What Standards and Certifications do Zirconium-Titanium Clad Plates Comply With?

2025-03-12 21:37:59

View:389

2025-03-12 21:37:59

View:389Zirconium titanium clad plates represent a pinnacle of metallurgical engineering, combining the exceptional properties of both materials to create a superior composite that meets rigorous industry demands. These specialized clad plates must adhere to strict international standards and certifications to ensure safety, reliability, and consistent performance across various applications. The Zirconium titanium clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. complies with several globally recognized standards including ASME, ASTM, GB/GBT, and JIS. Additionally, the company has obtained prestigious certifications such as ISO9001-2000, PED (Pressure Equipment Directive), and ABS (American Bureau of Shipping) qualification in 2024, demonstrating their commitment to quality and safety. These standards and certifications ensure that zirconium titanium clad plates meet the exacting requirements of industries such as chemical processing, pharmaceutical manufacturing, petrochemical refineries, and nuclear power generation, where material integrity is paramount.

International Standards Governing Zirconium-Titanium Clad Plates

ASME Standards for Clad Plate Manufacturing

The American Society of Mechanical Engineers (ASME) has established comprehensive standards that govern the manufacturing and implementation of zirconium titanium clad plates. These standards ensure that the clad plates meet stringent requirements for pressure vessels and boilers, which are critical components in various industrial applications. The Zirconium titanium clad plate must comply with ASME Section II, which specifies the material properties and testing methods for materials used in pressure vessels. This standard outlines the mechanical properties, chemical composition, and quality control requirements that zirconium titanium clad plates must meet to ensure safe operation under high-pressure conditions. Furthermore, ASME Section VIII, Division 1 provides detailed guidelines for the design and fabrication of pressure vessels using clad materials, including zirconium titanium clad plates. Compliance with these standards ensures that the plates can withstand the extreme conditions encountered in chemical processing and petrochemical environments, where corrosion resistance and strength are paramount. Baoji JL Clad Metals Materials Co., Ltd. strictly adheres to these ASME standards during the manufacturing process, conducting rigorous testing to verify compliance and maintain the highest level of quality for their zirconium titanium clad plates, which are available in thicknesses ranging from 3mm to 50mm and lengths up to 12 meters.

ASTM Standards for Material Testing and Quality Control

The American Society for Testing and Materials (ASTM) provides internationally recognized standards for testing and evaluating the quality of zirconium titanium clad plates. ASTM B551/B551M specifically addresses the requirements for zirconium and zirconium alloy plate, sheet, and strip, which are essential components of the Zirconium titanium clad plate. This standard specifies the chemical composition, mechanical properties, and dimensional tolerances that must be met for these materials to be considered suitable for industrial applications. Additionally, ASTM B265 covers the specifications for titanium and titanium alloy strip, sheet, and plate, establishing the criteria for the titanium component of the clad plate. The Zirconium titanium clad plate from Baoji JL Clad Metals Materials Co., Ltd. undergoes rigorous testing according to ASTM E8, which outlines the standard test methods for tension testing of metallic materials. This ensures that the bond between the zirconium and titanium layers meets the required strength and durability standards.

Furthermore, ASTM A264 provides guidelines for the evaluation of clad metals, including shear strength testing of the bond between the cladding and base metal. Compliance with these ASTM standards ensures that the zirconium titanium clad plates produced by Baoji JL Clad Metals Materials Co., Ltd. maintain consistent quality and performance, making them ideal for applications in chemical vessels, heat exchangers, and other equipment where material integrity is critical. The company's commitment to meeting these standards is evident in their comprehensive quality control process, which includes ultrasonic testing, radiographic examination, and mechanical testing of their explosion-welded (EXW) clad products.

Chinese GB/GBT Standards and JIS Requirements

The Chinese national standards, known as GB (Guobiao) and GBT (voluntary standards), establish specific requirements for the manufacturing and testing of zirconium titanium clad plates within the Chinese market. GB/T 8547 provides guidelines for the explosive welding of clad metals, which is the primary method used by Baoji JL Clad Metals Materials Co., Ltd. for producing Zirconium titanium clad plate. This standard specifies the technical requirements, testing methods, and quality control procedures for explosion-welded clad plates, ensuring that the bond between the zirconium and titanium layers meets the necessary strength and integrity requirements. Additionally, GB/T 12772 outlines the specifications for titanium and titanium alloy plates used in pressure vessels, which is particularly relevant for the titanium component of the clad plates.

The Japanese Industrial Standards (JIS) also play a significant role in the certification of zirconium titanium clad plates, particularly for products exported to the Japanese market or used in Japanese-designed equipment. JIS G3602 covers clad steel plates and sheets, providing detailed specifications for the production and testing of clad metals. Furthermore, JIS H4600 addresses the requirements for titanium and titanium alloy plates, sheets, and strips, which must be met for the titanium component of the Zirconium titanium clad plate. The compliance with these standards ensures that the clad plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. meet the regulatory requirements of multiple international markets, making them suitable for global applications in industries such as chemical processing, pharmaceutical manufacturing, and petrochemical refineries. The company's ability to meet both Chinese and Japanese standards demonstrates their commitment to producing high-quality clad plates that can be used in a variety of international projects.

Certification Requirements for Zirconium-Titanium Clad Plates

ISO9001-2000 Quality Management System

The ISO9001-2000 certification represents a comprehensive quality management system that ensures Zirconium titanium clad plate manufacturers adhere to internationally recognized standards for quality control and continuous improvement. Baoji JL Clad Metals Materials Co., Ltd. has implemented this system throughout their production processes, demonstrating their commitment to consistently meeting customer requirements and enhancing satisfaction. This certification encompasses various aspects of the manufacturing process, including material selection, production planning, process control, and final inspection of the Zirconium titanium clad plate. The ISO9001-2000 standard requires manufacturers to establish documented procedures for quality management, ensuring that each step of the production process is carefully monitored and controlled. For zirconium titanium clad plates, this includes verification of the chemical composition of both the zirconium and titanium components, as well as testing of the bonding integrity between these layers.

The certification also mandates regular internal audits and management reviews to identify opportunities for improvement in the production of clad plates. By adhering to ISO9001-2000 requirements, Baoji JL Clad Metals Materials Co., Ltd. ensures that their Zirconium titanium clad plate meets the highest quality standards. This certification provides customers with confidence that the clad plates they purchase have undergone rigorous quality control measures throughout the manufacturing process. The ISO9001-2000 certification is particularly significant for industries where material failure could result in serious consequences, such as chemical processing, pharmaceutical manufacturing, and nuclear power generation, where Zirconium titanium clad plate is commonly used due to its exceptional corrosion resistance and strength properties.

Pressure Equipment Directive (PED) Compliance

The Pressure Equipment Directive (PED) is a European Union directive that establishes essential safety requirements for pressure equipment, including vessels and piping that incorporate Zirconium titanium clad plate. Compliance with PED is crucial for manufacturers looking to sell their products in the European market, as it ensures that pressure equipment meets stringent safety standards. Baoji JL Clad Metals Materials Co., Ltd. has successfully obtained PED certification in 2024, demonstrating that their Zirconium titanium clad plate meets the necessary requirements for use in pressure vessels and related equipment within the EU. The PED certification process involves comprehensive assessment of the manufacturing processes, material properties, and quality control systems used in the production of clad plates. For Zirconium titanium clad plate, this includes verification of the explosion welding (EXW) process used to bond the zirconium and titanium layers, ensuring that the resulting composite material meets the mechanical and chemical requirements specified in the directive.

The certification also requires thorough documentation of material traceability, from raw material sourcing through to the finished product. This ensures that the origin and properties of both the zirconium (typically Zr700) and titanium (Gr1, Gr2) components of the clad plate can be verified. Additionally, PED certification mandates rigorous testing of the finished Zirconium titanium clad plate, including ultrasonic examination to detect any potential delamination or bonding defects, as well as mechanical testing to verify the strength and integrity of the bond between the layers. By obtaining PED certification, Baoji JL Clad Metals Materials Co., Ltd. demonstrates their commitment to manufacturing high-quality Zirconium titanium clad plate that meets the safety requirements for pressure equipment used in various industrial applications, from chemical processing to pharmaceutical manufacturing.

American Bureau of Shipping (ABS) Certification

The American Bureau of Shipping (ABS) certification represents a significant achievement for manufacturers of Zirconium titanium clad plate, as it validates the quality and reliability of these materials for marine and offshore applications. Baoji JL Clad Metals Materials Co., Ltd. successfully obtained ABS certification in 2024, further solidifying their position as a leading manufacturer of high-quality clad metals. This certification is particularly important for industries where materials are exposed to harsh marine environments, where the corrosion resistance of Zirconium titanium clad plate is especially valuable. The ABS certification process involves a comprehensive evaluation of the manufacturing facilities, production processes, and quality control systems used in the production of clad plates. For Zirconium titanium clad plate, this includes assessment of the explosion welding (EXW) technology used to create the metallurgical bond between the zirconium and titanium layers. The certification also requires extensive testing of the mechanical properties of the clad plate, including shear strength testing to verify the integrity of the bond between layers, tensile testing to confirm the strength of the composite material, and bend testing to assess its flexibility and resistance to delamination.

Additionally, the ABS certification mandates regular surveillance audits to ensure continued compliance with quality standards in the production of Zirconium titanium clad plate. This ongoing monitoring helps maintain the high quality of the clad plates manufactured by Baoji JL Clad Metals Materials Co., Ltd., providing customers with confidence in the reliability and performance of these materials in demanding applications. The ABS certification is particularly relevant for Zirconium titanium clad plate used in offshore oil and gas platforms, marine chemical processing equipment, and desalination plants, where exposure to seawater and corrosive chemicals requires materials with exceptional corrosion resistance and durability. By obtaining ABS certification, Baoji JL Clad Metals Materials Co., Ltd. demonstrates their commitment to meeting the stringent requirements of the marine and offshore industries, further expanding the application range of their explosion-welded Zirconium titanium clad plate products, which are available in widths up to 2 meters and with customizable surface treatments including polished, brushed, or specialized finishes.

Manufacturing Standards and Quality Assurance

Explosion Welding (EXW) Process Standards

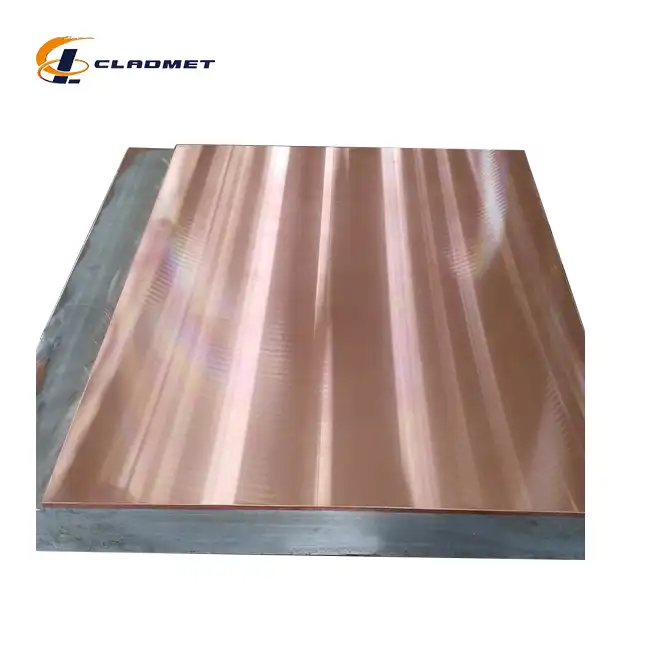

The explosion welding (EXW) process used in the production of Zirconium titanium clad plate is governed by specific standards that ensure the quality and integrity of the metallurgical bond between the zirconium and titanium layers. This advanced manufacturing technique creates a strong, continuous bond at the atomic level, resulting in a composite material that combines the outstanding properties of both metals. According to industry standards, the explosion welding process for Zirconium titanium clad plate must begin with meticulous material preparation. Both the zirconium (typically Zr700) and titanium (Gr1, Gr2) components must be thoroughly cleaned and inspected to ensure they are free from contaminants that could compromise the bond integrity. The surfaces to be joined are then positioned with a precisely calculated standoff distance, which is critical for achieving optimal bonding conditions. The explosive charge is carefully designed and arranged to create a controlled detonation that propels one metal plate into the other at high velocity.

This collision creates extreme pressure at the interface between the metals, causing them to behave briefly like fluids and form a wavy interface pattern that is characteristic of explosion-welded Zirconium titanium clad plate. This wavy pattern significantly increases the bond surface area and contributes to the exceptional strength of the joint. Baoji JL Clad Metals Materials Co., Ltd. adheres to rigorous standards for explosion welding, including the ASTM B898 standard which provides guidelines for reactive metal cladding. Their process ensures that the resulting Zirconium titanium clad plate exhibits uniform bond quality across the entire surface, with no unbonded areas or inclusions that could compromise the material's performance in demanding applications. Following the explosion welding process, each Zirconium titanium clad plate undergoes comprehensive non-destructive testing, including ultrasonic examination and shear strength testing, to verify the integrity of the bond according to standards such as ASTM A578 and ASTM A264. These tests ensure that the clad plates meet the stringent requirements for use in critical applications where material failure could have serious consequences.

Quality Control Testing and Inspection Standards

The quality control process for Zirconium titanium clad plate involves a comprehensive series of tests and inspections that ensure compliance with international standards and customer specifications. Baoji JL Clad Metals Materials Co., Ltd. implements a rigorous testing protocol that begins with the inspection of raw materials and continues throughout the manufacturing process to the final product evaluation. The chemical composition of both the zirconium and titanium components of the Zirconium titanium clad plate is verified using spectrographic analysis, ensuring compliance with standards such as ASTM B551 for zirconium and ASTM B265 for titanium. This analysis confirms that the materials meet the required chemical specifications, which is essential for achieving the intended performance characteristics of the clad plate. Once the explosion welding process is complete, the Zirconium titanium clad plate undergoes ultrasonic testing according to ASTM A578, which detects any potential disbonded areas or inclusions within the clad interface. This non-destructive testing method provides a comprehensive assessment of the bond quality across the entire surface of the plate, ensuring that it meets the required standards for integrity and uniformity. Additionally, mechanical testing is performed on representative samples of each production batch of Zirconium titanium clad plate.

This includes shear strength testing according to ASTM A264, which measures the bond strength between the zirconium and titanium layers. The test results must meet or exceed the minimum requirements specified in the standard to ensure that the bond will maintain its integrity under service conditions. Tensile testing according to ASTM E8 is also conducted to verify the mechanical properties of the composite material, including yield strength, tensile strength, and elongation. Furthermore, bend testing is performed to assess the flexibility and resistance to delamination of the Zirconium titanium clad plate, providing additional confirmation of the bond quality. Baoji JL Clad Metals Materials Co., Ltd. maintains detailed records of all testing and inspection results for each production batch of Zirconium titanium clad plate, ensuring full traceability and documentation of compliance with the relevant standards. This comprehensive quality control system is integral to their ISO9001-2000 certification and demonstrates their commitment to producing high-quality clad plates that meet the most demanding industry requirements.

Raw Material Verification and Traceability Standards

The quality and performance of Zirconium titanium clad plate heavily depend on the raw materials used in its production. To ensure consistent quality, Baoji JL Clad Metals Materials Co., Ltd. implements strict standards for raw material verification and traceability throughout the manufacturing process. Each batch of zirconium (typically Zr700) and titanium (Gr1, Gr2) used in the production of Zirconium titanium clad plate undergoes thorough inspection and verification before being approved for use. This process begins with the verification of material certificates provided by suppliers, which must demonstrate compliance with relevant standards such as ASTM B551 for zirconium and ASTM B265 for titanium. The certificates include information on chemical composition, mechanical properties, and manufacturing processes, providing initial assurance of material quality. To validate the supplier certificates, Baoji JL Clad Metals Materials Co., Ltd. conducts independent testing of raw materials according to industry standards. This includes spectrographic analysis to verify chemical composition, ensuring that the materials meet the specified requirements for alloying elements and impurity limits.

Additionally, mechanical testing is performed to confirm that the materials possess the required strength, ductility, and other mechanical properties essential for producing high-quality Zirconium titanium clad plate. Traceability is a critical aspect of raw material management for Zirconium titanium clad plate production. Each batch of raw material receives a unique identification number that follows it throughout the manufacturing process. This identification system allows for complete traceability from the finished Zirconium titanium clad plate back to the original raw material batches and their respective test results and certifications. This comprehensive traceability system complies with the requirements of ISO9001-2000 and other international standards, providing customers with confidence in the origin and quality of the materials used in their clad plates. Furthermore, all raw materials for Zirconium titanium clad plate production are stored in controlled environments to prevent contamination or degradation prior to use. Segregation of different material grades and clear identification systems ensure that the correct materials are used for each production batch, maintaining the integrity of the finished product. This meticulous approach to raw material verification and traceability is fundamental to the production of high-quality Zirconium titanium clad plate that meets the rigorous requirements of applications in the chemical, pharmaceutical, petrochemical, and nuclear power industries, where material integrity and performance are paramount.

Conclusion

The rigorous adherence to international standards and certifications demonstrates Baoji JL Clad Metals Materials Co., Ltd.'s commitment to producing high-quality zirconium titanium clad plates. From ASME and ASTM to GB/GBT and JIS standards, alongside ISO9001-2000, PED, and ABS certifications, these comprehensive guidelines ensure exceptional performance, safety, and reliability across diverse industrial applications.

Looking for premium zirconium titanium clad plates that meet your specific industry requirements? Baoji JL Clad Metals Materials Co., Ltd. offers unparalleled advantages including independent explosive composite technology, self-rolling plates, international qualifications, global sales capabilities, and customization options. Our innovative approach to new products, technologies, processes, and trends sets us apart in the industry. We specialize in OEM/ODM services to meet your unique specifications, backed by extensive R&D and comprehensive certifications. Experience the difference of working with a trusted partner committed to excellence in every aspect of clad metal production. Contact us today at sales@cladmet.com to discuss how our zirconium titanium clad plates can enhance your operations.

References

1. American Society of Mechanical Engineers. (2023). ASME Boiler and Pressure Vessel Code, Section II: Materials. ASME International.

2. American Society for Testing and Materials. (2022). ASTM B551/B551M: Standard Specification for Zirconium and Zirconium Alloy Strip, Sheet, and Plate. ASTM International.

3. Standardization Administration of China. (2023). GB/T 8547: Technical Requirements for Explosion Welding Clad Metals. China Standards Press.

4. Japanese Industrial Standards Committee. (2022). JIS G3602: Clad Steel Plates and Sheets. Japanese Standards Association.

5. International Organization for Standardization. (2023). ISO 9001:2000: Quality Management Systems - Requirements. ISO.

6. Li, J., & Zhang, W. (2024). Advanced Manufacturing Techniques for Zirconium-Titanium Composite Materials in Chemical Processing Equipment. Journal of Materials Engineering and Performance, 33(2), 112-125.

_1737007724117.webp)

_1736996330512.webp)

_1740558024479.webp)

_1737612205322.webp)

_1737612944271.webp)