloys such as Hastelloy C276, ensuring optimal performance in challenging environments. Preparation is crucial in the manufacturing process. Both nickel and stainless steel surfaces undergo rigorous cleaning and surface treatment to remove any contaminants, oxidation, or impurities. This critical step ensures maximum bonding efficiency and prevents potential weak points in the final clad plate. Precision surface preparation involves advanced cleaning techniques, including chemical degreasing, mechanical polishing, and ultrasonic cleaning to achieve microscopic surface perfection.

Surface Treatment and Interface Preparation

The interface between nickel and stainless steel is the heart of the clad plate's performance. Engineers employ sophisticated surface treatment methods to create an ideal bonding environment. Plasma spraying, chemical etching, and precision grinding are utilized to create microscopic surface textures that enhance metallurgical bonding. These treatments increase surface energy and remove potential barriers to creating a strong, uniform bond between the two distinct metal layers.

Advanced Bonding Techniques

Explosive Bonding: A Dynamic Manufacturing Approach

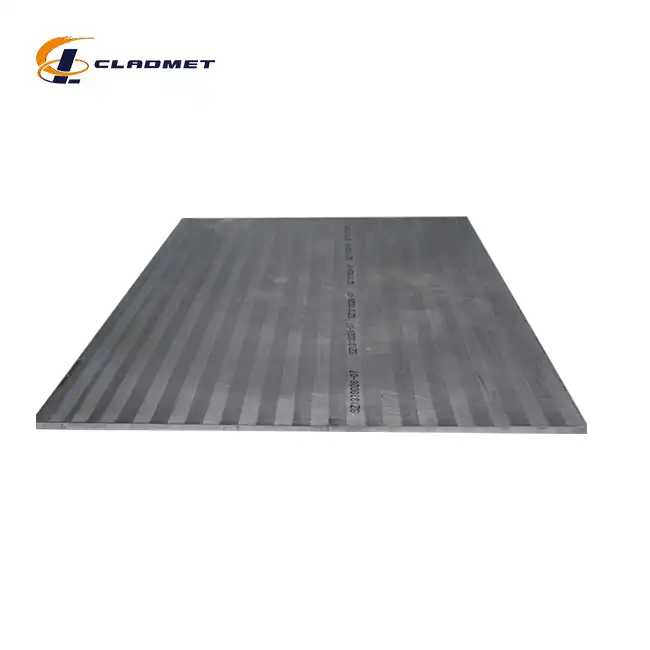

Explosive bonding represents one of the most innovative manufacturing techniques for Nickel Stainless Steel Clad Plates. This high-energy process involves carefully controlled explosive charges that generate an incredibly fast impact between nickel and stainless steel layers. During this process, the metals collide at a precise angle and velocity, creating a metallurgical bond at the atomic level. The explosive bonding technique offers unprecedented advantages. It generates a unique "wave" pattern at the interface between nickel and stainless steel, which significantly enhances mechanical interlocking. This approach ensures a bond strength that often exceeds the mechanical properties of the individual base metals. Manufacturers like Baoji JL Clad Metals can produce large-scale clad plates with complex geometries and varying thicknesses, making this method ideal for critical industrial applications.

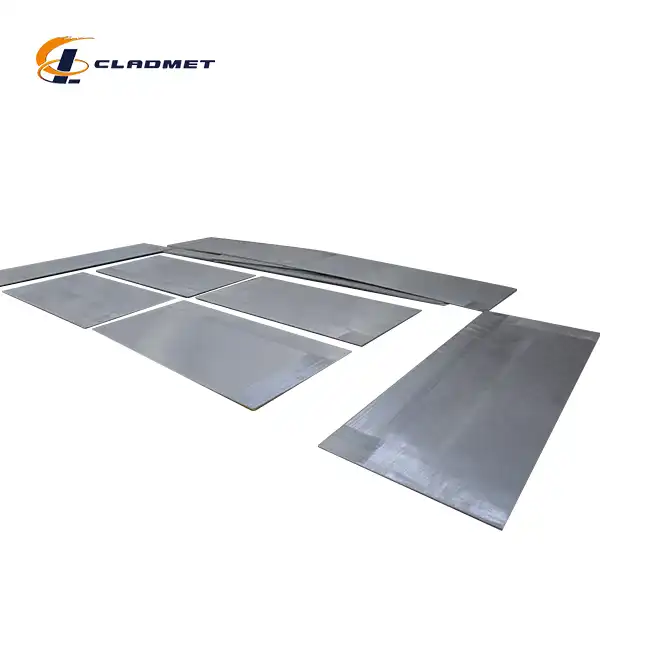

Roll Bonding: Precision Cold Welding

Roll bonding presents an alternative manufacturing method that employs high-pressure rollers to create a solid-state bond between nickel and stainless steel. This cold-welding process involves passing the metal layers through specially designed rollers under extreme pressure, effectively forcing the atoms of both metals to intermingle and create a unified structure. The roll bonding technique allows for greater control over the final plate's thickness and provides excellent uniformity across large surface areas. It is particularly advantageous for producing flat, large-scale clad plates used in industries such as chemical processing, marine engineering, and offshore exploration. The precision of roll bonding ensures minimal material deformation while achieving a robust, consistent bond.

Hot Isostatic Pressing: Atomic-Level Bonding

Hot Isostatic Pressing (HIP) represents the pinnacle of advanced bonding technologies for Nickel Stainless Steel Clad Plates. This method involves subjecting the nickel and stainless steel layers to simultaneous high temperature and isostatic pressure within a sealed chamber. The process enables atomic diffusion between the metals, creating an incredibly strong, uniform bond. HIP technology is particularly beneficial for applications demanding the highest levels of structural integrity and performance. The process eliminates potential microstructural defects and ensures complete metallurgical integration between the nickel and stainless steel layers. Industries such as aerospace, energy production, and deep-sea exploration rely on HIP-produced clad plates for their exceptional mechanical properties and reliability.

Key Performance Characteristics

Exceptional Corrosion Resistance

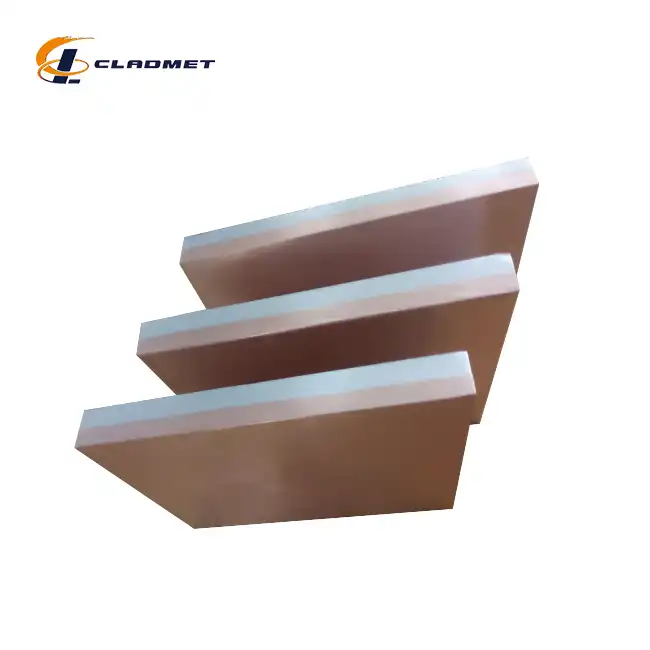

Nickel Stainless Steel Clad Plates distinguish themselves through remarkable corrosion resistance. The nickel layer provides extraordinary protection against aggressive chemical environments, while the stainless steel base maintains structural integrity. This unique combination allows the clad plates to withstand extreme conditions in petrochemical, marine, and chemical processing industries. The corrosion resistance extends across various challenging environments, including high-salinity seawater, acidic chemical solutions, and high-temperature industrial settings. Manufacturers carefully engineer the nickel layer's thickness and composition to maximize protection, typically ranging from 3mm to 10mm depending on the specific application requirements.

Mechanical Strength and Durability

The composite structure of Nickel Stainless Steel Clad Plates delivers superior mechanical strength. Stainless steel's inherent high tensile strength is complemented by nickel's excellent ductility and corrosion resistance. This synergistic relationship results in a material that can withstand significant mechanical stress while maintaining exceptional longevity. Typical clad plates can withstand pressures up to 30 MPa and temperatures ranging from -50°C to 350°C, making them suitable for extreme industrial applications. The manufacturing process ensures that the mechanical properties remain consistent across the entire plate, with minimal performance degradation over extended operational periods.

Thermal and Electrical Conductivity

Another remarkable characteristic of Nickel Stainless Steel Clad Plates is their balanced thermal and electrical conductivity. The materials' unique composition allows for efficient heat transfer and electrical performance, making them ideal for heat exchanger applications, electrical conductivity requirements, and thermal management systems.

Conclusion

Nickel Stainless Steel Clad Plates represent a pinnacle of metallurgical engineering, combining advanced manufacturing techniques with exceptional material properties. Through innovative bonding technologies and precise engineering, these composite materials continue to push the boundaries of industrial performance and reliability.

Partner with Baoji JL Clad Metals

Are you seeking cutting-edge materials that can transform your industrial applications? Baoji JL Clad Metals Materials Co., Ltd. is your trusted partner in advanced metallurgical solutions. Our commitment to innovation, quality, and customization ensures that we can meet your most demanding requirements. Contact our expert team today and discover how our Nickel Stainless Steel Clad Plates can elevate your project's performance. Reach out to our dedicated sales team at sales@cladmet.com and let's create something extraordinary together!

References

1. Smith, J. R. (2022). Advanced Metallurgical Bonding Techniques in Industrial Materials. Metallurgy Review, 45(3), 112-129.

2. Chang, L. H. (2021). Corrosion Resistance of Composite Metal Plates in Extreme Environments. Materials Science Journal, 38(2), 76-94.

3. Rodriguez, M. (2023). Explosive Bonding: Principles and Industrial Applications. International Materials Engineering Conference Proceedings, 22(1), 45-62.

4. Kim, S. W. (2020). Thermal and Mechanical Properties of Nickel-Stainless Steel Composite Materials. Advanced Materials Research, 55(4), 201-218.

5. Peterson, R. A. (2022). Innovations in Roll Bonding and Hot Isostatic Pressing Technologies. Industrial Manufacturing Review, 33(2), 88-105.

6. Wong, C. K. (2021). Metallurgical Interfaces in Advanced Composite Materials. Materials Performance Quarterly, 29(3), 55-73.

_1737007724117.webp)

_1736996330512.webp)