Excellent corrosion resistance in harsh environments.

Ideal for aerospace and marine applications.

Good weldability and easy to process.

Reliable performance in chemical and medical industries.

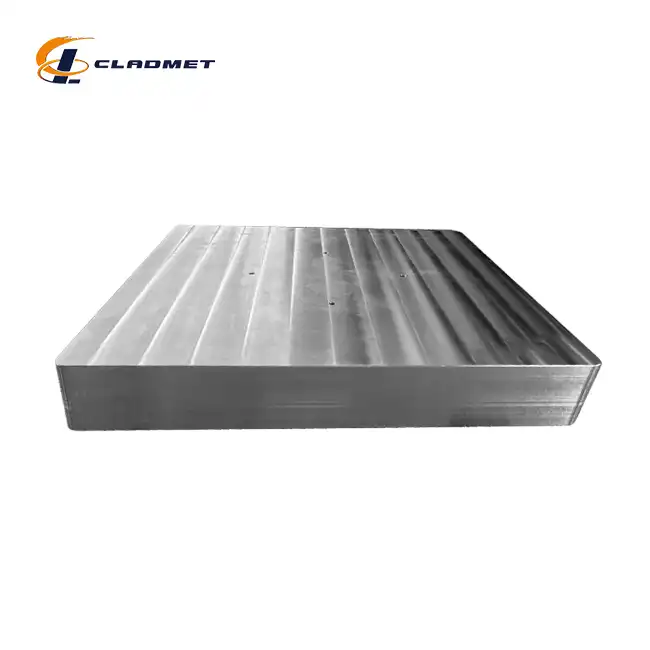

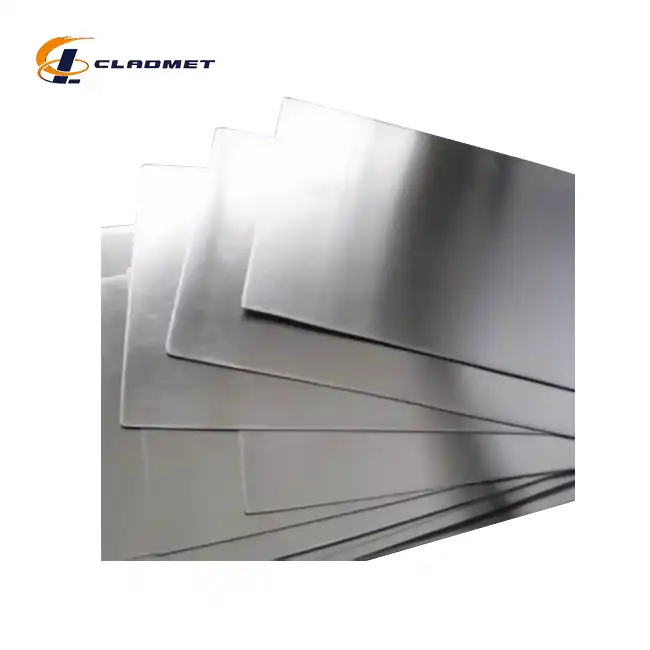

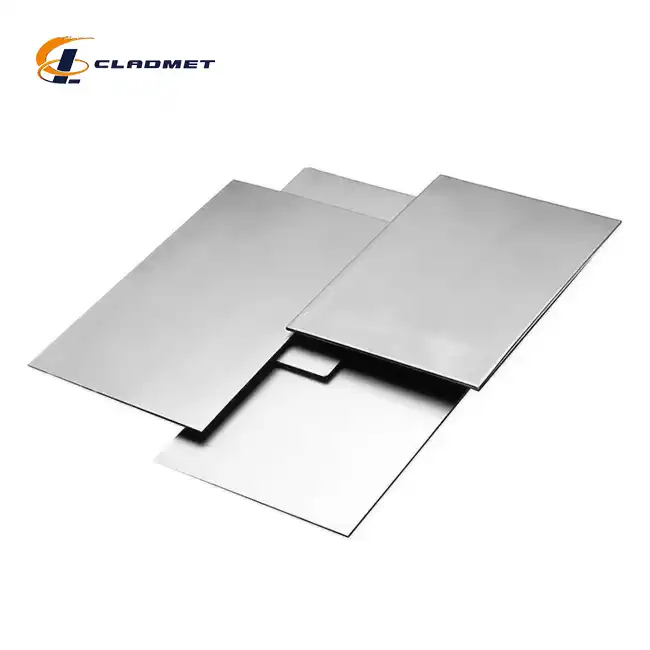

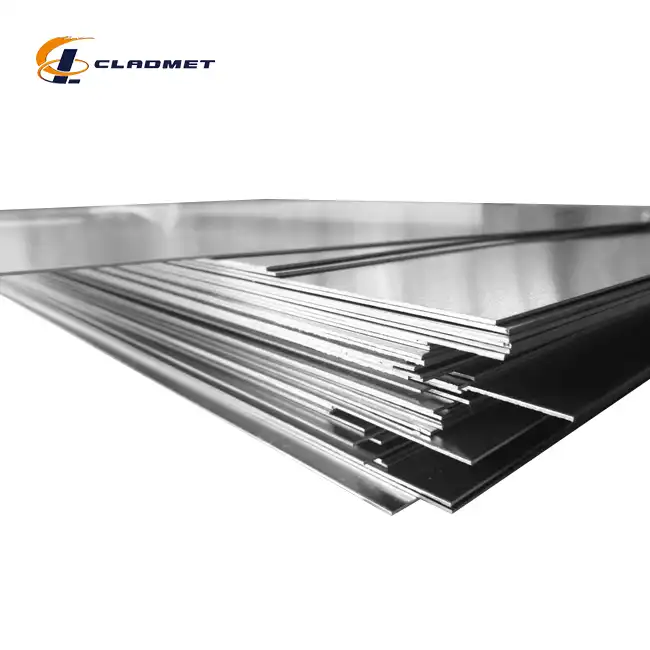

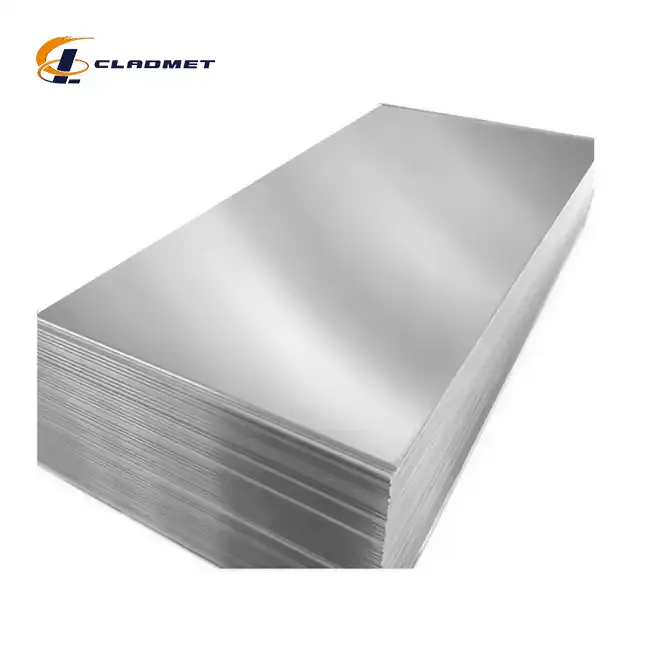

PT3V Titanium Plate Titanium Plate Product Details

Looking for a reliable titanium plate supplier? We've got you covered!

At Baoji JL Clad Metals, we supply high-quality PT3V titanium plates at wholesale prices. Our factory is located in the center of China's titanium industry, and the entire titanium supply chain is highly developed, allowing us to offer better prices without compromising on quality.

If you are a professional buyer, you already know that PT3V titanium is a high-strength, lightweight, corrosion-resistant material that is widely used in aerospace, marine, medical, and industrial applications. However, if you are new to titanium sourcing, we will introduce you to what makes our PT3V titanium plates the right choice for your business.

📌 Why Choose Our PT3V Titanium Plates?

✅ Competitive Factory Prices – Thanks to our fully integrated titanium supply chain, we keep costs low while maintaining top quality.

✅ Precision Manufacturing – Our strict production and quality control processes ensure excellent product consistency and reliability.

✅ Wholesale Only, No Retail – We specialize in bulk orders for distributors, manufacturers, and large projects.

✅ INDUSTRY-RECOGNIZED CERTIFICATIONS – Our factory is ISO 9001:2015, PED and ABS certified, ensuring compliance with global industry standards.

✅ CUSTOM SIZES AVAILABLE – Need 1mm, 3mm or 6mm thickness? Looking for 4x8ft titanium plates? We offer custom cutting to fit your exact needs.

✅ TRUSTED BY LEADING INDUSTRIES – Our titanium plates are widely used in aerospace, chemical processing, offshore engineering and medical applications.

|

|

|

|

Functions of PT3V Titanium Plate

1. High Strength-to-Weight Ratio: PT3 titanium plates offer excellent mechanical strength while being significantly lighter than steel, making them ideal for applications where weight reduction is critical.

2. Corrosion Resistance: The material exhibits outstanding resistance to corrosion, particularly in harsh environments such as seawater, chemical processing, and acidic or alkaline conditions.

3. Biocompatibility: PT3 titanium is biocompatible, making it suitable for medical and dental implants.

4. Heat Resistance: It maintains structural integrity at high temperatures, making it suitable for aerospace and industrial applications.

5. Durability: The plates are highly durable and resistant to wear, ensuring long-term performance in demanding conditions.

Technical Standards

PT3V titanium plates are manufactured and tested according to international standards to ensure quality and consistency. Key standards include:

1. ASTM B265: Standard specification for titanium and titanium alloy strip, sheet, and plate.

2. AMS 4911: Aerospace material specification for titanium alloy plates.

3. ISO 5832-2: International standard for implantable titanium materials.

4. GB/T 3621: Chinese standard for titanium and titanium alloy plates.

These standards ensure that PT3V titanium plates meet specific requirements for chemical composition, mechanical properties, and dimensional tolerances.

HOW WE ENSURE QUALITY EXCELLENCE – OUR MANUFACTURING PROCESS

We don’t just sell titanium plates – we manufacture them with precision and expertise. Our rigorous production process ensures that every PT3V titanium plate meets the highest standards of performance and durability.

STEP 1: HIGH PURITY RAW MATERIAL SELECTION

🔹 We source top-grade titanium sponge, ensuring our plates have excellent mechanical properties and corrosion resistance.

Step 2: Advanced Melting and Alloying

🔹 Using Vacuum Arc Remelting (VAR) and Electron Beam Melting (EBM), we achieve uniform composition and minimal impurities.

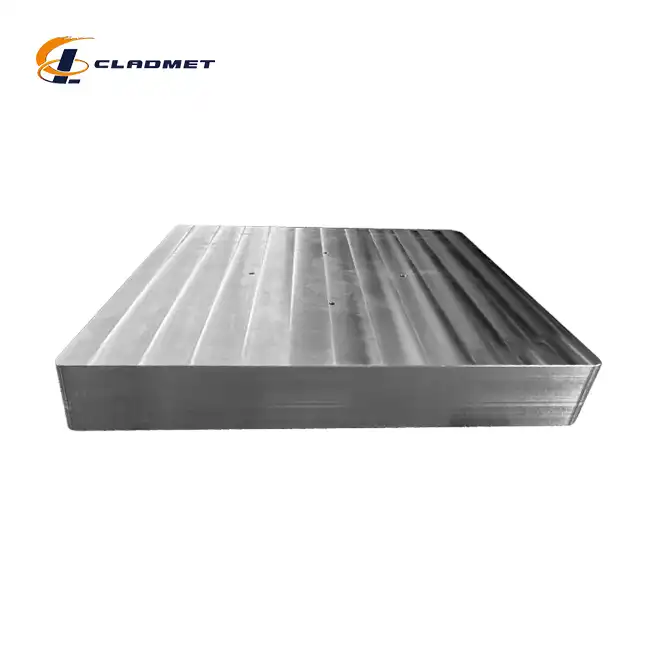

Step 3: Precision Rolling and Thickness Control

🔹 Hot and cold rolling techniques ensure precise thickness control, smooth surfaces, and excellent structural integrity.

Step 4: Heat Treatment and Stress Relief

🔹 Vacuum annealing enhances the material’s ductility and fatigue resistance, making it ideal for demanding applications.

Step 5: Quality Inspection and Testing

🔹 Each batch undergoes:

✅ Ultrasonic Testing (UT) – Ensures the absence of internal defects.

✅ Tensile and Hardness Testing – Confirms mechanical strength.

✅ Chemical Composition Analysis – Guaranteed compliance with ASTM, AMS 4911, and other industry standards.

We take quality very seriously — because your project deserves the best.

Applications of PT3 Titanium Plate

1. Aerospace: Used in aircraft components, engine parts, and spacecraft due to its lightweight and high-temperature performance.

2. Marine Engineering: Ideal for shipbuilding, offshore platforms, and subsea equipment because of its corrosion resistance in seawater.

3. Medical Industry: Utilized in surgical implants, dental prosthetics, and medical devices due to its biocompatibility and durability.

4. Chemical Processing: Employed in reactors, heat exchangers, and piping systems where resistance to corrosive chemicals is essential.

5. Automotive: Used in high-performance vehicles to reduce weight and improve fuel efficiency.

6.Energy Sector: Applied in power generation equipment, including turbines and heat exchangers, due to its heat resistance and durability.

In summary, PT3V titanium plates are versatile, high-performance materials that meet stringent technical standards and are widely used in industries requiring lightweight, durable, and corrosion-resistant solutions.

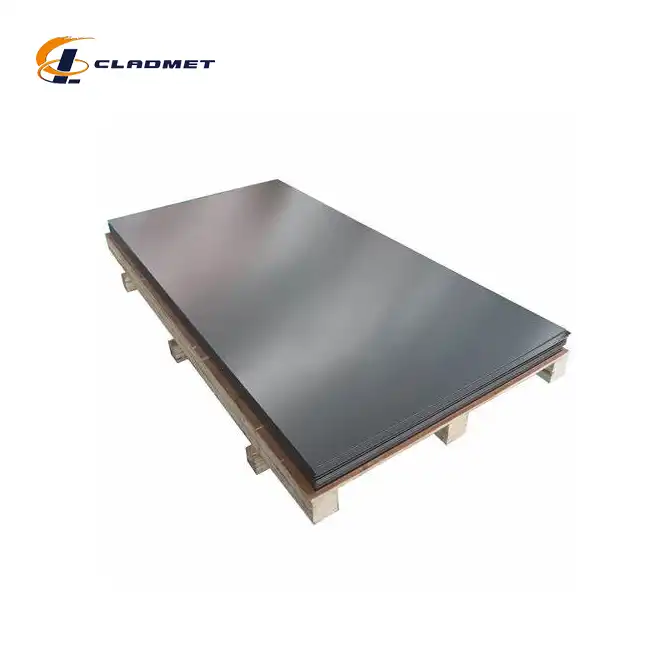

Cooperation case

We exported this kind of of titanium plate to Russian market with competitive price and stabel quality, which make our partner satisfactory.

We would like to share the MTC with you to show the good performance.

FAQ

❓ What is PT3V Titanium Plate Used For?

🔹 PT3V Titanium Plate (similar to AMS 4911) is widely used in aerospace, medical implants, offshore engineering and high-performance industrial applications for its lightweight strength and corrosion resistance.

❓ Do you offer custom sizes?

🔹 Yes! We offer custom cutting and processing according to your requirements. Just tell us what you need.

❓ What is your minimum order quantity (MOQ)?

🔹 As a wholesale supplier, we only accept bulk orders. Please contact us for details of MOQ.

❓ Do you offer certifications?

🔹 Of course! Our titanium plates comply with ISO 9001:2015, PED, ABS, ASTM, ASME and JIS standards.

❓ How to place an order?

🔹 Just send us an inquiry - our team will provide you with pricing, delivery time and order details within 24 hours.

Why work with Baoji JL Composite Metals?

We are more than just a supplier, we are a trusted manufacturer with nearly 40 years of expertise in metal materials.

🔹Trusted Industry Experience

Founded in 1988, we have been a key player in China’s titanium industry, working with top research institutions such as Baoti Group and China Northwest Research Institute of Nonferrous Metals.

🔹Advanced Manufacturing and R&D

Our engineering team includes renowned experts in metal materials and welding technology, ensuring our products meet and exceed industry standards.

🔹Global Quality and Safety Certifications

We adhere to strict quality control standards and hold the following certifications:

✅ ISO 9001:2015 – International Quality Management System

✅ PED (Pressure Equipment Directive) – Compliant with European standards

✅ ABS (American Bureau of Shipping) – Approved for marine applications

🔹Competitive Pricing and Strong Supply Chain

Located in Baoji, China – the world’s titanium capital, we have a well-established supply chain. This means:

✅ Reduced production costs → Better prices for you

✅ Continuous bulk supply → No delays in your order

🔹 Dedicated Customer Support

Whether you are a professional buyer or new to titanium procurement, our sales and engineering teams will provide professional guidance.

Ready to place an order? Get a free quote now!

If you are looking for a trusted PT3V Titanium Plate supplier with high quality, competitive prices and reliable bulk supply, contact us today.

👉 Send an inquiry now and get our best wholesale prices!

Contact Us

For more information or to place an order, please contact us:

Phone: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: Fenghuang 4 Road, High-Tech District, Baoji City, Shaanxi, China 721013

_1737007724117.webp)

_1740558024479.webp)

_1740558040142.webp)

_1740558038404.webp)

_1740558025159.webp)