Lightweight and durable for industrial applications.

Excellent weldability and biocompatibility.

Precision-crafted for aerospace and medical use.

Superior performance in extreme environments.

Product Introduction

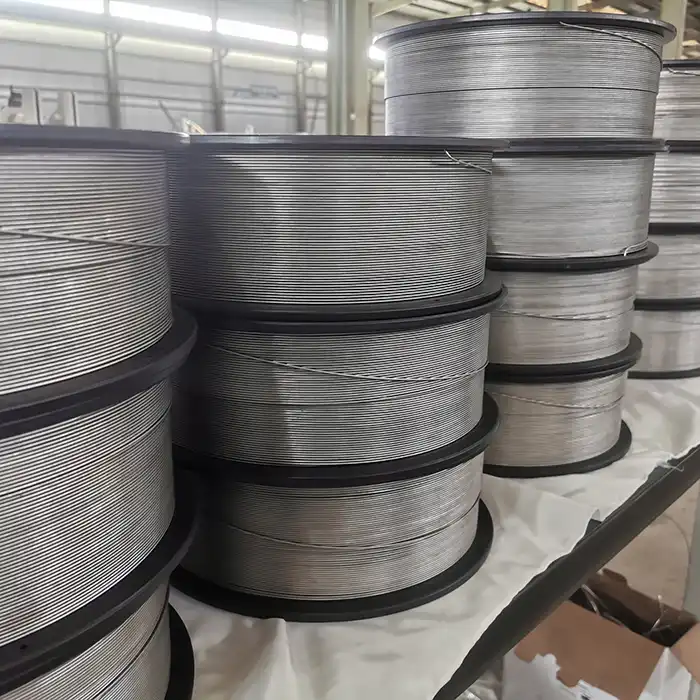

GR5 Titanium Wire, also known as TC4 Titanium Wire or Ti-6Al-4V Wire, is a high-strength, lightweight, and corrosion-resistant titanium alloy wire. As the most commonly used titanium alloy, GR5 is widely applied in aerospace, medical implants, chemical processing, marine engineering, and high-performance manufacturing industries.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grade | GR5 / TC4 (Ti-6Al-4V) |

| Standard Compliance | ASTM B348, ASTM F136, ASTM F1472, ISO 5832-3 |

| Diameter Range | 0.1mm - 6.0mm |

| Surface Finish | Pickled, Polished, Bright |

| Tensile Strength | ≥ 895 MPa |

| Yield Strength | ≥ 830 MPa |

| Elongation | ≥ 10% |

| Density | 4.43 g/cm³ |

| Melting Point | 1660°C |

|

|

|

|

Key Features

Exceptional Strength-to-Weight Ratio: High mechanical strength with low density.

Corrosion Resistance: Outstanding resistance to seawater, acids, and harsh environments.

Biocompatibility: Safe for medical implants and surgical applications.

Excellent Weldability & Ductility: Easy to process and fabricate.

High-Temperature Performance: Stable under extreme conditions.

Gr5 titanium wire material single

What are the advantages of titanium wire in GR5? What are the fields of application?

Regarding the performance advantages of GR5 titanium wire, application areas and customer promotion points, the comprehensive multi-disciplinary information is organized as follows:

I.Core advantages of GR5 titanium wire

1. High strength and light weight

- Tensile strength of up to 895-1100MPa, density of only 4.44g/cm³, specific strength (strength/density) is more than 2 times that of ordinary steel, can realize the effect of 30% weight reduction.

- Excellent high-temperature resistance, long-term working temperature up to 400°C, higher instantaneous temperature resistance, suitable for extreme environments.

2. Corrosion resistance and biocompatibility

- Stable oxide film formed on the surface, resistant to strong acid, alkali, seawater and other corrosive environments, outstanding performance in marine engineering and chemical equipment.

- Non-toxic and harmless, excellent human compatibility, widely used in medical implants (such as orthopedic fixation nails, dental crown supports).

3. Processing and functional advantages

- Combining toughness and weld ability, it can be processed into precision parts such as springs and rivets.

- Some titanium alloys (such as titanium-nickel alloy) have shape memory function, suitable for satellite antenna and other intelligent equipment.

II Main application areas

Industry Typical use

- Aerospace Engine turbine blades, compressor disks, fuselage bearing beams, high lock bolts and other key structural parts.

- Medical Orthopedic implants (skull fixation, dental bridges), surgical instruments, pacemaker wires

- Petrochemical Valve pressure springs, filters (corrosion-resistant), reactor seals

- Marine engineering Ship propellers, submarine probe housings, desalination equipment

- High-end manufacturing Automotive lightweight parts (connecting rods, exhaust systems), 3D printing metal powder

III the four major advantages of strategical application

1. the performance comparison

- Traditional material substitution: Compare with stainless steel (e.g. 30CrMnSiA) or nickel-based alloy, GR5 materials can reduce weight by 30% and extends life by 50%.

- Standard: GB/T 3623-2007, American Standard (ASTM B863) and other standards

2. Successful case analysis

- Aerospace: A certain type of airplane uses GR5 titanium wire bolts to increase fuel efficiency by 8% after weight reduction.

- Medical: A tertiary hospital used GR5 orthopedic screws, reducing the postoperative infection rate by 70%.

3. Customized service solutions

- Provide customized options from wire diameter (0.1-6.0mm) to surface treatment (pickled/bright finish).

- Recommend heat treatment process (e.g. solid solution strengthening or aging treatment) in line with customer needs.

4. Cost-benefit analysis

Although the initial cost is higher than ordinary steel, the comprehensive service life and maintenance cost can be reduced by more than 40%.

This kind of common titanium wires project we had cooperated with our Middle-east customer for over 5 years with stable quality and constant supplying, annual orders exceed 20 tons.

Except titanium wire, our customer developed new project with us on nickle wires.

_1737007724117.webp)

_1740558024479.webp)