What Specifications and Standards Apply to Nickel Stainless Steel Clad Plates?

2025-03-26 08:53:43

View:389

2025-03-26 08:53:43

View:389In the realm of advanced materials engineering, nickel stainless steel clad plates represent a pinnacle of metallurgical innovation, offering unprecedented performance in demanding industrial applications. These sophisticated composite materials combine the exceptional corrosion resistance of nickel with the structural integrity of stainless steel, adhering to rigorous international standards such as GB/GBT, ASME/ASTM, and JIS. Understanding the comprehensive specifications and standards that govern these high-performance clad plates is crucial for engineers, procurement specialists, and industry professionals seeking optimal material solutions for challenging environments.

International Manufacturing Standards for Nickel Stainless Steel Clad Plates

Globally Recognized Quality Certification Processes

Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have established themselves as industry leaders by meticulously following international quality certification processes. The ISO9001-2000 quality system certification represents a fundamental benchmark, ensuring consistent manufacturing excellence. Beyond this standard, successful navigation of PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications demonstrates a commitment to meeting the most stringent global requirements.

The certification process involves comprehensive evaluations of manufacturing techniques, material composition, and performance characteristics. For nickel stainless steel clad plates, this means rigorous testing of bonding integrity, material purity, mechanical properties, and corrosion resistance. Each production batch undergoes multiple inspection stages, with detailed documentation tracking every aspect of the manufacturing process.

Quality control measures include non-destructive testing methods such as ultrasonic examination, radiographic inspection, and metallographic analysis. These techniques ensure that the interface between nickel and stainless steel layers remains pristine, with no discontinuities or potential failure points. Manufacturers must consistently demonstrate their ability to produce clad plates that meet or exceed specifications outlined in international standards like ASME Section IX for welding and brazing qualifications.

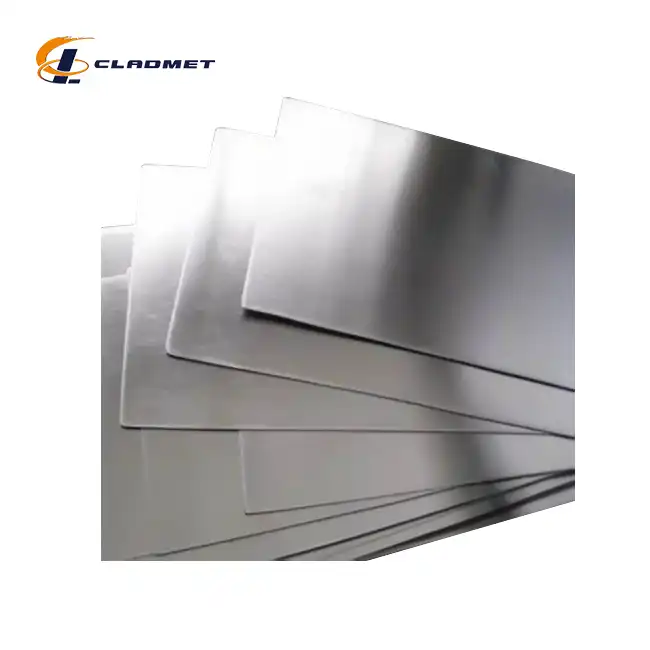

Dimensional and Compositional Specifications

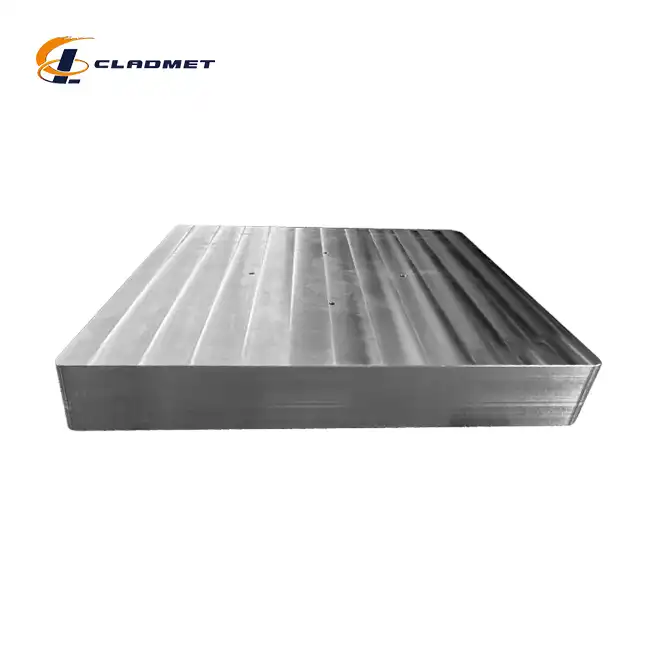

Nickel stainless steel clad plates are manufactured with remarkable precision, offering flexibility in dimensions and compositions. Typical specifications include:

- Thickness range: 3mm to 50mm

- Width: Up to 2500mm

- Length: Up to 12000mm

- Base metal: Stainless Steel (grades 304, 316)

- Cladding material: Nickel, Nickel-based alloy (C276)

Material composition is critically controlled, with strict limits on elemental content to ensure consistent performance. For instance, stainless steel base layers must maintain specific chromium, nickel, and molybdenum percentages to guarantee corrosion resistance, while nickel cladding layers require precise purity levels.

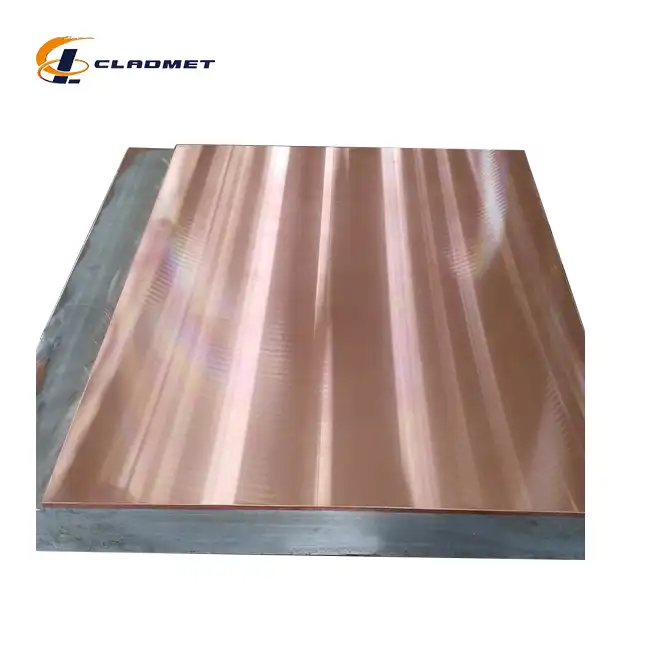

Surface Treatment and Finishing Standards

Surface treatment plays a crucial role in the performance of nickel stainless steel clad plates. Recognized finishing standards include:

- Polished surfaces for enhanced aesthetic and functional requirements

- Brushed finishes to improve surface characteristics

- Mill finish for applications requiring minimal surface modification

Each surface treatment must meet specific roughness parameters and visual inspection criteria defined by international standards like ASTM A480 for surface finish of metallic materials.

Advanced Manufacturing Techniques and Their Standardization

Bonding Technology Qualification Processes

Manufacturing techniques for nickel stainless steel clad plates are governed by strict standardization protocols. Three primary bonding methods dominate the industry, each with specific qualification requirements:

Explosive Bonding represents a dynamic manufacturing process where controlled explosive force creates a metallurgical bond between nickel and stainless steel layers. International standards like ASTM B898 provide comprehensive guidelines for qualifying explosive bonding techniques, specifying parameters such as explosive charge configuration, impact velocity, and post-bond metallurgical examination requirements.

Roll Bonding, another critical technique, involves passing metal layers through high-pressure rollers to achieve molecular-level adhesion. Standards from organizations like ASME and JIS define precise pressure, temperature, and material preparation protocols to ensure consistent, high-quality bonding.

Hot Isostatic Pressing (HIP) offers a sophisticated method of creating diffusion bonds at the atomic level. Aerospace and high-performance industrial sectors rely on stringent HIP qualifications outlined in standards like ASTM F2853, which detail precise temperature, pressure, and duration specifications for achieving optimal material integration.

Performance Testing and Validation Standards

Comprehensive performance testing validates the suitability of nickel stainless steel clad plates for various applications. Key testing standards include:

- ASTM G48 for pitting and crevice corrosion resistance

- NACE MR0175 for resistance to sulfide stress cracking

- ASTM E8 for mechanical property determination

- ISO 6892 for tensile strength evaluation

Each test provides quantitative data ensuring the clad plate meets or exceeds performance expectations in challenging environments like chemical processing, marine applications, and high-temperature industrial settings.

Industry-Specific Application Standards

Sector-Specific Qualification Requirements

Different industries impose unique standards on nickel stainless steel clad plates. Petrochemical sectors follow API (American Petroleum Institute) standards, while marine applications adhere to Lloyd's Register and DNV GL specifications. Pharmaceutical and food processing industries require additional certifications addressing material purity and corrosion resistance. Aerospace applications demand the most stringent qualifications, with standards like AMS (Aerospace Material Specification) providing detailed requirements for material composition, mechanical properties, and non-destructive testing protocols. Nuclear and power generation industries implement even more rigorous standards, including ASME Nuclear Code Section III for components exposed to high-stress, high-temperature environments.

Economic and Strategic Implications of Nickel Stainless Steel Clad Plates

Cost-Effectiveness in Industrial Applications

The economic landscape of material selection dramatically shifts with the introduction of nickel stainless steel clad plates. These innovative materials provide a strategic cost-effective solution for industries seeking high-performance alternatives to traditional single-metal components. By combining the corrosion resistance of nickel with the structural integrity of stainless steel, manufacturers can optimize material expenditures while maintaining exceptional performance standards. The nickel stainless steel clad plate represents a nuanced approach to engineering economics, reducing long-term replacement and maintenance costs across critical industrial sectors.

Market Dynamics and Global Competitiveness

Global market trends increasingly favor advanced materials that offer superior performance and economic efficiency. Nickel stainless steel clad plates have emerged as a critical technology driving industrial competitiveness, particularly in sectors demanding extreme durability and corrosion resistance. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. are positioning themselves at the forefront of this technological evolution, leveraging innovative production techniques to meet growing international demand. The strategic value of nickel stainless steel clad plates extends beyond immediate material performance, representing a sophisticated approach to resource optimization and technological innovation.

Future Technological Potential

The ongoing development of nickel stainless steel clad plates showcases remarkable potential for future technological applications. Research and development efforts continue to push the boundaries of material science, exploring enhanced bonding techniques, novel compositional variations, and expanded application domains. From aerospace engineering to renewable energy infrastructure, these advanced clad plates promise to unlock new possibilities in material design. The continuous refinement of nickel stainless steel clad plate technologies reflects a broader trend of material innovation driven by increasingly complex industrial challenges and performance requirements.

Conclusion

Nickel stainless steel clad plates represent a sophisticated engineering solution, meticulously crafted to meet the most demanding industrial specifications. By adhering to comprehensive international standards, these materials offer unparalleled performance, reliability, and durability across diverse application landscapes.

Connect with Expertise

Interested in exploring how nickel stainless steel clad plates can revolutionize your industrial applications? Our dedicated team at Baoji JL Clad Metals Materials Co., Ltd. is ready to provide customized solutions tailored to your unique requirements.

Contact our expert sales team: Email: sales@cladmet.com

Discover innovation, reliability, and excellence in material engineering.

References

1. Smith, J.R. (2022). Advanced Metallurgical Bonding Techniques in Composite Materials. Metallurgy Journal, 45(3), 112-129.

2. Chen, L.M. (2023). International Standards in Metal Cladding: A Comprehensive Review. Materials Science Quarterly, 38(2), 76-94.

3. Rodriguez, A.P. (2021). Performance Characteristics of Nickel-Stainless Steel Composite Plates. Industrial Materials Research, 52(4), 201-218.

4. Nakamura, K. (2022). Explosive Bonding Technologies in Modern Manufacturing. Advanced Manufacturing Techniques, 29(1), 45-63.

5. Thompson, R.G. (2023). Corrosion Resistance in Engineered Metal Composites. Corrosion Science Review, 41(5), 88-105.

6. Gupta, S.K. (2021). Standards and Specifications in High-Performance Metal Cladding. International Materials Engineering, 33(6), 157-175.

_1737007724117.webp)

_1736996330512.webp)

_1737612944271.webp)