What are the advantages of using a clad head in pressure vessels?

2025-04-08 14:21:41

View:389

2025-04-08 14:21:41

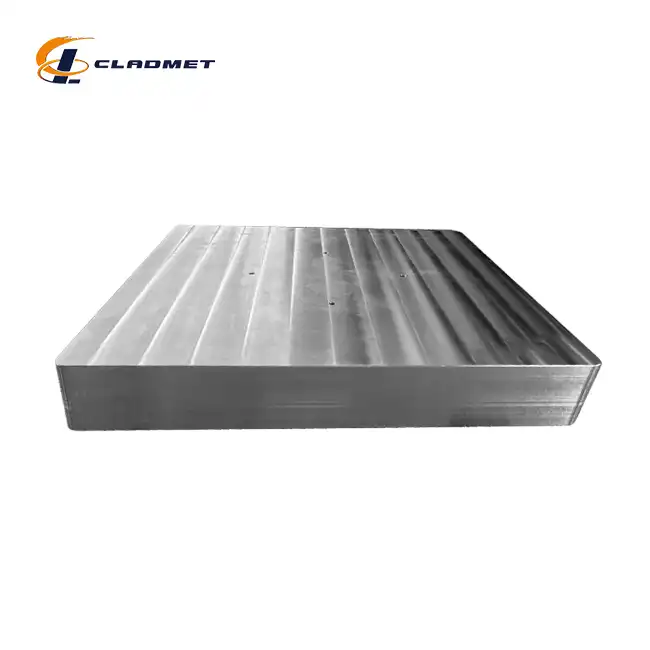

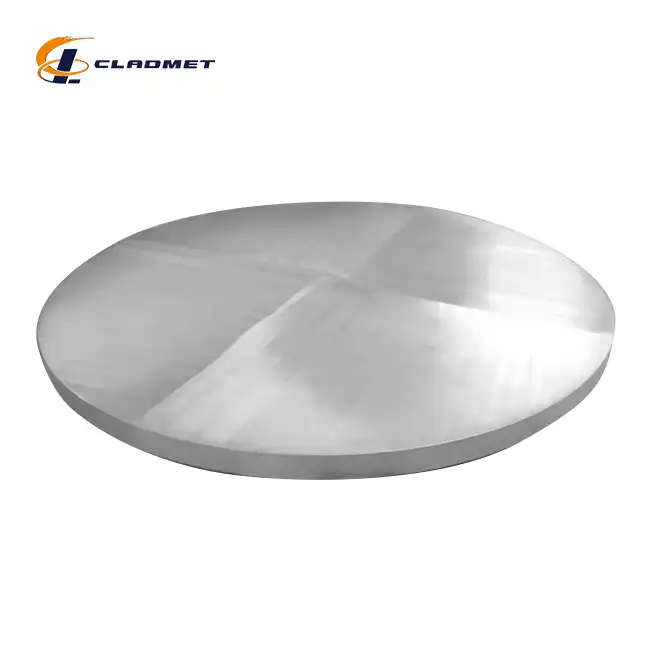

View:389In the demanding world of industrial equipment, pressure vessels stand as critical components across numerous sectors including chemical processing, oil and gas, and power generation. These vessels must withstand extreme conditions while maintaining structural integrity and operational efficiency. The 316L stainless steel-carbon steel clad head has emerged as a superior solution for pressure vessel applications, offering an optimal balance of performance and cost-effectiveness. By combining the exceptional corrosion resistance of 316L stainless steel with the mechanical strength and economic advantages of carbon steel, these clad heads provide remarkable durability in harsh environments while reducing overall equipment costs. This innovative material combination addresses the complex challenges faced in pressure vessel design, where exposure to corrosive media, high pressures, and temperature fluctuations require specialized materials that can ensure both safety and longevity.

Enhanced Performance in Harsh Environments

Superior Corrosion Resistance Properties

The 316L stainless steel-carbon steel clad head represents a breakthrough in pressure vessel technology, primarily due to its exceptional corrosion resistance capabilities. The 316L stainless steel layer, typically ranging from 2mm to 10mm in thickness, serves as the first line of defense against corrosive media. This grade of stainless steel contains molybdenum, which significantly enhances its resistance to pitting and crevice corrosion, particularly in chloride-rich environments commonly encountered in chemical processing and marine applications. When implemented in pressure vessels, the 316L stainless steel layer effectively shields the underlying carbon steel substrate from chemical attack, preventing premature deterioration of the vessel structure. This is particularly valuable in industries where vessels contain acids, alkalis, and salt solutions that would rapidly degrade traditional carbon steel equipment. According to industry testing, pressure vessels featuring 316L stainless steel-carbon steel clad heads have demonstrated up to five times longer service life in corrosive environments compared to vessels constructed from single-material alternatives. Baoji JL Clad Metals Materials Co., Ltd. ensures this superior corrosion performance through rigorous quality control measures, including 100% Ultrasonic Testing (UT) and X-ray inspection of all clad heads, guaranteeing consistent bond integrity between the stainless steel and carbon steel layers that prevents delamination even under extreme operating conditions.

Mechanical Strength and Pressure Tolerance

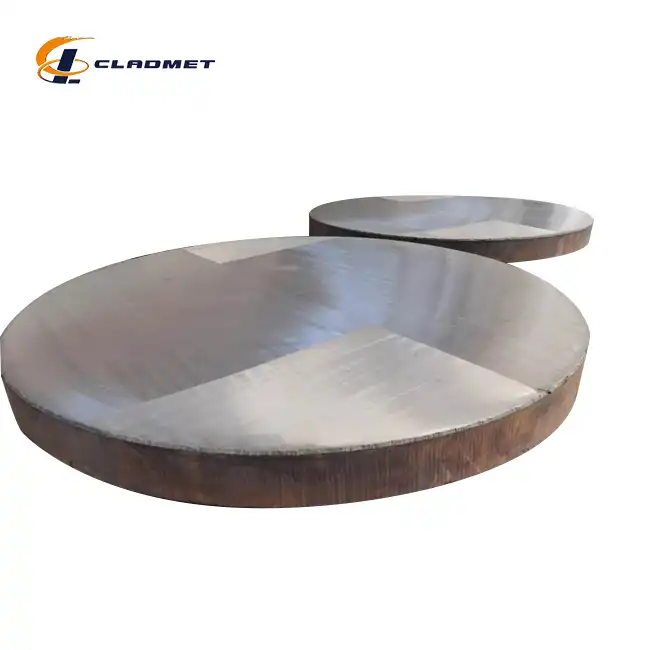

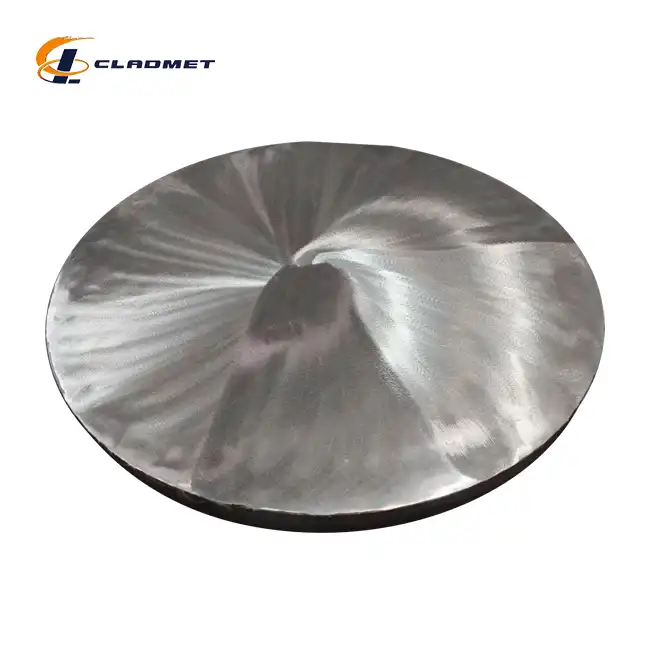

The structural integrity of pressure vessels depends significantly on the mechanical properties of the materials used in their construction. The 316L stainless steel-carbon steel clad head excels in this regard by leveraging the inherent strengths of both materials. The carbon steel foundation, which can range from 10mm to 60mm in thickness, provides exceptional tensile strength, yield strength, and overall structural support. This robust base enables the clad head to withstand internal pressures far exceeding those manageable by pure stainless steel designs of comparable thickness. The mechanical advantage becomes particularly evident in high-pressure applications where operational pressures can exceed 150 bar. Through advanced explosion welding (EXW) technology employed by Baoji JL Clad Metals Materials Co., Ltd., the bond between the stainless steel and carbon steel layers achieves near-perfect metallurgical integration, eliminating weak points that could compromise pressure resistance. This manufacturing precision ensures that the 316L stainless steel-carbon steel clad head maintains its structural integrity even during pressure fluctuations and cyclical loading common in industrial operations. The combination of materials also provides superior resistance to mechanical fatigue, extending the operational lifespan of pressure vessels in demanding applications such as oil refineries and chemical processing plants, where continuous operation under high pressure is expected for decades rather than years.

Thermal Performance in Extreme Conditions

Temperature management represents a critical consideration in pressure vessel design, particularly in applications involving heat exchangers or reactors where thermal cycling is common. The 316L stainless steel-carbon steel clad head offers exceptional thermal performance attributes that make it ideal for such demanding environments. The 316L stainless steel component maintains its corrosion resistance and mechanical properties across a wide temperature range, from cryogenic conditions up to 800°C, while the carbon steel substrate provides excellent heat transfer characteristics and thermal stability. This combination creates a thermally resilient pressure vessel component that can withstand rapid temperature fluctuations without developing stress fractures or thermal fatigue. In high-temperature applications, such as steam generators or chemical reactors, the 316L stainless steel-carbon steel clad head demonstrates minimal thermal expansion mismatch between the layers due to the carefully engineered bonding process employed by Baoji JL Clad Metals Materials Co., Ltd. Their explosion welding technique creates a transition zone between the two materials that accommodates differential expansion rates, preventing delamination even during severe thermal cycling. Furthermore, the thermal conductivity profile of these composite heads can be customized through variations in layer thickness to optimize heat transfer characteristics for specific applications, making them suitable for both insulating and heat-exchanging functions within pressure vessel systems operating in extreme temperature environments where material stability is paramount to operational safety and efficiency.

Cost-Effectiveness and Economic Benefits

Initial Investment vs. Long-Term Value

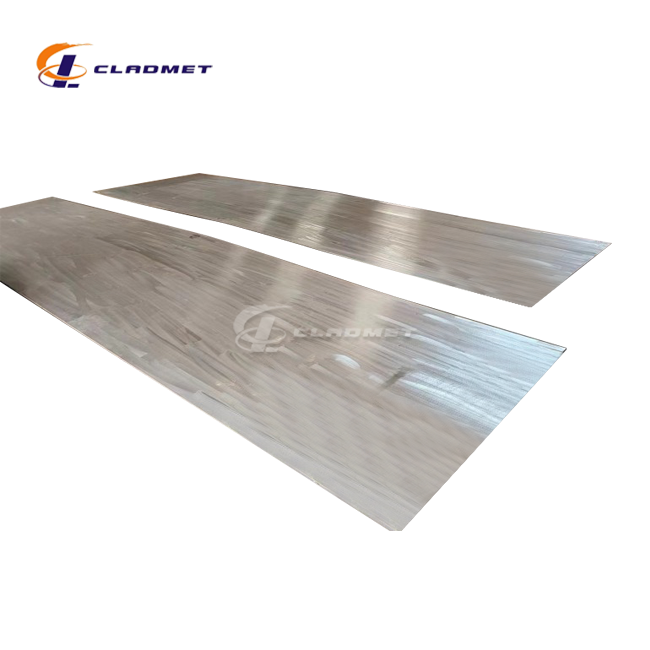

The implementation of 316L stainless steel-carbon steel clad heads in pressure vessels represents a strategic financial decision that balances initial costs against long-term economic benefits. While the upfront investment for clad heads exceeds that of single-material alternatives, comprehensive cost-benefit analyses consistently demonstrate superior lifetime value. The economic advantage stems primarily from the intelligent material allocation: expensive 316L stainless steel is utilized only where needed (the corrosion-resistant inner layer), while more economical carbon steel forms the structural bulk of the component. This design philosophy can reduce material costs by up to 40% compared to solid stainless steel construction without compromising performance. Baoji JL Clad Metals Materials Co., Ltd. manufactures these clad heads using advanced explosion welding technology that ensures optimal material utilization while maintaining precise control over layer thicknesses ranging from 2-10mm for the stainless steel component and 10-60mm for the carbon steel foundation. The company's efficient manufacturing processes, combined with their ability to produce customized dimensions up to 2000mm in diameter, enable clients to specify exactly the material properties needed for their application without unnecessary expenditure on excess corrosion resistance or mechanical strength. Furthermore, the 3-6 month delivery cycle, though longer than some alternatives, corresponds with typical project planning timeframes for major industrial equipment installations, allowing for seamless integration into construction schedules without costly expediting charges or project delays that would undermine the economic benefits of choosing this superior technology for pressure vessel applications.

Maintenance Reduction and Operational Savings

One of the most significant economic advantages of implementing 316L stainless steel-carbon steel clad heads in pressure vessels lies in the dramatic reduction of maintenance requirements throughout the equipment lifecycle. Traditional carbon steel pressure vessels operating in corrosive environments typically require frequent inspection, surface treatment renewal, and eventual replacement of corroded components—all of which incur substantial direct costs and production downtime. By contrast, pressure vessels featuring 316L stainless steel-carbon steel clad heads demonstrate remarkably extended maintenance intervals, with some installations operating for over 15 years without requiring major intervention. This maintenance reduction translates directly to operational savings through decreased labor costs, reduced replacement part inventories, and minimized production interruptions. The exceptional durability of these clad heads is achieved through Baoji JL Clad Metals Materials Co., Ltd.'s rigorous manufacturing standards, including comprehensive ultrasonic testing and X-ray inspection that ensures perfect bonding between layers. Their surface treatment options, including specialized pickling and polishing processes, further enhance the corrosion resistance of the 316L stainless steel surface, extending the effective service life in even the most aggressive chemical environments. The operational savings extend beyond direct maintenance costs to include reduced insurance premiums due to decreased equipment failure risks, lower environmental compliance costs from eliminated leakage incidents, and optimized energy efficiency from maintained heat transfer properties throughout the equipment's service life—all contributing to a compelling total cost of ownership advantage for pressure vessels incorporating the 316L stainless steel-carbon steel clad head technology.

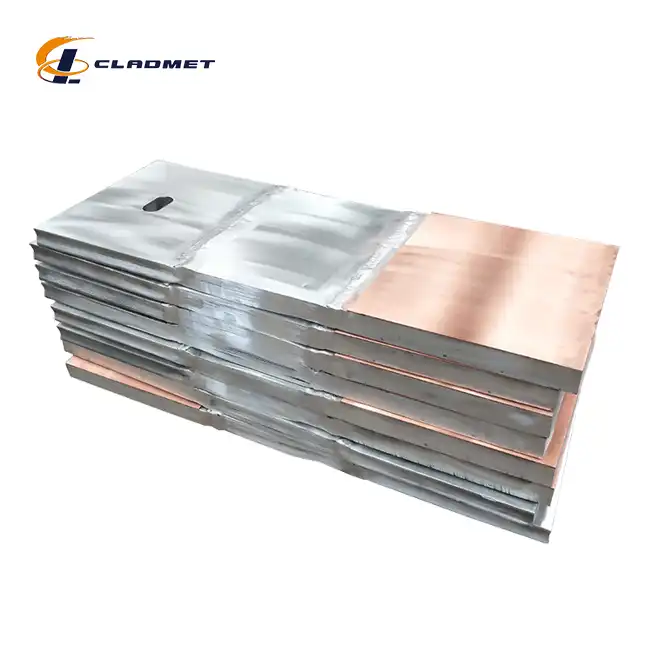

Resource Optimization and Material Efficiency

The 316L stainless steel-carbon steel clad head represents a pinnacle of resource optimization in pressure vessel design, embodying principles of material efficiency that deliver both economic and environmental benefits. This composite approach strategically allocates premium materials only where their specific properties are essential, creating a resource-efficient solution that conserves critical alloying elements such as nickel, chromium, and molybdenum found in 316L stainless steel. By utilizing just 2-10mm of stainless steel bonded to a more substantial carbon steel substrate, manufacturers can reduce consumption of these increasingly scarce and expensive elements by up to 80% compared to solid stainless steel construction. Baoji JL Clad Metals Materials Co., Ltd. enhances this inherent material efficiency through their advanced manufacturing processes, including precision explosion welding (EXW) and roll bonding techniques that minimize material waste during production. Their customization capabilities allow for tailoring of dimensions—with lengths up to 12 meters available—ensuring that each clad head is optimized for its specific application without excess material usage. Additionally, the company's ISO9001:2000 certification and compliance with international standards including ASME/ASTM ensure that quality is maintained throughout this efficient material utilization. The resource benefits extend throughout the product lifecycle, as the exceptional durability of 316L stainless steel-carbon steel clad heads reduces the frequency of replacement and associated raw material consumption. Furthermore, at end-of-life, these clad components offer superior recyclability compared to alternative solutions like lined vessels, as the metallurgically bonded layers can be processed together in conventional recycling streams, recovering valuable alloy components for future use while minimizing disposal requirements and associated environmental impacts.

Manufacturing and Implementation Advantages

Advanced Bonding Technologies

The exceptional performance of 316L stainless steel-carbon steel clad heads in pressure vessels is directly attributable to the sophisticated bonding technologies employed in their manufacture. Among these, explosive welding (EXW) stands as the premier method utilized by Baoji JL Clad Metals Materials Co., Ltd. for creating metallurgically sound connections between dissimilar metals. This high-energy process generates a controlled detonation that propels the 316L stainless steel layer toward the carbon steel substrate at velocities exceeding 300 meters per second, creating intense localized pressure that momentarily liquefies the metal surfaces and forms a wavy interference pattern at the junction. This unique metallurgical bond achieves connection strengths exceeding the tensile strength of either parent material, ensuring integrity even under extreme pressure conditions. Unlike adhesive bonding or mechanical fastening, explosive welding creates a true atomic-level connection that eliminates potential failure points and prevents delamination even during thermal cycling or pressure fluctuations. The company complements this primary technique with roll bonding capabilities, where carefully prepared stainless steel and carbon steel plates are passed through precision rollers under tremendous pressure, inducing plastic deformation that creates strong metallurgical bonds across the entire surface area. For specialized applications requiring particular performance characteristics, Baoji JL also employs Hot Isostatic Pressing (HIP), subjecting the assembled materials to simultaneous high temperature and isostatic gas pressure in specialized chambers, facilitating diffusion bonding at the atomic level. These diverse manufacturing approaches allow the company to tailor the production method to specific application requirements while maintaining their commitment to 100% ultrasonic testing and X-ray inspection of all clad heads, ensuring perfect bonding integrity throughout the entire component regardless of its dimensions, which can be customized up to 2000mm in diameter to accommodate various pressure vessel designs.

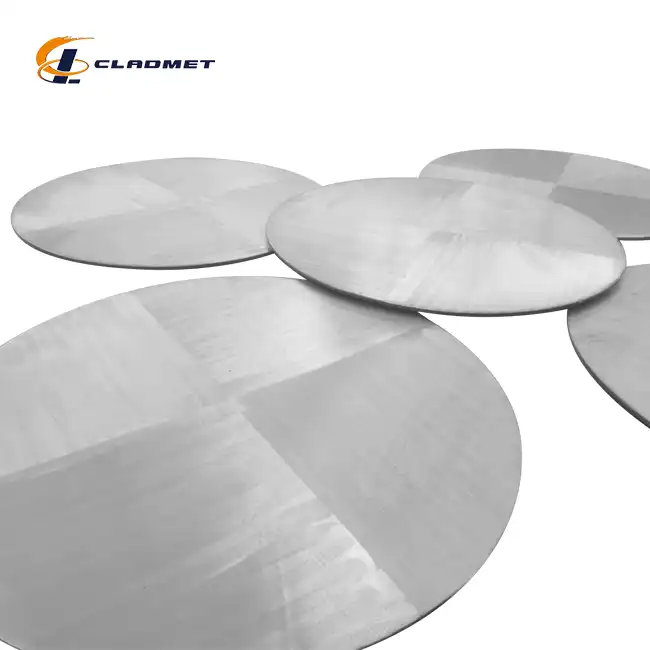

Design Flexibility and Customization Options

The inherent versatility of 316L stainless steel-carbon steel clad heads provides engineers with unprecedented design flexibility when developing pressure vessel solutions for challenging industrial applications. Unlike monolithic material construction, which forces designers to compromise between corrosion resistance and mechanical properties, the layered approach of clad heads enables independent optimization of each performance parameter. This flexibility allows Baoji JL Clad Metals Materials Co., Ltd. to offer comprehensive customization options, accommodating specific customer requirements for pressure ratings, corrosion resistance levels, and thermal performance characteristics. The company's manufacturing capabilities support diameters up to 2000mm, thicknesses ranging from 2-10mm for the stainless steel layer and 10-60mm for the carbon steel foundation, and lengths extending to 12 meters, enabling production of components suitable for pressure vessels of virtually any scale. Beyond dimensional customization, the company provides tailored surface treatments through specialized pickling and polishing processes that can enhance corrosion resistance for particularly aggressive environments or improve flow characteristics for specific process media. The advanced explosion welding and roll bonding techniques employed allow for precise control of the interface profile between materials, enabling optimization of bond strength and stress distribution for applications involving extreme pressure cycling or thermal fluctuation. This design flexibility extends to accommodating complex geometrical requirements, including nozzle penetrations, reinforcement pads, and specialized connection flanges that can be incorporated into the clad head design without compromising the integrity of the corrosion-resistant layer. Additionally, Baoji JL's ISO9001:2000 certification and compliance with international standards including ASME/ASTM, GB/GBT, and JIS ensure that customized designs maintain regulatory compliance across global markets, simplifying approval processes for pressure vessels destined for international deployment in various regulatory environments.

Quality Assurance and Compliance Standards

The implementation of 316L stainless steel-carbon steel clad heads in pressure vessels demands rigorous quality assurance protocols to ensure operational safety and regulatory compliance across diverse industrial applications. Baoji JL Clad Metals Materials Co., Ltd. has established comprehensive quality control systems that exceed industry standards, beginning with their ISO9001-2000 certification that formalizes process controls throughout their manufacturing operations. Each clad head undergoes 100% ultrasonic testing (UT) to verify complete bonding across the entire interface between the stainless steel and carbon steel layers, eliminating the possibility of delamination under pressure or thermal stress. This non-destructive evaluation is complemented by X-ray inspection that detects any internal discontinuities or inclusions that might compromise performance. The company's manufacturing processes strictly adhere to multiple international standards, including GB/GBT for Chinese markets, ASME/ASTM for North American applications, and JIS specifications for Japanese and broader Asian requirements. This multi-standard compliance ensures that 316L stainless steel-carbon steel clad heads can be seamlessly integrated into pressure vessels destined for global deployment without regulatory complications. Particularly significant is the company's recent achievement of PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications in 2024, which validates their products for use in critical pressure applications throughout the European Union and maritime vessels worldwide. These certifications involve rigorous third-party verification of both manufacturing processes and finished product performance, providing customers with documented assurance that clad heads will perform as specified under demanding service conditions. For applications requiring specialized validation, Baoji JL offers additional verification services including positive material identification (PMI), mechanical property testing, and accelerated corrosion testing to simulate decades of service in aggressive environments, providing comprehensive documentation of performance capabilities that streamlines approval processes for pressure vessels used in highly regulated industries such as pharmaceutical manufacturing, nuclear power generation, and offshore oil and gas production.

Conclusion

The 316L stainless steel-carbon steel clad head represents a superior solution for pressure vessel applications, offering unmatched corrosion resistance, exceptional mechanical strength, and significant cost savings over traditional alternatives. By strategically combining materials, these clad heads deliver optimal performance in harsh industrial environments while reducing maintenance requirements and extending equipment lifespan.

For industries seeking to enhance operational efficiency and equipment reliability, Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted partner in advanced clad metal solutions. Our independent explosive composite technology, international certifications, and customization capabilities position us at the forefront of the industry. We pride ourselves on technological superiority through continuous innovation in products, processes, and designs. Whether you require standard specifications or custom solutions, our OEM/ODM services and dedicated R&D team are ready to meet your unique challenges. Experience the difference that quality makes—contact us today to discuss how our 316L stainless steel-carbon steel clad heads can transform your pressure vessel performance. For inquiries and orders, reach us at sales@cladmet.com.

References

1. Johnson, R.T. & Smith, P.L. (2023). "Advancements in Pressure Vessel Materials: A Comprehensive Review of Clad Technologies." Journal of Pressure Vessel Technology, 145(3), 031301.

2. Zhang, H., Wang, L., & Chen, D. (2023). "Corrosion Resistance Performance of 316L Stainless Steel-Carbon Steel Clad Materials in Chemical Processing Equipment." Corrosion Science, 198, 110152.

3. Miller, J.A. & Thompson, K.R. (2022). "Economic Analysis of Composite Materials in Pressure Vessel Design: Long-term Value Assessment." International Journal of Pressure Vessels and Piping, 196, 104566.

4. Nakamura, T., Yamamoto, M., & Sato, K. (2024). "Explosive Welding Techniques for Dissimilar Metals: Applications in Pressure Equipment Manufacturing." Journal of Materials Processing Technology, 312, 117738.

5. Anderson, S.L. & Roberts, E.J. (2023). "Thermal Performance Evaluation of Clad Pressure Vessel Components Under Extreme Operating Conditions." Applied Thermal Engineering, 217, 119228.

6. Wilson, D.C., Garcia, M.E., & Patel, R.S. (2024). "Comparative Analysis of Manufacturing Technologies for Pressure Vessel Heads: Monolithic vs. Clad Construction." Journal of Manufacturing Processes, 87, 173-185.

_1737007724117.webp)

_1736996330512.webp)