Standard sizes available, full customization on request.

Product Applications

Used in chemical, petrochemical, and marine industries.

Processing Technology

Advanced explosive welding ensures strong bond integrity.

Product Implementation Standards

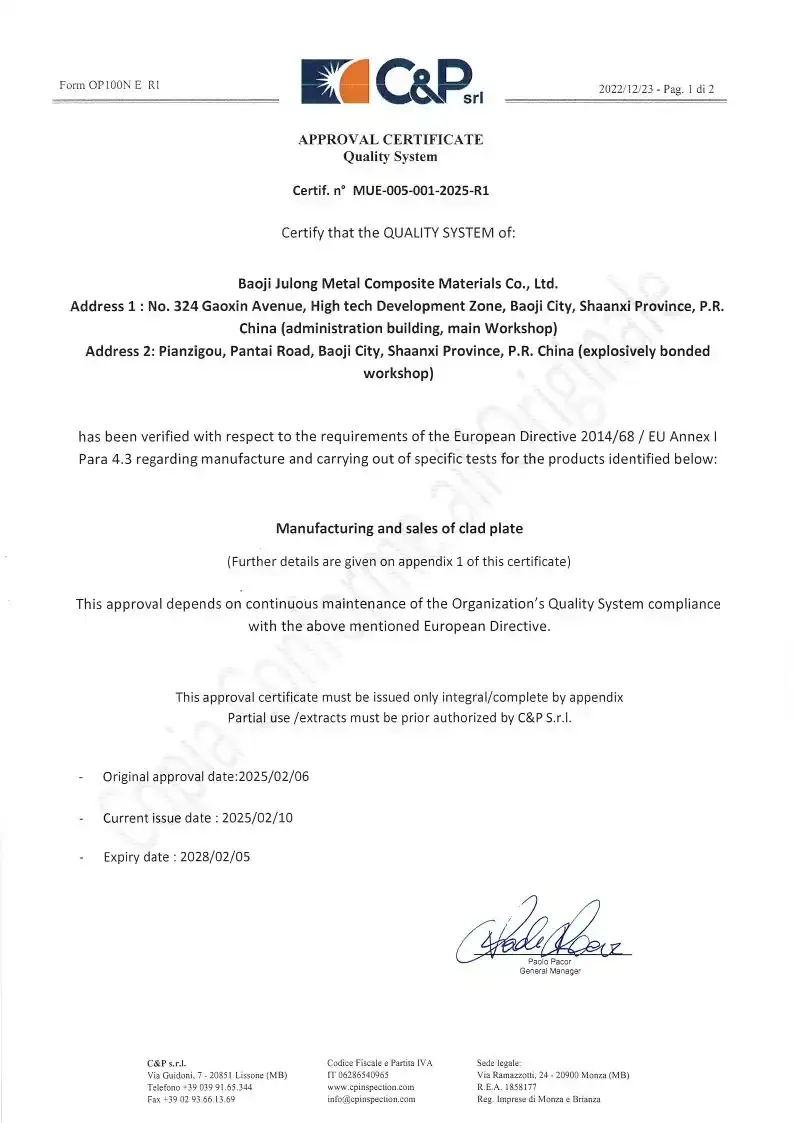

Complies with ASME, ASTM, JIS; ISO9001:2000, PED, ABS certified in 2024.

Delivery

Worldwide shipping options, express delivery available.

Packaging

Secure wooden crate packaging for international shipping.

Product Introduction

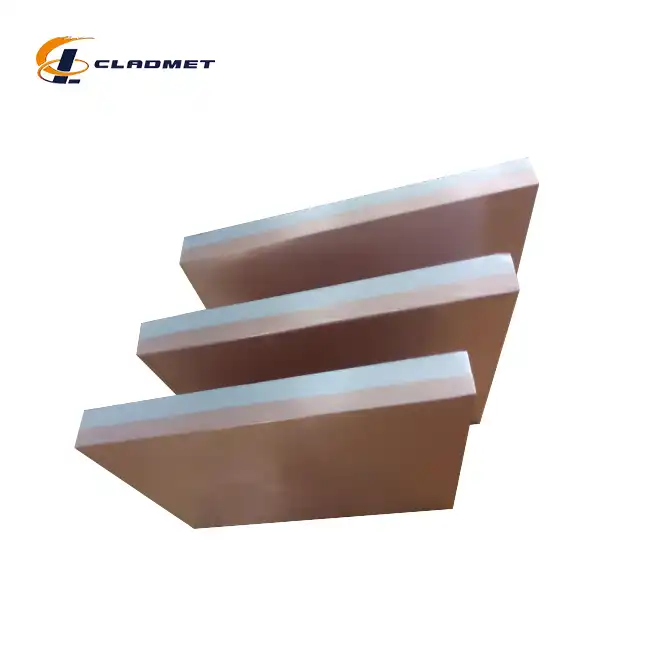

At BAOJI JL CLAD METALS MATERIALS CO., LTD, we specialize in advanced Titanium/Copper/Steel Composite Rods—engineered for demanding industrial environments. These rods combine the superior corrosion resistance of titanium, the excellent conductivity of copper, and the mechanical strength of steel in one composite product. Manufactured through rigorous standards such as GB/GBT, ASME/ASTM, and JIS, they ensure high performance, durability, and cost-efficiency.

Ideal for applications in chemical processing, power generation, metallurgy, and environmental equipment, these rods are the smart choice for industries seeking enhanced lifespan and reduced operational costs.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | Titanium/Copper/Steel Composite Rod |

| Material Classification | Clad Metal Rod |

| Material Composition | Titanium (Gr1/Gr2), Copper (T2/C11000), Steel (Q235/Q345 or custom) |

| Shape | Solid Rod / Round Bar |

| Alloy Type | Customized alloy combinations available |

| Standards | GB/GBT, ASME B265, ASTM B348, JIS H4600 |

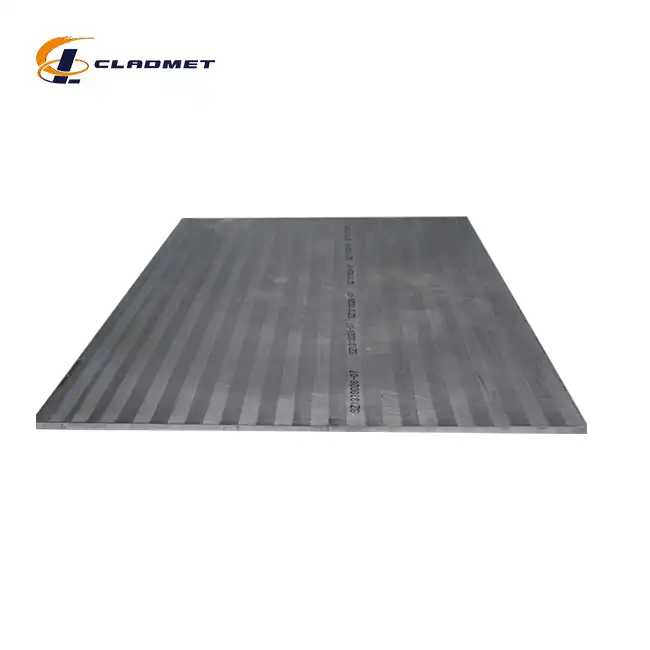

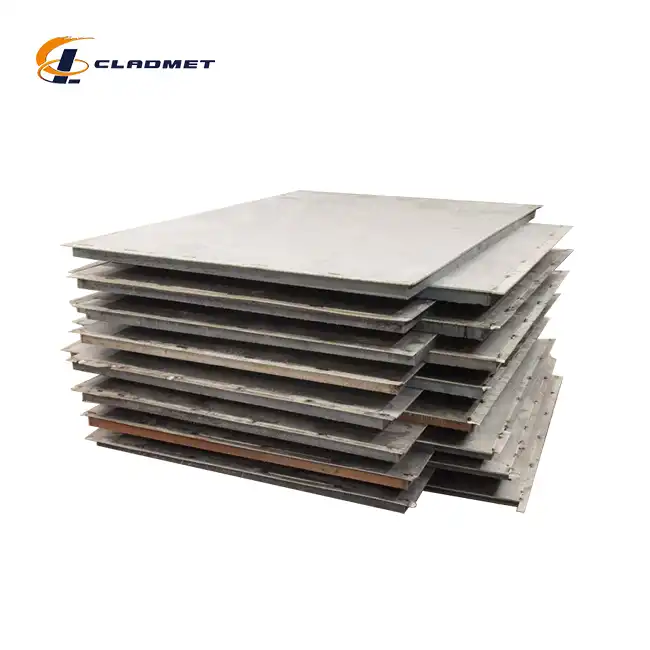

| Production Process | Explosive Bonding + Hot Rolling or Hot Extrusion |

| Diameter | 8mm to 150mm |

| Length | Up to 6000mm or customized |

| Thickness Ratio | Custom titanium, copper, and steel layer ratios |

| Surface Finish | Polished / Pickled / Machined |

| Applications | Electrochemical, Chlor-Alkali, PCB Equipment, Plating Lines |

| Packaging | Seaworthy wooden crates, foam protection, plastic wrapping |

| Transportation | Air/Sea freight or express, based on customer preference |

| Delivery Cycle | 15–30 working days depending on order volume |

PREMIUM COMPOSITE RODS

Baoji JL Clad Metals Materials Co., Ltd. specializes in advanced metal composites, offering high-performance Titanium/Copper/Steel Composite Rods engineered for demanding industrial applications. Our composite rods combine the strength of steel, conductivity of copper, and corrosion resistance of titanium in a single optimized solution.

With over 35 years of experience in clad metal technology, we've perfected the explosive welding and rolling bonding processes to create seamless, high-integrity composite rods that outperform conventional materials in chemical processing, marine engineering, and power generation applications.

Years Experience

Technical Staff

Annual Production

Square Meters

Product Advantages

Superior Corrosion Resistance

Titanium outer layer provides exceptional resistance to acids, chlorides and seawater corrosion, extending service life 3-5x longer than standard materials.

Excellent Conductivity

Copper intermediate layer ensures optimal electrical and thermal conductivity while maintaining structural integrity.

High Strength Core

Steel core provides the structural strength needed for load-bearing applications while reducing overall material costs.

Cost-Effective Solution

Strategic material combination delivers premium performance at 40-60% lower cost than solid titanium alternatives.

Technical Specifications

Material Composition

- Outer Layer: Grade 1/2/5 Titanium (0.5-5mm thickness options)

- Intermediate Layer: C11000 Copper (1-3mm thickness)

- Core Material: Carbon Steel or Stainless Steel (Custom diameters 5-200mm)

- Bond Strength: ≥210MPa (Explosive welded interface)

01

Physical Properties

- Density: 6.8-7.8 g/cm³ (varies by configuration)

- Thermal Conductivity: 45-65 W/m·K

- Electrical Resistivity: 0.08-0.12 μΩ·m

- Operating Temperature: -196°C to 450°C

02

Mechanical Properties

- Tensile Strength: 380-650 MPa

- Yield Strength: 250-550 MPa

- Elongation: 15-25%

- Hardness: 150-220 HB

03

Standard Compliance

- ASTM B265 (Titanium Standards)

- ASTM B152 (Copper Standards)

- ASTM A36/A240 (Steel Standards)

- ISO 9001:2015 Certified Manufacturing

- PED & ABS Certified (2024)

04

Industry Applications

Chemical Processing

Anodes, heat exchangers, reactor components in acid production

Marine Engineering

Shipbuilding components, offshore platform fixtures

Power Generation

Condenser tubes, grounding rods, busbar components

Oil & Gas

Downhole tools, piping systems, valves

Advanced Manufacturing Process

Our Titanium/Copper/Steel Composite Rods are produced using proprietary explosive welding technology developed through our 35+ years of experience. The process begins with precision surface preparation of all metal layers, followed by controlled explosive bonding that creates a permanent metallurgical bond without compromising the base materials' properties. Post-welding, the composites undergo hot rolling, heat treatment, and precision machining to achieve final dimensions with tight tolerances (±0.05mm).

Quality Assurance Protocol

Every composite rod undergoes rigorous testing including ultrasonic examination (100% coverage), tensile shear testing, metallographic analysis, and corrosion testing per ASTM standards. Our quality management system is certified to ISO 9001:2015, with additional certifications for pressure equipment (PED) and marine applications (ABS). Batch traceability is maintained throughout production, with full material certifications available for all orders.

Obtained ABS marine certification and PED pressure equipment certification, expanding our composite materials into European and North American markets.

Developed next-generation explosive welding technology for improved bond strength in titanium-copper-steel composites, achieving 230MPa interface strength.

Expanded production facility to 45,500 square meters with dedicated composite rod manufacturing lines, increasing annual capacity to 2,000+ metric tons.

Launched corrosion-resistant composite rod series for chemical processing industry, reducing client maintenance costs by 40% compared to traditional materials.

Established joint R&D center with Northwest Nonferrous Metals Research Institute to advance clad metal technologies.

Received ISO 9001:2015 certification for quality management system, becoming first clad metal manufacturer in region to achieve this standard.

OEM Service

At JL CLAD METALS, we provide full OEM/ODM services tailored to your specifications:

-

Customized dimensions, alloy combinations, and surface finishes

-

Private labeling and packaging

-

Professional design and material consulting

-

Sample prototyping and fast lead times

We support partners in innovation, customization, and rapid market response.

FAQs

Q1: Can I get a sample for testing before bulk order?

Yes, samples are available upon request. Please contact our sales team for details.

Q2: What is the bonding strength of the composite rod?

Our rods exceed standard shear strength benchmarks as defined in GB/ASTM standards, ensuring stable bonding through explosion welding and post-treatment.

Q3: Are your products certified internationally?

Yes, our factory is certified by ISO9001, and our products are PED and ABS approved.

Q4: Can I customize the rod’s diameter and length?

Absolutely. Custom sizes and compositions are available based on your technical drawings or requirements.

Q5: How do you ensure product quality?

We employ a complete in-house inspection system covering chemical analysis, tensile testing, ultrasonic testing, and visual inspections to ensure every product meets specification.

Contact Us

BAOJI JL CLAD METALS MATERIALS CO., LTD

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

Tel: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

_1737007724117.webp)

_1745547127259.webp)

_1745544225862.webp)

_1737612205322.webp)