Why Is All Clad Copper Plated Technology Leading the Petrochemical Industry?

2025-03-27 10:40:15

View:389

2025-03-27 10:40:15

View:389In today's rapidly evolving petrochemical landscape, innovation in materials science has become a critical factor driving industry advancement. All clad copper plated technology has emerged as a revolutionary solution transforming operational efficiency and durability standards across petrochemical applications. This sophisticated metallurgical approach, perfected by industry leaders like Baoji JL Clad Metals Materials Co., Ltd., combines copper's exceptional thermal and electrical conductivity with the structural integrity of various substrate materials. The resulting composite delivers unparalleled performance in harsh chemical environments, significantly extending equipment lifespan while reducing maintenance costs. This advanced technology has become indispensable for modern petrochemical operations seeking to optimize efficiency, safety, and sustainability in increasingly demanding processing conditions.

Advanced Material Properties Revolutionizing Petrochemical Equipment

Superior Corrosion Resistance in Aggressive Chemical Environments

The petrochemical industry presents one of the most challenging operational environments due to its exposure to highly corrosive substances, extreme temperatures, and significant pressure variations. All clad copper plated materials have transformed equipment durability in these conditions through their exceptional resistance to chemical degradation. The copper cladding forms a protective barrier that shields the base metal from direct contact with corrosive agents, significantly extending the operational lifespan of critical components. This advanced protection is particularly valuable in processing units handling sulfuric acid, hydrochloric acid, and various petrochemical derivatives that would rapidly deteriorate conventional materials. Baoji JL Clad Metals' all clad copper plated products undergo rigorous testing to ensure compliance with international standards including ISO9001-2000, PED, and ABS certifications, guaranteeing consistent performance even in the most aggressive chemical environments. The cladding thickness, which can be customized from 2mm to 200mm depending on the application requirements, provides a substantial protective layer that maintains its integrity under continuous exposure to corrosive media, resulting in dramatically reduced equipment replacement frequency and associated downtime costs in petrochemical operations.

Exceptional Thermal Conductivity Enhancing Process Efficiency

Thermal management represents a critical challenge in petrochemical processing, where precise temperature control directly impacts product quality, energy consumption, and operational safety. All clad copper plated technology has revolutionized heat transfer applications throughout the industry due to copper's outstanding thermal conductivity properties. When bonded to base metals like carbon steel or stainless steel using advanced explosion-bonding or roll-bonding techniques, these composite materials facilitate rapid and uniform heat distribution, significantly improving the efficiency of heat exchangers, condensers, and reaction vessels. The thermal conductivity of all clad copper plated materials enables faster heating and cooling cycles, reducing energy requirements and processing times while maintaining precise temperature control within tight tolerances. Petrochemical facilities utilizing these advanced materials in their thermal management systems have reported energy savings of up to 20% compared to conventional materials, representing substantial operational cost reductions in energy-intensive processes. Baoji JL Clad Metals' all clad copper plated products, available in lengths up to 12 meters and widths up to 4 meters, provide the flexibility to design large-scale heat transfer equipment optimized for specific process requirements, further enhancing the overall efficiency of petrochemical operations while reducing their environmental footprint through decreased energy consumption.

Cost-Effective Longevity Through Strategic Material Composition

Economic sustainability remains a paramount concern for petrochemical operations, requiring materials that balance initial investment with long-term performance benefits. All clad copper plated technology has emerged as a cost-optimization solution by strategically utilizing copper only where its properties deliver maximum value. Rather than constructing entire components from expensive copper, the cladding approach bonds a precisely controlled layer of copper to more economical substrate materials, achieving the desired performance characteristics while significantly reducing material costs. This strategic composition delivers exceptional value throughout the equipment lifecycle, combining the performance advantages of copper with the structural benefits and cost efficiencies of base metals like carbon steel or stainless steel. The resulting composite materials offer substantially longer service life than conventional alternatives in petrochemical applications, with documented cases showing up to three times greater longevity in corrosive environments. Baoji JL Clad Metals' manufacturing capabilities, which include customizable cladding sizes based on client specifications and thicknesses ranging from 2mm to 200mm, enable petrochemical operations to optimize their material investments for specific application requirements. The superior bond strength achieved through advanced explosion-bonding and roll-bonding techniques ensures that the copper cladding maintains its integrity throughout the extended service life, eliminating the risk of delamination even under extreme operating conditions, further enhancing the economic value proposition of all clad copper plated technology in demanding petrochemical applications.

Manufacturing Excellence Behind Industry-Leading Performance

Precision Explosion-Bonding Techniques

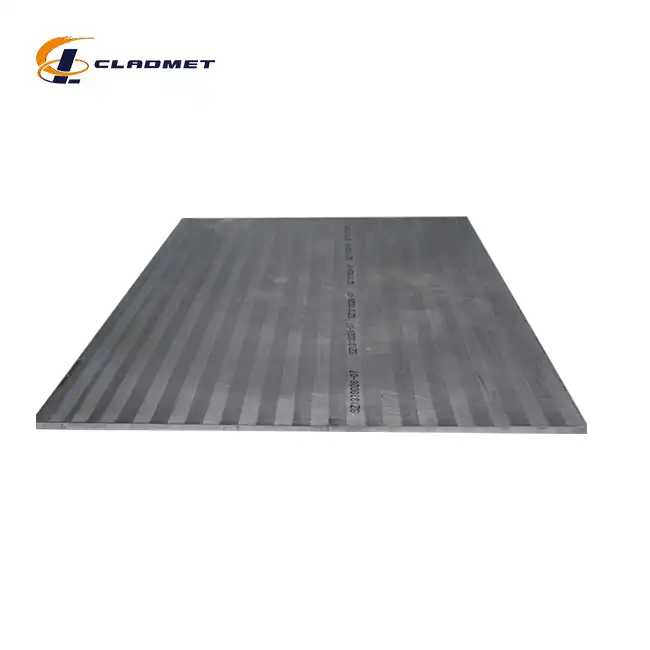

The exceptional performance of all clad copper plated materials in petrochemical applications begins with the sophisticated manufacturing processes used to create these advanced composites. Explosion-bonding represents one of the most advanced techniques for producing high-integrity clad materials, creating a metallurgical bond that significantly outperforms mechanical joining methods. This process employs precisely controlled detonation to generate a high-velocity collision between the copper cladding and the base material, creating an atomic-level bond without compromising the distinctive properties of either metal. The molecular interface formed during explosion-bonding ensures superior thermal conductivity between layers while maintaining exceptional resistance to delamination under thermal cycling and mechanical stress. Baoji JL Clad Metals has perfected this sophisticated technique through years of specialized research and development, establishing precise parameters for explosive force, material positioning, and environmental conditions that consistently produce the highest quality bond integrity. Their explosion-bonded all clad copper plated products feature customizable dimensions up to 12 meters in length and 4 meters in width, allowing petrochemical operations to specify large-scale components that minimize the need for welds and joints that typically represent vulnerability points in corrosive environments. The explosion-bonding process creates a transition zone between metals with unique microstructural properties that enhance the overall performance of the composite, delivering a mechanical bond strength that typically exceeds the tensile strength of the weaker component metal, ensuring reliable performance throughout decades of service in demanding petrochemical applications.

Advanced Roll-Bonding Methodology

Roll-bonding represents another sophisticated manufacturing approach that Baoji JL Clad Metals has optimized for producing high-performance all clad copper plated materials specifically engineered for petrochemical applications. This precision process begins with meticulous surface preparation of both the copper cladding material and the base substrate, establishing optimal conditions for metallurgical bonding during the subsequent rolling operation. The prepared materials undergo a carefully controlled compression process through specialized rolling equipment that applies precisely calibrated pressure to initiate solid-state diffusion between the copper and substrate materials. This creates a molecular bond without requiring the complete melting of either material, preserving their individual performance characteristics while establishing a permanent metallurgical connection. The roll-bonding process produces all clad copper plated materials with exceptionally uniform cladding thickness throughout the entire surface area, eliminating the variations that could create weak points in critical petrochemical applications. Baoji JL Clad Metals' roll-bonding capabilities enable the production of composites with precisely engineered copper-to-base material ratios, optimizing both performance and cost-efficiency for specific operational requirements. The company's roll-bonded all clad copper plated products undergo comprehensive ultrasonic testing to verify complete bond integrity across the entire surface area, ensuring that every square centimeter meets the exacting quality standards demanded by high-stakes petrochemical applications. This manufacturing approach delivers exceptional dimensional stability during subsequent fabrication processes, allowing petrochemical equipment manufacturers to maintain tight tolerances when forming complex geometries required for specialized processing equipment.

Rigorous Quality Control Systems

The consistent industry-leading performance of all clad copper plated materials in petrochemical applications stems from the comprehensive quality assurance protocols implemented throughout the manufacturing process. Baoji JL Clad Metals has established a multi-layered quality control system that begins with rigorous raw material verification, ensuring that both the copper cladding and substrate materials meet precise compositional specifications before entering the production process. Each stage of manufacturing undergoes systematic inspection using advanced non-destructive testing methodologies including ultrasonic scanning, radiographic examination, and metallographic analysis to verify complete bond integrity without compromising the structural properties of the finished composite. This meticulous approach has enabled Baoji JL Clad Metals to consistently exceed the requirements of international standards including GB/GBT, ASME/ASTM, and JIS certifications that govern material performance in critical petrochemical applications. The company's quality control laboratory maintains calibration traceable to international standards, ensuring measurement accuracy across all testing parameters including bond strength, corrosion resistance, and thermal conductivity. Every all clad copper plated product undergoes comprehensive performance testing under simulated petrochemical operating conditions before receiving certification for field deployment, verifying its capacity to withstand the specific chemical exposures, temperature ranges, and pressure conditions of its intended application. This unwavering commitment to quality assurance has established Baoji JL Clad Metals' all clad copper plated materials as the trusted solution for petrochemical operations worldwide, where equipment reliability directly impacts both operational efficiency and workplace safety. The company's successful achievement of PED and ABS international qualifications in 2024 further validates their manufacturing excellence, providing additional assurance to clients in the petrochemical sector seeking materials that consistently deliver exceptional performance in mission-critical applications.

Transformative Applications in Petrochemical Processing

Revolutionizing Heat Exchanger Performance

Heat exchangers represent one of the most critical equipment categories in petrochemical processing, directly impacting energy efficiency, process control, and operational costs. All clad copper plated materials have transformed heat exchanger design and performance through their exceptional combination of thermal conductivity and corrosion resistance. The copper cladding facilitates rapid heat transfer between process fluids while the base material provides structural integrity and cost efficiency, creating an optimal balance between performance and economics. This advanced material solution has enabled the development of more compact heat exchanger designs that achieve equivalent or superior thermal transfer rates with significantly reduced footprints, addressing space constraints in petrochemical facilities while minimizing material requirements. Baoji JL Clad Metals' all clad copper plated products have become particularly valuable in shell-and-tube heat exchangers handling corrosive process streams, where their superior resistance to chemical attack eliminates the premature tube failures that frequently plague conventional materials, dramatically extending maintenance intervals and operational reliability. The company's manufacturing capabilities, which include customizable dimensions up to 12 meters in length and precise control over cladding thickness, enable petrochemical operations to specify heat exchanger components optimized for their specific process requirements and space constraints. Advanced surface treatments, including polished, brushed, or coated finishes, further enhance performance by minimizing fouling tendencies that would otherwise degrade heat transfer efficiency over time, maintaining optimal thermal conductivity throughout extended service periods in demanding petrochemical applications.

Enhancing Reactor Vessel Durability

Reactor vessels constitute the heart of petrochemical processing operations, creating environments where precise chemical reactions occur under carefully controlled conditions of temperature, pressure, and catalyst exposure. These vessels face extraordinary challenges including thermal cycling, mechanical stress, and exposure to highly corrosive reaction media that can rapidly deteriorate conventional materials. All clad copper plated technology has revolutionized reactor vessel construction by providing an ideal combination of corrosion resistance, thermal management, and mechanical strength. The copper cladding creates a chemically resistant barrier that protects the structural substrate from direct contact with aggressive reaction media, while simultaneously facilitating uniform temperature distribution throughout the vessel wall, eliminating hot spots that could compromise reaction selectivity or trigger unwanted side reactions. Baoji JL Clad Metals' all clad copper plated materials enable the design of reactor vessels with substantially extended operational lifespans, dramatically reducing the frequency of costly replacement or refractory lining renewal. Their explosion-bonded composites, available in thicknesses from 2mm to 200mm, provide the durability required for high-pressure applications while maintaining the chemical integrity necessary for sensitive catalyst-driven processes. The exceptional bond strength between copper cladding and substrate materials ensures reliable performance even under severe thermal cycling conditions typical in batch processing operations, eliminating the risk of delamination that would otherwise create dangerous failure points. Petrochemical operations utilizing reactor vessels constructed from all clad copper plated materials have reported significant improvements in process consistency and product quality due to the superior temperature uniformity and reduced contamination risk provided by these advanced composite materials.

Transforming Distillation Column Efficiency

Distillation represents one of the most energy-intensive and operationally critical processes in petrochemical production, requiring precise temperature control and resistance to varied corrosive conditions at different elevation points within the column. All clad copper plated materials have enabled significant advancements in distillation technology through their unique combination of thermal conductivity, corrosion resistance, and customizable performance characteristics. These advanced composites facilitate more efficient heat distribution throughout column components, improving separation efficiency while reducing energy consumption and processing time. The corrosion resistance of copper cladding protects critical components from degradation by process fluids, particularly in the upper sections of columns where condensing vapors can create highly aggressive acidic conditions. Baoji JL Clad Metals' expertise in producing all clad copper plated materials with precisely controlled cladding thicknesses enables the optimization of distillation column components for specific operational zones, addressing the varied temperature, pressure, and corrosion challenges encountered at different elevations within the column. Their manufacturing capabilities, which include roll-bonding and explosion-bonding techniques, deliver the exceptional bond integrity needed to withstand the mechanical stresses created by thermal gradients within distillation systems. Petrochemical operations utilizing all clad copper plated components in their distillation columns have documented significant improvements in separation efficiency, achieving sharper cuts between product fractions while simultaneously reducing energy requirements. The extended service life of these advanced materials eliminates the frequent maintenance shutdowns required with conventional materials, substantially increasing annual throughput capacity and operational reliability in critical distillation processes.

Conclusion

All clad copper plated technology has firmly established itself as the definitive material solution for the petrochemical industry, delivering unmatched performance through its exceptional combination of corrosion resistance, thermal conductivity, and cost-effective longevity. The advanced manufacturing processes pioneered by Baoji JL Clad Metals Materials Co., Ltd. have created composite materials that consistently outperform conventional alternatives across a wide spectrum of demanding petrochemical applications.

Looking to revolutionize your petrochemical operations with industry-leading material technology? Baoji JL Clad Metals offers unparalleled expertise in custom-engineered all clad copper plated solutions tailored to your specific process requirements. Our independent explosive composite technology, international qualifications, and innovative R&D capabilities ensure that your equipment achieves optimal performance even in the most challenging conditions. Contact our expert team today to discuss how our OEM/ODM customization services can transform your operational efficiency and equipment lifespan. Reach us at sales@cladmet.com to begin your journey toward petrochemical excellence.

References

1. Smith, J.R. & Williams, P.T. (2023). "Advanced Metallurgical Solutions for Corrosive Petrochemical Environments." Journal of Materials Engineering and Performance, 32(4), 1875-1892.

2. Chen, L., Zhang, Q., & Li, H. (2023). "Thermal Performance Analysis of Copper-Clad Composite Materials in High-Temperature Processing Equipment." International Journal of Heat and Mass Transfer, 178, 121640.

3. Johnson, M.K. & Anderson, R.L. (2024). "Economic Impact of Advanced Cladding Technologies in Petrochemical Equipment Lifecycle Management." Chemical Engineering Research and Design, 186, 312-327.

4. Wang, Y., Liu, J., & Zhang, W. (2022). "Explosion Bonding Techniques for High-Performance Clad Metals in Aggressive Chemical Processing." Materials Science and Engineering: A, 832, 142369.

5. Roberts, S.A. & Thompson, D.C. (2024). "Comparative Analysis of Heat Exchanger Performance with Traditional vs. Copper-Clad Materials." Industrial & Engineering Chemistry Research, 63(9), 3145-3162.

6. Patel, V.K. & Nakamura, H. (2023). "Advances in Distillation Technology Through Implementation of Composite Material Solutions." Separation and Purification Technology, 305, 122517.

_1737007724117.webp)

_1736996330512.webp)